The lightweight and easy-to-use metal stove “potbelly stove”, with all its advantages, has one significant drawback: low efficiency.

To heat a room, an ordinary metal potbelly stove usually spends 50-70% of its efficiency, the rest of the heat simply flies out into the chimney.

It is clear that it is very difficult to reconcile with such a situation, but unfortunately, few stove owners take radical measures to increase the efficiency of the furnace. Although, as experience shows, with a little skill and spending a little time you can get a fairly effective stove from this gluttonous design.

How to increase the heat output of a furnace

So, how to increase the efficiency of such a stove?

There are several simple ways. The most basic one is to put a brick screen around the stove. The bricks don’t even need to be held together with clay; just lay them on top of each other. You can fold such a screen near the side walls, or you can fold it at both side and rear walls. The brick will heat up while the fire is burning, and when it becomes small or goes out, it will give off heat. You won't have to add fuel often. One of the features of a potbelly stove is that the stove is light and mobile. With such a screen, it will not lose its mobility, because the bricks can be disassembled at any time, the stove can be rearranged and the screen can be folded in a new place. https://youtube.com/watch?v=SNKEQmQMxl4

There is another method with a screen, which also increases heat transfer. In this case, a sheet metal screen is mounted at some distance from the side and/or rear wall of the stove. The sheets can be secured using long bolts. In this case, the effect of convection is added.

There is another simple way to increase heat transfer. This time the stove's chimney is being modernized. Typically, such stoves have a straight chimney. It is removed through the roof of the room in which the stove is installed. If you add several bends to the pipe, then the heat transfer will increase, although not by much. In this case, the pipe will resemble the letter S.

If you want it to be much warmer, then you need to take 2 tanks from old-style washing machines. The tanks are welded together, and a chimney is passed through them. Thus, above the potbelly stove, which is heated with wood, there is also a stove of the same size, heated by hot smoke. Heat transfer almost doubles.

Another method is to weld additional ribs onto the stove and chimney, for example, from metal angles. In this case, the chimney must be made of thick metal. Such fins significantly increase the heated surface area. An increase in area leads to faster heating of the surrounding air. The room becomes warmer. In addition, thick metal retains heat even when the fire in the firebox is no longer burning.

But still, it will not be possible to endlessly increase the efficiency of this heating device. And if you want to have a full-fledged stove in the room, you will have to build it out of brick according to all the rules, so that the stove retains heat for a long time, for example, all night. For example, there is no need to increase the efficiency of a Russian stove; it already retains heat for a very long time. True, in order to fold it correctly, you will have to call a stove specialist.

How to check traction?

Wind surge

Wind affects traction. Having hit, it changes direction towards the top of the pipe. In this embodiment, the wind helps the draft. If it changes direction down the pipe, it throws gases into the chimney. To ensure the normal operation of the chimney, it is necessary to strictly follow several rules during construction, namely:

- The top of the pipe should be 50 cm above the roof ridge;

- The treetops should not be nearby;

- Level with the ridge, if the pipe is more than 1.6 m from the ridge;

- Below the ridge, if the pipe is located more than 3 m from it.

Incorrect stove design

The design of the heating device must be factory-made. The plant must determine the fuel parameters and operating rules for its product. If there are identified deficiencies, the consumer has the right to make claims to suppliers.

In most cases, the main drawback that can be identified is that there is no heat in the house. Constructive flaws are much more difficult to identify. First of all, it is necessary to carry out an external inspection and determine whether the stove with the design scheme declared by the factory. What must be there.

- The chimney hole has the diameter indicated in the passport (120 mm).

- An ash pan of sufficient volume for the daily amount of burned fuel.

- Cold air inlet and hot air outlet with the hole diameter specified in the product passport. It must be checked for functionality.

- Condition of fans at the inlet and outlet of the hot air pipe.

- Determine the serviceability of the ash pan by allowing air to pass directly into the firebox and into the coal afterburning system through the grate.

- Check the possibility of adjusting the air supply to the firebox from the intake system.

If these elements are missing or do not work correctly, then the potbelly stove is not working properly. Needs repair or complete replacement.

Ways to increase efficiency

Potbelly stoves are made in various shapes and sizes. But they have one drawback in common - low efficiency. More than half of the thermal energy, in the literal sense of the word, flies out into the chimney. The irrational use of heat has led to the fact that the owners of these heating devices began to think about possible changes in the design of the furnace to increase its efficiency. The solution to this problem could be a partial modernization of the potbelly stove. There was no single concept for solving this issue, and each stove owner began to solve the problem independently, by trial and error.

Increasing the efficiency of a potbelly stove means receiving additional heat from the heating device while maintaining a constant amount of burned fuel. This can be achieved in several ways:

- changing the heat transfer surface,

- increase in heat removal;

- using more high-calorie fuel;

- increasing the heat capacity of the furnace.

The potbelly stove gives off heat to the surrounding space not only with its body, but also with its metal chimney. You can increase the heat transfer surface of the device by revising its dimensions upward. This option is possible when creating a stove with your own hands. Having already made a potbelly stove, you can do it in another way. Usually a corner is welded to a chimney made of a metal pipe. Position it with its apex facing the element along its entire length. The angle is installed around the pipe. Thus, the area of the heat transfer surface can be increased by 3-4 times, depending on the size of the corner.

Another option for increasing the heat transfer surface is to make a chimney running inside a large area. For this purpose, a chimney with turns is made. They are performed in the form of smooth transitions. It is undesirable to create turns at right angles, as the potbelly stove may start to smoke. The last section of the chimney is installed vertically. A pocket is made on it with a hatch for cleaning soot.

If it is impossible to lengthen the pipe, its design is changed. Cylinders made of pipes with a diameter of 300-400 mm are welded onto the pipe coming out of the furnace body. They are connected to each other by pipe sections with a diameter no less than that of the smoke pipe. They are welded out of alignment to increase the smoke path.

How to increase draft in a potbelly stove using a chimney

The design of a high-efficiency potbelly stove chimney should have the following features:

- The chimney should be made high enough. So, the optimal distance from the furnace itself to the top of the pipe is about 5-6 m.

- There should be no horizontal or inclined sections of less than 45 degrees in the pipe shape, or their number should be kept to a minimum.

An increase in the efficiency of a potbelly stove will also be facilitated by the creation of thermal insulation on the pipe, which will significantly reduce the damage from the formation of condensation.

- When establishing the cross-section of the chimney, you need to choose the optimal size. If at the time of establishing the efficiency of the potbelly stove there is already a too narrow chimney, you can put a deflector on top, which will protect the structure from precipitation and increase draft.

- The height of the pipe should also be affected by the level of the ridge. If the chimney is lower than it, you need to extend the pipe.

The history of the invention of the potbelly stove dates back to the 18th century. A potbelly stove has been and remains a cheaper alternative to expensive fireplaces and stoves. The device became most popular during the October Revolution, when heating rooms became quite difficult. Thus, the potbelly stove began to actively spread and gain popularity among the population.

Tip: The draft force in the stove is determined by the color of the flame: if there is not enough air, it is red with dark stripes, if there is too much air, it is bright white, and the chimney often makes a hum. If the color of the flame is golden-orange, then the potbelly stove’s draft is normal.

Readers found these materials useful:

Increasing heat capacity

The heat capacity of a potbelly stove can be increased both by increasing its weight and dimensions and by using additional heated materials. In any case, it is necessary to make design changes to the heating system. One option may be to use smoke circulation inside the oven. This can be done by installing sheets of heat-resistant metal in the firebox, thereby providing additional paths for the movement of gases. At the same time, they are burned, heating the furnace to a higher temperature. But at the same time, the temperature of the exiting smoke also increases. With a short chimney, the heat is simply released into the atmosphere.

To use this heat, a heat-storing container is installed on the exhaust pipe of the potbelly stove, which can be made either from an old gas cylinder or from a large-diameter pipe. The container is filled with large stones that retain heat well. At the same time, it is loaded to approximately 2/3 of the volume. The stones are placed on the grate. Hot gases flowing through the battery heat them up and, giving off heat, go outside.

The stones are heated to a temperature of about 400 °C. After the fuel burns out in the stove, the damper on the chimney is closed and the room is heated using the heat accumulated by the stones. In this case, the stove is in a cold state. Using such a battery allows you not only to save fuel, but also to receive heat after the stove stops working.

The battery, which increases the efficiency of the furnace, can be made of brick and installed on metal supports above its surface. But such a design cannot be used with a round stove.

The calorie content of fuel depends on its type and quality. Replacing fuel with a higher-calorie fuel is expensive and requires additional storage space. As a rule, garages are heated with waste material that is easy to find. Now, knowing how to increase the efficiency of a potbelly stove, you can begin work. It should be noted that the best results are obtained with the integrated use of methods that increase the heating efficiency of the furnace.

What to drown with

In general, a potbelly stove can be heated with anything, wood, oil, coal, etc. When considering tree species, many prefer oak. Dry wood from this tree can add about two more degrees of heat when burning.

If you're worried about cleaning up the ash, you're in vain. The resulting bedding at the bottom of the stove from coals and ash will not only protect the bottom from burnout, but also what remains as coals during the first fire will burn out the next time. Accordingly, the combustion percentage increases.

Using simple ways to modernize a potbelly stove that you made with your own hands or bought in a store, you can achieve its maximum, but at the same time correct operation. To improve the device and increase efficiency, you do not need special skills or large financial costs.

Furnace characteristics

Each device has its pros and cons during use. In the case of a potbelly stove, we highlight the following positive aspects:

- The design of the furnace is simple and does not require large financial expenditures. Everything you need to make a stove with your own hands can be easily found in the utility room.

- If necessary, the potbelly stove can be easily transported to another house or garage. Its weight usually does not exceed 30 kilograms and its small dimensions will only be a plus.

- The stove can be quickly heated regardless of weather conditions.

- In fact, almost anyone can heat a potbelly stove. That is, it can be coals, sawdust, firewood branches, or even household garbage.

As for the negative characteristics, we highlight the main ones:

- The heated surface area is quite small, and therefore a small amount of heat enters the room.

- The room, even after using the stove for a long time, cools down quickly.

Taking into account such shortcomings, we are talking about a low efficiency, that is, the level of efficiency of the stove.

We recommend: How to make a convenient smokehouse yourself

Why do you need furnace modifications?

Every model, and not just stoves, is imperfect, and you always want more and better. So it is in this case with heating partings. Any modifications are carried out in order to obtain maximum effect without reducing the service life of the heating device.

For example, with the help of improvements, you can achieve maximum proper combustion, with a good level of heat transfer, without heating the potbelly stove to the limit so that the metal turns red.

Watch the air damper. It must be at a level so that the flame does not enter the chimney. The fire should not exceed the level of the top of the stove. The heat must be distributed evenly throughout the device in order to properly warm the room.

There are many options for modification; you should choose the optimal one for yourself in order to ensure a comfortable temperature for being in the room.

Ways to increase efficiency

The designs and diagrams of finished furnaces do not provide for modes with variable efficiency. It all depends on proper operation, as well as the ability to independently upgrade the design. There are three simple ways to increase the efficiency of wood-burning stoves: installing a steel pipe in the ash pit, a metal rod in the chimney, or transferring heat from the tiles through the hood back into the room. Each of the methods for improving efficiency indicators is discussed below.

By the way, you can combine them with each other, then the efficiency of the stove will increase even more.

Installation of a steel pipe in the ash pit

If a wood stove is the only way to heat the room, then the air temperature in the room will continue to decrease for the first 40 minutes after ignition. Moreover, such a decrease will be more intense than after turning off the stove. The reason is the open vent, through which the rarefied warm air of the room is sucked into the smoke exhaust ducts.

As the stove heats up, air will flow through the view in the same quantity, but due to the sufficiently heated walls of the stove, heat transfer will begin to prevail. But is it possible to speed up this stage and thereby increase efficiency by 10-15%? You can - to do this, when laying it in the ash pit, install a steel pipe with a damper. As a result, when the view is opened, much less warm air is sucked in (it will be drawn not from the room, but from under the floor).

It is important to remember: the described method of increasing the efficiency of a wood-burning stove has a drawback - the chimney draws air from under the floor, so it will cool down quickly. Walking on a frozen floor is unpleasant

To fix this, you can attach a rubber extension with a diameter of 50 millimeters to the end of a steel pipe, then take it outside the wall of the house (then the ash pan will draw in street air).

Install a steel pipe into the chimney

A well-known fact: very hot air is exhausted through the chimney. Moreover, the longer the stove is heated, the less heat will be removed from the brickwork of the chimney and the hotter the evaporated smoke will be. Consequently, due to intensive operation of the furnace, the efficiency will decrease. People have come up with a trick that helps them use the heated air of the chimney to their advantage and prevent the efficiency from decreasing (such a modification is not found anywhere in finished projects).

The essence of modernizing a wood stove is as follows:

- Take a round metal pipe with a diameter of 20-30 cm.

- The pipe is inserted into the chimney elbow at a slight angle.

- If the stove is large and has several smoke exhaust pipe bends, you can insert 3-4 metal pipes.

- The thermal conductivity properties of the metal ensure that heat is removed from the chimney. This heat does not go outside, but returns back into the room.

As a result, due to such simple modifications, a stove with high efficiency is obtained (the efficiency will increase by 15-20%). Warming up the room will be 2 times faster, and fuel consumption, on the contrary, will be reduced.

The only difficulty: modification of the stove with a homemade and simple heat exchanger can only be carried out at the time of laying the chimney. If you need to improve the efficiency of an already installed stove, the chimney will have to be disassembled and then reassembled.

Additional heat extraction from the stove

The heat emitted from the cooking surface of the stove can be redirected back into the room, thereby increasing the rate at which the house warms up. This process is called recycling. As a result, fuel consumption will decrease and efficiency will increase.

This simple upgrade is done as follows:

- A stainless steel hood is made above the stove surface (not close to avoid overheating).

- A quickly heated pipe (cross section 8-10 centimeters) is connected to the hood. For example, the material for it can be galvanized steel.

- The metal base of the tubular outlet must be at least 1 meter long. Further, it is allowed to be fastened with PVC pipes.

- The pipe should be stretched under the ceiling and brought to the coldest part of the room. It is recommended to supplement the design with small fans (a device with a power of 13 watts is sufficient).

Hood on stove

There are no obvious disadvantages to the described method of increasing efficiency. The only inconvenience: when you turn off the stove, the installed tube will stop conducting heat and the indicators will return to their original values.

As an option: you can install filters (anti-grease and carbon) in the hood. Then the air from the stove will be cleared of the odors of food being cooked on the stove (you will get a simple version of an air conditioner, only without discharging warm air through the ventilation shaft outside the house).

How to increase cravings: the best ways

The first thing to do is to remove soot. This is done either mechanically or chemically. To achieve a positive result, it is recommended to involve specialists.

Next, we pay attention to the sealing of the chimney.

Those same cracks and cracks must be sealed with a special heat-resistant sealant. Otherwise, the increase in traction will only be a temporary phenomenon, since cracks and cracks tend to expand.

Additionally, specialized devices can be used. These include: deflectors, fans, weather vanes. They provide rarefaction around the chimney, which inevitably leads to an increase in draft inside it.

See also:

- Do you know what a coaxial chimney is and what its advantages are?

- Recommendations regarding the installation of smoke removal systems - https://postroyka.org/montazh-sistem-dyimoudaleniya/

In the video, the master will talk about how to increase the draft in the furnace:

Most heating appliances technically cannot operate without draft in the chimney. To generate sufficient air flow, a competent channel design is needed. To understand the principle of formation, you need to understand the simplest physical concepts, such as the interaction of temperatures, air, and smoke density. All these indicators are equally “guilty” for the formation of outgoing flows. When they become insufficient or a return channel is formed, then the escaping gases will simply enter the room. Therefore, today we will reveal one of the most important topics in private house-building - how to increase draft in a private chimney?

Calculation of basic parameters (with drawings and dimensions)

High efficiency of a potbelly stove can only be achieved if all the main design parameters are correctly calculated.

Pipe

In this case, the diameter of this element is very important. The throughput of the chimney should be less than the productivity of the furnace firebox, which is the main distinguishing feature of a potbelly stove. This will allow warm air not to immediately leave the stove, but to linger in it and heat the surrounding air.

It is very important to make an accurate calculation for it. The diameter should be 2.7 times the volume of the firebox. In this case, the diameter is determined in millimeters, and the volume of the firebox in liters

For example, the volume of the combustion chamber is 40 liters, which means the chimney diameter should be about 106 mm

In this case, the diameter is determined in millimeters, and the volume of the firebox in liters. For example, the volume of the combustion chamber is 40 liters, which means that the chimney diameter should be about 106 mm.

If the potbelly stove provides for the installation of grates, then the height of the firebox is calculated without taking into account the volume of this part, that is, from the top of the grate.

Screen

It is very important to force the hot gases not to cool, but to burn out completely. In addition, the fuel must burn through partial pyrolysis, which requires extremely high temperatures. A metal screen located on three sides of the stove will help to achieve a similar effect.

It should be placed at a distance of 50–70 mm from the stove walls, due to which most of the heat will return to the stove. This air movement will give the necessary high temperature and protect against fire.

A metal screen located on three sides of the stove will help to achieve a similar effect. It should be placed at a distance of 50–70 mm from the stove walls, due to which most of the heat will return to the stove. This air movement will give the necessary high temperature and protect against fire.

The screen of a potbelly stove made of red brick is capable of accumulating heat

Litter

It definitely has to be there. There are two reasons for this:

- some of the heat is radiated downwards;

- the floor on which the stove stands gets hot, which means there is a risk of fire.

The litter solves these two problems at once. As such, you can use a metal sheet with a projection of 350 mm (ideally 600 mm) beyond the contour of the furnace itself. There are also more modern materials that do an excellent job of this task, for example, a sheet of asbestos or kaolin cardboard, at least 6 mm thick.

You can use an asbestos sheet for bedding under a potbelly stove.

Chimney

Despite all the calculations, gases sometimes escape into the chimney not completely burned out. Therefore, it must be done in a special way. The chimney consists of:

- the vertical part (1–1.2 m), which is recommended to be wrapped in thermal insulation material;

- hog (slightly inclined part or completely horizontal), 2.5–4.5 m long, which should be 1.2 m from the ceiling, which is not protected with heat-resistant materials (1.5 m from the wooden surface), from the floor - by 2.2 m.

The chimney must be vented to the street

Photo gallery: diagrams of a potbelly stove for a garage

The diagram must indicate all the exact measurements. The chimney must be led out onto the street. The potbelly stove can be round or square. The volume of the firebox depends on the presence of grates. The layout of the potbelly stove depends on the material used.

Solving backdraft problems

If there is reverse draft in a stove heating system, an accident with fire hazardous consequences and carbon monoxide poisoning is possible. This situation can only arise if the chimney design is incorrect.

Installing the deflector

The deflector is designed to ensure a continuous process of removing burnt gases in any weather. It is installed at the upper end of the chimney. The design of the deflector does not allow air to mix with smoke in the pipe itself. It prevents backdraft.

Installation of the draft regulator

Installing a draft regulator does not solve the problem of smoke backflow in the chimney. Rather, it is designed to establish an economical fuel combustion mode. The same function is performed by a standard valve in the pipe.

Increasing the length of the chimney

The problem of reverse draft can only be solved by reconstructing the chimney. To do this, it is necessary to increase the length of the chimney and take measures to prevent clogging of the chimney pipelines, as indicated earlier. The pipe should be at a height of 500 mm from the roof ridge. If backdraft occurs at this height, then it is necessary to increase the length of the chimney.

Improving the quality of the chimney

The best material for pipes may be the use of asbestos-cement and ceramic pipes up to 4 m long. Such chimneys have less resistance to smoke movement than brick pipes with a plastered surface. Even pipes made from sections of monolithic reinforced concrete have a worse throughput than asbestos-cement ones. Metal pipes rust in air and fail after a few years of use.

Use ceramic pipes

What is furnace efficiency?

- What affects efficiency?

- Ways to increase efficiency

- Installation of a steel pipe in the ash pit

- Install a steel pipe into the chimney

- Additional heat extraction from the stove

- Conclusion

Of course, a lot depends on the design of the heating system (this will be discussed in more detail in the next chapter). But there are also external factors:

- The quality of the fuel used is of great importance. The efficiency of a wood-burning stove will drop by 3 times if it is heated with raw material.

- Efficiency depends on the completeness of fuel combustion; this is affected not only by its quality, but also by air humidity, room temperature, and atmospheric pressure.

- Operating mode. If a person constantly keeps the firebox door open, one can only dream of high efficiency.

It becomes obvious that the efficiency factor is not a strictly fixed indicator. It can be reduced if the stove is used incorrectly, or the design can be improved by significantly increasing the efficiency parameter.

How to increase the efficiency of a potbelly stove by working with the design

Sometimes the draft force is influenced not by the shape of the chimney, but by the influence of operating conditions:

- You should periodically check the stove for cracks, especially around the perimeter of the firebox door and stove. If cracks are present, slabs and covers are replaced and the cracks are sealed.

- Usually the question of how to increase the heat transfer of a potbelly stove is asked after some time of use. This is due to the fact that soot gradually accumulates on the pipe walls, which reduces the clearance and makes the draft lower.

To mechanically clean a chimney pipe, you can use a brush or a simple homemade device: a figure-of-eight wire wound on a wooden strip.

- It is also worth removing soot from other parts of the furnace periodically. So, when cleaning the chimney, some of it falls into the channels of the potbelly stove. They are removed through existing cleaning doors or through holes made.

Types of homemade long-burning stoves

For heating small rooms, brick or metal stoves (potbelly stoves) can be used, capable of operating on both solid and liquid fuels.

Long-burning brick stoves are rarely built, since not everyone is able to lay them out with their own hands, taking into account the special requirements for the material and design of the chimney.

After all, an incorrectly made chimney pipe will result in continuous problems with insufficient draft and smoke in the room. In addition, purchasing fireclay bricks and the same powder for mortar will require a lot of money. And the brick oven itself takes up a lot of space, which is completely unacceptable for premises such as a garage, small country house or greenhouse.

Metal stoves, called potbelly stoves, can use free fuel in the form of waste oil, which does not require further disposal and brings tangible benefits.

Design and operating principle

The peculiarity of a potbelly stove is that it does not require the construction of a foundation or the installation of a major chimney. In most cases, this is precisely why it is chosen for use in the garage. This room does not always have electricity or a gas pipeline, which means that a potbelly stove is the only solution to the heating problem.

The potbelly stove does not require the construction of a foundation

This design is a metal box with a door and a pipe, which is located outside the heated room.

The pipe can also serve as a heating element if it is slightly modified. Make it stepped rather than straight, which will allow the hot air to linger in it a little.

How to increase the heat output of a furnace

So, how to increase the efficiency of such a stove? There are several simple ways. The most basic one is to put a brick screen around the stove. The bricks don’t even need to be held together with clay; just lay them on top of each other. You can fold such a screen near the side walls, or you can fold it at both side and rear walls. The brick will heat up while the fire is burning, and when it becomes small or goes out, it will give off heat. You won't have to add fuel often. One of the features of a potbelly stove is that the stove is light and mobile. With such a screen, it will not lose its mobility, because the bricks can be disassembled at any time, the stove can be rearranged and the screen can be folded in a new place.

https://youtube.com/watch?v=SNKEQmQMxl4

There is another method with a screen, which also increases heat transfer. In this case, a sheet metal screen is mounted at some distance from the side and/or rear wall of the stove. The sheets can be secured using long bolts. In this case, the effect of convection is added.

There is another simple way to increase heat transfer. This time the stove's chimney is being modernized. Typically, such stoves have a straight chimney. It is removed through the roof of the room in which the stove is installed. If you add several bends to the pipe, then the heat transfer will increase, although not by much. In this case, the pipe will resemble the letter S.

If you want it to be much warmer, then you need to take 2 tanks from old-style washing machines. The tanks are welded together, and a chimney is passed through them. Thus, above the potbelly stove, which is heated with wood, there is also a stove of the same size, heated by hot smoke. Heat transfer almost doubles.

Another method is to weld additional ribs onto the stove and chimney, for example, from metal angles. In this case, the chimney must be made of thick metal. Such fins significantly increase the heated surface area. An increase in area leads to faster heating of the surrounding air. The room becomes warmer. In addition, thick metal retains heat even when the fire in the firebox is no longer burning.

But still, it will not be possible to endlessly increase the efficiency of this heating device. And if you want to have a full-fledged stove in the room, you will have to build it out of brick according to all the rules, so that the stove retains heat for a long time, for example, all night. For example, there is no need to increase the efficiency of a Russian stove; it already retains heat for a very long time. True, in order to fold it correctly, you will have to call a stove specialist.

Causes of poor traction

- Amount of supply air.

- The amount of burnt gases exiting through the chimney.

When carrying out measures to improve combustion, it is necessary to take into account the fact that draft is a kind of indicator of the natural ventilation of the room. Air movement should be in one direction. If there are two different directions of exhaust or air flow, then the draft in the potbelly stove will decrease.

If you open two windows on different sides of the room, the air will move in the same direction from one window to the other, even with a slight wind. The flame in the stove will sharply reduce the burning power, and in the worst case, it will begin to smoke into the room. Compliance with the requirements for a room with natural ventilation is the first necessary condition for normal draft in a potbelly stove.

Increasing the length of the chimney

Increased efficiency is achieved by increasing the total length of the chimney. Moreover, it is not the vertical part that increases, but the horizontal one. The bottom line is that combustion products will heat the metal of the chimney, which is why most of the heat will be retained indoors. The gases at the outlet of the chimney will become much colder.

When increasing the length of the chimney pipe, it is necessary to place the potbelly stove at one end of the room, and place the chimney itself at the other end. The horizontal section of the pipe will connect the chimney to the stove and ensure efficient heat removal.

An additional way to increase efficiency is to retrofit the chimney with convection pipes. This step will increase the heat transfer area and create additional convection.

Why modernize?

The potbelly stove is a very simple heating device, although today it is deeply modernized. Such a stove, which has become a favorite solution for heating small country houses, can have not only a single-chamber, but also a two-chamber design. A modernized potbelly stove can provide heat even to houses where residents live permanently.

The simplicity of design and manufacture makes it accessible to purchase and use. In addition, a significant advantage for the construction of such a structure is the absence of a foundation. But, despite so many positive properties, the potbelly stove also has significant disadvantages:

- Its efficiency is quite small, the simplicity of the design carries with it an inherent drawback - a huge part of the heat from the potbelly stove “flies into the chimney”.

- To work with such a stove, strict safety requirements must be observed, since falling combustion elements can damage nearby premises and even lead to a fire.

- To heat a room with a potbelly stove, it is necessary to consume a significant amount of fuel elements, which is due to the fact that this type of heating is used only for short-term operation.

But this is not a reason to be discouraged; over the years, our “Kulibins” have found several simple but effective ways to increase the efficiency of a potbelly stove. In this article we will look at the modernization of the stove design itself.

Rules for safe installation of a metal stove

A potbelly stove heats up much hotter than a brick stove, so all flammable objects should be kept at a sufficient distance from the stove. If the floor in the room is wooden, it is installed only on bricks or metal sheets. The metal, in turn, is laid on an asbestos sheet with its removal 35 cm or more from the edges of the stove. In the front part in front of the firebox it should protrude 5.5 cm. Asbestos can be replaced with felt impregnated with clay. You can also install such a screen to reflect heat on concrete.

Important! A working oven requires supervision. You should not leave the room where the potbelly stove is heated for a long time.

Installing a potbelly stove on a brick base

How to improve oven performance

This stove has one significant drawback - it cools down very quickly. However, this is very easy to fix with the help of a brick screen, which is installed on three sides of the structure. This will allow you to accumulate heat and release it to the room even after the stove stops burning.

It should be placed at a distance of 5–7 cm from the walls of the stove, and in no case end-to-end. In this case, you need to take care of the presence of ventilation holes.

The screen should not be close to the walls of the stove

A structure with a brick screen will weigh much more than a conventional metal stove, so it is recommended to first build an individual foundation.

In some cases, it may be necessary to install a custom foundation. It's very easy to do:

- Dig a hole about 50 cm deep. All other dimensions depend on the size of the stove itself and the screen.

- Fill the bottom of the hole with sand (usually this takes about 3-4 buckets), after which it needs to be compacted. Cover the sand with a 10–15 cm layer of crushed stone and compact it as well.

- Level the backfill and fill it with prepared cement mortar. Leave it for a day (you can do it for several days, the foundation will only benefit from this).

- Cover the base with several layers of roofing felt.

- Now you can start laying out the screen in the brick floor. In this case, the first two rows should be laid out in continuous masonry directly on the roofing material. In rows 3–4 it is necessary to make ventilation gaps. Continue solid masonry.

- It is recommended to make the screen without a top covering.

Ensuring heat removal

It is possible to increase heat removal by creating devices that promote natural and forced convection. To ensure natural air circulation, screens are made with a guide device that allows you to create a powerful convection flow and distribute it throughout the room. The guide apparatus is made in the form of curved strips of metal, welded to the screen and directing warm air not only upwards, but also to the sides. The prepared device is attached to the oven.

The heat removal device can also be made from scraps of water supply and profile pipes. The distance from the floor to the bottom edge of the elements must be at least 15-20 cm. The pipes are welded to the stove body and covered with a screen on the sides to protect against accidental contact. A traditional potbelly stove heats the air around it by 0.5-1.0 m, and the use of such a design allows you to increase not only the radius, but also the rate of temperature rise in the room. When the body of the heating device is heated above 60 °C, a stable convection draft appears in the device, the power of which increases as the temperature of the furnace increases.

Heat removal can be increased by using fans to blow over the heat transfer surface. Both household and old car fans are used. Devices with variable rotation speeds have proven themselves especially well. They allow you to regulate the temperature and heating time of the room in various oven operating modes.

For more efficient blowing of the furnace elements, special casings are installed that allow cold air to be directed to the hottest areas of the heating device, while it can be taken from various places in the room. A potbelly stove with pipes welded into the firebox for heating air has proven itself well. A multi-speed car fan installed on a common discharge manifold allows you to effectively heat the room.

The combined use of devices for artificial airflow and natural convection can significantly increase the efficiency of a potbelly stove, which means heating the room more efficiently.

Potbelly stove stove design

One of the biggest problems with furnaces of this type is the design itself.

Conventionally, the model of a potbelly stove can be imagined as a hearth wrapped in metal and slightly raised above the floor level. Classic cast iron stoves have a firebox and a blower. The design does not provide a gate to regulate the air supply to the combustion chamber, so this is done by opening and closing the blower door. Such an operation is unsafe - when the ash pit is filled with ash, sparks often roll out, which causes a fire. So the “potbelly stove” fully lives up to its name and the appetite is exorbitant and a fire can break out at any minute. The fuel combustion process also looks specific, which is the reason for the low efficiency of the potbelly stove. When wood burns, the metal shell of the stove body heats up and the heat spreads into the room through thermal radiation. The burning of wood usually occurs irrationally; when burning, the wood simply does not have time to reach the required temperature and therefore some of the combustible gases from the firebox simply go into the chimney. By the way, the pipe itself, like the furnace body, wastes precious heat irrationally - heating of the room occurs due to thermal radiation, and occurs only when the fire is burning in the firebox. As you can see, everything is quite simple - the fuel burns inefficiently in the firebox, while this type of heat energy release such as convection is used irrationally. So it turns out that any improvement immediately allows you to increase the efficiency of the potbelly stove, which means it will allow you to use fuel more efficiently.

Requirements for the construction of potbelly stoves

An economical, long-burning wood-burning stove must meet certain requirements and design rules:

- It is mandatory that such a structure is equipped with a smoke exhaust pipe, and the room is equipped with a supply and exhaust ventilation system.

- Considering that the design of a potbelly stove will heat up to very high temperatures when heated, it is necessary to comply with fire safety requirements when installing it indoors.

The stove should be located away from flammable structures of walls, ceilings and floors, and also have a fence to prevent fire and the risk of burns during its operation. A potbelly stove surrounded by a wall made of heat-resistant brick not only becomes safe during operation, but also creates additional heating areas.

Why increase efficiency?

The compact dimensions of the stove mean that the surface that heats up during operation is small. Not much heat flows outside and the room quickly cools down. Sometimes it seems that the return from the potbelly stove is weak.

To help it increase efficiency, several tasks are solved:

- the duration of combustion and smoldering increases;

- a sufficiently high combustion temperature is ensured;

- a high level of traction is achieved.

Standard potbelly stove efficiency

The third type of stove-stove

Now let’s figure out how to construct a homemade potbelly stove with a square body with thin walls and an adjustable draft. The main advantage of a square-shaped potbelly stove is its larger surface area of interaction with air, that is, greater efficiency compared to a stove based on a pipe.

The most optimal dimensions for a homemade stove will be a structure height of 800 mm and a base of 450 × 450 mm. A potbelly stove of this size will not take up much space and can easily accept almost any piece of wood.

Chimney installation diagram.

You should also determine what thickness of metal will serve as the material for the stove. Here, as in everything, a golden mean should be observed: very thick walls (about 1 cm) take too long to warm up, thin-walled metal sheets swell after heating, and the stove will become shapeless.

For these purposes, choose an average wall thickness - approximately 0.3-0.5 cm. Then the potbelly stove will retain its original appearance and will perfectly warm the room.

Integrated approach and technical solutions

increase the efficiency of a potbelly stove to the maximum level. For example, combine smoke circulation and pyrolysis combustion, add fins to the body and increase the length of the chimney. A potbelly stove with a fan is good on its own, but nothing prevents you from covering it with bricks. The implementation of the described methods also varies - it all depends on the materials available and the design of the furnace itself.

Hi all! So I decided to make a homemade stove with increased efficiency with my own hands, I suggest you look at step-by-step photos of making a potbelly stove.

So, I will make the side walls from a profile pipe 60 x 30 x 3 mm. In essence, this will be an air heat exchanger; air will be forced through it. I want to distribute the heated air using a corrugated pipe along the walls of the garage and heat it evenly.

Creation of a convection system (fins)

Increasing the efficiency of a potbelly stove with your own hands involves creating a convector. Natural convection improves heat removal and ensures quick heating of the room. By installing a stove with a convector in the garage, we will get an excellent heating device. Literally 15-20 minutes after ignition, a comfortable temperature will be established in the garage. Our task is the following - we need to create a convector that sucks in air from below and exhausts it from above.

The easiest way to increase efficiency is to equip your potbelly stove with a metal screen. It is a sheet of iron that wraps the stove on the sides and back like a shirt. The distance between the body and the sheet is from 3 to 5 cm. The sheet is welded onto metal spacers - make them from thin reinforcement. The result is a fairly simple convector. The only problem is that the area of thermal energy dissipation will remain the same.

Fins will help increase the efficiency of a potbelly stove. It can be done:

- From a profile rectangular pipe 20x40 mm.

- Made from a U-shaped metal profile.

- From a traditional round inch pipe.

We scald the back and side walls with the selected material. This will help increase the dispersion area. At the same time, we will get an effective convector.

Ways to increase efficiency

Potbelly stoves are made in various shapes and sizes. But they have one drawback in common - low efficiency. More than half of the thermal energy, in the literal sense of the word, flies out into the chimney. The irrational use of heat has led to the fact that the owners of these heating devices began to think about possible changes in the design of the furnace to increase its efficiency. The solution to this problem could be a partial modernization of the potbelly stove. There was no single concept for solving this issue, and each stove owner began to solve the problem independently, by trial and error.

Increasing the efficiency of a potbelly stove means receiving additional heat from the heating device while maintaining a constant amount of burned fuel. This can be achieved in several ways:

- changing the heat transfer surface,

- increase in heat removal;

- using more high-calorie fuel;

- increasing the heat capacity of the furnace.

The potbelly stove gives off heat to the surrounding space not only with its body, but also with its metal chimney. You can increase the heat transfer surface of the device by revising its dimensions upward. This option is possible when creating a stove with your own hands. Having already made a potbelly stove, you can do it in another way. Usually a corner is welded to a chimney made of a metal pipe. Position it with its apex facing the element along its entire length. The angle is installed around the pipe. Thus, the area of the heat transfer surface can be increased by 3-4 times, depending on the size of the corner.

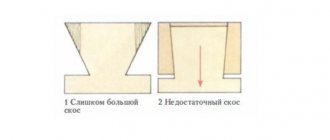

Another option for increasing the heat transfer surface is to make a chimney running inside a large area. For this purpose, a chimney with turns is made. They are performed in the form of smooth transitions. It is undesirable to create turns at right angles, as the potbelly stove may start to smoke. The last section of the chimney is installed vertically. A pocket is made on it with a hatch for cleaning soot.

If it is impossible to lengthen the pipe, its design is changed. Cylinders made of pipes with a diameter of 300-400 mm are welded onto the pipe coming out of the furnace body. They are connected to each other by pipe sections with a diameter no less than that of the smoke pipe. They are welded out of alignment to increase the smoke path.

Increased utility

Potbelly stoves can come in a variety of sizes and shapes. They are invariably connected by one fact - low efficiency. Thermal energy does not enter the desired room, but flies away into the chimney. Therefore, the owners of such stoves decided to experiment with the design to increase utility.

In this case, they often resort to partial modernization of the furnace. There was no single solution for everyone in this matter, so each owner, using his own trial and error, looked for a solution to the problem.

To increase the amount of heat released without increasing the volume of fuel required, you can do the following:

- Improve heat transfer surface

- Increase heat removal

- Change the type of fuel to a higher calorie one

- Increase the heat capacity of a potbelly stove

Option 1

The heat in a house or garage from a potbelly stove comes not only from the outgoing heat of the structure, but also from the metal chimney. Therefore, the heat transfer surface can be increased. This is quite possible when making a stove with your own hands.

We recommend: Self-made electric smokehouse

If you already have a ready-made device, then here’s how to implement the idea. Weld a corner to a metal chimney pipe. You need to position it with its apex facing the entire length of the element, and set the angle along the circumference of the pipe. Using this method, it is possible to increase the heat transfer surface by about 4 times (depending on the size of the selected corner).

You can also resort to the option of making a metal pipe that will pass over a larger area. It is necessary to make a chimney with turns. Turns should be smooth, without right angles, so that the device does not start smoking. The final section of the chimney is made vertical; a compartment is located in the last section to subsequently clean out soot.

When it is impossible to lengthen the pipe, then change its composition. To do this, cylinders with a circumference of about 40 cm are welded onto the pipe, which protrudes from the body of the structure. They are connected to each other by pieces of pipe, the diameter of which is no less than the diameter of the pipe.

Option 2

To modify the stove, you can install side screens. Everything is quite simple, but effective in the end.

Sheets of metal are attached to the side parts of the potbelly stove using self-tapping screws. The metal must be unpainted and of any thickness. The screens are mounted at a distance of 6 cm from the body.

In this simple way, the principle of heat transfer changes. That is, thermal energy enters the room through convection, and not through radiation. The air begins to circulate in the prepared space, which will save on fuel purchases and increase the rate of heating of the garage or house.

Folk way

A curious way to ensure that the heat continues to spread even after the stove is no longer working.

After all the fuel in the stove has already burned out, an iron box is placed on it and two buckets filled with sand are placed on top of it.

This design will allow heat to accumulate, and the garage will heat up for some time without additional fuel.

Ensuring heat removal

It is possible to increase heat removal by creating devices that promote natural and forced convection. To ensure natural air circulation, screens are made with a guide device that allows you to create a powerful convection flow and distribute it throughout the room. The guide apparatus is made in the form of curved strips of metal, welded to the screen and directing warm air not only upwards, but also to the sides. The prepared device is attached to the oven.

The heat removal device can also be made from scraps of water supply and profile pipes. The distance from the floor to the bottom edge of the elements must be at least 15-20 cm. The pipes are welded to the stove body and covered with a screen on the sides to protect against accidental contact. A traditional potbelly stove heats the air around it by 0.5-1.0 m, and the use of such a design allows you to increase not only the radius, but also the rate of temperature rise in the room. When the body of the heating device is heated above 60 °C, a stable convection draft appears in the device, the power of which increases as the temperature of the furnace increases.

Heat removal can be increased by using fans to blow over the heat transfer surface. Both household and old car fans are used. Devices with variable rotation speeds have proven themselves especially well. They allow you to regulate the temperature and heating time of the room in various oven operating modes.

For more efficient blowing of the furnace elements, special casings are installed that allow cold air to be directed to the hottest areas of the heating device, while it can be taken from various places in the room. A potbelly stove with pipes welded into the firebox for heating air has proven itself well. A multi-speed car fan installed on a common discharge manifold allows you to effectively heat the room.