Cold welding "Almaz" - a series of adhesives. The manufacturer offers several types: for plumbing products, wooden materials, automotive parts, metal elements. The work can be done independently. It is possible to connect oiled and wet parts. The product is not intended for use in industrial environments.

Almaz cold welding classification

Cold welding of the Almaz-Press series has high adhesion rates with various materials (wood, metals, ceramics, plastic, etc.). The manufacturer produces the following types within the series:

- "Universal". Suitable for joining metal and non-metal parts and products. Can be used for repair work in hard-to-reach places.

- "For woodworking." The composition allows you to firmly connect and fix various types of wood, plywood, veneer, bars and other wooden materials. Can be used for repair and restoration work on furniture. Has a natural wood tone.

- "For plumbing repairs." Used to restore ceramics, earthenware, porcelain and other materials from which plumbing fixtures and decorative elements are made. It has a white tint, which allows you to hide the places where repair work is being carried out.

- "To repair a car." Used for sealing cracks, eliminating chips, restoring threads, sealing various surfaces, and fixing decorative elements on car surfaces.

- "With steel filling." This type of Almaz cold welding contains steel filler. The substance is used for gluing metal products (cast iron, steel, copper, aluminum and other types of ferrous and non-ferrous metals).

general information

Almaz cold welding is produced in polymer cylindrical tubes. The glue is additionally protected by cellophane. The manufacturer produces tubes of different sizes for consumer convenience.

Application area

Cold welding "Almaz" according to the instructions has the following scope of use:

- Connecting wooden, ceramic, plastic, concrete, glass, metal parts.

- Connection of products, parts and surfaces made from different materials.

- Elimination of leaks in pipelines, containers, tanks.

- Repair of garden and sports equipment.

- Repairs in hard-to-reach areas or when it is impossible to dismantle or disassemble equipment and structures.

Types of sealing compounds

Sealants intended for treating plumbing fixtures and bathroom elements are classified as single-component. They harden upon contact with air; no auxiliary substances are required. For comparison: in industry, two-component sealants are more often used, the curing of which requires a catalyst. This greatly complicates the process of using them.

Important! For complete and rapid hardening, a one-component sealant should be applied to the surface in a layer no more than 15 mm thick.

Single-component products, in turn, are divided into acid sealants and sealants with a neutral composition. In the first, acid (most often acetic) acts as a vulcanizing component. Such compositions have a characteristic pungent odor; it is recommended to work with them only in well-ventilated areas and, preferably, in a respirator.

Important! Contact of acetic acid with some metals used to manufacture plumbing fixtures can cause corrosive effects. In addition, the acid easily reacts with marble and cement compounds, resulting in whitish marks on the surfaces of these materials. To avoid damage, before using silicone waterproof sealant on copper, zinc, brass or marble plumbing fixtures, test the formulation on a small, inconspicuous area of these items.

In the composition of neutral sealants, acetic acid is replaced by alcohol or ketoxime. These substances do not cause corrosion and do not harm people when evaporated. They adhere well to any surface and do not emit unpleasant odors during drying. In addition, sealants with the addition of alcohol are characterized by a high degree of antibacterial protection and the ability to withstand temperatures up to +300⁰C. These compositions are usually used when finishing baths or saunas.

We recommend reading how to remove insects from the bathroom.

Read: what are the disadvantages of a free-standing clawfoot bathtub?

Find out what features you need to consider when creating a green bathroom design.

Release form of sealants

Whether you need clear silicone plumber's caulk, colored caulk, or matte white caulk, the packages containing these compounds will look pretty much the same. Most often this is a standard tube with a volume of 280 to 310 ml, intended for use with a special gun. On one side the tube is crowned with a thin spout, convenient for dispensing the composition. On the other hand, a piston is built into it, with the help of which the gun squeezes out the sealing agent.

Important! If you don't have a special gun, you can purchase sealant in an aluminum tube that resembles a cream package. It will be much more convenient to squeeze the composition out of it manually.

Advantages of Almaz cold welding

What explains the popularity of Almaz glue - of course, its ease of use; in order to use cold welding you do not need any additional knowledge or tools. Almaz glue is universal, so it can be used in almost all everyday conditions, from gluing metal and wood to joining glass and plastic.

A distinctive feature of cold welding is the possibility of gluing non-homogeneous materials. “Diamond” can easily connect, for example, metal with wood or glass with rubber. This glue is available in packages of different sizes and is sold at an affordable price. The shelf life of the substance is very long and it does not require any special storage conditions. Another good advantage is that it can be used over a relatively wide temperature range. It is very easy to maintain the required setting for the glue to harden.

Flaws

The main and most important disadvantage of Almaz glue is its low quality, compared to analogues produced abroad. The material in a dried state has a very increased fragility. Almaz cold welding cannot be used in critical joints, because their tensile strength will be very low. This glue is primarily used for repairing small household items and decorative items. Lumps are also a major problem.

When mixing the material, lumps form in the consistency, which negatively affect the properties of the glue, and accordingly the quality of the connection. The outer layer does not have a very good property; when it comes into contact with dry surfaces of various kinds, it begins to stick to them. When using repaired products in unfavorable conditions, the service life of the connection is quite short.

Application area

“Diamond” cold welding is an epoxy-based adhesive. Most often it is used when it is necessary to connect any objects for which there is no alternative means for gluing. This substance can also be used to repair broken ceramic products. If any fragment has been lost, cold welding can easily replace it.

Almaz glue can connect parts made of metal, plastic, glass, wood (the parts do not have to be from the same material). However, in order for the connection of the above materials to be good, it is necessary to carry out a number of preliminary works before the gluing process. Namely, you need to thoroughly clean both bonded surfaces from various types of contaminants (traces of grease, oils, etc.). Any solvent can help with this without any problems.

One of the main features of glue is its ability to repair holes. That is, if an object breaks and a hole appears in it, cold welding can seal this hole and provide a sufficiently strong connection. In order to seal a hole, it is necessary to apply a thin layer of the substance to the surface of the hole; after the mass hardens, a durable layer is formed. Once cured, the area can be treated (sanded, painted, polished, etc.).

In a similar way, using cold welding, you can restore small lost parts; to do this, you need to give the mass the shape of the required part, as if using plasticine. After the resulting part has dried, high loads should not be placed on it. Therefore, cold welding is very rarely used in various industries. Universal adhesive "Diamond" can only be used in normal temperature conditions. It is not able to perform its functions at extremely high and low temperatures and in extreme climates.

In order for cold welding to perform its functions, it is necessary to strictly follow the instructions for use

It is important to know: after joining the parts to be glued together, it is imperative to maintain the time specified in the instructions, since only after this period the process of complete drying of the joint occurs

Review of popular brands and manufacturers

To understand unfamiliar names and brands, let's look at the most popular ones. At the same time, we will study a brief description of the composition, advantages and disadvantages.

Diamond

Russian manufacturer producing universal glue. Supplied in plastic tubes, inside of which there is a mixture packed in polyethylene. It is made of two layers: on the outside there is resin, on the inside there is a hardener. It will be enough to roll a small sausage in your hands, mixing the ingredients so that the mixture hardens. Disadvantages: does not withstand high loads, suitable for domestic use.

Polymet

Another domestic manufacturer recommended for critical connections, including those operating at high temperatures.

Usage algorithm

Before starting work, you need to carefully study the rules for working with Mastix cold welding. Instructions for use help you follow the sequence of actions.

First you should clean the parts well. There are varieties of Mastix composition adapted to oily materials. In any case, dust, dirt, and mechanical deposits should be removed.

The oil layer must be removed before using universal compounds; it is advisable to remove specialized adhesives. Extra cleaning won't hurt in any case.

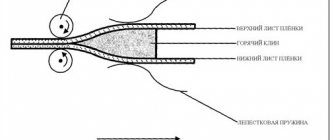

Then you need to cut off the required piece from the cold-welded bar and mix it well with your fingers until a completely homogeneous mass is obtained.

The softened paste should be applied to the repair site. After which the parts need to be fixed and waited in this position for 45 minutes.

If there were residual moisture or oil on the surface, you need to carefully rub the paste until you feel it sticking to the material being glued. For smoothing, you can use flat objects such as a spatula.

After 2.5 hours, any glued parts will be finally ready for use.

Mastix adhesive composite can be used for 2 years from the date of release. At the end of this period, the cold welding composition can simply be thrown into the trash.

It does not require special disposal. The glue is harmless when used correctly. During work, you need to ensure that the composite does not come into contact with the mucous membranes of the eyes and nasopharynx; it is better to work with it while wearing rubber gloves.

One of the ways to form a strong connection between parts made of metal, wood, and plastic is cold welding. It is called so because of the seam, which resembles a weld. In fact, the connection is made using a special polymer material that has good adhesive properties. The temperature effect is not applied in this case.

Instructions for use

The use of the composition must be carried out according to the instructions, in compliance with all requirements, then the work performed will please you for a long period of time. To summarize, we can distinguish several stages of work with Almaz cold welding.

The process must begin with surface preparation. It is cleaned of dust and other contaminants and thoroughly degreased.

After this, the glue is mixed. It is necessary to pay special attention to the equal volume of the external and internal parts of the composition. Since the glue dries quite quickly, it is best to use a small amount of the product for the job.

The glue is thoroughly mixed and kneaded. It should become soft and resemble plasticine in consistency. After this, the necessary shapes are molded from it, or the composition is applied to one of the surfaces to be glued.

Complete drying of Almaz cold welding takes approximately 24 hours. After this, the processed item is completely ready for use.

For testing of Almaz cold welding, see below.

Cold welding with glue solves a lot of different problems: the polymer composition reliably holds together the parts to be joined, creating a joint that is immune to the effects of load and temperature. This method was called welding because of its unique strength characteristics. And you don’t need to heat anything: you need to prepare the mixture at room temperature, apply it to the repair area, and combine.

Peculiarities

The composition can be used in any area where conventional metal welding is effective, but a number of objective reasons prevent the latter from working. This method of joining metal surfaces consists of combining elements using the plasticity of the welding mixture, which penetrates into the material.

A special feature of cold welding is also the fact that to ensure productive work there is no need to purchase specialized expensive equipment. This method can be classified as pressure welding, but the soldering is obtained due to deep plastic deformation, which destroys the oxide layer of the material, which makes the distance between the elements similar to the parameters of the crystal lattice. It is the increase in the energy level of substances that favors the creation of a strong chemical bond.

The properties of this material make it possible to work with surfaces and structures made of non-ferrous and ferrous metals. The main feature of this method of fastening is the fact that cold welding is an ideal option for repairing metal products that are sensitive to heat and provides a reliable connection between different metals.

The method has a number of advantages.

- The products are available to consumers and sold in many supermarkets.

- In most cases, it is possible to connect elements without first dismantling them.

- The work does not take much time.

- The bonded surfaces do not deform because they are not exposed to high temperatures.

- The weld seam meets the requirements of aesthetic appeal.

- Often this method is the only way to connect parts. This applies to welding elements made of copper and aluminum, as well as containers that contain explosive substances.

- The technology eliminates the generation of waste.

- There is no need to make maximum efforts to carry out the process of joining parts.

- The material is absolutely harmless.

- The work does not require special skills or special tools.

- There are heat-resistant varieties of the composition that can be worked with at temperatures above +1000 C.

The disadvantages of the material include several features.

- The strength of the welding seam is still lower compared to conventional welding, so the products are not always suitable for use on an industrial scale.

- Cold welding is not positioned as a material for sealing large defects.

- Surfaces to be joined need to be thoroughly cleaned before applying the compound. Otherwise, the quality of adhesion decreases sharply.

Sealant for plumbing work: composition

Plumbing sealing compounds are made on the basis of silicone with the addition of various kinds of auxiliary substances. When choosing this material, pay attention to its composition. A high-quality sealant should contain:

- not less than 26% silicone rubber;

- 4–6% organic rubber-based mastics;

- up to 2% epoxy resin;

- not less than 2%, but not more than 3% acrylic-based mastics;

- less than 0.3% mechanical fillers.

This ratio of components allows the composition to dry quickly under the influence of atmospheric moisture, providing a reliable waterproof connection.

Silicone plumbing sealant: technical characteristics

Among the technical characteristics that determine the use of silicone-based sealants when finishing wet rooms, the first place is occupied by the resistance of these compounds to moisture and their complete waterproofness. In second place you can put the elasticity that silicone acquires after drying. With any deformation, it is capable of stretching by 900% of its original volume, while maintaining integrity. Therefore, such compositions are actively used for sealing moving joints.

Third place is given to increased viscosity and fluidity of the sealant. When applied to a surface or a joint, it fills all voids and penetrates into the smallest cracks. This explains the high reliability of the final connection.

We advise you to learn how to install a triangular bathtub with your own hands.

Read: what contraindications does Charcot's shower have?

Silicone rubbers withstand temperature changes well. The operating range for these compounds is considered to be from -50 to +200⁰С. This is why plumbing sealant is actively used in the installation of water supply systems: its pipes constantly have to undergo strong temperature fluctuations.

An important advantage of silicone compounds is their high adhesive properties. Silicone adheres well to a wide variety of materials: from plastic to glass. In this case, no additional priming or sanding of the surface is required before application; it is enough to simply clean it of dirt and dry it thoroughly.

Silicone’s resistance to aggressive chemical and biological factors is also very important. A good sealant will not be damaged by cleaning products for plumbing fixtures, it will not grow mold, and it will not be spoiled by fungus. For use in bathrooms, this is truly an invaluable property.

Disadvantages of silicone sealant

Along with numerous advantages due to its technical characteristics, silicone plumbing sealant also has a number of disadvantages. Among them:

- poor adhesion to wet surfaces;

- difficulty in painting after drying;

- low degree of adhesion to polycarbonate, polyethylene and fluoroplastic.

However, these shortcomings are most often present in cheap sealing compounds from the mass market category. Professional line sealants containing mechanical fillers and organic additives do not have the above disadvantages.

Important! If you are not satisfied with white silicone sealant, any plumbing store will offer you a transparent version of the composition. And in large supermarkets you can even find tinted sealing materials, the color of which can be easily matched to the bathroom finish.

Disadvantages of Mastix

- The drying time is a little higher than other brands, so there may be some problems when working with it at different temperatures;

- During preparation, lumps may form, which reduces the quality of the connection and may lead to the need for rework.

Application area

Mastix cold welding for metal is used both at home and in various professional repair procedures, depending on the type of material. It is mainly used as ordinary glue, which should connect metal, wood, plastic, stone and other things that are difficult to glue

An equally important function is the repair of pipelines, various containers, car parts and other things. By applying a plastic mass, cracks can be sealed, penetrating into the internal parts

Cold welding Mastix for metal

If the product is not used at temperatures above 150 degrees Celsius, then it can repair chips, restore parts and perform other repair procedures. The main thing is to withstand the time it takes for the cold weld to dry, after which you can put the part into operation. The strength properties here are not so strong as to withstand strong impacts, but vibration loads, which are often found in moving mechanisms, are tolerated quite normally.

Compound:

- Mineral fillers;

- Metal fillers;

- Amine resin;

- Epoxy resin.

Kinds

For metal – it has a metal filler in its composition, which improves the quality of connection with metal surfaces. It tolerates contact with moisture well, so it can be used in plumbing repairs. It is not highly sensitive to surface cleanliness, so it can be used with wet and oily parts.

Cold welding Mastix for metal welding

Universal - the mixture is used for quick repair of any surfaces. Has a wide range of operating temperatures. This is the most popular and frequently used option that may be needed in every home.

Universal cold welding Mastix

Heat-resistant - this cold welding has the highest destruction temperature, which is 250 degrees Celsius. It is used to join metals, both ferrous and non-ferrous, used in thermally active applications.

Heat Resistant Cold Welding Mastix

For plumbing – glue is used for working in damp conditions. Most often, this is a plumbing repair that requires high moisture resistance and the ability to withstand work under pressure. Connects metal, porcelain, can be used to restore carvings, and so on.

Cold welding Mastix for welding plumbing fixtures

Cold welding Mastix fast steel - contains a steel filler, which improves the quality of the connection and the restoration of lost elements with steel.

Cold welding fast steel Mastix

Mastix cold welding for aluminum – contains aluminum filler, which makes the connection to this metal stronger.

Cold Welding Mastix for Aluminum Welding

Properties and characteristics of Mastix

Before using Mastix cold welding, you should study its characteristics:

| Parameter | Parameter value |

| Package weight | 55 grams |

| Minimum operating temperature | -60 degrees Celsius |

| Maximum operating temperature | +150-250 degrees Celsius |

| Storage temperature | up to +30 degrees Celsius |

| Drying start time | from 7 minutes |

Features of use

Instructions for use of Mastix cold welding require adherence to all rules. At the initial stage, you need to clean the surface on which you will work.

After this, you need to cut off the part that you will use from the total mass. Here it should be taken into account that both components are equal. After this comes kneading and application to the surface. Next, you need to wait from 20 minutes to an hour for everything to set securely.

Key points when working

The maximum operating temperature when using Almaz cold welding is +145 degrees. The composition hardens in a period of time of about 20 minutes, but it takes about a day for it to completely harden. It is recommended to apply glue at +5 degrees.

Before using the composition, it is necessary to prepare the surface. It must be cleaned of dust and dirt and then degreased.

The composition itself must be used in the correct proportions. The volume of the outer part must be equal to the volume of the core. The glue is mixed until it has a soft, homogeneous consistency, after which you can work with it.

If the surfaces treated with the composition are wet, when applying glue it must be smoothed for better adhesion to the material. After this, apply a tourniquet for 20 minutes. If you need to speed up the drying process, you can use a regular hairdryer. When heated, the composition hardens much faster.

The room in which work is carried out must be properly ventilated. It would be a good idea to use gloves.

Composition and properties

To understand what you have to work with, you need to know the characteristics and composition of cold welding. Compound:

- Epoxy resin is the main element of the adhesive mass. Only thanks to it, it is possible to combine different materials.

- Metal chips (powder). Thanks to this filler, after hardening the mass becomes durable. In addition to this, the protective properties in terms of temperature changes are increased.

- Additional elements. There are different types of cold welding that have different characteristics. These indicators are influenced by chemical elements and substances added to the composition.

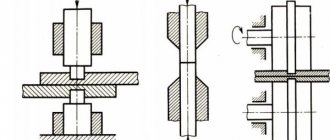

The product is available in finished form or together with a hardener. Ready-made cold welding is a plasticine-shaped bar or cylinder, which must be kneaded in your hands before application. Epoxy resin with hardener is sold in liquid form. As for the hardened seam, the strength of the bond directly depends on the components included in the epoxy resin.

When carrying out quick repairs, it is important to know how long it takes for the glue to dry and when further work can begin. Most types of cold welding require 2-3 hours to cure

However, complete hardening occurs within 24 hours.

Regarding the temperature that the finished seam can withstand, it all depends on the additional components. Classic epoxy resins, after hardening, retain their binding properties at temperatures up to 260 degrees. Specialized compounds can withstand heating up to 1316 degrees.

Varieties and manufacturers

The industry has mastered the production of cold welding of the following types:

- for motorists;

- for plumbing work;

- for gluing metals;

- universal.

There are both domestic and foreign brands. We study the compositions to choose the right one.

Universal

As the name suggests, this composition is suitable for the lion's share of situations. Withstands temperatures up to 260 degrees without destruction. In some cases, where underwater welding or particularly strong welding is required, these properties will not be enough. In all other cases, the stock of quality of the universal product is more than enough.

For metal products

A polymer for joining products made of ferrous or non-ferrous metal, malleable cast iron must have special properties. This includes a strong seam and the introduction of additional components into the composition.

Welding underwater

A non-standard way of connecting parts - under water - will be in demand in plumbing when it is impossible to drain the work area.

For car repair

Car enthusiasts often need to repair cracks, through holes in body parts, and eliminate leaks in the radiator. Cold welding will ensure flawless performance of work even at home, without resorting to expensive service.

Precautionary measures

To avoid skin irritation, work with the liquid composition should be done with gloves. If the composition gets on open areas of the body or mucous membrane, immediately rinse the contaminated areas with water. The glued parts should not be subjected to loads until the resin has cured. If you heat the composition, it will harden faster. Welds produced by this method do not have the same high characteristics as those achieved with conventional welding. Their permissible tensile stresses are much lower. Therefore, there is no need to subject the products to tearing forces.

Repairing cast iron and other types of radiators

Working with radiators is similar to sealing defects on pipes. The surface is cleaned and degreased. You can use alcohol for this purpose, applying it with a cotton swab. Next, take a ball of resin approximately 2 cm in diameter, knead it, mixing the components. Press the resin to the damaged area, smooth it out, and hold it with a rag or clamp.

Usually 30-40 minutes are enough for polymerization, but it is better to use the battery after a day, not earlier. Naturally, the water supply must be turned off before repairs. If you need to remove a fistula, you need to take fiberglass and a liquid solution, wrap the area and seal it securely.

Cold welding is an excellent temporary measure until the end of the heating season. It will help eliminate pipe or radiator leaks quickly and without hassle!

Flaws

- The quality of Almaz Press cold welding is inferior to many other manufacturers;

- When the material dries, it becomes very brittle;

- It cannot be used for critical connections, since it is suitable primarily for domestic purposes where there are no high loads;

- During use, problems arise with the appearance of lumps inside the mixture itself, since it is poorly mixed, which negatively affects the quality;

- When in contact with dry surfaces, the outer layer tends to stick to them;

- The service life of used products under unfavorable conditions is relatively short.

Application area

Diamond adhesive cold welding on an epoxy basis is used to connect various objects that cannot be glued with other mixtures. It can be used as a cold welder for ceramics, which helps not only to connect broken objects, but also to restore lost parts. With special preparation so that the surface of things is clean from dirt and grease films, Almaz Press cold welding adhesive can join metals, plastic, wood, both homogeneous and dissimilar materials.

One of the features of the application is its restorative function. It can be used to seal holes in structures and objects. To do this, the glue is applied in a thick layer to the hole, filling the existing hole, after which it hardens, forming a dense layer. In the same way, you can restore lost parts on various objects. It’s as if a shape is being molded from plasticine that will hold after hardening.

Cold welding Diamond for restoring lost parts on various objects

The main thing here is not to create large loads, as it may simply not withstand them. It is for this reason that such things are practically not used in industry. Almaz universal cold welding adhesive 58 g is intended for use in ordinary temperature conditions without extreme excesses.

Cold welding Diamond universal 58 g

Kinds

In addition to the varieties depending on the volume of packaging, there are several more types based on the composition. According to this principle, several main types can be distinguished:

- Cold welding Almaz Union is universal - it has a composition that is suitable for most procedures. Can work with both metal and other substances.

- For woodworking – intended for veneer and multi-layer wood. Glues both the parts themselves and the delaminated plates. Often used in furniture repair.

- For machine repair - used for connecting small parts, as well as eliminating cracks and chips in the housings of internal parts. It can be used to restore threaded connections.

- With steel filler - this is a cold welding for metal, which can glue both colored and black varieties.

- Cold welding Diamond for plumbing is a moisture-resistant mixture that can form tight joints, which is very useful for repairing pipes and other connections in plumbing.

Compound:

- Hardener;

- Epoxy resin;

- Metal filler;

- Mineral filler.

Properties and technical specifications

| Parameter | Units | Quantity |

| Peel strength | Kg/cm2 | 120 |

| Brinell hardness | – | 120 |

| Maximum operating temperature | degrees Celsius | +145 |

| Time until hardening | minutes | 20 |

| Complete hardening time | watch | 24 |

| Recommended application temperature | degrees Celsius | +5 |

Features of use

Instructions for cold welding Diamond suggest preliminary preparation of the surface before use. It needs to be degreased and mechanically processed. After this, you should separate the required volume of glue so that everything is in equal proportions, both the internal and external parts. Then the substance is kneaded to a soft state, which is the main working state. In this state, it can be used as glue or sculpted into shapes to fill defects.

Manufacturer

The manufacturer is, which specializes in the production of composite materials and supplies its products throughout Russia.

Where is it used?

In cases where objects cannot be glued using other compounds, it is recommended to use Almaz cold welding. In cases where a broken ceramic item is badly damaged or a small part is missing, glue can be used to restore it. A figure is molded from it, or the resulting hole is filled with material, and after hardening the area becomes dense, and the parts are securely fastened.

This mixture can glue not only homogeneous materials, but also those of different textures. To do this, you need to thoroughly clean the surfaces from dirt and dust and then degrease them.

The only caveat is that the restored items will not withstand heavy loads and strong mechanical stress. Cold welding “Universal Diamond” with a volume of 58 g is used at normal temperatures; it is recommended to exclude their strong differences.

Cold welding "Diamond" can vary in volume and composition. Based on its composition, it is divided into several types.

Universal adhesive "Soyuz" can be used in various types of work. The type of surface does not matter; it is used with both homogeneous and dissimilar materials.

When repairing furniture and working with wood, cold welding is used for woodworking. It helps eliminate delamination and also connects the coatings themselves well.

A special type of glue is also used in car repairs. It can be used to glue small parts and get rid of chips on the car body. Also used for thread restoration.

When working with metal objects, it is recommended to use Almaz cold welding, which contains a steel filler. Can connect non-ferrous metal and other types of metal.

Plumbing adhesive is moisture-resistant and heat-resistant. When using it, tightness is achieved. Used when working with pipes and other plumbing connections.

Composition and properties

Cold welding is essentially an adhesive for metals. Includes:

- adhesive - epoxy resins, which ensure the plasticity of the composition and its uniformity;

- filler – metal powder;

- activating additives (sulfur).

The strength of the weld seam depends on the suitability of the adhesive composition for the types of metals being welded, on the quality of preparation of the bonded surfaces and its proper use. Under optimal conditions, the strength of the seam reaches the strength of the metal, but in practice, no matter how hard you try, it is almost impossible to achieve ideal conditions, and accordingly, the strength of the seam will be significantly lower than with hot welding. For this reason, it can only be used for minor repairs and welding of parts that do not carry a large load.

The temperature limit of the resistance of the seam depends on the composition of the glue. This indicator can be found on the packaging and if the gluing technology is followed, the seam will be strong within the specified temperature value.

For inexpensive formulations, the maximum temperature is set at 260 degrees. Special adhesive compositions allow the weld to not lose its strength at temperatures of about 1300 degrees. These compositions are used where products operate at high temperatures and in situations where it is impossible to use traditional welding.

Additional tips and tricks

Cold welding is used anywhere, but it is most often used by motorists. When the muffler burns out, the crankcase or radiator leaks, a tube of glue is indispensable.

To ensure that the choice of composition meets expectations and does not cause disappointment, carefully study the operating conditions of the unit or part, as well as the instructions on the packaging with glue. High temperature environments require a suitable product. The same applies to parts in contact with liquids.

Oil-resistant adhesives deserve special mention; these also exist. Metal is better joined by compounds with additives that enhance adhesion and strength of the seam. Cold welding does not tolerate high pressure environments. Universal adhesives, in fact, have a narrow scope of application: if special working conditions are required, then it is better not to save money, but to buy a specialized product with the required properties.

The quality of the seam and the durability of the restored product largely depend on the preparation of surfaces for gluing. This includes cleaning, degreasing, dusting, removing traces of moisture and roughening with fine sandpaper. And you can use the finished unit, the glued part, no earlier than the seam has finally polymerized. The setting time for the composition can be found in the instructions.

Cold welding “Almaz” – a series of adhesives. The manufacturer offers several types: for plumbing products, wooden materials, automotive parts, metal elements. The work can be done independently. It is possible to connect oiled and wet parts. The product is not intended for use in industrial environments.

Advantages and disadvantages

The advantages of the Almaz series adhesive compositions lie in their good ability to be fixed to the surface and firmly connect dissimilar materials, such as metal parts and wood.

Cold welding can be used in emergency conditions when it is not possible to use a welding machine or soldering iron. It successfully replaces adhesives for wood and ceramics.

Its cost is low, and it can be used to seal a hole in a few minutes without any special training or knowledge, following the instructions.

Disadvantages include the tendency of the mass to form lumps during application, and the inability of the compound to withstand large dynamic loads. Over time, after drying, the Almaz composition becomes brittle, so it cannot be used in critical areas.