Beginner users of such equipment are probably wondering: which semi-automatic welding machine has the necessary settings and does not require additional debugging? However, such models do not exist for two reasons. Firstly, the manufacturing technology itself does not make it possible to set the same parameters for each instance. Secondly, such uniformity does not make sense, because the equipment is designed to weld different materials.

At the same time, maintaining factory settings significantly reduces the possibility of using the device, because different metals and alloys need to be combined under different conditions. The delivery package usually includes instructions for debugging the equipment yourself, but they are often not enough. Therefore, every experienced master knows how to connect and correctly configure a semi-automatic welding machine to work with a specific material. Such experience often complements and clarifies factory instructions.

Settings are influenced by external parameters

The thickness of the workpieces, the spatial position of the welded joint, the configuration of the joint, the need to strengthen the leg and other indicators require adjustments in the machine settings. Basic settings for semi-automatic welding:

- current strength – filler wire feed. The dependence is directly proportional: increasing the wire feed speed requires higher values in the current settings;

- arc voltage. The adjustment values affect the amount of current;

- shielding gas consumption depends on the basic welding parameters.

Primary values can be set using the tuning table. Next, test welding of a certain number of elements is performed. Based on its results, the settings are adjusted.

After purchasing a semi-automatic device, it takes time to get used to the features of its operation. Over time, even the sound of an electric arc will become informative for the user. In the meantime, you need to get used to the changes:

- The equipment of semi-automatic devices with identical performance indicators can differ greatly. Differences in settings are not uncommon even among models from the same manufacturer;

- due to voltage fluctuations, semi-automatic welding settings are lost;

- changing the brand and composition of the wire;

- change in gas composition;

- Even minor repairs, and even more so the replacement of components, lead to changes in the operation of the equipment.

Semi-automatic devices that allow changes in its operating parameters

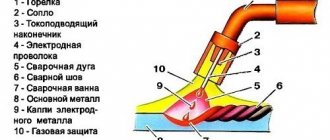

Functional diagram of the power source of a semi-automatic welding machine.

The operation of any welding device is related to the functioning of the welding transformer in it. Semi-automatic devices use mechanical or non-contact methods for adjusting operating current parameters. When using a non-contact control method, the design of the device provides for the installation of a switching electronic board. This adjustment method is more preferable, since it has a significant resource in terms of switching.

The simplest device that allows you to configure the unit for operation is a throttle. It has several stages of adjustment when switching the lever. Each of them corresponds to an increase or decrease in the inductance level. Another device used in the design of the device for tuning is an active choke.

When used in the design of a welder, this device does not require mechanical switching during adjustment, which ensures smooth adjustment of the unit. The use of an active choke in the device makes it possible to more accurately adjust the welding machine.

The operating current when using a semi-automatic machine must be adjusted in such a way that the metal does not burn through during welding. In order to correctly determine the required operating current parameters, when carrying out critical work, it is necessary to perform experimental welding on a metal plate made of the same metal as the workpiece that is being welded. The change in welding current parameters occurs due to the use of a rheostat in the design of the device, which is the most effective device that allows you to change the current parameters.

Gas protection

The gas flow is also a reference value and does not directly affect the settings of the welding unit. Control of gas consumption is greatly simplified, provided that the reducer has two scales. More precisely, the flow volume is taken into account by the rotameter, which is quite often installed on industrial welding lines.

The rotametric indicator of gas flow provides data on the supply of inert gas to the welding process zone in constant quantities. The static pressure will be reduced when the burner fires and creates a cloud of shielding gas. The starting range for the rotameter is 6 to 10 liters per minute. In cases where a pressure gauge is installed - about 1-2 atmospheres.

The gas consumption rate is selected depending on the presence of pores in the weld area. The gas flow increases in volume until the pores disappear. The use of gas in windy or drafty rooms is not justified. Here it is better to resort to flux-coated wire.

Selection of gas mixture

The choice of protective gas mixture is influenced by two factors - the properties of the materials being welded and the quality requirements:

- carbon dioxide ideally protects weld pools. It is an ideal option for ensuring deep penetration. But it is not suitable for fine work due to the rough appearance of the seam and high spattering;

- argon in combination with carbon dioxide in a 3:1 ratio is used for welding thin-sheet workpieces. A thin, high-quality seam is formed and a minimal amount of spatter is generated;

- for stainless steel, the optimal gas mixture is a composition of argon (98%) and carbon dioxide (2%);

- When welding aluminum, pure argon is used.

Recommendations in the instructions

Before starting work, it is necessary to reliably ground the welding machine and only then begin setting up. The semi-automatic welding machine must be connected to a gas cylinder system with protective gas.

It is necessary to check the presence of welding wire in the spool, if you need to reload it and stretch it to the torch handle. The gas supply speed is of great importance in the welding process.

Therefore, it also needs to be installed. Gas equipment has gearboxes indicating gas consumption in liters. This is very convenient; you just need to set the required flow rate within 6-16 liters.

The operating instructions for the device provide recommendations on how to properly set up a semi-automatic welding machine, what current to use to weld a specific metal, and at what speed to feed the wire.

The instructions should contain special tables in which everything is described. If you set all the parameters in accordance with them, then everything should work out.

In practice there may be difficulties. The quality of semi-automatic welding is influenced by many parameters. If the supply network does not meet the standards, then the power source will produce voltage and current that is not what is needed, the parameters will be unstable.

The temperature of the medium, the thickness of the metal, its type, the condition of the surfaces being welded, the type of seam, the diameter of the wire, the volume of gas supply and many other factors affect the quality of semi-automatic welding.

Tables of recommended welding conditions are given for certain conditions, which cannot always be achieved. Therefore, when welding semi-automatically, many adjustments are made experimentally.

Of course, the recommended values are initially set, then the welding parameters are fine-tuned.

Voltage setting

Changes in voltage are determined by the energy costs of melting the metal and burning the arc. An increase in energy consumption causes an increase in the thickness of the consumable material and the penetration depth of the workpieces. Household semi-automatic devices are configured using a stepwise method.

There is a reference table for selecting voltage values on the inside of the casing cover. This is important information from the manufacturer, which allows you to select optimal power values for each model, taking into account specific operating conditions.

Wire feed speed

The value of the current depends on the speed at which the consumable material is supplied to the melt zone. The amount of wire feed is one of the main variable parameters. It is selected after the voltage has already been set, since the intensity of melting directly affects the feed rate.

The value varies depending on the grade and diameter of the material used and after each change in voltage values. There is equipment on the market with automatic parameter settings. However, it is one of the expensive semi-automatic machines.

To optimize semi-automatic welding settings, fine adjustments of values are required. If the filler wire is fed too quickly, sagging will form; Slow feed will cause seam breaks, sag or waviness. A good roller is impossible without precise balancing of three parameters: voltage, current and consumable feed speed.

Too high a feed appears immediately after starting work. With the arc ignited, the feed speed decreases, but the wire does not stop bending, sticking to the metal surface and does not have time to melt. In this case, active production of splashes is observed. Insufficient supply manifests itself in the fact that the electrode burns out even before touching the metal. In this case, the tip from which the consumable material is supplied will become clogged. Thus, we can conclude: the correct choice of feed speed mode and current value with previously set voltage settings is the first step to professional growth.

Table of the direct relationship between the adjustments and the result of the work:

Carbon dioxide consumption during semi-automatic welding: what it depends on and how to reduce it

Many industries and repair shops that qualify for welding work use cylinders with protective gases. These are:

- inert - argon or helium, mixtures thereof;

- active - hydrogen, carbon dioxide, nitrogen, which in turn are divided into gases with reducing, oxidizing properties and selective activity;

- a conglomerate of inert and active products.

Relevance of the issue

Shielding gas prevents hydrogen, oxygen, and other harmful substances from entering the weld pool from the air, which deteriorate the quality of the weld. In some cases, gas removes such elements from the weld pool.

Gas is supplied to enterprises by the oxygen shops of factories; a home welder can buy a cylinder of it in a retail chain. For example, a 10-liter cylinder of carbon dioxide costs a little more than 500 rubles, but after using up the gas supply, the container can be filled with a new portion of dioxide.

Every welder tries to increase the operating time of a cylinder with a controlled gas environment, and simply reducing its consumption by simply tightening the valve will not work.

Any welding, at home or in production, strives not only to reduce carbon dioxide consumption, but also to improve the quality of the parts being joined, which for a beginner often occurs in inverse proportion.

However, the output of CO 2 - carbon dioxide, when working with semi-automatic welding, can be pre-calculated so as not to run to the store for a new cylinder just before the end of the working day.

Consumption factors

The most significant conditions for the consumption of the welding mixture - a controlled atmosphere - are the following mediators:

- Type and thickness of metal being connected.

- Welding rod diameter.

- Current strength of the welding machine.

Taking into account each of the above factors, the consumption of the protective medium can be derived. The data below determines the amount of welding mixture output when operating semi-automatically, taking into account the wire diameter and current strength:

- wire 0.8-1.0 mm, device current 60-160 amp. — 8 liters of gas per minute;

- 1.2 mm, 100-200 A - 9.5-12 l/min;

- 1.4 millimeters, 120-320 apm. — 12-15 l;

- 1.6 mm, 240-380 - from 15 to 18 liters;

- 2.0 mm, 280-450 A - up to 20 l/min.

These are average mathematical conclusions that, in addition to the diameter and thickness of the parts, do not take into account environmental factors. The process in an enclosed space will require less consumption of the controlled gas medium, while in an open area some volatilization of carbon dioxide occurs, which is reflected by its greater outflow from the cylinder.

When working outside on a windy day, evaporation, and therefore carbon dioxide consumption, will increase even more.

Last but not least is the quality of the controlled atmosphere. Using unpurified gas, the welder will inevitably face increased production costs.

Carbon dioxide consumption

In order not to be unfounded in assessing the yield of carbon dioxide for production needs, a specific example should be given. A standard gas container is a 40-liter cylinder, containing 24 kg of pure carbon dioxide, which at the outlet forms 12 cubic meters of a protective environment.

Using a filler thread with a diameter of 1.0 mm, we set the lowest current strength - 100 A. If you refer to the data in the reference books, a continuous mode similar to welding will last exactly one day - 24 hours.

However, work shifts with such a work duration are almost never found; let’s take a regular shift - 8 hours. Dividing the gas volume by one working day, we get 8 liters of controlled atmosphere.

The reference book indicates that 1 kg of surfacing will require 1100 g of carbon and 1300 g of filler material. Using simple calculations, we can come to the following conclusion: 1200 g of additive will be taken from a cylinder of 1000 g of gas.

Based on this, it can be stated that a 40-liter gas container is enough to melt almost 29 kg of welding material.

Of course, this is approximate information, but it often coincides with actual data. For novice welders, a table of carbon dioxide consumption is provided, depending on the diameter of the thread and the current rating.

Saving mixture

Based on the foregoing, we can conclude that the consumption of a controlled carbon dioxide medium depends not only on direct factors - the diameter of the rod, the current strength and the thickness of the metal elements being connected. Indirect factors affecting carbon dioxide consumption are weather conditions - wind, open area.

However, taking into account the latter, it is possible to minimize the costs of the welding process.

An optimized option would be to carry out the work in a closed, artificially ventilated room, with the involvement of an experienced welder. You can also entrust the process to a beginner, but the expense will still be slightly or significantly higher. An inexperienced employee has the right to suggest achieving savings by screwing on the valve on a carbon dioxide cylinder during semi-automatic welding.

Such an operation will reduce the flow of the mixture to the weld pool, but will increase the flow of oxygen from the atmosphere, which will affect the quality of the weld. However, there is a way out of this situation.

Experts advise using multi-component controlled gas compositions in your work, which can reduce carbon dioxide consumption while simultaneously improving the quality of the seam. For example, an argon mixture consists of 20% carbon dioxide and 80% argon. Its main advantages are:

- reduction in the amount of wire used up to 80%;

- reducing the amount of stuck metal splashes;

- increased penetration depth of elements;

- fewer pores in the weld.

The total cost of the operation is reduced to 20%.

Conclusion

Please note that multi-component welding gas is somewhat more expensive. Therefore, before purchasing, you should make sure of the economic benefits of such a mixture.

Experienced craftsmen know how much controlled gas environment is required for welding various materials and what the carbon dioxide consumption will be.

Beginners need to gain experience in order to save carbon dioxide when working with semi-automatic welding.

Polarity

Changing polarity is one of the simplest adjustments. Under the cover of most semi-automatic machines there is a sign with information about which metal requires direct or reverse polarity. A novice welder must firmly understand that with direct polarity, the torch is connected to the negative terminal. With this switching scheme, the wire melts one and a half times faster, but the stability of the electric arc deteriorates.

With direct connection, workpieces are welded using flux-coated wire. Most of the thermal energy goes to protect the welded joint. The flux reacts completely and there is no free residue. The main costs of the method are an abundance of splashes and a decent amount of slag.

The copper-clad solid wire must be powered from the positive terminal. Preparation of workpieces to be welded consists of cleaning the surface and cutting. As the diameter of the wire increases, the conductivity also increases. Therefore, when working with large workpieces, it is advisable to increase the diameter of the consumable.

Getting started with a semi-automatic welding machine

To start working, the semi-automatic welding machine must be completely ready for the welding process. The wire must be installed and the gas cylinder connected. It is necessary to install a ground clamp on the metal being welded. It must be installed at a distance of 15 to 50 cm from the welding zone. The metal must be free of rust, paint, oils and dirt. Any slight resistance will affect the welding process. Dirty metal during welding will cause spatter and burn through, as well as fire.

Correctly adjusted voltage and wire feed speed should result in good welding flow. The correct settings will produce the characteristic hissing-buzzing sound that all welders know well. More details about the welding process can be found in the article “MIG/MAG semi-automatic welding technology”.

Wire release and ejection

The quality of the weld is affected by the length of the consumable material extending from the tip, as well as the size of the gap between the wire and the working surface. The discrepancy between the diameter of the wire and the size of its exit from the tip leads to excess spatter, metal burning, lack of fusion and warping.

Some designs of semi-automatic machines provide the ability to change the location of the burner tip relative to the nozzle. They are located at the same level, but the contact tube in relation to the nozzle can be extended or, conversely, recessed. The adjustment amplitude is 3.2 mm.

Short overhang is used to form welds on low alloy structural steel. As the distance increases in this case, the effectiveness of the protective gas cloud decreases. In order to increase the melting point, you can lengthen the flux wire slightly.

Release and overhang directly depend on the diameter of the filler wire:

What is the carbon dioxide pressure when welding semi-automatically - Metalworker's Handbook

Carbon dioxide welding is a type of submerged arc welding. It is produced with a consumable electrode and is widely used for installation work, repair and restoration of thin-walled parts.

Application of carbon dioxide welding

The simplicity of the process, low consumption of materials and the availability of carbon dioxide welding allow its use in many industries. Welding and surfacing in a carbon dioxide environment are most widespread in the following areas:

- shipbuilding;

- mechanical engineering;

- construction and repair of pipelines;

- installation work;

- production of boilers and equipment;

- welding damage to steel castings and others.

Welding in a carbon dioxide environment is used, in particular, to restore thin-walled car body parts.

Advantages of carbon dioxide welding

Welding work in a carbon dioxide environment has a number of advantages compared to other types of welding:

- Visibility of the welding process and arc burning for the welder.

- No need for devices for supplying and discharging flux.

- Good quality seams. Welded seams do not require subsequent cleaning of flux and slag residues.

- Increased productivity of welding in carbon dioxide, due to the high-quality use of arc heat.

- Possibility of carrying out work in different spatial positions in automatic and semi-automatic welding modes.

- Low carbon cost.

- Use for welding electric rivets and metals of small thicknesses.

- Availability of welding work on weight without the use of a support.

The essence of the carbon dioxide welding process

Carbon dioxide prevents the negative impact of the atmosphere on the welding process. The high temperature of the arc partially decomposes carbon dioxide into carbon monoxide and oxygen. As a result, a mixture of three gases is formed in the arc zone: oxygen, carbon dioxide and carbon monoxide.

Oxygen enters into an oxidation reaction with the metal. The temperature of the electric arc is much higher than the temperature of the weld pool, so burnout (additional consumption) of the metal occurs primarily in the welding wire. The base metal in the weld pool does not oxidize as intensely.

To reduce the negative consequences of burnout, welding wire is made with the addition of alloying additives. The increased content of manganese, titanium and silicon reduces the amount of carbon monoxide and prevents the formation of pores in the weld.

The degree of oxidation increases with increasing voltage consumption. A decrease in oxidation intensity occurs with an increase in current density. Direct polarity of current when welding with carbon dioxide leads to more oxidation than reverse polarity.

Carbon dioxide welding technology

Before welding, the surface of the edges is cleaned of rust, dirt, scale and slag. Ceiling and vertical seams are made with small diameter wires and low currents. Carbon dioxide welding can be carried out using the following processes:

- with frequent forced short circuits;

- with large droplet transfer;

- with continuous arc burning.

The choice of electrode metal transfer process depends on the type of welding wire. Typically, welding work in a carbon dioxide environment is carried out using alternating current. Direct current is used less frequently. The diameter of the welding wire and the magnitude of the current depend on the location of the seam in space and the thickness of the metal being welded.

Carbon dioxide welding materials

Welding work with carbon dioxide is carried out in semi-automatic or automatic mode. The choice of materials for welding in a carbon dioxide environment is determined by the characteristics of this method of work. To perform them use:

- special welding wire;

- liquefied carbon dioxide.

Welding wire

Electrodes used for semi-automatic welding in carbon dioxide have their own characteristics. Submerged arc welding wires are generally not suitable for carbon dioxide applications. For welding in carbon dioxide, electrodes with a high content of alloying additives from manganese and silicon are used.

The diameter of the wire depends on the type of semi-automatic welding machine and the thickness of the main metal being welded. The surface of the electrodes must be clean, free of rust, scale and organic contaminants. The presence of foreign impurities increases the porosity of the weld and spatters the metal.

To clean the electrodes, they are etched in a weak (20%) solution of sulfuric acid and subsequently calcined in an oven.

Carbon dioxide for welding

Carbon dioxide is non-toxic and colorless. Black liquefied carbon dioxide cylinders are used in welding work. The working pressure of the cylinders is 60-70 kgf/cm².

The yellow inscription “Carbon Dioxide” is applied to their surface. The volume of a standard cylinder is 40 liters. It contains approximately 25 kg of liquid carbon dioxide, which occupies 60-80% of the volume.

The rest of the container is occupied by carbon dioxide.

For welding, carbon dioxide is used with a concentration above 98%, and when performing the most critical work - above 99%. The increased moisture content in carbon dioxide leads to large spattering of metal during welding. Using a special desiccant based on silica gel, copper sulfate or aluminum helps remove excess moisture.

The volume of carbon dioxide contained in standard cylinders ensures that work can be completed within 15-20 hours; gas consumption depends on the intensity of work.

Before use, the container must be installed and kept in an upright position to allow excess moisture to settle to the bottom. It is important to ensure that the pressure in the cylinders does not fall below 4 kgf/cm².

When this value is reached, carbon dioxide contains a large amount of moisture, so use of the cylinder is stopped.

The consumption of carbon dioxide is controlled using a special reduction reducer, which is installed at the gas outlet from the cylinder.

The reducer reduces the pressure to a normal level of 0.5 atmospheres and ensures optimal carbon dioxide consumption. When the gas leaves the cylinder, it quickly cools due to the evaporation of liquid carbon dioxide.

This may lead to clogging of the gearbox. To prevent moisture from freezing, use a heater.

Features of welding work in a carbon dioxide environment

Semi-automatic or automatic welding machines for welding in carbon dioxide must have burners that provide laminar gas release from the nozzle. When using non-standard holders, it is worth considering that they must guarantee radial gas flow relative to the electrode axis.

Before passing the wire into the hose, its end must be rolled; in addition, the tip must be removed from the mouthpiece, and the hose must be checked for kinks. These standards must be observed at all times. Failure to comply with the rules may cause deformation of the wire in the rollers and wear of the holder and hose parts.

Before welding work, you need to set the welding mode required for this type of welded joint, the diameter of the wire used and the thickness of the metal.

In accordance with the mode, set the gas flow and wait some time for the air to completely escape from the hoses.

Wire consumption rates are 35-40 mm, with the condition that the gap from the end of the wire to the nozzle is within 15-25 mm. Check the pressure in the cylinder.

The electric arc is excited by touching the end of the welding wire to the surface of the product, and the wire is released by pressing the start button on the holder.

The stability of the arc, the resistance of the gas protection of the arc from exposure to air, the speed of cooling of the metal, the shape of the weld, and the possibility of visual observation of the work area depend to a large extent on the movement and location of the torch relative to the product.

Approaching the torch to the surface of the product makes it difficult to monitor the welding process and causes contamination of the torch with splashes, and too much distance leads to defects in the welds, due to a decrease in the reliability of metal protection with carbon dioxide.

Assembling joints during welding in a carbon dioxide environment

When assembling welded edges, certain standards are observed; the displacement of the edges should not exceed 1 mm for metal with a thickness of 4-10 mm and 10% for thicknesses more than 10 mm. The assembly of joints for carbon dioxide welding depends on:

- location of the seam in space;

- connection type;

- metal thickness;

- welding method (semi-automatic or automatic).

The lower the assembly quality of the joint, the lower the productivity of welding work, and the wire consumption increases. It is recommended to weld and assemble joints without tacks.

When assembling with tacks, they should be placed on the opposite side of the joint. Tack welding can be carried out using a non-consumable electrode, resistance welding and carbon dioxide wire welding.

The location of the tacks and their dimensions must correspond to the type of joint being welded and the thickness of the metal.

Carbon dioxide welding is a common type of work. Compliance with technological standards of the welding process and the use of optimal materials allows you to quickly obtain high-quality welds and ensure reliable connections for many years.

All about semi-automatic welding in a carbon dioxide environment

Semi-automatic welding in a carbon dioxide environment makes it possible to connect metal parts. The weld seam when using this type of welding is highly durable. Therefore, welding metals using carbon dioxide is widely in demand among both beginners and professionals.

The operating principle of semi-automatic soldering using carbon dioxide is quite simple. Simultaneously with the electrode, CO2 is supplied to the weld pool. Gas fills the bath, thereby protecting the metal from the negative influence of air.

Modes and features of welding in carbon dioxide

The main feature of welding in a CO2 environment is the displacement of air when welding parts. This allows you to achieve high quality seams.

It is necessary to take into account that the iron and carbon contained in the workpieces, entering into a chemical reaction with CO2, are oxidized.

To prevent oxidation, you should use specialized wire containing a large amount of silicon and manganese.

Technology of welding in carbon dioxide

Another feature of semi-automatic welding in a gas environment is the possibility of using both direct and reverse polarity. Using reverse polarity for forward current is great for beginner welders. This method makes it possible to easily hold the arc. Straight polarity is used when welding metal is required.

Arc setting

Even relatively inexpensive models of semi-automatic welding are equipped with inductance control verniers. These settings change the temperature of the welding arc, the depth of metal penetration, and the convexity of the joint. You can work with parts that are sensitive to overheating; thin sheet materials no longer pose a serious problem for the welding machine.

The increase in inductance occurs due to compression of the current channel. As the index increases, the melting temperature and melt depth will also increase; the weld pool becomes more liquid. The bead of the finished seam will be flatter. With a small diameter of the filler wire, the arc becomes more stable, the melting coefficient and the depth of metal penetration increase; the amount of splashes is reduced.

Weld parameters depending on inductance:

Operating principles of semi-automatic welding

Semi-automatic welding is a type of arc welding and differs from it in that the process is carried out by automating the supply of electrode wire into the weld pool and the simultaneous exposure of it to shielding gas. The remaining operations are performed manually. The gas used in welding is intended to completely protect the heated and molten base materials and electrodes from exposure to air, which can not only slow down the process, but also stop it completely.

When welding metals, the key task is to maintain a certain temperature regime. Insufficient heating of the seam will not ensure high-quality melting of the edges of the workpieces being welded and mixing them with each other and with the filler material. When the temperature rises, the metal boils and evaporates, which causes chemical reactions with atmospheric gases. What complicates the situation is that for some metals and alloys such processes can begin to occur even at temperatures below those required for the formation of a high-quality weld.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

When using different types of welding equipment, this problem is solved in different ways. The semi-automatic welding we are considering today, which is also called MIG/MAG, has two technological distinctive points. The first is that the shielding gas is supplied directly to the melting zone, and the second is that the installation is equipped with automatic adjustment to regulate the feed rate of the filler material and change the strength of the welding current.

The welding wire is fed using a broaching mechanism, for which, before performing the operation, it is necessary to calculate the semi-automatic welding modes, taking into account the correct ratio of speed and melting temperature, in order to ensure uniform filling of the seam and high productivity.

The function of a protective medium can be performed by active gases (hydrogen, nitrogen or oxygen) or inert gases - argon or helium. In industrial production, a mixture of carbon dioxide and argon is predominantly used in a ratio of 1:4, which is quite sufficient for standard processes. When welding specific materials, for example, duralumin, brass or high-alloy tool steels, it is necessary to vary the ratio of the mixture composition.

Despite the fact that consumables (welding wire and gas) are expensive, mastering semi-automatic welding is the best option for beginners for two reasons. The first advantage is the ease of performing the weld; to do this, you just need to read the reference documentation and use it to set the required technological parameters of the inverter for a specific type of welding joint.

The second advantage is ergonomics, that is, complete visual control of the condition of the seam, the ability to use any spatial position and, most importantly, the feasibility of the weld even on very thin-walled parts.

Problems and errors

In the case of blind copying of average data on equipment settings, which are given in various reference books and tables, problems and mistakes cannot be ruled out. The fault here lies entirely with the welder. It is important to consider not only recommendations, but also the subtleties of performing each specific task. Attention to detail and a creative approach are the keys to successful completion of the job.

Experienced specialists immediately detect incorrect operation of the equipment. Here are some of the signs:

- Clicks and crackles indicate that the supply speed of the consumable is not high enough;

- if the solder begins to melt near the tip itself at a decent distance from the joint, then its feed speed is low;

- too much splashing: you need to increase the inductance and gas supply;

- the seam is replete with shades of green or brown and turns out to be porous - gas protection is not good enough;

- uncooked areas, as well as burned areas, indicate the need to adjust the voltage. It is possible that you need to turn the inductance regulator;

- a combination of lack of penetration, instability of the arc and an inhomogeneous seam - the contact of the mass has weakened or there is a lot of different debris in the welding environment (possibly due to the surface of the workpieces being poorly prepared for work);

- notches and uneven fullness of the bead; the speed of the torch along the seam is impaired;

- intermittent seam + excessive spatter – arc length is very long.

Relevance

The first thing you should definitely pay attention to if you decide to use this method of work is the qualifications of the master. It will be difficult for a beginner to understand the settings and choose materials wisely.

Work experience plays an important role and should not be underestimated. Professionals especially like to repeat how important it is to spend decades on self-study, become familiar with books, study standards and, of course, practice.

Without this, it is difficult to achieve success and quality. It’s hard to disagree with this, but let’s not give up on young specialists, because we all started somewhere.

It is for those who want to learn all the intricacies of this work, the correct calculation of the semi-automatic welding mode in a shielding gas environment, that this article was written.

Study the theory carefully and put it into practice – that’s the whole secret. It contains not only the knowledge of specialists, but also information from reference books and professional literature.