This article provides a selection of step-by-step instructions, how to make a round table with your own hands. Out of habit, for many, a rectangular table design is an almost automatic choice. However, the round shape offers many benefits that may be just right for your specific needs. For example, round dining table provides more space. This shape works well in an open plan where the dining area is set back from a larger room. Fits good round table for living room, because the space around the table is convenient for moving. And if you're hosting a holiday feast in the living room, a round table makes better use of the space so there's less jostling or crowding as guests move around. You don't have to worry about someone bumping into a corner when trying to get to the other side. And then, the round shape is beautiful. They look especially attractive round coffee tables, attached, decorative options for the bedroom. Make a round table with your own hands no more complicated than any other table shape, although there are some peculiarities. You can learn about all the nuances of making this design in this article.

Required Tools

Each fastening method requires a list of tools. Accordingly, in the order of listing the installation methods, you need to prepare the following tools:

- Screwdrivers or screwdriver - to facilitate the screwing process.

- Drill for drilling holes, hammer, pliers, screwdriver.

- A screwdriver (you can additionally use glue) for better fixation of the drawer. You will also need a semicircular chisel to make a pocket for a self-tapping screw.

- Screwdriver or screwdriver.

- Saw or machine for making wooden clamps. You also need a chisel and screwdrivers.

- Saw or thin chisel for cutting a cavity in the drawer, chisel, screwdrivers.

- Saw or thin chisel for drawer, screwdriver.

It is important not only to install it evenly, but also to properly secure the legs to the tabletop. There are various ways to attach the legs to the table, all that remains is to choose the most suitable option. There is nothing difficult about making a dining table with your own hands. This makes it possible to take into account all the design features of the kitchen unit and the dimensions of the room. Making a table with your own hands is a task that even novice craftsmen can do.

Did you manage to solve your problem using the recommendations from the article?

Yes!

45.45%

No. More answers required. I'll ask in the comments now.

38.29%

Partially. There are still questions. I'll write in the comments now.

16.25%

Voted: 363

APPENDIX 2 (recommended). PROTOCOL

Head of testing organization

A table is a necessary attribute of kitchen furniture. Today, manufacturers use a lot of materials to produce tables. There is a great variety of table leg shapes; there are more than twenty of them. The traditional version has four legs. In most cases, standard models have a square or rectangular tabletop shape.

Wooden rectangular dining table with four legs

A table with three legs is usually round. It can be used as a small coffee table or as a dining area.

Round wooden kitchen table with three legs

Tables are also produced with two legs; they can be of various types, but the most common models are those with two X-shaped legs or durable ones made of solid wood.

Wooden table with X-shaped legs complete with chairs for a summer cottage

Model selection

A round table is a safe, comfortable design without sharp corners. At the same time, it provides maximum usable space. At the first stage, you should choose a suitable model, focusing on the interior design and the size of the room.

There are several options for a round table, differing in functionality:

- Magazine - usually multi-tiered, contains open shelves. The walls of this design are its legs, holding the entire product.

- Kitchen - is a semicircular structure installed in the corner of the room. In such a table you can install a shelf for dishes, cutlery, and install built-in appliances. The semicircle area usually houses a large work area, where it is convenient to cut and mix products.

- The dining room is large in size, which easily accommodates a lot of dishes and ensures full seating for guests. The round shape makes the table fit perfectly into a square dining room without making it difficult to move around.

- Folding - the oval model is most often equipped with a folding tabletop. When folded, the table does not take up much space, and if there are a large number of guests, it can be expanded to increase its size.

Magazine

Kitchen

Dining

Folding

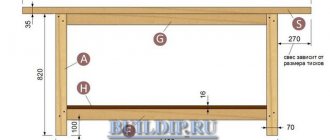

Dimensions are not the only factor you should pay attention to when planning to make a table. The space under the tabletop is also important; it not only complements the design, but is also responsible for the comfort of people sitting. There are several variations of what the underframe can be:

- Four legs are the most stable design, which is a classic. It is convenient to use, since those sitting will be able to sit comfortably without worrying about their legs getting in the way.

- The lintel is a massive composition of wooden joints on which the tabletop rests. Such a table is durable and easy to create, but the knees of those sitting will rest against the crossbars.

- Crosshairs - more convenient than the option with jumpers, it is a base in the form of crossed connections that form a stable structure.

- One post with a cross or disk - the table top is placed on it, and the disk at the bottom (or spacers) provides stability to the table.

Among modern developments, one can note the latest trend, which involves the presence of curved supports diverging in the upper and lower zones. Offers sufficient legroom for those seated.

You need to select a table design that matches the existing interior. If it is classic, wood species with a naturally dark color will do. A white table or a structure in light pastel shades will fit perfectly into the loft style.

Step-by-step making of a table from boards with your own hands, examples of decor

Four legs

Jumper

Crosshairs

One pillar

Materials used

You can use different materials to make your own round table. This should include:

Chipboard and fibreboard are well suited to make a budget option. Despite the cheapness of this design, with proper care it will last a long time.

Using a tablecloth, you can hide the material used, and it will look no worse than a product made from natural wood.

Coniferous wood provides the opportunity to make a high-quality product at minimal cost. Such wood is easy to process and can last for a long time.

Read here - How to make a bench from pallets: do-it-yourself bench from pallets

It is important to strictly adhere to the technological process and at the initial stage, treat the structure well with paint and varnish material.

Check it out here too!

How to make a bench from pallets: do-it-yourself bench from palletsInstructions on how to make a table with your own hands: step-by-step photo instructions, drawings, assembly diagrams for tables of different types for the garden and at home

How to make a hanging chair with your own hands - 100 photo ideas for chair design, instructions for their implementation. Creating the perfect vacation spot

Solid wood in the form of oak or beech will allow you to make a truly high-quality product that will become the real pride of any room.

Such a table will have a decent appearance; it amazes with its massiveness and grandeur. You will have to try a little when processing this solid wood, but the result will not be long in coming.

This design emphasizes the status of the owner and his family members.

There really are a lot of options. There are also modern solutions to the issue using plastic.

PREPARATION FOR TESTS

3.1. Before testing, the samples are preliminarily kept for at least 3 days in a room with a relative air humidity of 45 to 70% at a temperature of 15 to 30 °C.

(Changed edition, Amendment No. 2).

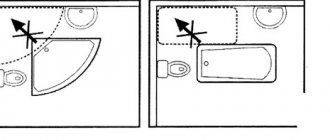

3.2. The base of the sample is rigidly fixed so that the load application point is at a distance of (10±1) mm from the supporting surface of the leg (Fig. 2).

(Changed edition, Amendment No. 3).

3.3. Loading of samples with a leg located perpendicular to the base is carried out in one direction (see Fig. 2).

Loading of samples that have a reinforcement bar or a leg attached directly to the bar is carried out in the direction perpendicular to the longitudinal axis of symmetry of the bar.

(Changed edition, Amendment No. 1, 2).

3.4. Loading of samples with a leg located at an angle to the base is carried out in two mutually perpendicular directions (Fig. 3 a, b).

How to make legs yourself?

Without the proper experience and special equipment, it is most likely impossible to make a full-fledged furniture support. However, if you need a temporary replacement for a broken support or it will be placed where appearance is not important, you can try making it yourself.

You can make table legs yourself. To do this you will need a beam, preferably square. Next, you need to saw off a part of the required length from the lamella and process it: sand it, remove sharp corners and clean it with sandpaper. If desired, the “leg” can be opened with stain and varnish, and then attached to the tabletop using already known options for attaching legs to the tabletop.

For manufacturing, timber is used, ideally with a square cross-section.

Wood is the most accessible material, while being the easiest to process. This should be taken into account when deciding whether to make a support yourself.

Compared to other materials, wood will be the easiest to process. Thus, the ability to “deal with” a broken leg or correct a loose fastening of table legs to the table top will be useful in any case, since at home tables and chairs are subject to the greatest wear and tear among all available furniture. It is known that there is nothing more annoying than a swaying table!

The ability to independently secure or change a table leg will never be superfluous.

Project development

Regardless of the chosen model or design solution, the instructions on how to properly make a round table on your own remain the same. It looks like this:

- it is important to decide what tasks this product should solve, how many people will sit at it, where it will be located;

- calculate its dimensions and select materials according to your budget;

- make accurate drawings of the proposed design;

- prepare the necessary tools.

If you responsibly approach the implementation of the above points and do everything correctly, the work itself will not be difficult at all.