Types of semi-automatic welding machines

Such equipment is not cheap, so you should correctly understand what types of semi-automatic machines there are and choose the appropriate device:

- According to the method of protection of welding seams that are created:

- submerged arc welding – rarely used;

- gas shielded welding is the most common type;

- welding using flux-cored wire – used together with shielding gases.

- By power source:

- transformer - have a large size and weight, used in stationary places of work;

- rectifier - quite large in size, consume a lot of energy, mainly used in stationary operating conditions;

- inverter - small in size and weight, require little power from the power source, used in everyday life, at home.

- By number of components:

- single-body - all the necessary parts are located in one block;

- double-body - two parts of the body that contain the necessary components. One part contains the wire feeder, welding torch and control panel, the other contains the welding power source, control monitor and ballasts.

- According to the method of movement in the workplace:

- stationary - mainly used in medium and large serial production for welding specialized posts;

- mobile – used at home, can be easily carried or moved on wheels.

- According to the method of connecting to the electrical network:

- single-phase - plug into the simplest household electrical outlet;

- three-phase - connected using special electrical connectors.

- According to the method of connecting the electrode wire:

- push type - the feed drive pushes the wire into the mouth of the welding torch;

- pulling type - the wire is pulled from the reel of the equipment surface using the feed drive, which is located in the burner handle;

- push-pull type - combines both types of wire feeding.

- According to the number of rollers that deliver the wire:

- a pair;

- two pairs.

- According to the form of welding current:

- constant;

- throbbing;

- impulsive.

- By connection polarity:

- straight polarity – minus on the electrode;

- reverse polarity – plus on the electrode.

The quality and speed of the required work will directly depend on the correctly selected semi-automatic welding machine.

Semi-automatic device

Semi-automatic arc welding provides high-quality welding of ferrous and non-ferrous metal products. It is even suitable for rusty and galvanized metal. But when welding components made of difficult-to-weld materials, it is recommended to use copper and aluminum wire. The use of these elements ensures the formation of a durable and strong seam.

Welding requires semi-automatic welding equipment. And before starting the process, it is worth considering the important features of the device.

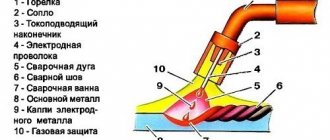

To understand what semi-automatic welding machine is needed, you need to study its structure. The design of the device includes the following components:

- main block This is an important element of the equipment; it is responsible for supplying power to the electrode wire;

- welding sleeve or hose;

- a burner with a wire inside;

- conductive type tip;

- shielding gas supply system.

To carry out the work, a mechanical unit is used, the device of which includes a coil of wire, which performs the functions of a consumable electrode. Additionally, there is a mechanism that automatically feeds the coil. The welder selects the current strength and speed indicators for supplying the electrode on the equipment independently; these parameters depend on the type of metal being fused and on the speed of movement of the torch.

There are many types of machines that are used for the welding process. Various classifications are used to organize them. Depending on the method of protecting the material during welding, the following types are distinguished:

- semi-automatic welding of metal under a layer of flux. Flux is a powdery composition that is present in the core of the working wire. In terms of chemical properties, it is similar to a coating composition for an electrode;

- semi-automatic welding using inert and active gas mixtures.

Depending on the method of feeding the electrode wire, welding equipment is divided into:

- Stationary . The devices are fixed on a stand or a special console.

- Portable . The equipment looks like a portable cabinet.

- Mobile . This is a special cart that is designed to be moved within the premises.

Characteristics of semi-automatic welding machine

The semi-automatic welding machine is designed to perform arc welding using an electrode in a protective environment. With the help of such welding it is possible to make jewelry work on very thin metals. Rust protection and seam quality with such equipment increases several times, and work productivity increases.

One good welding machine should include:

- current source for welding - rectifier or inverter;

- mechanism feeding welding wire;

- welding torch;

- wires and cables that are needed to connect to the electrical network;

- package of welding cables – with holder and clamp;

- a sleeve for connecting protective gas to the source;

- a cylinder with gas for protection - carbon dioxide, argon or helium;

- terminal for controlling equipment with regulating and control equipment.

Set of semi-automatic welding machine

The most important characteristics of the semi-automatic welding machine are:

- Maximum current. This parameter affects the diameter of the wire used and the maximum thickness of the metal being welded. In the technical document, the manufacturer indicates the required current to work with any material.

- Network settings. Depending on the voltage, you can use more powerful devices with additional capabilities and functions. For normal use at home, a voltage of 220 V is sufficient.

- Duration of switching on. This characteristic shows how long the semi-automatic welding machine can work continuously. The higher this parameter, the longer the device can operate. For domestic conditions, 30% is enough, and for professional models – at least 60%.

Semi-automatic welding circuit diagram

The performance of the equipment fully corresponds to the power consumption. The magnitude of the no-load voltage is different on the models of semi-automatic welding machine. The output current range for all modes is indicated separately. The weight of the device and its dimensions do not greatly affect the device.

Advantages and disadvantages

Let us formulate the main positive properties that a semi-automatic welding inverter has, making the choice in favor of such a device more preferable.

The ability to create high-quality connections, including materials that are usually difficult to weld. This advantage is due to the use of specific technology, which consists in the use of special gases that form a protective microenvironment in the welding zone.- Ability to weld thin sheet metal. The semi-automatic machine has this property due to the fact that, thanks to the protective environment and the possibility of using thin (up to 1 mm) welding wire, it is possible to work with low welding currents. This mode is not available when using a piece electrode, or requires the highest skill from the welder.

- Low heating of parts during welding. This quality is due to the use of thin welding wire, due to which the arc combustion zone is localized more narrowly, the total arc energy, and, consequently, the amount of heat generated, is reduced. This is very important when working with thin sheet material, uneven heating of which can lead to warping. During body repair of motor vehicles, low heating ensures the safety of the paint coating of parts adjacent to the welding site.

- Ability to work for a long time in welding mode without extinguishing the arc. This property is especially important in industrial use. When welding critical large-sized parts, long welds can be performed in one pass, thanks to the presence of an “endless” electrode in the form of a welding wire.

- Ease of use. Setting the semi-automatic machine to the desired operating mode ensures further stability, regardless of the qualifications of the welder. This allows even beginners to successfully operate the semi-automatic machine.

Semi-automatic welding machine with gas

Welding various products made of copper, titanium or steel with a welding machine is the process of combining parts of metal by feeding wire to the joint. Along with this process, shielding gas is supplied. This gas ensures that the air does not negatively affect the heated and molten metal.

Welding using shielding gas does not require the additional purchase of expensive equipment. An even greater advantage is that work with carbon dioxide can be done anywhere without installing a special energy source.

When welding with gas, you can easily change the flame power to join different materials that have different melting points. Cast iron, copper, lead and brass weld much better, faster and stronger with this type of welding. If all rules and instructions are followed, the seams will be of the highest quality.

This type of welding can not only weld, but also cut and harden various metals. Welding can take place in an environment of argon, carbon dioxide or other inert gas. Special wire for welding with gas contains manganese and silicon, which protect against the negative effects of the external environment.

Saving time with this type of welding is easy because the electrodes do not need to be changed and the seams do not need to be cleaned after welding. When using pure carbon dioxide, the seam will have a scaly texture, and when adding argon, the seam will be smooth and even.

Operating modes MIG, MAG, MMA, TIG

At the present stage, many welding methods have been created. The best known methods are mig, mag, tig, and mma welding. These symbols differ depending on the type of gas that protects the structure from oxidation.

MIG welding is the world's definition of metals in an inert gas environment. MIG – Metal Inert Gas indicates the use of argon. Gas is supplied from the cylinders through high-pressure pipes to the burner

MIG welding technology

Using MIG technology it is possible to weld the most complex groups of metals in welding activities.

MAG welding is the global designation for welding in an active gas environment. This technology uses carbon dioxide. Active gases have a similar task to inert gases - protecting oxygen.

MMA or RDG - manual arc welding with a molten conductor is considered an auxiliary function of the equipment. The conductor, melting, falls into the welded bowl, which appears as a result of melting the edges of the workpieces. The coating also melts and provides a protective layer on top of the bowl.

TIG semi-automatic welding with a melting conductor in an argon environment is considered an addition to more expensive semi-automatic machines. The electrode has a constant length, which facilitates simplified welding, and the exclusion of other impurities ensures high-quality seams.

Semi-automatic welding machine without gas

Welding in this way occurs using a flux wire containing a special welding powder. In appearance, welding with gas and without gas are similar due to the combustion of flux with the formation of a cloud of gas.

The main advantage of this type of welding is the absence of cylinders that are under gas pressure. The wire for work can be made of any material, it all depends on the metal being welded. After applying one seam, it is necessary to make another one on top, because due to the flux, slag can get onto the seam. After this, additional processing may be required.

Semi-automatic welding machine without gas

Working with such welding is a little more difficult: the wire must be fed into the welding area with force, and throughout the entire work you need to monitor the bends of the hoses, the polarity and the phase of the operation.

How does a semi-automatic machine work?

To understand how semi-automatic welding works, it is worth considering the operating principle of the equipment. During processing, an electrode wire is continuously fed to the area to be welded. For this reason, the welder should not constantly install new electrodes.

During welding, the products being welded are heated and deformed. An electrical discharge is formed between the metal element and the electrode, which is energized, in the gas mixture. The quality characteristics of the connection are enhanced by the use of inert gas, which prevents the formation of oxides.

It is worth noting! Semi-automatic welding technology received this name because the wire is fed automatically, and the feed control and welding process is carried out manually by the welder.

Among the main features of the semi-automatic machine are:

- Semi-automatic equipment has two poles - with a positive and negative charge. The polarity of the connection is selected in accordance with the metal that is being welded. One clamp is attached to the workpiece being welded, the other is fed to the sliding contact of the torch.

- The current parameters are selected according to the characteristics of the material used for welding.

- To select optimal current values, welders use special tables and follow the recommendations of the welding equipment manufacturer.

- Feed speeds are set using a gearbox or gear.

- Gas semi-automatic equipment is designed to work with inert or carbon dioxide. To carry out welding work, welding wire is supplied for a semi-automatic device, which contains magnesium and silicon. Gradually, it melts and is subsequently supplied to the area to be welded.

- Along with the wire, gas is supplied, which protects the metal product and the electrode from the negative effects of oxygen.

- When using equipment for flux-cored wire, no gas is required. When semi-automatic welding is carried out without gas, the flux burns and gas is formed, which neutralizes the negative effects of air.

Semiautomatic welding machine for home

To select a semi-automatic welding machine, you need to decide how this device will be used. There is no point in purchasing expensive professional equipment for your home, so you should focus on household and semi-professional ones. Household devices are perfect for similar and simple work with the same metals. The second type of semi-automatic machine will fit well with people who carry out operations with materials of different structure and thickness.

Welding current is of great importance. You need to immediately decide what thickness of metal you will have to work with. Current to thickness ratio:

- up to 50 A – 1.5 mm;

- up to 80 A – 2 mm;

- up to 130 A – 3 mm;

- up to 160 A – 4 mm;

- up to 180 A – 5 mm.

These are average values; the exact value must be determined for a specific metal. It must be taken into account that the device should not operate at maximum power, because it can quickly fail. It is best to take a semi-automatic welding machine with a small reserve. If neat seams are required, then when choosing a device for your home you should pay attention to current regulation.

Supply voltage is one of the most important issues for welding work. For home operations, equipment with a single-phase connection is ideal. But very often there are power surges in the network, due to which electricity can be lost. Therefore, it is necessary to look at deviations at face value. If jumps are frequent, then the deviation should be as large as possible.

If finances allow you to take a more expensive model, then you should take an inverter semi-automatic machine. It has additional functions, current regulation and arc stability.

What criteria do you use to choose the right device for yourself?

The consumer does not always know how to choose an inverter with a long service life at a low price. Important parameters for selecting a welding unit are highlighted:

- Application area.

Semi-automatic welding equipment is suitable for any type of activity.

Repairing a car using a semi-automatic welding machine

- Appearance and size of the weld.

For external work, the aesthetics of the weld seam is required. For others, the strength of the welded area is important. These indicators become the main ones in the final selection of equipment.

- Type of metal to weld.

When selecting a semi-automatic welding machine from a huge assortment, you should know what metal the workpiece to be welded is made of. When carrying out body repairs, you will need a simpler welder, and to work with steel structures you will need a more high-torque and expensive model. Aluminum workpieces require a semi-automatic machine with an additional TIG function with inert gas.

- Electrical network parameters.

When carrying out welding activities in the village, in an area with old wiring, you should remember about possible voltage surges. For such conditions, special welding models have been produced that have a large coverage of voltage surges.

Table of approximate welding conditions for carbon steels

Professional opinion.

Professional semi-automatic welding machines - the choice of experienced specialists . For beginners in welding work, a simpler device, without additional functions, is suitable.

Semi-automatic welding machine for cars

A simple welding machine with a voltage of 220 V is suitable for car repairs. For more in-depth work with the machine, a powerful welding machine with 380 V is required. In this case, the welding seam will be much better and stronger.

A device with a mixture of argon and carbon dioxide in a ratio of 80 to 20 will help you get an even seam without splashes. You need to choose a manufacturer from leading European manufacturers; the investment will pay off for many years.

The switching duration must be selected at least 50%, and the power must be at least 150 A. Depending on the work, a choice must be made between mechanical and electrical wire feeding.

Differences between semi-automatic machines

The main differences between semi-automatic welding machines include:

- Using welding wire instead of piece electrodes;

- The use of protective gases to form the environment;

- Availability of an automatic mechanism for continuous wire feeding during the welding process.

The listed design features determine the unique capabilities that semi-automatic welding machines have.

We recommend similar articles from the section:

Features and criteria for choosing Resanta welding machines, advantages and disadvantages, current models with reviews.

Is it worth purchasing Kempey welding machines, what features and advantages do they have, examples of the company’s machines and consumer reviews.

Tips for choosing a semi-automatic welding machine

Before purchasing a device you need:

- Determine through which electrical network the work will be carried out.

- Find out what type of operations will be performed on this device.

- Learn how the welding process occurs using a semi-automatic machine.

- Pay attention to the manufacturer, reviews about working with him.

The quality of seams will be 1.5-2 times higher if you use foreign equipment. But their price exceeds the cost of domestic ones. It is important to determine what is most important to you personally.

Basics of semi-automatic welding

Using a semi-automatic machine, it is convenient to weld even rusted or galvanized metal. The surface will not be damaged during processing. The main thing is to know which wire to choose for a semi-automatic machine in accordance with GOST, so that the seam is strong. use both copper and aluminum wire. Having selected suitable consumables, such as a semi-automatic torch with the required power, you can proceed directly to the welding process. First, the equipment is configured and protective measures are taken. You need to work in a mask and special clothing. The type of seam is chosen based on GOST standards.

- The procedure for carrying out preparatory operations:

- Clean and degrease the parts to be welded. This will require solvents.

- Make sure gas equipment is in working order.

- Make a test seam to determine the accuracy of the settings.

- Select current and voltage.

Carbon dioxide - welding for beginners

Automotive parts often have fragile elements that need to be welded from time to time. Service station employees usually use carbon dioxide machines. During processing, the parts retain their impeccable appearance and the paint does not crack. Therefore, you can save on further priming and painting. It is possible to treat even a small, hard-to-reach area. A minimum of waste is generated, the seam is strong and at the same time quite thin. The welding wire melts quickly, but the welder does not need to waste time installing electrodes. Therefore, the speed of work increases significantly.

We recommend! How to cook cast iron using electric welding. Welding with inverter

Even a beginner can master the technology of semi-automatic inverter welding with carbon dioxide. It can also be used to process stainless steel. Even if the movements are not very careful, the seam will be smooth. Parts that vary in thickness will fit together securely.

Professionals usually use argon Tig welding when carbon dioxide is not suitable. The crucial point is the choice of pressure. It should be high enough so that the weld pool does not spread. But if you set the pressure too high, air will start to be pumped in.

Welding without gas - an alternative option

Using an inert gas, you can prevent the formation of oxides and make a high-quality seam. But many amateurs do not dare to work with gas cylinders. Moreover, the cost of argon is quite high, and the device will not be used on the farm very often. At a summer cottage or in a garage, it is more convenient to weld without gas with direct current. To do this, you need to purchase flux-cored or flux-cored wire. Gas is formed during the combustion of the wire, as when using a standard electrode. The resulting vapors protect the treated area.

How to weld a steel product semi-automatically without gas

First you need to purchase a coil of steel wire with flux. Then the wire feed for the semi-automatic machine is turned on. To do this, turn the switch on the device body. Then the flux is placed inside the funnel. It is necessary to monitor the position of the holder so that the flux gets only into the working area. Then carefully open the safety flap to release the flux. Now you can start the device by pressing the “Start” button and start moving the electrode. As soon as an electric arc is formed, the master begins cooking.

There are high hopes for the semi-automatic. There is no need to spend a lot of time and effort, as is the case with manual instruments. Anyone can learn to cook. But first you will have to devote time to studying the structure of the semi-automatic device and brewing techniques. Before taking on important operations, it is worth practicing. It is simply impossible to become a welder without training. Also, the increased risk of injury should be taken into account. Therefore, you should first of all follow safety precautions.

Cost of semi-automatic welding machine

The price of an automatic welding machine depends on many factors. The simplest option can be purchased for $200. For a home, the cost of the most expensive device will be $400. But professional equipment for welding will cost $1500-5000.

To use the semi-automatic welding machine correctly, you must study all the instructions and follow simple safety rules. To begin with, you should learn how to cook simple elements, and with experience move on to more complex designs.

How to choose a semi-automatic welding machine: types, characteristics, cost

tools how to choose semi-automatic welding

Semi-automatic welding modes - theory and practice

Semi-automatic welding involves the ability to set the settings yourself. A person can change 4 main parameters - melting speed, height of the seam and wire feed, direction of movement of the electrode. Also, craftsmen must be able to adjust welding torches for semi-automatic machines. The mode is selected taking into account the thickness of the metal sheet and GOST. Due to the use of gas, the heat affected area is reduced. Therefore, it is possible to apply several sutures without deforming the metal.

The welder must remember all operating parameters by heart. The following semi-automatic welding modes are distinguished:

- cyclic - use a short arc

- pulse

- spot

- constant circular movement of a metal sheet

- jet movement of the workpiece

Helpful information. If the thickness of the part is more than 5 millimeters, you will have to process it in several steps.

To operate in accordance with GOST requirements, an inert gas is required - argon or helium. Sometimes mixtures of these two gases are used. Otherwise, not only does the quality of the weld decrease, but the likelihood of injury and burns to the worker increases. Welding of low-alloy steels is carried out in a carbon dioxide environment. Therefore, it is important to correctly determine the required volume of the cylinder and constantly monitor the flow of gas.

We recommend! How is welding indicated in the drawings?

Feed mechanism

A special feeding mechanism for a semi-automatic machine is designed for drawing wire. It reduces the consumption of welding wire. Modern models are equipped with electronic controls, so they are easy to use. Some have the ability to record more than five welding mode programs. Expensive models usually have several additional regulators. The wire is pulled through the torch channel by rollers for semi-automatic welding machines. At the same time, the consumable is supplied at a speed specified by the welder. There are 3 modifications of feeding mechanisms to choose from:

- Push - used quite often, but has limitations on the length of the hose. Inconvenient if you need to weld parts located at a distance from the power source.

- Pulling action – a long hose can be connected.

- Combined - combines the advantages of the previous two varieties.

After setting the semi-automatic welding modes, you can proceed to a test run. Cooking is carried out on a small workpiece. If the quality of the seam is satisfactory, you can start working. When the result is not satisfactory, the device is re-adjusted. It is very important to make the correct adjustment so that the arc does not break and the seam is even.

For the intricacies of setting up the mechanism, watch the video: