Most customers who purchase wastewater treatment plants from us prefer to install them themselves with the help of local construction companies. This method is the most optimal, since the cost of services from local construction organizations is generally more acceptable due to the absence of transportation costs. However, the installation of treatment equipment has its own nuances and subtleties, which not all builders may be aware of. And in order for the installation of sewage treatment equipment or storm water treatment facilities to work correctly, it is necessary, first of all, to carry out competent installation of the treatment facility equipment. In order to have complete confidence that the installation work was carried out according to the technology, we recommend that you contact our company for help.

Among the wide range of services of our company there are such as installation of a biological treatment station and installation of sewage treatment facilities. Our company’s specialists have special education and extensive work experience, which together allows us to carry out work of any complexity at the highest professional level. Much depends on how the treatment plant is installed, from the efficiency of its operation to the safety of the people servicing it. Therefore, we recommend ordering our installation services. Even if you cooperate with a local construction company that has assured you that it can carry out all the work according to the project, we recommend at least using our installation supervision service. By taking advantage of this offer, you will be sure and calm in the fact that all work will be carried out under the close supervision of our specialist, who will tell you how to do it right and warn you against mistakes.

Types of local sewerage for wastewater treatment

Cesspools and storage tanks

They are autonomous sewers, but do not belong to VOCs:

- Cesspool (septic tank without bottom). Essentially, this is a filter well. According to SNiP 2.04.03-85, a sump tank must be installed in front of the filter well.

- Storage capacity. Designed to collect wastewater without cleaning it. Removal and disposal of waste using a vacuum truck.

Local treatment facilities include septic tanks with sediment treatment facilities, as well as biological treatment stations (aeration septic tanks).

Septic tanks

A septic tank is a container divided into several chambers. The wastewater settles in them. Gravity overflows are made between the septic tank chambers. The clarified wastewater is discharged from the last compartment.

Where to drain water after a septic tank

SNiPs say that a septic tank is an unfinished treatment facility. After it, you need to make a filter well or filtration field for post-treatment.

A layer of crushed stone 50 cm thick is poured into the well. It serves as a bioload on which bacteria multiply. They purify the water coming from the septic tank.

The Zagorod company does not install wells made of concrete rings or bricks, as in the picture. Their installation is costly in terms of money and time. Instead, we install conical filter wells from a drainage pipe. They look like this:

The filtration field is a crushed stone or gravel bed with perforated pipes laid in it. This system works in the same way as a filter well.

More often they order not a filtration field, but a well. There are three reasons:

- Well is cheaper

- It is easier to install, since the volume of excavation work is less.

- The well takes up less space on the site.

Clay does not allow water to pass through very well. In such soil it will not be possible to perform soil filtration. The water will stagnate and flow back into the septic tank. If clay soil predominates on the site, then a biofilter is installed with the septic tank for additional treatment. Water flows from the septic tank into the biofilter and then into the storage well. From the well, a pump pumps water into the ditch.

Minimum design volume of a septic tank

Vmin = (3 x N x Vday x k)/1000, m3

3 – daily inflow ratio

N – number of residents

Vday – average daily water consumption by 1 user (200 l/day)

k – decreasing or increasing coefficient, can be taken as 0.8 (volume reduction at wastewater temperature of 0.8 and water consumption more than 150 l/day per 1 resident)

Example: for 10 people Vmin = (3 x 10 x 200 x 0.8)/1000=4.8≈5 m3

Maintenance of septic tanks

It is advisable to pump out septic tanks once a year. Pumping is carried out by a sewer truck. The sediment is pumped out from each chamber in turn.

It is also necessary to maintain the drainage well and filtration field. They gradually silt up, and the runoff stops going into the ground. The filtration field is dug up and installed again approximately once every 3-5 years. The well is periodically pumped out and cleaned.

You cannot install a septic tank in an area with high groundwater and in clay. After a septic tank, filtration is required, but it cannot be done in such soil. For a complex area, it is better to buy a biological treatment station with forced pumping.

Biological treatment stations

When talking about local treatment facilities, we usually mean stations. The main difference between a VOC and a septic tank is the presence of an aeration chamber. Thanks to this, the following occurs in the station:

- Decomposition and absorption of organic matter by anaerobic bacteria.

- Nitrification is the oxidation of ammonium NH4+ contained in the urine to nitrates NO3−. Oxidation occurs in the presence of enzymes secreted by aerobic microorganisms.

- Denitrification is the reduction of nitrates NO3 - to nitrogen oxides (NO2,NO, N2O) and further to gaseous nitrogen N2. Denitrification occurs in anaerobic zones – settling tanks.

As a result of nitrification and denitrification, wastewater is completely cleared of nitrates and nitrogen. Sanitary standards allow water to be discharged from local sewers without further treatment. There is no need to create a filtration field or well.

We already said above that VOCs are similar to city wastewater treatment plants. In them, as in central sewerage structures, there are zones for aerobic treatment (aeration tanks) and zones for settling.

Scheme of urban wastewater treatment plants

Local wastewater treatment plants do not have separate sand traps. Their analogue can be considered a filter for coarse fractions in the receiving chamber. It traps large debris. The function of the primary settling tank in local treatment plants is performed by the first chamber. Ultraviolet treatment in VOCs is not used except when the effluent is discharged into a body of water.

We divide biological treatment stations into 4 types:

1.With a receiving chamber for settling (BioPurit, Tver, Ergobox)

. Such treatment plants do not have aeration and flow averaging in the receiving chamber. The water settles, as in septic tanks. Overflows between chambers are gravity-fed. Due to their structural similarity to septic tanks, such stations are also called “hybrid”. They don't get clogged. With large volley discharges, bacteria are washed out and a bioload is provided to secure them.

Local treatment facilities BioPurit

- Advantages

. Simple device, gravity overflow, no blockages. - Flaws

. The pipe is inserted through a rubber sleeve; it dries out in the ground. There are manufacturing defects and leaks between chambers. - It suits

him . For those who need inexpensive and unpretentious sewerage.

Local wastewater treatment plants BioPurit in our catalog

2. With a receiving settling chamber and pumping wastewater through a biofilter (Eurolos BIO)

. These treatment plants do not have a compressor. The effluent is pumped through the bioload in the neck. When sprayed over the bioload, the water is saturated with oxygen. Conditions are created for aerobic cleaning. There is debate about the effectiveness of this technology. Manufacturers offer new technological solutions. Local sewage system Eurolos BIO is equipped with an ejector aeration system, which improves the quality of cleaning.

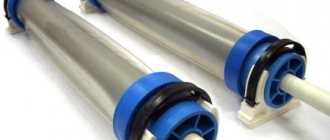

Local treatment facilities Eurolos BIO

- Advantages

: Cylinder-shaped body, resistant to compression. There are lugs. Reliable circuit (no compressor). There is an ejector for additional aeration (partially compensates for the lack of a compressor). - Disadvantages

: Aeration when spraying water over a bioload is less effective than compressor aeration. - Suitable for

: Those who need a septic tank without the risk of blockages, with rare pumping.

Local wastewater treatment plant Eurolos BIO in our catalog

3. With a receiving chamber-aerotank (Eurobion, Crystal)

. Local treatment plants of this type do not have a separate receiving chamber. The first chamber into which wastewater flows is an aeration tank. Cleaning begins immediately. Such stations take a long time to reach operating mode and are very sensitive to the chemical composition of the wastewater. However, after entering the mode, they work reliably and almost do not clog. The condition for normal operation is a regular flow of wastewater, so for non-permanent residents it is not recommended to install such a station.

Local treatment facilities Eurobion

- Advantages

. Gravity overflows and vertical arrangement of chambers. As a result, there are no blockages. Increased salvo discharge thanks to the Aerosliv system. - Flaws

. It takes a long time to get ready and is not recommended for seasonal living. - Suitable for

: For those who live outside the city permanently and who need reliable sewage treatment systems without clogging. For those who have a lot of plumbing in their home and require a large volley discharge.

Local wastewater treatment plant EuroBion in our catalog

4. With a receiving chamber for flow averaging (Topas, Unilos Astra, BioDeka, Genesis)

. There is a coarse bubble aerator in the receiving chamber. The effluent is mixed and averaged before being fed into the aeration tank. These are the most famous VOCs. They are suitable for both permanent and seasonal residence.

Local wastewater treatment plants BioDeka

- Advantages

. Cylindrical body made of homogeneous polypropylene, resistant to compression. Lugs for high groundwater levels. One compressor and one operating mode. - Flaws

. Due to the cylindrical shape, the volume is smaller than that of Astra and Topas with a rectangular body. The wall thickness is 8 mm up to the 10th model (for comparison, Astra has 15 mm). - Suitable for

: For those who live in a private house permanently or seasonally, who do not want to call a sewer for pumping.

Local wastewater treatment plants BioDeca in our catalog

Local treatment facilities Genesis

- Advantages

: Cylindrical polypropylene body with reinforcing strips and lugs. Special overflow system to protect against blockages. GSM module for sending SMS in an emergency. - Disadvantages

: High price. - Suitable for

: Those who want local sewerage without the risk of blockages. Who needs to monitor treatment plants remotely?

Local wastewater treatment plants Genesis in our catalog

Local treatment facilities Unilos Astra

- Advantages

: Wall thickness 15 mm. The useful volume is larger than that of stations with a cylindrical body. Can be equipped with a pumping station and a post-treatment unit. - Disadvantages

: Heavy weight. The body is rectangular, without lugs, welded by hand from 4 sheets of polypropylene. To obtain a guarantee, you must install a voltage stabilizer. - Suitable for

: Those who live outside the city permanently. For those who want to service VOCs without a vacuum cleaner.

Local treatment plants Unilos Astra in our catalog

Local treatment facilities Topas

- Advantages

: Large usable volume due to the rectangular body. - Disadvantages

: Heavy weight. Rectangular body, no lugs. Two compressors and two operating modes (not the most reliable scheme). - Who is it suitable for

: Those who don’t want to spend money on a sewer truck, those who have low groundwater in their area, those who live outside the city all year round.

Local treatment plants Topas in our catalog

Types of VOCs. General information

VOCs accumulate in the wastewater tank where treatment occurs. All wastewater must undergo treatment. You cannot discharge untreated water into water bodies, because it can disrupt the ecological situation and spread various epidemics.

Local devices differ in their location relative to the sewer:

- 1. Structures that belong to the general sewerage system. After cleaning, the wastewater is transported to the central water supply.

- 2. Facilities located far from the general sewer system are separate treatment facilities for servicing residential and industrial facilities.

The structures in the central sewer line are huge structures consisting of several buildings. The devices process wastewater from enterprises, residential complexes, and private households. Such complexes are built outside the city, there are no residential buildings near them, specialists supervise the work, and the whole process is automated.

The independently designed cleaning device is small in size. Serves VOC private houses, small industries. The device is based on low power.

How wastewater is recycled. Facilities installed in storm sewers or in autonomous sewers carry out cleaning in several stages.

1.The first stage of mechanical cleaning separates large particles from the wastewater using filters. Rough water purification occurs. Next, the wastewater is filtered again, where small fragments are separated, then the water enters storage tanks, where they are clarified.

2. The second stage of chemical purification helps to separate substances of organic and inorganic origin that are harmful to the environment. Polluting elements are neutralized in composition.

Reference! If the wastewater contains acidic contaminants, alkali is added to the wastewater, or vice versa.

3. The third stage of purification using bacteria involves the natural decomposition of organic inclusions. Beneficial microorganisms, as a result of their vital activity, help break down organic particles, which are then removed from the structure.

Reference! There is wastewater processing due to bacteria of aerobic and anaerobic origin, some live off oxygen, others do not need it.

Pumping of local treatment facilities

Local sewerage needs to be pumped out once every 6 months. At the Topas, Yunilos Astra, Biodeka, Genesis, and Eurobion stations there is a special airlift for pumping out sludge. With its help, you can perform pumping yourself. A more effective pumping method is using a drainage pump, which is lowered into a sludge stabilizer. The sludge is pumped into a bucket or other suitable container.

After pumping, the local treatment facility must be filled with water. If you leave the septic tank empty, it will float or be crushed by the soil.

Local treatment plants with a receiving chamber for settling (BioPurit, Tver), as well as pumping wastewater through a biofilter (Evrolos, Kolo Vesi), are serviced by a sewer truck.

Station maintenance is not just pumping out sludge. It is necessary to disconnect and wash the airlifts, check the condition of the electrics and other equipment. To perform this work, it is better to call a service engineer who will quickly and professionally perform the service. When purchasing a local cleaning station from the Zagorod company, you can enter into a service agreement with us. Maintenance under a contract is cheaper than one-time maintenance.

Main cleaning steps

Let's look at the main stages of cleaning using the example of local treatment facilities. They come in four types - mechanical stage, biological and physico-chemical, as well as the last disinfection stage.

Mechanical

At this stage, all water-insoluble components are retained, which are then transported to places where solid waste is processed. Several types of devices are used as catchers:

- Lattices. Used to filter large organic and inorganic elements.

- Sita. They retain clay, plankton, silt and various suspensions.

- Sand traps. Designed for catching sand and small broken glass.

- Oil catchers. Separate fat from water.

- Membranes. Used for deep cleaning of wastewater.

Biological

Biological treatment plants process wastewater with microorganisms that represent two groups. Anaerobic microorganisms can live with little or no oxygen and are used in closed containers. Aerobic bacteria, on the contrary, require oxygen; they purify wastewater in open tanks.

Physico-chemical

At this stage, the sewage system is cleared of oil products, technical and industrial impurities. In this case they use:

- Coagulation.

- Electromagnetic separation.

- Flotation.

- Flocculation, etc.

One of the popular ones is the coagulation method, in which, as a result of the action of the reagent, fine particles are combined into flakes that settle at the bottom. The reagents are aluminum sulfate and aluminum oxychloride.

The essence of flotation is the action of a directed air flow, which causes the appearance of bubbles, the formation of foam and then the appearance of flotation sludge, which is removed by a scraper. Flocculation involves the sticking together of impurities under the influence of reagents: organic, inorganic and synthetic.

Disinfection

Disinfection is carried out at the last stage, when after previous treatments a lot of chemicals and microorganisms remain in the water. This stage involves exposing the liquid to ultraviolet light, which is under the sun in an open tank. Treatment with chlorine, hydrochloride or ozonation is possible.

Price of local treatment facilities

The cost of a local treatment plant is the price of the product itself plus the cost of its installation on the site. The price of a treatment plant depends on the volume and design features. Biological treatment stations with forced drainage are more expensive than gravity-flow ones. The price of models with an extended neck is higher than that of standard ones. The cost of installation is calculated individually using measurements before installation. It depends on the complexity of the work and the total cost of the required materials and components. The engineer provides the customer with an estimate that takes into account everything that is needed to install the VOC.

The most important costs when installing local sewerage:

- Pipeline

. 500 rub./meter. - Filter well

. The price of the well itself is 5,500 rubles, together with installation – 12,500 rubles. - Sand for sprinkling

. Approximately 500 rub./cubic. meter, delivery – 3000-4000 rubles, depending on the distance.

If some company immediately tells you a turnkey price, then most likely:

- The price of local sewerage is unrealistic. After measurements, it will increase significantly.

- The company does not take into account the most important factors when selecting a treatment plant (soil composition, groundwater level). Typically, such installers bury what the customer has chosen. For example, they install a septic tank in clay, it does not work, and to the customer’s question the manager answers: “You yourself wanted this.” This is not a professional approach.

- customer during installation. Much of what is needed is not included in the estimate. As a result, the cost increases. In addition, the installer goes to buy everything on the day of work, and the customer remains in charge of the workers.

We work according to the contract, we meet deadlines

In the modern world, it is extremely important to work under a contract so as not to find yourself in a disadvantageous situation. Our company operates exclusively on this principle. Before starting any work, we sign an agreement that specifies all the necessary nuances, prices and deadlines for the contract. We rightfully consider punctuality to be one of our key advantages. After all, we always adhere to the deadlines initially agreed with the customer. In our practice, there have been a few cases where deadlines were not met, and this was either due to the fault of the customer or due to difficulties associated with transporting the cargo. We also draw your attention to the fact that we sell certified products that have high quality standards and are suitable for work even in the harshest conditions. By the way, if your facility is located in a place with difficult climatic conditions, then this fact also plays an important role in the process of equipment installation. Our specialists know about all the features of operating equipment in hot and cold climates, which ordinary construction companies may not know. Order a product or service from us and see for yourself that we are a serious company that works honestly and conscientiously!