A machine for sealing plastic bags or other polymer fabrics is called a bag sealer. Using this device, you can make a permanent connection of polyethylene by acting on it thermally. The bag sealer allows you to quickly and hermetically wrap an item or product in plastic packaging. Moreover, equipment for sealing plastic bags is available not only for industrial or food enterprises. Thermal bag sealer is also purchased for home use.

Application of bag sealers

Sealing bags is an important technological process. Not a single enterprise that produces products for sale can do without it. The device is used for packaging, packaging, storage, transportation, and sale of goods, such as:

- textile;

- cloth;

- linen;

- food products (in shops, canteens, catering establishments);

- medicines;

- accessories;

- Appliances;

- toys;

- disposable tableware;

- gifts, souvenirs;

- flowers;

- printing products.

The polyethylene sealer is widely used for domestic purposes.

Welding machine for PVC film in

To buy a welding machine for PVC film, you no longer need to choose a seller for a long time - you have already found it! Absolutely anyone can buy high-quality equipment with a guarantee on our website. To purchase a welding machine for PVC film from us, you just need to place an order for the product, and then all you have to do is wait for the parcel to arrive. We work on a flexible system of mutual settlements, so clients do not have to worry about payment. Call at any convenient time and order high-quality equipment at competitive prices!

Classification of package welders

Manual bag sealer

This is an inexpensive and versatile device. It is used at home and in production, where there is no need to package large volumes of products, and also where speed is not important. Manual bag sealers can be floor-mounted or table-top.

- Floor sealers have foot pedals. The device itself has Teflon strips built into it, which are larger in size than in desktop devices. The edges of the package are laid out there, the pedal is pressed, and the lid is lowered. The number of seals per minute is 25.

Automatic sealer

They are used in large stores and supermarkets for high-speed packaging of goods, clothing, and food products. If a manual bag sealer requires control and constant presence of a person nearby, an automatic sealer works with one click of a button.

Advantages of automatic sealers:

- The heating elements are hidden inside the housing, so there is no risk of body parts or foreign objects getting in. The desired item in the package is brought to the sealer and inserted into the neck hole. After pressing the button, sealing occurs within 3 seconds.

- You do not need to align the film yourself so that it is packed evenly. The device is configured to do this automatically.

- Ready-made bags with a clip look neat and airtight.

Impulse bag sealers

This is a hand-held, lightweight and compact device with a plastic body. It is used for sealing polypropylene or polyethylene with a thickness of up to 150 microns and a width of up to 40 cm. The width of the finished sealed seam is 3 mm, and its length is 400 mm. The device is not equipped with an automatic film cutting system.

The principle of operation is pulsed heating of elements during soldering when the film comes into contact with the strip. The timer sets the sealing time (from 1 to 5 s), the melting temperature and its density. The product is laid out on the heating surface, the lid is closed, the power is turned on and the surface is heated. At the end of the process, the power is turned off.

Sealers with constant heating

The device is used for large volumes of products and high sealing speed. The package includes 2 sponges that press against the product and a thermal knife that separates the packages from each other. The sponges are heated to the required temperature using a heating element built into them.

Types of polyethylene welding

Also read: Everything about plumbing and pipes from A to Z.

contact welding

First, set the mode on the device; its choice depends on the properties of the polymer, the type of film and thickness.

The simplest and most economical way to connect individual film fragments. The result is a very reliable connection. To do this, the edges of the polyethylene are connected and heated with hot air, or the so-called hot wedge, until the melting temperature is reached. The edges of the film are connected and compressed using special clamping rollers. The result is a single or double seam of very high strength.

Hot air is an air flow heated to a certain temperature. He brings the film being welded to a temperature at which it begins to melt. A hot wedge works on the same principle. This is an ordinary heating element. It contacts the material being welded on both sides and forms a strong seam. Its strength reaches 90%.

Extrusion welding

It works on the following principle: molten polymer is supplied under pressure to the welding site, the welded surfaces become viscous. In this state they are pressed tightly and welded. Welding strength is about 70%.

Hot welding

A special apparatus heats the polyethylene through a heating element made of metal. What happens next is the same as with other connection methods. Hot welding is used to join not only polyethylene, but also for welding polypropylene, HDPE, PVC and other polymers.

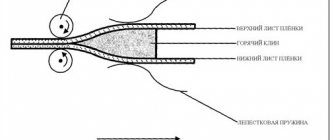

Welding diagram with a TN series machine.

The film sealing machine has a fairly simple operating principle. The engine drives 2 wheels through a gearbox. Using a tripod, a hot wedge is inserted between the sheets of material to be welded. A special thermostat ensures that the hot wedge maintains a constant temperature. The speed of material movement is adjustable. The device meets all fire and electrical safety requirements.

As a result of using such a device, a double seam is obtained. Its strength is about 85%. The welding process occurs automatically. Manually only changes the temperature of the hot wedge, as well as the film feed speed. The device is used mainly in industry, but it can also be used for personal use.

A hand-held hot air device is a type of hair dryer for industrial use. It has a number of advantages. The device is characterized by its low weight, high power, and compliance with technical requirements. Can work with LDPE, HDPE and PVC.

How to choose a bag sealer

To choose the right bag sealer, you need to consider several points:

- packaging material. LDPE or HDPE polyethylene, polypropylene, BOPP, multilayer film - not every machine can solder these polymers. Therefore, it is important to read the instructions for use;

- film density. The device is designed for a certain thickness of the package. It is better to take a device with high density parameters, taking into account the folds of the package;

- package size. One machine can seal bags of different widths and lengths;

- view of the finished seam. The seams can be cut, flat, embossed, or euro-seams;

- engraving. You can put a logo, production date, series, batch number or other required information on the soldered seam;

- presence of a thermal knife. If you need to automatically cut off excess parts of the package or make the packaging look perfect, you can look for devices equipped with a mechanical knife;

- sealing speed. If you need a small number of sealed bags, a manual tabletop sealer is suitable, and if the scale of production is large, a conveyor machine would be the best option.

General recommendations

One of the important advantages of welding from SIGN SERVICE is silicone rollers; even when molten polyvinyl chloride flows out, there will be no sticking.

The scope of application of welding machines is wide, but each type of welded fabric has its own characteristics. For high-quality work, it is necessary to take into account even the temperature regime when cutting the canvas, it is important that the film surface does not have contaminated areas, and all processes must take place on a flat plane.

If for some reason the suture fails, which is extremely rare, it is not worth repeating the operation in the same place. The damaged section is cut off and the blades are welded again.

In addition to the temperature indicators of the air flow, pressure, and speed of movement, the quality of the resulting seam is influenced by many indirect factors. An experienced specialist carrying out the work must take them into account when completing the order. Weather conditions, such as humidity and temperature of air masses, physical and chemical data of the material used, are important. Compliance with all technology requirements helps to carry out welding at a high level.

To place an order with SIGN SERVICE, just call or fill out the feedback form; also for a quick order, a window for requesting a call back is available on the website. We do everything to make it convenient for our customers not only to buy, but also to use and maintain the purchased machines in the future. Save with us and purchase only high-quality products that can last for decades.

Principle of operation

Sealing of packages occurs in several stages:

- Select sealing bags that are suitable in size and composition.

- Turn on the device by pressing the handle, the light should light up.

- Open the lid.

- Place the two ends of the film on the heating surface. Close the lid.

- Click on the “Spike” button. The bag sealer heats the material to a partial melting temperature. Thanks to this they connect.

- When the indicator light goes out, the process is over. Repeat for the other two sides.

- Place the finished product in a package sealed on three sides. Place the fourth edge of the polyethylene on the heating surface. Close the lid.

- The sealing of the products is completed.

Advantages of purchasing a welding machine for PVC film from SIGN SERVICE

Purchasing a unit for welding sheets requires quite a significant investment, so it is important to buy a reliable and durable device. Our models are characterized by an optimal price-quality ratio; they are worth every ruble spent. The devices consist of two key components: industrial Swiss hair dryers and a wheelbase. The high level of performance of the equipment is confirmed by a long warranty.

Welding a banner or any other product with such devices will no longer be a problem, all work is carried out promptly, and our specialists are ready, if necessary, to advise each client on any issues that arise.

How to seal a plastic bag at home?

Using available tools such as an iron, curling iron, soldering iron or hair straightener, you can seal the edges of the bag at home. To do this, you need to fold the edges of the film together, put fabric, paper, newspaper on top so that the film does not come into contact with the heating part. Heat the device to 200-250°C, then slowly move it across the entire width of the seam.

Important: you do not need to remove the paper immediately. It is better to give it time to cool and then remove it so that the film does not tear.

To seal a plastic bag at home, you also use a candle or lighter, slowly bringing it to the package. It is important to adjust the distance to the cellophane so as not to burn it.

Warning: It is important to be very careful so that your actions do not lead to a fire.

A sealer is a device that allows you to give products a marketable appearance. By choosing the right device, you can save effort on packaging and do it efficiently and airtight.

A bag sealer is a device designed for gluing (sealing) polyethylene film, PVC and other types of polyethylene. Manual desktop sealers, in contrast to automatic pulse sealers, began to be actively used relatively recently in the food industry, in medical and pharmaceutical institutions and in the cosmetics industry. Manufacturers of food, cosmetics, medical devices and drugs have realized the need for proper packaging to ensure the freshness and safety of the product, as well as preventing the loss of important qualities and properties.

- In stock

- Wholesale / Retail

- 25.11.19

Country of origin: South Korea Power (W) : 510 Weld length (mm) : 300 Voltage (V) : 220 Weld width (mm) : 2 Heating temperature (°C) : 150 Max. thickness of welded material (mm) : 0.5 Weight (kg) : 3.4 Dimensions (mm) :

- In stock

- Wholesale / Retail

- 20.11.19

All types of shrink equipment, manual and automatic lines, packers, sealers. Availability. Warranty and service.

- In stock

- Wholesale / Retail

- 20.11.19

All types of shrink equipment, manual and automatic lines, packers, sealers. Availability. Warranty and service.

- In stock

- Wholesale / Retail

- 20.11.19

All types of shrink equipment, manual and automatic lines, packers, sealers. Availability. Warranty and service.

- To order

- Wholesale

- 25.11.19

We supply and install electrical products, video surveillance, security alarms, and also sell plumbing fixtures, building materials, fire alarms and fire equipment.

- In stock

- Wholesale / Retail

- 26.11.19

Sealing length 200mm, seam width 2mm. The body is made of plastic.

- In stock

- Wholesale / Retail

- 26.11.19

The staplers are designed for sealing polyethylene. Case material: painted metal.

Film gluing technologies and preparation for work ↑

Problems when gluing polyethylene are a fairly common situation. It's all about the characteristics of the material. Once you understand them, you can easily avoid difficulties.

High temperature sinteres two layers

What you need to remember from chemistry and physics ↑

Polyethylene is the most common polymer in the world. Its extraordinary popularity is explained by the excellent properties of the material - impact resistance, ductility, low gas and water permeability. Films reinforced with mesh or fabric are used for roofing, which increases the strength of the material.

Despite the advantages, polyethylene films are very rarely glued together in industry. To understand why connecting parts is problematic, just remember your school chemistry lessons. The molecule of this polymer is a long chain of similar -CH2- units. The charges inside such a molecule are distributed evenly, it is non-polar. And the higher the polarity, the more suitable the polymer is for gluing.

This device is suitable for small parts

Connection methods without glue and solvent ↑

The method of gluing with its own solution, which is common for many polymers, is also not suitable - polyethylene is practically insoluble in organic solvents. The answer to the question: how to glue polyethylene film is actually very simple: it is best to use welding.

Of the many methods for welding polyethylene film, two are worth highlighting:

- Welding with a heated object.

- Open flame welding.

Both methods are equally effective, but in non-industrial conditions it is still easier and safer to use the first. However, everyone can choose the most suitable option for themselves, taking into account the availability of the necessary tools and their own skills. In any case, these methods make it possible to firmly connect parts together, creating reliable building elements, agricultural and protective structures.

When laying film on the roof, you can do without soldering

Preparatory stages for work ↑

Popular wisdom says: “Measure seven times, cut once.” And before starting to work with polyethylene, you need to not only carefully take measurements, but also think through every detail. First of all, answer the questions:

- What loads will the finished structure be subject to?

- What is its expected lifespan?

- Do you need 100% hydro resistance?

Polyethylene greenhouse

Maybe after such questions the need to glue together many parts will disappear. For example, to insulate transported goods or preserve equipment, some parts of the plastic film can be secured with metal staples or twine. And to protect the building structure from moisture, it is recommended to overlap the polymer, covering individual parts.

But when the question arises about how to glue reinforced film for a greenhouse, you should not neglect reliability. After all, such a design, as a rule, should serve for a long time, perfectly protecting plants from all kinds of weather surprises. Connecting with staples and strong ropes will not work in this case, and welding (any of the proposed types) would be an ideal option.