Home page » steel welding wire

This section discusses steel welding wire.

For blacksmiths, forges, industries and individuals (homemade workers, self-taught people and enthusiasts).

See below for useful information to help you choose.

Choose brands from the list below the article.

Copper-plated welding wire SV08G2S-O ChZSM. Photo Welding Technologies

Steel wire occupies an impressive niche in the list of materials used in industry and in everyday life . Welding, as one of the types, has the properties of effective use in welding technologies.

Scope, purpose

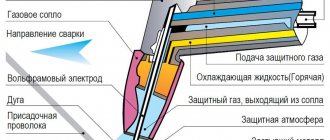

Steel material in the form of wire has found application in automatic and semi-automatic welding . For solid wire, welding is performed in a shielding gas atmosphere (!materials for argon arc welding are in great demand). In cases where the use of a gas cylinder is difficult, the consumable material is made in the form of steel cored wire. Tubular wire is filled inside with a special powder (flux). The flux contains components that protect the weld from the external environment.

Copper-plated steel welding wire (1 kg; diameter 0.8 mm) Elitech. Photo VseInstruments.ru

Steel welding wire serves as a blank for the production of piece electrodes . It is used as an additive for surfacing surfaces in order to give them the necessary mechanical (wear resistance, corrosion resistance and others) properties.

Wire GOST 3282 - 74 low-carbon steel general purpose, scope

Ordinary quality wire or GOST 3282 wire is used in almost any industry, from heavy engineering to activities such as waste paper collection. Where it is used as a strapping. And also in the production of public goods. General purpose low-carbon steel wire GOST 3282-74 is intended for the manufacture of nails, lashings, fences, barbed wire and other products.

The wire is produced: black and light (heat-treated and thermally untreated), coated or uncoated (without coating, with shiny zinc and matte zinc coating). The wire is manufactured with a diameter from 0.16 mm to 10.00 mm - without coating, and from 0.20 mm to 6.00 mm with coating.

High-quality wire GOST 3282 is always available in our warehouse. For questions about prices and delivery, call our managers at +7 (495) 781-20-45. There is a flexible system of discounts and deferments.

Technical requirements

The mechanical properties of the wire must correspond to those indicated in Table 1.

The wire is supplied in coils, the overall dimensions and weight of which are indicated in Table 2.

Characteristics of wire coils

Table 1

| Wire diameter, mm | Maximum deviation, mm | Tensile strength, N/mm2, (kgf/mm2) | Relative elongation, % for heat-treated wire, not less | ||||

| Thermally untreated | Heat treated | ||||||

| Group I | Group II | without cover | coated | without cover | coated | ||

| 0.3-0.45 | -0.03 | 690-1370 (70-140) | 690-1370 (70-140) | 290-490 (30-50) | 340-540 (35-55) | 15 | 12 |

| 0.45-1,00 | -0.04 | 690-1270 (70-130) | 690-1180 (70-120) | » | » | 15 | 12 |

| 1.00-1.20 | -0.06 | 590-1270 (60-130) | 690-1180 (70-120) | » | » | 15 | 12 |

| 1.20-2.00 2.00-2.50 | -0.10 -0.12 | 590-1180 (60-120) | 690-980 (70-100) | » | » | 15 | 12 |

| 2.50-3.20 | -0.12 | 540-1080 (55-110) | 640-930 (65-95) | » | » | 20 | 18 |

| 3.20-3.60 | -0.16 | 440-930 (45-95) | 640-930 (65-95) | » | » | 20 | 18 |

| 3.60-4.50 | -0.16 | 440-930 (45-95) | 590-880 (60-90) | » | » | 20 | 18 |

| 4.50-6.00 | -0.16 | 390-830 (40-85) | 490-780 (50-80) | » | » | 20 | 18 |

Mechanical properties of wire

table 2

| Wire diameter, mm | Parameters of the skein, socket | Type of packaging | |||

| weight, kg skein no more, socket | outer diameter, mm | internal diameter, mm | height, mm | ||

| light | At the customer's request, the wire can be packaged in soft containers (paper + fabric or film) | ||||

| 0.35-0.45 | skein 10 | 200 | |||

| 0.50-0.80 | skein 20 | 250 | |||

| 0.90-1.40 | skein 60 | 350 | |||

| 1.60-5.00 | skein 120 | 550 | |||

| skein 1000 | 780 | 400 | 500 | ||

| 6.00-8.00 | skein 250 | 650 | |||

| galvanized | |||||

| 0.50-0.80 | skein 20 | 200 | |||

| 0.90-1.40 | skein 60 | 400 | |||

| socket 200-300 | 650 | 230 | 600-1000 | ||

| Over 1.60 | skein 100 | 800 | 600 | ||

| socket not less than 600 | 400 | 800-1000 | |||

Symbols and markings

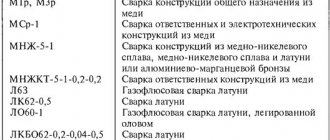

Solid wire for welding or surfacing is marked in accordance with GOST 2246-70. The designation includes the standard size, method of application, chemical composition, information about manufacturing technology, indicates the possibility of manufacturing electrodes, as well as whether they belong to a wire with a copper-plated surface.

Marking of flux-cored steel wire is based on GOST 26271-84 . The designation of welding and surfacing wire differs.

The designation of welding flux-cored wire does not specify the detailed chemical composition; only the content of carbon, phosphorus and sulfur is specified. The standard size, whether the wire is flux-cored, mechanical characteristics (yield strength, impact strength), and permissible spatial positions during welding operations are indicated. The designation determines the type of seam protection - self-protective or gas-protective.

Copper-coated wire SV-08G2S-O (18 kg; 1.6 mm) CEDAR. Photo VseInstruments.ru

Flux-cored wire for surfacing, in addition to indicating the category of flux-cored wire and the technology of use, the chemical composition of the powder material must be given.

Together with the standard size of the wire, the conditions of use are regulated: with gas or other protection, with submerged arc surfacing or in any of the options. In some cases, it is useful to know the accuracy class for deviations of the nominal diameter size. It is also indicated in the designation.

Main indicators

First of all, it contains requirements for the mechanical characteristics of annealed wire. GOST stipulates that the relative elongation of heat-treated wire should be in the range of 15-20% for “bare” wire, or 12-18% (if the wire is coated).

GOST 3282-74 also divides wire into several varieties:

- in terms of production accuracy into normal and increased accuracy;

- by processing method - annealed and unannealed;

- by surface type - with and without special coatings;

- in terms of tensile strength (for wire that has not undergone heat treatment) - for products of the first and second groups;

For thermally untreated wire, the main indicator will be tensile strength, which should have the following values:

| Section in mm. | Tensile strength in N/mm² |

| 8 — 10 | 390-690 |

| 8 | 390-780 |

| 4,5 — 7,5 | 390-830 |

| 3,2 — 4,5 | 440-930 |

| 2,5 — 3,2 | 540-1080 |

| 1,0 — 2.5 | 590-1270 |

| less than 1 | 690-1370 |

To control these main indicators of the quality of knitting wire, GOST requires the acceptance of finished products, testing the mechanical characteristics of 3 percent of the coils or coils from each delivery batch.

The geometric parameters of the wire (thickness and cross-sectional shape) must be checked on 5% of the coils, and the surface quality (scratches, dents, and rips with a depth not exceeding 0.25 of the maximum permissible) must be checked in general in all packages.

If the test results for at least one of these parameters turn out to be unsatisfactory, then another series of tests is carried out - but this time using a sample doubled.

Kinds

Steel welding wire is divided into the following groups :

- low carbon;

- alloyed;

- highly alloyed.

Low-carbon and alloy wires are produced with a copper-plated surface. Copper plating increases corrosion resistance. The stability of the welding arc is increased by reducing friction when feeding through the tip hole and improving the current-carrying characteristics characteristic of copper.

Copper-coated wire SV-08G2S BARS. Photo VseInstruments.ru

The development of wire drawing technology makes it possible to obtain it with a perfectly clean surface. This is where the name of steel welding wire came from - polished . In terms of its characteristics, it is close to copper-plated and creates a more stable arc than steel with a regular surface. Some high-alloy wires (mostly molybdenum-containing wires) are poorly coated with copper. Such products are made with a polished surface.

Useful video

Packaging of knitting wire GOST 3282-74

| Nominal diameter, d | Parameters of skein, rosette | Type of packaging | |||

| weight, kg no more | outer Ø, mm | internal Ø, mm | height, mm | ||

| Black | |||||

| 0.2-0.45 | 10 | Not regulated | 200 | — | Wooden or cardboard containers weighing up to 1000 kg |

| 0.45-0.80 | 20 | Not regulated | 250 | — | Wooden or cardboard containers weighing up to 1000 kg |

| 0,80 -1,60 | 60 | Not regulated | 350 | — | Skeins and coils, as agreed with the consumer, can be packed in soft packaging |

| 1,60 — 5,00 | 120 | Not regulated | 550 | — | Skeins and coils, as agreed with the consumer, can be packed in soft packaging |

| 1,60 — 5,00 | 1000 (riot) | 800 | 400 | 500 | Skeins and coils, as agreed with the consumer, can be packed in soft packaging |

| 6,00 | 250 | — | 650 | — | Without packaging |

| 6,00 | 1000 (riot) | 800 | 400 | 500 | Without packaging |

| Galvanized | |||||

| 0,40-0,80 | 25 | — | not less than 140 | — | Wooden or cardboard containers weighing up to 1000 kg |

| 0,90-1,40 | 60 | — | Not regulated | 800-1100 | Skeins can be packed in soft packaging (film), rosettes - in a sleeve made of polypropylene fabric |

| 0,90-1,40 | 200-300 (rosetta) | 500-550 | at least 360 | 800-1100 | Skeins can be packed in soft packaging (film), rosettes - in a sleeve made of polypropylene fabric |

| 1,60-4,00 | 100 (skein) | 800-900 | not less than 450 | 800-1100 | Skeins can be packed in soft packaging (film), rosettes - in a sleeve made of polypropylene fabric |

| 1,60-4,00 | 600 (rosetta) | 800-900 | at least 360 | 800-1100 | Skeins can be packed in soft packaging (film), rosettes - in a sleeve made of polypropylene fabric |

Wire GOST 3282-74 with zinc coating is divided into:

- galvanized wire, class I - 1C;

- galvanized wire of the 2nd class - 2C.

Characteristics

the same requirements apply to each of them .

Mechanical characteristics should ensure that the wire is pulled through the semi-automatic machine without breaks . The weld filler material must match the strength and other mechanical properties of the base material.

Low-carbon copper-plated welding wire ER70S-6 (1 mm; 15 kg) ELKRAFT. Photo VseInstruments.ru

The chemical composition of filler materials is selected for specific types of metals being welded. It must comply with them, and also take into account the losses of individual elements during different welding methods.

Wire mesh VR-1

The VR-1 wire used is made from wire rod with a diameter of 3, 4 and 5 mm.

By drawing through special rollers to create a periodic profile (punching). As a result, the periodic profile consists of dents alternating with protrusions along the entire length of the wire. The depth of the dents is 0.15, 0.20 and 0.25 mm, respectively, given the diameters. The length of the protrusions is 0.6, 0.8 and 1 mm in the same order. are produced with square cells of 50, 100 and 150 mm, Ø 3, 4 and 5 mm. A mesh with a cell size of 200x200 mm is also produced from Ø 5 mm wire

Taking into account the elasticity of the steel used, the meshes are supplied in cards. The length of which is 2 m and width: 0.25, 0.38, 0.5 and 1 m

Other sizes or galvanized mesh BP, regulated by technical specifications, are also available for sale.

Distinctive features, advantages and disadvantages

The base of any steel welding wire is low carbon steel. The plastic properties of this steel make it possible to provide a drawing process to obtain wire diameters up to 0.3 mm. Carbon content up to 0.12% is its distinctive feature.

The advantage of wire is the variety of properties it can have. Alloying elements in their quantity and percentage allow it to be used for welding metals of various purposes.

Wire ESAB SV-08G2S. Photo 220Volt

Perhaps the main disadvantage is the difficulty in choosing the right filler material for welding not very common alloy steels. Despite the variety in the number of welding wires, it is rarely possible to find complete compliance in chemical composition. This requires a lot of experience and practice.

Surface density of zinc coating wire

| Wire diameter, mm | Surface density of zinc, g/m2, not less | |

| for 1st grade | for 2nd grade | |

| From 0.20 to 0.32 inclusive | 10 | — |

| St. 0.32 to 0.40 inclusive | 15 | — |

| St. 0.40 to 0.50 inclusive | 20 | — |

| St. 0.50 to 0.63 inclusive | 30 | — |

| St. 0.63 to 0.80 inclusive | 30 | 40 |

| 0,85 | 35 | 60 |

| St. 0.85 to 1.00 inclusive | 35 | 75 |

| St. 1.00 to 1.20 inclusive | 40 | |

| St. 1.2 to 1.60 inclusive | 50 | 80 |

| St. 1.6 to 2.00 inclusive | 90 | |

| 2,20 | 60 | 100 |

| 2,50 | 60 | 120 |

| 2,80 | 70 | |

| St. 2.8 to 3.60 inclusive | 70 | 135 |

| St. 3.6 to 5.50 inclusive | 80 | 155 |

| St. 5.5 to 6.00 inclusive | 85 | |

As mentioned above, in the production of knitting wire, thermally untreated wire GOST 3282-743 is used, where its heat treatment process is necessary. Our company performs heat treatment (annealing) of wire, which consists of controlled heating and cooling in special furnaces to restore the crystalline structure of the metal, altered by previous processing operations. The heat treatment process involves heating the wire to a strictly defined temperature, maintaining it at this temperature for a certain time and then cooling it. Heat treatment of wire is of great importance, since when internal stresses caused by mechanical processing are destroyed, its crystal structure changes: metal atoms, using thermal energy, form bonds between new crystals.

Annealed low-carbon wire becomes softer, which is why it is called knitting wire, widely used in construction when knitting reinforcement. Thanks to the obtained consumer properties: good ductility with high mechanical strength, knitting wire is widely used.

In addition to services for heat treatment (annealing) of steel wire, our company also offers services for wire rewinding. Wire is rewinded from heavy-duty coils of 150-250 kg or coils of 500-1500 kg into small coils of 15-50 kg.

Tie wire is supplied in skeins or on spools. A coil of wire consists of one piece of wire. No more than 3 pieces of wire are allowed on reels.

Recommendations for use

When welding using semi-automatic machines, the diameter of the welding wire must be selected depending on the thickness of the workpieces being welded. The wire feed speed should be determined by the welding parameters that are set on the machine. The normal process is ensured by the correct polarity. Basically, welding occurs in reverse polarity , when the torch is connected to the positive terminal, and the body of the device to the negative terminal. Some types of wire, such as flux-cored steel, are used with straight polarity.

How to understand the thickness of the wire

Why is the thickness of floral wire measured in strange numbers? How much is this in mm? Which of these wires is thick?

Such questions are asked not only by beginners in floral design, but also by experienced craftsmen who choose floral wire for making flowers. At MakeFlowers.ru, we designate wire this way and that, which can make things even more confusing. Therefore, below is an article about why this happened and how to understand these notations.

A group of Egyptian florists calibrating metal rods

Wire was made back in Ancient Egypt, using a method that was then used in ancient times, in the Middle Ages, and sometimes even now: the wire was pulled through a hole in a solid material of slightly smaller diameter than the wire itself. Due to this, the wire became thinner and lengthened. Then a hole of an even smaller diameter was taken and the process was repeated until the desired thickness was obtained. In Egypt, stone beads were used for this, and in antiquity and now hard alloys with holes of the required diameter. This method is called “drawing” in Russian, and the plate or washer through which the wire was pulled is called “volok”.

A sad medieval German who is not allowed to just ride on a swing, but is forced to pull a wire

The wire that was pulled only once was thicker than 10 times. Well, is it logical? From this method came the old designation of wire in gauges - by the number of drawings. Here the most cunning ones might say that gauge 1 wire should be immediately pulled through hole 3 or 4 and get a thinner wire faster. But it’s not that simple... If you look at the pictures, it’s clear that previously only muscle strength was used for drawing, and this did not make it possible to skip at least one hole and make a smaller caliber without necessarily drawing. Therefore, the correspondence between the number of drawings and the caliber is the same. But let’s not get distracted, because we have reached the most important paradox that bothers our customers: the greater the number of drawings, the larger the caliber of the wire, and the thinner it is! Perhaps this is one of the main ideas of this article.

Well, is it logical? From this method came the old designation of wire in gauges - by the number of drawings. Here the most cunning ones might say that gauge 1 wire should be immediately pulled through hole 3 or 4 and get a thinner wire faster. But it’s not that simple... If you look at the pictures, it’s clear that previously only muscle strength was used for drawing, and this did not make it possible to skip at least one hole and make a smaller caliber without necessarily drawing. Therefore, the correspondence between the number of drawings and the caliber is the same. But let’s not get distracted, because we have reached the most important paradox that bothers our customers: the greater the number of drawings, the larger the caliber of the wire, and the thinner it is! Perhaps this is one of the main ideas of this article.

Despite the appearance of drawing mechanisms in Europe in the 14th century, hats would begin to be removed indoors much later.

Over time, the size of the holes became established and, despite the advent of mechanisms and machine tools, a wire of a certain caliber was named according to the last size of the hole in the die through which the wire was pulled. In different countries, such as the USA and the UK, these holes were slightly different, but were approximately similar. In America in the 19th century. adopted the AWG (American Wire Gauge) standard, which is still used in the USA and in countries where the influence of American standards has historically been great. Therefore, the designation of wire AWG20 means that a piece of AWG 0 with a diameter over 8 mm was drawn 20 times to obtain a thickness of about 0.8 mm. Therefore, if the wire is made in the USA, Japan or Thailand, then it will be designated in gauges . Common gauges for floristry are from thick 18 to thin 30. Here, for example, is Thai floral wire of various colors

French wire drawers move closer to the metric system and confusion over wire sizes

However, let's return to Europe. The Great French Revolution happened in France and the metric system of measures took root in Europe, the successor of which was the SI System of Measures and the Soviet GOST. Therefore, wire made in Europe, in accordance with these systems, is designated not in calibers, but in mm . For example, Polish gerbera wire in a plastic braid

China stands apart: given the position “he who pays calls the tune,” wire from China can be in both mm and calibers, depending on the customer or what labels are left in the warehouse. At the same time, for Chinese floral wire, the gauge or diameter indicated in production is nominal and rather reflects the desire of the Chinese seller than the actual size. Therefore, we measure Chinese wire with a caliper before putting it up for sale.

Now it’s time for the results, or rather for a table that would clearly show the correspondence of the millimeters we are used to to the calibers.

| What do we do? | Gauge AWG | Diameter, mm | Examples |

| Thick stems or branches | 3 | 5,827 | Stems in a thick paper braid, or thick rigid wire with an additional sleeve for greater thickness |

| 10 | 2,588 | ||

| Supporting stems, support for foam balls, bases for heavy compositions | 12 | 2,053 | Thick, rigid wire in a paper braid, 30 to 80 cm long |

| 14 | 1,628 | ||

| 16 | 1,291 | ||

| The basis of thin stems and wreaths | 18 | 1,024 | Thick floral wire |

| 20 | 0,812 | ||

| Base for stems or leaves, for small buds, inflorescences and berries | 22 | 0,644 | Medium thickness floral wire |

| 24 | 0,511 | ||

| The smallest buds and flowers, as well as leaves on thin cuttings | 26 | 0,405 | Thin floral wire. Suitable for most floral design tasks |

| 28 | 0,321 | ||

| The finest elements of composition, the basis for stamens | 30 | 0,255 | The thinnest floral wire |

As a conclusion, some interesting facts and tips:

- If you need a thick stem, then instead of thick stems in a paper braid, you can take a floral sleeve and thin wire for the frame.

- Any wire can be painted a different color. But it is much easier to tint white wire dark than dark wire white.

- You can save on thick wire by tying several thin wires and then wrapping them with floral tape

- In addition to the classification of wire by gauge, diameter or cross-sectional area, Wikipedia claims that there is a classification by the note emitted by the wire... This is how the conventional Petrovich appears at the factory, holding a coil of wire and saying “Kuzmich, well, this is Do, and not Re.”

Manufacturers

Companies related to welding materials must produce a range of steel welding wire. Among them are the best representatives in the production of welding technology products:

- ESAB is a Swedish concern offering a wide range of stainless, copper-plated, aluminum and other types of wire;

- "PRIMA" is a Chinese manufacturer offering a wide range of materials, among which ER70S-6 steel wire stands out;

- "OLIVER" is an enterprise from the Republic of Belarus, whose products are in demand in many countries;

- “LINCOLN” is an American brand that does not have many official dealers in Russia and the CIS countries;

- "HYNDAI" is a world leader in the market for the manufacture of welding materials;

- "DEKA" is a company from China, whose products are in demand due to the optimal price-quality ratio.

Reference. The production of titanium wires is mainly carried out by Russian enterprises, offering the most popular brands, for example, VT1-00Sv.

ESAB welding wire

Consumable material in the form of welding wire is widely used in various welding technologies. The presence of this product in the range of manufacturers with influence in the welding materials market is a prerequisite. ESAB, as a world leader, is distinguished by its production of wide-purpose wires, covering all possible areas of its application. Areas of application ESAB welding wire is in demand in oil and gas, shipbuilding, mechanical engineering, chemical and other industries. IN…

Welding wire: consumption, threading, feeding

To perform one-time welding work at home, you need to decide on the amount of consumables that you will need to purchase in the store. In industrial conditions, the amount of welding wire consumed will affect the final price of the product produced and, ultimately, customer demand. Features of wire Wire consumption is influenced by many factors, including the human factor in the context of whether the welder has the required qualifications. However, the most objective is the meaning...

Welding wire manufacturers

Wire is a consumable material that is in high demand today. Therefore, many companies, in Russia and abroad, specialize in the production of welding wire. The most significant manufacturers, as well as the features of their products, popular brands of consumables and other information useful for craftsmen are presented in this review. List of countries and manufacturing plants The company has modern equipment at its disposal, qualified employees of the enterprises use the latest…

Welding wire: brands, markings, types

Welding work is carried out with any materials - it can be cast iron, steel or non-ferrous metals. Technologies make it possible to perform these works on productive automatic and semi-automatic machines. The functionality of this equipment is ensured by consumables in the form of wire. Application The main purpose is to use consumables on semi-automatic machines in an atmosphere of protective gas. In cases where self-shielding wire is used, welding is performed without gas. The wire is used as surfacing…

Welding wire ER70S

ER70S-6 is a high quality copper-plated welding wire that meets all Russian and international standards. Scope of application, purpose Copper-coated wire (not to be confused with copper consumables) ER70S-6 is used in automatic and semi-automatic welding machines; this material is produced for working with parts, elements and structures made of low-alloy or unalloyed, structural and carbon steel. Widely used in various industries: power generation, electrical engineering,…

Welding wire SV08G2S

Welding wire SV08G2S (spelling Sv-08G2S is also acceptable) is one of the most common brands of filler materials. This brand is often called universal, since it is used for welding and surfacing. In addition, it is used in the manufacture of electrodes. Full information is provided below. Scope of application, purpose SV08G2S wire is used for welding low-alloy and carbon steels, which are widely used in various industries: machine, aircraft and...

Welding wire deck

The DEKA trademark is represented on the market with products related to welding technology. In addition to welding equipment and welder protective equipment, a large range of consumables is sold - welding wire, which has found application in many areas of business where there is a need to create strong connections: in the manufacture of various types of industrial, medical and some other types of equipment of complex design. Also in the shipbuilding industry and mechanical engineering. What…

Requirements for welding wire

The correct wire is the key to a reliable welded connection. When purchasing materials, pay attention to the following parameters:

Technical features of hot-rolled sheet - classification, manufacturing method, application options and processing featuresInstructions on how to choose an I-beam: characteristics, dimensions, calculation of parameters and loads on the beam

We choose VGP pipes wisely: standard sizes, selection tips and characteristics of water and gas pipes

The main characteristic of welding wire is its chemical composition. It should be as close as possible to what is present in the metal being welded. The less sulfur and phosphorus in the wire, the better the connection.

The wire must be clean; no traces of dirt or oil are allowed on its surface. Otherwise, it is better to degrease the material in solvents.

The melting point of the electrode must be lower than that of the base metal. In this case, the melting should be uniform. This will help avoid seam defects and reduce sagging and unevenness.