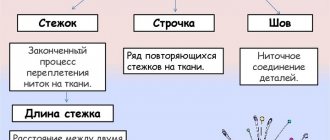

The difference between seams on a machine and an overlocker

The machine is designed to make connecting seams. Its work is based on a two-thread shuttle stitch. Its main purpose is to sew together clothing parts.

An overlocker is intended for processing edges so that the edge does not crumble or unravel. An overlocker creates a seam using needles (depending on the model of the device there may be one or two) and loopers. Different models of overlockers have from 3 to 5 threads.

Simultaneously with the formation of the stitch, it trims off excess material, forming a neat edge. The stitch turns out to be more elastic, it can stretch in certain areas, so it is used when sewing knitwear.

Page 2 of 16Connecting seams

Connecting seams are divided into types: stitching, stitching, overhead, butt, locking, sewing and double.

The stitch seam is the most common. Its stitching is not visible from the front side. Before joining with a stitch seam, the parts are folded with their right sides inward, the cuts and notches are aligned and ground on stitching machines, possibly with devices that limit the width of the seam (special rulers, tabs with a side, etc.), at a distance from the cuts, depending on the purpose seam

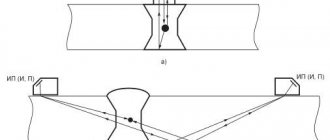

Depending on the thickness of the material and the purpose of the garment, the seam allowances are given different positions, secured by wet-heat treatment. In this case, seam allowances can be located on both sides of the stitch (ironed) (Fig. 4.4, a) or on one side of it (ironed) (Fig. 4.4, b). Such seams are called, respectively, pressed seams and pressed seams.

In products made from non-fraying materials or knitwear, stitched seams on the edge are possible (Fig. 4.4, c). The stitch seam can have overcast sections (Fig. 4.4, c, d). Such seams are made on a stitching and overcasting machine or on a stitching and overcasting machine.

In table 4.1 shows the main stitch seams coded according to GOST 12807-88.

Stitched seams are used for the following purposes:

- connecting parts of the main parts of the product, side and shoulder sections, connecting sleeves to the product, side, step, middle sections of trousers, panels of skirts;

- sewing straps, cuffs, sewing collars, sewing split darts, sewing extensions, etc.;

- connection of parts of the lining, insulating gasket.

The stitch seam is the basis for other types of connecting and edge seams.

On the basis of the stitch seam, a topstitch seam is made (Fig. 4.5). The allowances of such a seam are spread out (fastened to the part) along the front side of the parts with two parallel lines at an equal distance from the seam line, which

Rice. 4.4. Stitched seams:

a – flat ironing; b – ironing; c – on the edge; d – ironed with overcast sections; d – pressed with overcast edges;

Rice. 4.5. Topstitch stitch

Table 4.1. Coding of stitch seams in accordance with GOST 12807-88

Seam name

| Graphic representation of a seam | Conditional image of a seam | Seam code | |

| Stitch seam (with combining cuts): | – | – | – |

| made in one line without overcasting the edges | 1.01.01 | ||

| made in one line with edge stitching | 1.01.02 | ||

| made in two lines without overcasting the edges | 1.01.03 | ||

| made in two lines with overcasting of sections | 1.01.04 | ||

| made in one line with separate overcasting of sections | 1.01.05 | ||

| made in two lines with separate overcasting of sections | 1.01.06 |

The adjustment seam is made with two lines: stitching (on the wrong side of the parts) and adjusting (on the front side).

The adjustment seam is used to connect parts along the same sections as the stitch seam, in cases where increased joint strength, a finishing effect are required, when the material is poorly or not at all amenable to wet-heat treatment (linen fabrics, coated materials, rubberized, leather etc.).

The stitching seam comes with open cuts (Fig. 4.6, a), in products made from crumbling materials they are overcast (Fig. 4.6, b) and one closed cut (Fig. 4.6, c), where the cut of the upper part is closed with a stitching line. After stitching, the seam allowances are first ironed to obtain a clear seam line, and then both cuts are ironed and secured on the front side with a finishing stitch at the distance specified in the model description.

There are a number of varieties of adjustment seams (Fig. 4.6, d, e).

Rice. 4.6. Adjustment seams:

a – with open cuts (code 2.02.03); b – with overcast sections (code 2.02.04); c – with closed sections (code 2.02.03); g – with edging (code 2.02.03); d – type of adjustment seam (code 2.02.03);

Overlay seams come with open cuts, one closed and two closed cuts. The seams are made with one stitch along the front side of the part, applied on the wrong side to the front side of the other, guided by notches, punctures, marking lines or previously made lines.

Overlay seam with open cuts (Fig. 4.7, a) is used:

- for fastening parts of parts that are invisible from the front side of the product;

- sewing darts and parts of the gaskets with a zigzag or linear stitch of shuttle weave (distance from the cuts to the stitch is 3 - 5 mm);

- adjusting the cut of the collar stand onto the neck of coats and suits (the distance from the cuts to the stitching is 7 - 10 mm);

- The same seam is used to sew valances and facings onto the lining of pockets in trousers. To protect the cuts from fraying, the stitching is done using a zigzag stitch machine or a two-needle, three-thread chain weave machine (stitch type 406).

An overlay seam with a closed cut (Fig. 4.7, b) is used instead of an adjustment seam when the seam has a complex shape. It is used, for example, to connect inserts and yokes with the main parts of the product; undercuts, darts in products made of raincoat and similar materials; for connecting the front with the skirt, as well as for sewing patch pockets onto the main part; neck collar; strips in fasteners, etc. The cut of the upper part is ironed (or swept and ironed) and the folded edge of the upper part is adjusted to the lower one.

An overlay seam with two closed sections (Fig. 4.7, c) is used to connect parts with preliminary folding of the sections, for which special devices are used.

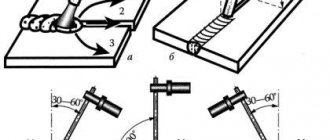

A butt seam can be with open cuts or closed on one or both sides with a strip or braid (Fig. 4.8, a, b, d). A feature of a butt seam is the alignment of open or folded sections of the parts to be joined into one line on the plane and securing them with stitches.

The seam is made on a two-needle machine with devices that combine the sections of the parts while feeding a strip of material without folding or with folding the sections.

Rice. 4.7. Overlay seams:

a – with open cuts (code 2.01.01); b – with one closed cut (code 2.02.01); c, d, e – with two closed sections (code 1.06.01, 1.06.04 and 1.15.01); e – with a closed cut (code 2.05.01); g – adjusting parts with bent sections (code 5.31.01)

Rice. 4.8. Butt seams:

a – with open cuts (code 4.01.01); b – with closed sections (code 4.03.02); c, d – with braid (code 4.05.01 and 4.05.03), d – with a strip of material (code 4.06.01); e – with braid (code 4.07.01); g – with closed cuts (code 4.12.01)

Seams with open cuts are used to connect darts, parts of side linings, and collar linings in the manufacture of products from thin fabrics, when it is possible to “run” the seam on the front side of the product. For this purpose, zigzag stitch machines are used.

Seams with cuts covered on one or both sides with a strip of material are used when finishing clothes.

Linen connecting seams include locking, closed and double seams. These seams have increased allowances and firmly secure the cuts inside.

A distinctive feature of closed, lock and double seams is their design, in which the sections of the parts to be joined are located inside the seam. This gives the seams special strength, as it prevents the threads from shedding along the cuts, as well as the threads shifting along the seam allowances. Therefore, they are used in clothing subject to frequent washing and difficult operating conditions: in industrial clothing, outerwear made from cotton fabrics without lining, and when sewing linen.

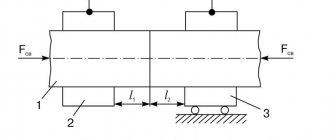

The most economical to process is the lock seam (Fig. 4.9, a), which has the same appearance from the front and back, since it is performed using a serial-parallel method on a two-needle machine with a device for bending and combining cuts. When making a seam, the parts are unfolded on both sides of the needle, the sections are tucked into the device.

Narrow and wide sewing seams (Fig. 4.9, c, d) are used less frequently, since they are performed sequentially.

A narrow sewing seam is obtained by laying the first line along the folded edge of the lower part. Hemming devices are used to form the edge, then the resulting seam is sewn onto the second part.

In a wide closed seam, the first stitching stitch holds together two layers of material of the parts, folded with the right sides inward. Then the folded allowance of the lower part is adjusted. A wide sewing seam is more elastic and softer; it is used in seams that are in direct contact with the body.

The double seam (Fig. 4.9, b) is performed sequentially with two stitching lines. The parts are sewn down by folding them inside out. The second line is used to sew the parts turned out and straightened along the seam at a distance of 5 - 7 mm from the edge of the part.

The seam is used for sewing together pocket linings, connecting the main parts of outerwear without lining or with a lining that does not reach the bottom, and connecting single collars and cuffs in clothes made of soft materials to the product.

Rice. 4.9. Linen seams:

a – lock (code 2.04.03, 2.04.07); b – double (code 1.06.03); c – narrow lining (code 2.04.06); g – wide lining*

* - not included in GOST 12807-88

<< Home < Previous 2 Next > Last >>

Types of seams

There are dozens of types of working and decorative lines used in sewing. The most common are straight (regular) and zigzag seams. However, a modern electronic sewing machine is capable of making any of the following stitches (except for a simple zigzag and a straight seam without special features):

- left-shifted straight line;

- right straight;

- quilting (reminiscent of hand stitching);

- elastic for “grooving” knitwear;

- triple elastic fixing straight line;

- 5 types of lines for sewing buttonholes;

- zigzag three-stage for knitwear and “broken”;

- satin and triple knit zigzag;

- “house”, “double”, knitted and “thin” overlocks;

- hidden bottom seams for stretchy and rough fabrics;

- patchwork lines;

- double and triple herringbone.

Connecting seams

1. Stitch seam. To perform it, the parts are folded face-up or wrong-side down and stitched. Then the sections are ironed on one side or ironed on opposite sides.

2. Topstitch stitch. First, the parts are connected using a stitching line, then the sections are unbent and two more finishing lines are laid at equal distances from the first line. This stitch can be used if ironing the seam allowances is not possible, for example in the case of leather.

3. The adjustment seam is designed to connect the yoke to the shelf and other similar parts. Can be performed with one or two open cuts.

4. An overlay seam is used to fasten parts of the gaskets, attach braid, lace, process straps and belts, cuffs. It comes with two closed or open cuts, one open, and also end-to-end.

5. Linen seam. Divided into zipper, double and lock. This seam is used when sewing linen (bedding or underwear), when working with very thin or transparent fabrics without lining.

Stitch seam

This machine seam is used when connecting shoulder and side sections, connecting a bodice with a skirt, sewing down sleeve sections, as well as when sewing a sleeve into an armhole, etc. The parts are folded right sides together, basted and stitched, stepping back from the cut to the width of the seam.

Wet-heat treatment of fabric (ironing) can be done edge-on (the sections retain their position after steaming), flat-ironed (the sections are ironed in different directions) and ironed (the sections are ironed on one side). The seam width is from 0.5 to 2 cm. A stitch seam can be made either without a fit or with a fit of one of the edges of the garment parts being sewn.

In this video you will see what kind of machine sewing stitches the Brother sewing machine performs.

Adjustment stitch

The machine sewing stitch is performed in two steps. First, we sew the parts to the required seam width and steam them “on edge”. Fold the top piece to the right side (turn the seam allowances to the top piece). We sweep, iron, lightly fixing the folds with an iron, and add a finishing stitch.

The distance between lines depends on the density of the fabric, style and fashion. If you make the allowance of the upper part 0.3-0.5 cm narrower than the lower one, then the open cut of the part will be closed with the top stitch.

A - adjustment seam with an open cut. B - adjustment seam with a closed cut.

Overlay machine stitch

There are two types of machine overlay seam: with an open cut (for joining parts of gaskets in order to reduce the overall thickness of the seam) and with a closed cut (for attaching yokes, patch pockets and other patch parts).

In the first case, parts of the parts are placed one on top of the other with a cut offset of 1.5-2 cm and connected with a straight or zigzag stitch.

In the second case, the cut of the invoice (upper) part is folded inward to the required amount, ironed, placed along the marked lines on the main (lower) part, basted and adjusted. The width of the seam depends on the model of clothing.

A - overlay seam with an open cut. B - overlay seam with a closed cut.

Double reverse seam

A double reverse seam (French) is used when sewing products made from transparent fabrics, as well as some types of bed linen. See How to sew bedding.

To make a reverse seam, the parts need to be folded with the wrong sides, aligning the cuts, and stitched at a distance of 0.3-0.4 cm from the cut (A). Then bend the parts along the seam line, turning them face to face and stitch a second time, retreating from the edge 0.5-0.7 cm (B). In this case, the allowances of the first seam are closed inside the second.

Name the connecting seams. Types and purpose

Connecting seams are characterized by the fact that the parts to be connected lie on both sides of the seam.

1.Stitched seams: pressed, pressed, stitched with edge overcasting.

The parts are folded with the right sides inward, the cuts are aligned and ground down by machine. In mass production, the seam width can be 5, 7, 10, 12, 15 mm, depending on the purpose and type of material.

A seam whose allowances are laid out in different directions and secured with a WTO is called a pressed seam, and with processing on one side it is called a pressed seam.

Used: for connecting the main parts of the product (side seams), sewing small parts to large ones (cuffs to sleeves), connecting parts along an oval contour (collar to neck).

2.Overlay seams: with open cuts, with one closed cut, with two closed cuts.

They are made with one stitch, the parts are superimposed on one another. Used to connect small parts to the product.

· Invoice with open cuts (adjusting braid).

· An invoice with one closed cut (patch pockets, the upper side of the belt on a skirt and apron, when processing the fastener with braid - a zipper).

· Invoice with two closed sections (when processing a robe belt, belt loops on a trouser belt).

3.Adjustment seams: with open cuts, with closed cuts.

The seams are made with two machine stitches (stitching along the wrong side and stitching along the front side). They are used to connect side and shoulder sections, parts of shelves, back, if it is necessary to increase the strength of the seam and for finishing.

4.Topstitch seam.

It is made on the basis of stitched seams (the pressed stitch is additionally secured with two parallel lines on both sides of the seam). More often it is finishing. Used for securing folds and wedges on skirts and for making finishing stitches on products.

3. Double, closed and lock seams have strong fastening of the cuts, as a result of which they do not fray and the threads do not move along the allowances.

· The double seam is performed in two lines in succession. First, the parts are folded with the wrong sides inward and stitched with the first line, then they are turned out, the seam is straightened and a second line is laid along the wrong side.

· To make a sewing seam, the parts are folded with their right sides inward, releasing a cut of the lower part by 7 - 8 mm; This cut is used to bend around the top cut and a stitch is laid at a distance of 1 - 2 mm from the cut. Then the parts are laid out with their right sides down, the seam is folded to the side, closing the cut and adjusted at a distance of 1 - 2 mm from the fold.

· The lock seam is performed on a two-needle machine with a special device.

Seams are used in clothes that are subject to frequent washing (robes, storm jackets), when sewing linen (nightgown, bed linen), as well as clothes made from cotton fabrics without lining.

Designation on typewriters

The designation of each of the stitching modes on any machine is so simple and clear that even a beginner will get used to its control after studying the theory and trying to sew something with his own hands, turning his knowledge into practical skills. For example, zigzag stitches appear as fine-tooth markings. But a zigzag should be distinguished from edge seam markers, which vaguely resemble a mathematical square root icon with a raised mustache.

A simple seam is a dotted line. The number of such lines indicates the multiplicity of the stitch (double, triple, multiple - depends on the number of needles working simultaneously).

Loop stitches are designated as a figure (for example, a rectangle) of parallel strokes.

The selected stitching mode will immediately be translated into practice from the designation on the machine selector into exactly the same execution of a real seam.

Application

The work of a seamstress in time immemorial began with a simple seam. Anyone who knows how to at least work with a needle or a sewing stapler can make an even seam by hand. Next, overcast seams were added to simple seams - its first use was associated with giving buttonholes and garters a finished, neat look. Zigzag, and many simple seams, are also easy to do by hand, but for very busy people a sewing machine will always come to the rescue.

The zigzag line is an “advanced” version of sewing and decorating products. More complex seams, including elaborate ones, are an activity for craftsmen who have long and sincerely been passionate about sewing and embroidery.

Sources

- https://www.modniy-style.ru/uroki-stilya/overlochnyj-shov.html

- https://vplate.ru/shvejnaya-mashinka/vidy-shvov/

- https://vce-tkani.ru/stati/vidy-i-primeneniye-mashinnykh-shvov

- https://www.shyu.ru/mashinnye-shvy.html

- https://korfiati.ru/2015/02/vidyi-shvov/

- https://www.sewing-master.ru/potajnoj-shov-na-shvejnoj-mashinke.html

- https://www.transmetall.ru/articles/?ID=560105