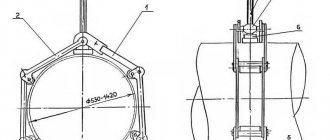

Floats on mounting rod

One tank can contain up to several switches, each of which has its own function: one controls the auxiliary pump, another controls the main pump, the third acts as an emergency water level sensor, and the fourth monitors overflow.

In any case, the number of floats is determined by the number of connected pumps, as well as the need for protective devices in the system. Several floats are mounted on a special mounting rod. In its role, you can successfully use a plastic pipe securely fixed in the tank. The float switches are fixed on the rod at a distance from each other so as not to interfere with the work of the neighbor. The cable of each switch is secured using clamps. There are situations when necessity dictates the use of several rods at once for attaching floats. Taking into account operating conditions and project features, the number of float switches required to organize the work of a particular system is determined. There are two types of float switches:

- Lightweight - for a system that controls water supply or water disposal;

- Heavy - designed to control drainage or sewage pumps.

Types of floats and their purpose

All floats that are used in pumps are divided into two types:

- Lightweight – used when working with clean water for drinking or domestic needs;

- Heavy - used in large sewage and drainage pumps.

This classification of floats should be taken into account when choosing a pump. Light elements will not be able to cope with heavily polluted water, and it is not practical to buy units with heavy floats for pumping clean water due to their high cost.

Float in the pump device description of the element

Both the sump pump and the submersible float pump operate in conditions where debris can get into the fluid or it can run out. In the first case, solid waste fractions can severely damage the system. In order to avoid this, pumps are equipped with shut-off floats, which are activated when there is no water or when there is a large amount of debris in it.

Pumps can be placed and operated in various containers, wells or wells. Depending on where the unit is used, the functions of the float may differ. However, in all cases, the tasks of floats include:

- Adjusting the operation of the main pump;

- Adjusting the operation of the auxiliary pump and increasing its efficiency;

- Water level alarm;

- Overflow alarm.

A liquid level indicator is required to prevent the pump from running dry. An overflow alarm is necessary to eliminate the possibility of overfilling the tank in which the pump is located. This often leads to a short circuit in the device.

Principle of operation

Depending on the operation scheme of the float switch, the operating principle of the device also changes.

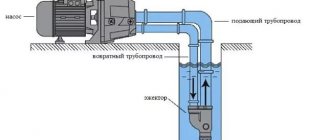

Water supply system, filling and emptying the tank . When the float operates according to this scheme, at the moment of ascent it de-energizes the pump that supplies water to the tank. When the float is on the surface, it gives a signal to turn on the automatic water supply station. The station can only be turned off when the device is immersed to the bottom when the container is empty.

Sewage system . The fecal pumping equipment is switched on when the main control device is raised. The pumping unit turns on when it sinks to the bottom. One float is capable of servicing two pumps at the same time: the first can supply water to the container if the float is in its lower position, the second pump is inactive at this time. When the float is at the top, the second pump is turned on, pumping out water. During this time the feed pump is inactive. This scheme is quite effective, as it eliminates problems with the regular delivery of water when filling the container.

Equipment classification

Float sensors can independently monitor the liquid level or send a signal to the control circuit. According to this principle, they can be divided into two large groups: mechanical and electrical.

Mechanical devices

Mechanical valves include a wide variety of float valves for the water level in the tank. The principle of their operation is that the float is connected to a lever; when the liquid level changes, the float moves this lever up or down, and it, in turn, acts on the valve, which shuts off (opens) the water supply. Such valves can be seen in toilet flush tanks. They are very convenient to use where you need to constantly add water from the central water supply system.

Mechanical sensors have a number of advantages:

- simplicity of design;

- compactness;

- safety;

- autonomy - do not require any sources of electricity;

- reliability;

- cheapness;

- ease of installation and configuration.

But these sensors have one significant drawback: they can control only one (upper) level, which depends on the installation location, and regulate it, if possible, then within very small limits. On sale, such a valve may be called a “float valve for containers.”

Electrical sensors

An electric liquid level sensor (float) differs from a mechanical one in that it itself does not shut off the water. The float, moving when the amount of liquid changes, affects the electrical contacts that are included in the control circuit. Based on these signals, the automatic control system makes a decision on the need for certain actions. In the simplest case, such a sensor has a float. This float acts on the contact through which the pump is turned on.

Reed switches are most often used as contacts. A reed switch is a sealed glass bulb with contacts inside. Switching of these contacts occurs under the influence of a magnetic field. Reed switches are miniature in size and can be easily placed inside a thin tube made of non-magnetic material (plastic, aluminum). A float with a magnet moves freely along the tube under the influence of liquid, and when it approaches, the contacts are activated. This entire system is installed vertically in the tank. By changing the position of the reed switch inside the tube, you can adjust the moment the automation operates.

If you need to monitor the upper level in the tank, then the sensor is installed at the top. As soon as the level drops below the set level, the contact closes and the pump turns on. The water will begin to increase, and when the water level reaches the upper limit, the float will return to its original state and the pump will turn off. However, in practice such a scheme cannot be used. The fact is that the sensor is triggered by the slightest change in the level, after which the pump turns on, the level rises, and the pump turns off. If the water flow from the tank is less than the supply, a situation arises when the pump constantly turns on and off, and it quickly overheats and fails.

Therefore, water level sensors for pump control work differently. There are at least two contacts in the container. One is responsible for the upper level; it turns off the pump. The second determines the position of the lower level, upon reaching which the pump turns on. Thus, the number of starts is significantly reduced, which ensures reliable operation of the entire system. If the level difference is small, then it is convenient to use a tube with two reed switches inside and one float that connects them. If the difference is more than a meter, two separate sensors are used, installed at the required heights.

Despite their more complex design and the need for a control circuit, electric float sensors allow fully automated liquid level control.

The principle of operation of the float in different systems

The scope of application of float-type switches is very wide. The element functions correctly in standard water supply systems, effectively controls the filling and emptying of the storage tank, protects the equipment from running dry and extends its service life.

The role of the switch in water supply systems

A device placed in a container floats to the surface when the tank is filled with water and promptly turns off the operating pump, preventing it from overflowing in this way. When the water level drops, the float drops with it and immediately activates the pump to subsequently fill the container with water.

While on the surface of the tank (when the container is full), the device will give a signal to the operation of the automatic water supply station and turn it off when it sinks to the bottom (when the container is empty).

Many manufacturers of modern household pumps initially equip their products with a practical, convenient, highly durable, heat-resistant and waterproof floating switch. Having purchased such a unit, the owners will no longer have to select a float for it and bother with the correct connection of the device to the water pumping equipment

The float will command to close the valve or lower the valve with a servo drive when it appears on the surface of the container filled with liquid. Having dropped to the bottom (when the tank is empty), the device will again open the valve or gate, reactivating the filling of the tank with water.

The float will send a signal to the control center or directly to the operator when it reaches the surface of the filled container. The device will report the absence of water in the tank when it sinks to the bottom of the working container.

Contact with drainage or sewer system

For drainage, sewer and sewage pumps, a heavy duty float switch is recommended. It is adapted to work in high-density liquids and easily copes with the assigned tasks.

The device clearly monitors the operation of the pumping complex and, having floated to the surface when the container is full, immediately activates the equipment. The shutdown occurs at the moment when the device sinks to the bottom as a result of emptying the tank.

The presence of a float-type switch in the drainage and sewer system allows you to automatically turn off the pump at the moment when the tank is empty. The signal to stop work will be given by the barorelay regulator located in the float device

The functionality allows connecting two pumps to one float switch. In this case, the pumping units will work in turn. One will begin to fill the container when the float is in the lower position, and the second will start working when the switch is at the top.

However, experts point to the low efficiency of the system and draw attention to potential differences in the supply of household water while filling the tank.

Float maintenance and repair

Subject to the operating rules, the float to turn on the pump will work for a long time and properly. If the element is used in conditions of working with clean water, then it does not require special maintenance. If the float is used when working with dirty water and a large amount of solid fractions, then it, like the entire system, must be washed under running clean water. This must be done at least once a month. This will prevent the part from sticking to the pressure pipe or pump.

If water gets inside the float, its contacts burn, or the integrity of the cable insulation is damaged, all faulty elements must be replaced, since they cannot be repaired. If the electronic float itself is completely out of order, then it must be changed at special service centers.

Advantages of the device

This procedure will prevent the float from sticking or sticking to the pump or discharge pipe. When the preparatory work is done, the float is connected to the pumping system.

Then the floats are mounted on the rod base. After this, the cable itself must be firmly fixed on the outside of the tank.

It is better to contact a specialized service center and purchase a branded certified part with documents that fully meets all the requirements for equipment of this type. They should be located on the sides of the body inside, so that the ball, falling between them, makes contact. It is the change in the indicators of this signal that makes it possible to assess the level of the substance in the container being used.

The cable of each switch is secured using clamps. Depending on the pressure value, the amount of water in the tank is determined. Thus, they can be easily adjusted manually to prevent overflow or dry running.

Equipment classification

This must be done at least once a month. Three-core copper wire with a wire cross-section of 0.5 mm2.

How to connect a float switch to a pump

Installation of the float can be done in different ways. Before installation, make sure that the current consumed by the pump is less than the maximum permissible current specified in the system operating manual.

The easiest way to install a float is to install it in a container using a cable and a special sinker, which is included with the unit. Installation of the float is carried out according to the following algorithm:

- First, the sinker must be put on the cable and the free play of the float must be determined;

- After this, the sinker must be secured to the cable using a latch;

- Next you will need to fix the cable on the outside of the container.

After installing the element, you should connect the float switch to the pump. Before setting up the float, you need to carefully study the diagrams that come with the device.

Once connected, you will need to check if the system is working. To do this, start the pump and wait a couple of hours. If the device pumps out water stably, it means that the installation and connection were carried out correctly.

Reed switch device

The main actuator element of the reed switch is the reed switch. The device is a small glass cylinder filled with an inert gas or with air evacuated. Gas or vacuum prevents the formation of sparks and oxidation of the contact group. Inside the flask there are closed contacts made of a ferromagnetic alloy of rectangular cross-section (permalloy wire) coated with gold or silver. When exposed to a magnetic flux, the contacts of the reed switch are magnetized and repel each other - the circuit through which the electric current flows opens.

Rice. 6 Float vertical water level sensors

A similar pump control circuit, placed in the control cabinet, can be used when monitoring the level in a tank with liquid, if the reed switches are swapped, that is, SV2 will be at the top and turn off the pump, and SV1 in the depths of the water tank will turn it on.

Level sensors can be used in everyday life to automate the process when filling large containers with water using electric water pumps. The easiest types of reed switches to install and operate are those produced by industry in the form of vertical floats on rods and horizontal structures.

Float switch in action

Before connecting a newly purchased float switch to a pump, it is advisable to ensure that their technical characteristics are compatible. An elementary way to set up the operation of a switch for electric pumps is inside a water tank.

Serial connection diagram for float switch:

- A special sinker (from the kit) is attached to the float cable.

- The cable is securely fixed at the edge of the tank.

- The amplitude of the free movement of the float switch is adjusted to set the highest and lowest levels at which the float switch will operate.

- The float switch is connected to the pump last.

The main functions performed by a float switch:

- The float connected to the pump that performs the task of filling the tank will turn off when ascending and connect when it reaches the bottom mark.

- For an automatic station: switching on when the upper liquid level mark is reached and switching off at the lower mark (reaching the bottom of the container).

- Valves or valves with a servo drive: the switch will give a signal to close when it is in the upper position (full capacity) and will open the way for water when it reaches the lower position.

- Control room: monitoring of excess and shortage of water.

It is possible to connect two pumping devices to one float: the function of the first pump is to fill the tank when the float is located at the bottom, the mission of the second is to pump out water when it is at the top. The scheme is effective only if there is an uninterrupted supply of water to the tank. Some options for connecting switches to prevent pumps from running dry.

Types of sensors

Sensors differ in the method of measuring liquid level and are divided into two types: alarms and level meters. Alarms monitor the specified filling point of the container and, when the required volume of liquid is reached, stop its flow (for example, a float in a toilet tank).

Level gauges continuously monitor the degree of filling of the tank (for example, a sensor on a mine drainage system).

According to the principle of operation, water level sensors in a tank are divided into the following types:

- Float - their design includes a float with a magnet and two sealed contacts (reed switches). When the minimum level of liquid in the tank is reached, the float moves down and acts with a magnet on the reed switch, at the same time the relay turns on and the pump starts, pumping water into the tank begins. When the container is completely filled, the float reaches the upper reed switch, and the relay is activated, turning off the pump.

- Ultrasonic - used not only in liquid environments, but also in dry ones. The devices work in this way: the emitter sends pulses that reach the reservoir and return to the receiver. The built-in signal processing controller analyzes the strength and duration of attenuation of the ultrasonic wave (these parameters are different for a full and empty tank).

- Electrode - used in liquid electrically conductive media. They consist of two electrodes that control the desired liquid level. The third electrode is an emergency electrode and is used when the specified parameters are exceeded and the pumping mode is turned on.

- Radar devices are universal mechanisms due to the fact that they can be used when working with aggressive and explosive liquids. The operating principle of the devices is based on the use of radio wave radiation - waves of a certain length are directed to the surface of the liquid process medium, reflected from it and entering the analyzer. The filling level of the container is determined by the speed of signal return.

These are the most common level sensors; in addition to them, there are capacitive, hydrostatic, radioisotope and other types of devices that are used in various industries.

The role of alarms in drainage pumps

A drainage pump with a float switch is widely used both in industry and in everyday life. Its scope of use is cleaning wells, removing dirty liquid, etc. In a drainage pump, the float is equipped with the function of turning the drive on and off automatically. The switch is lowered into the wastewater via an extended cable along with a pipe for collecting liquid. The vertical type drain pump kit includes a vertical float switch with the function of pumping liquid out of a confined space. Such a drainage pump can, for example, drain inactive pipelines.

Use in everyday life

A float valve for the water level in a tank for irrigation or an outdoor shower in the country has become widespread.

The simplest design is connected to a barrel for collecting rainwater and is connected with a hose that drains the excess into a drainage ditch. When filling the barrel, in order to avoid overflow, the float blocks access to the barrel, and excess water is removed from the house. In fecal and sludge pumps, the presence of a float allows owners to free themselves from constant monitoring of the level of wastewater in septic tanks and drainage wells. When a certain waste limit is reached, the float turns on the pump and the liquid is removed for further purification naturally in the filtration field.

In this case, special attention must be paid to the correct installation of the pump. Since the float is located outside the device, when immersed in a drainage well or septic tank, you need to carefully check that the lever does not catch on the walls of the container and can move freely. Otherwise, the float valve in the container or tank will not be able to regulate the level of wastewater, which will lead to rapid failure of pump parts or to burnout.

Instruments with float valves should not be used in sub-zero temperatures as frozen liquid will cause damage. To avoid this, you need to either install heating in the room where the container is located, or drain the tank and the float valve itself so as not to damage the plastic parts and the membrane.

Source

Making a float switch with your own hands

To make a part yourself, you will need to prepare:

- Metal ball;

- 2 buildings;

- 2 small magnets;

- Contact plates.

The plates can be made of brass or copper. They must be on different sides of the housing so that the ball between them can make contact. To make the metal strips more springy, they can be placed on a file and beaten with a hammer.

The magnets should lift the ball and hold it at an angle of 65 degrees. The housing itself can be made of any material that does not conduct electricity. Further work looks like this:

- First, wires with a cross-section of no more than 2 mm are soldered to the contacts;

- Next, the wires need to be insulated and placed in the housing;

- It is also necessary to carefully insulate the inside of the case;

- You will need to pour polyurethane foam into the float cavity and insulate the outer side of the housing;

- After this, you need to install loops at the ends of the case and connect the cord.

The manufactured float will last quite a long time, and you will save a lot of money on the purchase of equipment.

Design and principle of operation of the drainage pump

The design of the drainage pump is quite simple; its main elements are:

Rice. 3 Internal structure of the drainage electric pump

Frame

A typical drainage system has two bodies: external and internal. The internal casing houses the main unit of the device - an electric motor, which is cooled by the water flow washing it, flowing between the casings to the outlet located at the top.

The outer body of the device is equipped with a convenient handle for carrying or hanging in the water column; it also contains an outlet pipe (pipe) to which hoses are connected.

The inner case is made of metal to organize better cooling; the outer case is usually metal (stainless steel) or impact-resistant plastic.

Electric motor

In the internal, completely insulated pump casing, there is an electric motor consisting of a stator with a winding and a rotor, the shaft of which rotates on the upper and lower bearings. Power is supplied to the electric motor using a cable through a sealed input unit; a capacitor is built in for starting.

To lubricate and cool the bearings, special chambers are provided in the lower part of the inner housing, filled with technical oil. There are also O-rings there that prevent water from penetrating into the engine.

Working wheel

The disk-shaped impeller, on which curved blades are placed, is fixed to the motor shaft. The usual material for its manufacture is metal, sometimes it is made of high-strength plastic.

At the bottom of the pump body there is a stand with legs on which the pump is usually placed. A little higher is a cover with water intake holes (filter), eliminating the possibility of particles with sizes exceeding its technical characteristics from penetrating into the electric pump.

Float switch for electric pumps: profitable, convenient, reliable

There are many different control techniques to prevent pumps from running dry.

The use of a water level float switch is one of the most affordable and effective ways to protect equipment from possible breakdowns. The indisputable advantage of its use is the possibility of simultaneous use in two guises - as an executive element for controlling equipment and as a controller that determines the water level. The field of activity of water level switches is very wide, for example, in systems responsible for water supply and drainage. Float switches serve wells, storage tanks, and are used in all kinds of containers. They are also used in sewerage systems.

Floats on mounting rod

One tank can contain up to several switches, each of which has its own function: one controls the auxiliary pump, another controls the main pump, the third acts as an emergency water level sensor, and the fourth monitors overflow. In any case, the number of floats is determined by the number of connected pumps, as well as the need for protective devices in the system. Several floats are mounted on a special mounting rod. In its role, you can successfully use a plastic pipe securely fixed in the tank. The float switches are fixed on the rod at a distance from each other so as not to interfere with the work of the neighbor. The cable of each switch is secured using clamps. There are situations when necessity dictates the use of several rods at once for attaching floats. Taking into account operating conditions and project features, the number of float switches required to organize the work of a particular system is determined.

There are two types of float switches:

- Lightweight - for a system that controls water supply or water disposal;

- Heavy - designed to control drainage or sewage pumps.

What is a "float"

Drainage pumps with float switches operate in automatic mode, which avoids overfilling the storage tank and prevents the engine from running dry if there is no water in the tank. The device turns off the pump when the liquid level decreases below the set limit and turns on when the volume of wastewater increases above the permissible level.

It is not recommended to set the minimum water level on the device to turn off the pump less than 5 mm, so that the motor cannot overheat under extreme pumping conditions, and the working elements cannot fail as a result of unacceptable operating conditions.

The very small low-voltage submersible pump ensures maximum safety. It only operates on 12 volts and damage to the cable or pump will not result in electric shock if it touches the water. The pump can work with a power source, but also with a car battery, so it is often used in a campsite, caravan or mobile home. Of course, the flow rate is correspondingly low, ranging from 100 to 150 liters per hour. However, it is also particularly suitable for pumping out water in aquariums.

In addition, there are other special submersible pumps, such as the pressure submersible pump, which are suitable for particularly high flow rates. The feed height is also adapted accordingly, so that many and large particles can be processed. The devices have very high power, but are not very economical in consumption.

The float is a special sensor that can be:

- built into the body (aquasensor);

- separately located (classic option).

Remote float switches are made in the form of sealed plastic boxes, inside of which there is a metal ball and a switch connected to the electrical network. Depending on the level at which the float is currently located, the internal contacts are closed or opened using the ball. The electrical switch can also be located outside the container. In this case, a special cable or synthetic cord connects it to the float.

This area also includes special pumps that, instead of water, promote the circulation of other liquid materials, such as fuel oil, biodiesel or gasoline. Particularly narrow submersible pump designs are again required for emptying deeper wells and tanks. They fit into very narrow shafts due to their shape and are very expensive to purchase.

Scuba Pump Test - We tested these diving pumps for you

The rhythm of the pump always adapts exactly to the volume of water. It has a power of 100 W and provides a flow rate of 000 liters per hour. The discharge height is 9 meters, the maximum outlet pressure is 0.9 bar, the immersion depth is 8 meters, the particle size is 30 millimeters, so even large dirt particles and sediment can be extracted without problems. The body is also made of plastic, and the submersible pump has a protective function. Dry running protection. The price is 149 euros.

Autonomous float switches, in turn, are divided depending on the density of the waste liquid into:

- lightweight, installed in drainage and water supply systems;

- heavy, intended for fecal, drainage and rainwater.

Depending on the equipment model, remote floats are equipped with cables 2-10 meters long.

Vertical single-stage submersible motor with horizontal pressure, high operational safety and built-in circuit breaker. It has a power of 320 watts. Weight is only 3.4 kilograms. The consumption is 500 liters per hour, the unloading height is 7 meters, the grain size is 20 millimeters. Unlike other submersible pumps, the maximum water temperature is 40 degrees Celsius, which is 5 degrees higher. The submersible pump costs 151 euros.

Thanks to the built-in aqua sensor function, the pump automatically starts automatically at a water level of 5 mm and pumps or quickly changes speed. This way, you can effectively prevent water damage—even when you're not at home. The output is 320 watts, the output is 000 liters per hour, the discharge height is 7 meters and the immersion depth is 8 meters. The body is made of plastic, so the submersible pump is also very lightweight.

Recently, submersible drainage pumps with a float built into the housing have appeared on the market. During operation, such a device showed itself from a more advantageous position. The switch will not be able to catch on uneven surfaces or rest on any protrusion located in the container, including the top of the pump, which the “floating box” is not immune to. But when choosing equipment with a built-in float, you should take into account the fact that such a pump can only be intended for clean water.

The float switch performs two functions at once:

- water level sensor;

- pump control element.

In one stationary tank, several floats can be installed at once, which are also responsible for liquid overflow, emergency situations, as well as for the operation of the auxiliary pump.

Float switch in action

Before connecting a newly purchased float switch to a pump, it is advisable to ensure that their technical characteristics are compatible. An elementary way to set up the operation of a switch for electric pumps is inside a water tank.

Serial connection diagram for float switch:

- A special sinker (from the kit) is attached to the float cable.

- The cable is securely fixed at the edge of the tank.

- The amplitude of the free movement of the float switch is adjusted to set the highest and lowest levels at which the float switch will operate.

- The float switch is connected to the pump last.

If there is a danger of the float freezing or impeding its free movement in the container, the connection cannot be made.

The main functions performed by a float switch:

- The float connected to the pump that performs the task of filling the tank will turn off when ascending and connect when it reaches the bottom mark.

- For an automatic station: switching on when the upper liquid level mark is reached and switching off at the lower mark (reaching the bottom of the container).

- Valves or valves with a servo drive: the switch will give a signal to close when it is in the upper position (full capacity) and will open the way for water when it reaches the lower position.

- Control room: monitoring of excess and shortage of water.

It is possible to connect two pumping devices to one float: the function of the first pump is to fill the tank when the float is located at the bottom, the mission of the second is to pump out water when it is at the top. The scheme is effective only if there is an uninterrupted supply of water to the tank. Some options for connecting switches to prevent pumps from running dry.

Select and buy a float valve for a container or tank

Using modern solutions and the necessary equipment, you can automate various processes of dacha life. Turning the well pump on and off for water supply, energy saving, heating - all these are important elements of country life.

An important factor is watering the garden, and heated water in the reservoir is the key to the health of your plants. To maintain automatic control of the water level in the tank, you will need a float valve for the tank as well as several fittings for its installation.

Let's look at the different types of these devices.

Before you buy a mechanical or electric type float valve for a tank, think about the implementation of your goals. It is necessary to take into account the productivity with which water will be drawn from the tank, as well as the volume of the irrigation tank itself.

At the same time, your tank will quickly fill and warm up, which means the time between watering cycles will be significantly reduced.

This float valve for a tank has a waterproof body and a wire of 3 or 6 meters. It can also be used to turn the automatic pump on and off during dry running by setting the float to the lowest point of the water level.

In this case, you do not have to constantly turn on the pump by hand when the automatic operation is activated during dry running. This solution is very convenient if you rarely visit the site, and the water in the village water supply runs rather slowly. The energy dependence of the system on a constant power source is perhaps the only negative.

If this is not available, you should consider a 1” mechanical type float valve.

Upon supplying the top-up pipe, a hole of 1” or 25 mm is made in the tank. The valve itself with a crimp nut and a rubber gasket is inserted into it. At the output we will get a threaded pipe for connecting the topping pipe using a fitting.

We adjust the plastic float of the valve to the maximum water level by loosening or tightening the nut on the movable float arm.

All is ready! We open the main valve to supply water to the tank; as it fills, the float will move to the upper adjusted level mark, and the valve mechanism will block the access of water to the tank.

Thus, the main control of the water level in the tank is provided by an electric float valve for the tank, and auxiliary control is provided by a mechanical float valve for the tank. In the event of a malfunction of the top-up electromagnetic valve (membrane clogged, old age, leakage, etc.)

) the mechanical valve will stop adding water to the tank when it reaches its maximum level. This method will protect the container from overflowing and unforeseen consequences for its owner.

Source

The role of alarms in drainage pumps

A drainage pump with a float switch is widely used both in industry and in everyday life. Its scope of use is cleaning wells, removing dirty liquid, etc. In a drainage pump, the float is equipped with the function of turning the drive on and off automatically. The switch is lowered into the wastewater via an extended cable along with a pipe for collecting liquid. The vertical type drain pump kit includes a vertical float switch with the function of pumping liquid out of a confined space. Such a drainage pump can, for example, drain inactive pipelines.

Design and principle of operation of the switch

Float design: electric switch and steel ball placed in the internal cavity of a plastic housing.

The cable length varies from 3 to 10 m. When the float switch reaches the upper mark, the switch contacts close, turning on the pump. As soon as the float descends to the lower mark, the steel ball acts on the switch lever, changing its location. The circuit opens and the system turns off. Float switch connection diagram: a cable with three wires is connected to the switch.

They vary in color, often being black, blue and brown. The common wire is marked in black. In the upper location of the float switch, the contacts of the common wire and the normally closed wire, indicated in brown, are closed. At the minimum mark, the circuit is closed with the participation of a common wire and a normally open wire, indicated in blue. The insulation of wires not currently used in the circuit must be very reliable. It is understood that in an aquatic environment the cable must have sufficient moisture resistance, and the plastic case must be leak-tight. The cable outlet is equipped to relieve mechanical stress and is reliably sealed. The polymer resin filling the cavity of the cable glands prevents moisture from getting inside. And the last word in favor of the float switch is the price, which usually varies from 300 to 500 rubles. The combination of a reasonable price and reliability makes the purchase of a float switch the best option for providing protection against unwanted breakdowns of expensive equipment, such as household and industrial pumps. Source

Float switch connection diagram – Float switch: operating principle and application

Float switch connection diagram

- if you entered just such a query in the search bar, then you can only be assured that this procedure will be carried out at the highest level, since it is quite easy to do. There are a lot of recommendations on the Internet.

Which educate the user on this issue. Of course, it is better if such a person performs such a procedure. who has actually encountered such a problem and can do everything correctly. But if you are an average person who is not very knowledgeable about this procedure, then you need instructions for use that will describe in detail the situation on how exactly you need to connect this system.

In general, the float, as it is called, is a kind of protection for the pump, which can block its operation at the moment when it is necessary, for example, if there is no liquid in the pumping tank. The situation is quite common.

But it is precisely this that can completely bring the pump out of its working state and into non-working state. To avoid this, you need to purchase a float switch, install it successfully, and then just pick it up and use it. It’s just that if you understand electrics, then this installation, which should happen successfully, is not a problem for you. But for the average resident of the country it will not be so easy. You just need to create an electrical circuit that, in case of a positive effect, will open it. This will lower the float below the level set in the system.

How to connect a float switch?

You just need to read the operating instructions for both the pump and this device very carefully so that there are no problems in the future. And don’t forget that no one can do this job better than a real specialist.

This is an unwritten law, because only he can understand this system. And understand whether the connection is possible at all, and where it needs to be connected. The best option would be to just invite an installer. And one more thing - if you purchase a float, pay attention to the cat who is the manufacturer, as well as who issued the license.

Passport, and whether these documents are available at all. The situation is quite common when frivolous sellers are going to sell you a product that simply does not really meet all the standards. Just take a closer look at this issue. And everything will be pretty good for you during the entire period of operation.

In a water supply system, universal float switches are used to control the water level and operate in one of two cases:

- When the container (or well, borehole) from which pumping occurs is empty, in this case the float switch serves to protect the electric pump from dry running.

- When filling a container into which water is supplied, for example, into a watering tank, swimming pool, etc. In this case, the switch protects against overflow.

In what case the electric pump will be turned on and in what case it will be turned off depends on which circuit the pump is connected to. If you need protection against dry running and turning off the pump when the water source is empty, then you need to connect the electric pump to circuit No. 1. The pump will be able to operate until the float drops to the bottom position and opens the electrical circuit. If overfill protection is needed, then the pump must be connected to circuit No. 2; it will work until the float rises to the upper position.