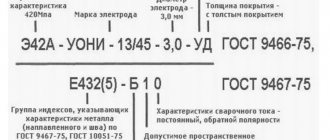

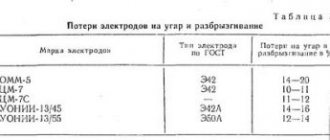

Characteristics

- The deposited metal corresponds to mild or semi-mild steel.

- In terms of the mechanical properties of welded joints, the cellulose coating corresponds to electrodes of grade E42-50 (according to GOST).

- Low-oxidizing atmosphere of the welding arc.

Benefits of coverage

- Wide possibilities of use. Welding can be carried out in any spatial position. It is convenient to weld structures in hard-to-reach places, since the electrodes are very thin.

- Provides high speed. The welder can work at speeds of up to 25 m/hour due to the ease of welding.

- High-quality welding of the seam to the very root.

- Gas protection protects the deposited metal from the influx of hydrogen or oxygen.

- During cooking, a little slag is released. This makes it convenient to weld vertical seams, since the slag does not flow down and interfere with work. Slag is easily removed from the surface of a cooled seam.

Flaws

- The seams are obtained with a rough-scaled surface. Therefore, additional grinding of the metal of the welded structure may be necessary.

- The ductility of the weld metal decreases, since the combustion of organic compounds releases a large amount of hydrogen, which will also be in the deposited metal. May cause cracks.

- During welding, strong metal spattering is observed (up to 15%).

- Sensitive to overheating during the calcination process.

Rutile electrode coating

Rutile coating (designated according to GOST 9466-75 by the letter “P”) is created on the basis of rutile concentrate TiO2, which provides slag protection, as well as aluminosilicates (feldspar, mica, kaolin) and carbonates (marble, magnesite). Gas protection is provided by carbonates and organic compounds (cellulose). Ferromanganese is used as an alloying component and deoxidizer; iron powder is introduced into some coatings (designated according to GOST 9466-75 by the letters “RZh”). With the help of calcium present in CaCO3 carbonate, sulfur and phosphorus are removed from the weld metal.

Advantages of rutile coated welding electrodes:

- higher deposition rate when adding iron powder;

- low toxicity;

- compared to electrodes with a base coating - stability of the arc when welding on direct and alternating current, higher resistance to pore formation, better formation of a weld with a smooth transition to the base metal, less sensitivity to increasing arc length, lower metal spatter coefficient, more convenient welding in vertical and overhead positions (in the absence of iron powder or its content is less than 20%).

Disadvantages of rutile-coated electrodes:

- reduced ductility and impact toughness of the weld metal due to SiO2 inclusions;

- not used for welding structures operating at high temperatures;

- compared to electrodes with a basic coating - lower resistance of the deposited metal to hydrogen sulfide cracking, leading to the destruction of welded pipelines in deposits with hydrogen sulfide compounds; resistance against crystallization cracks; alloying elements and iron oxidize more strongly and therefore are not used for welding medium- and high-alloy steels; increased phosphorus content in the deposited metal and a tendency to cold brittleness.

Scope of application of welding electrodes with rutile coating:

- welding and surfacing of critical structures made of low-carbon and some types of low-alloy steels, with the exception of structures operating at high temperatures;

- in some cases for welding medium-carbon steels, if the coating contains a large amount of iron powder.

Application

Cellulose-coated electrodes are used for welding carbon and low-alloy steels. Their small thickness allows them to be used when working with hard-to-reach structures. Often used for welding main pipelines.

The cellulose coating ensures stable burning of the welding arc both at alternating and direct current. But for better welding, it is recommended to use a current of direct polarity. This way the arc will melt the metal more powerfully, eliminating the possibility of undercuts and pores forming.

When using cellulose electrodes, several nuances should also be taken into account:

- You cannot weld structures made of hardening steels that contain a lot of carbon and alloying elements;

- When preparing electrodes for work, they must be calcined strictly at the temperature specified by the manufacturer.

IMPORTANT! The electrodes must not be overheated during calcination, since they must maintain a humidity level of 1.5 to 5.0%.

If the electrodes are heated at temperatures above 170 °C, they become significantly overdried. As a result, the deposited metal will be more saturated with carbon.

The optimal calcination temperature is 120-130 °C.

Types of coating

Types of electrode coating are divided into a number of groups, each of which has its own designation. Types of electrode coating are divided into:

- the main one, designated as “B”, is white or beige;

- sour, designated “A”, gray in color;

- cellulose, designated “C”, light gray with a brownish tint;

- rutile, designated “P”, in various colors such as gray, blue, green, reddish.

There are also mixed-type coatings, which is reflected in their designation. So, for example, the combination of letters RC should be deciphered as rutile-cellulose, and “RA”, respectively, as rutile-acid. The letter “P” is a designation for other types of coatings. This gradation is determined by the presence of chemical elements included in the coating. The choice of coating should be made depending on the metals being joined.

Basics

The main coating of the electrodes contains mostly calcium and magnesium carbonates. In order for the slag crust to be diluted, a special element in the form of fluorspar is added to the coating. This somewhat impairs the ability to work when using alternating current, so it is recommended to use electrodes with a basic coating when working with constant current.

The difference between this type of coating is that there is no hydrogen in the resulting gaseous environment, which can lead to the formation of cold-type cracks. When using electrodes with a basic coating, the seam results in increased ductility.

A big advantage is the ability to weld in all positions, however, it should be taken into account that the seam, due to its significant viscosity, will be somewhat convex and not entirely aesthetically pleasing.

Sour

Acid-coated electrodes have a coating containing iron and manganese ores. This contributes to the release of a significant amount of oxygen to the welding site. The result is an increase in temperature and at the same time a decrease in surface tension, which gives it fluidity.

The speed of the welding process increases, but there is a danger of undercuts. Acidic electrodes pose some danger because their coating contains manganese oxides, which are toxic. There are brands of acid coated electrodes, but rutile acid coated electrodes are preferred.

Pulp

According to the name, the main element of this type of coating is cellulose. It also includes organic substances in the form of resins. A special feature is that during combustion in a welded arc a significant amount of shielding gas is formed. In this case, little slag is formed.

Cellulose-coated electrodes have the disadvantage of producing hot metal spatters during welding. In addition, the weld metal has low ductility. This is due to the presence of a considerable amount of hydrogen released during the combustion of organic substances.

Existing brands of cellulose-coated electrodes are characterized by a high speed of the welding process. Their advantages include the ability to weld in all positions, even one in which the electrode moves from top to bottom, which is beyond the capabilities of most electrodes. The disadvantages are large spattering of hot metal, the formation of undercuts on the edges, and the rough surface of the resulting seam.

Rutile

This coating contains an element such as natural rutile concentrate. Additives include feldspar and magnesite. Titanium dioxide guarantees easy arc ignition. There is little splashing.

The electrodes have good technological characteristics. The harmfulness of working with them is less than with other electrodes. Another advantage is that the arc can be ignited without direct contact of the electrode with the surface of the part, since the film formed in the crater acts as a conductor. This is of particular importance when welding is carried out with short stitches.

Electrodes can be used to connect even primed surfaces and the seam will not be inferior in strength and reliability. The arc is stable and it is possible to use any type of current. There are practically no splashes of hot metal. The seam is free from pores.

Pros and cons of cellulose-coated electrodes

The use of cellulose-coated electrodes significantly reduces harmful fumes compared to standard ones. The coating consists half of cellulose with the addition of grass meal, starch and other organic substances. Talc, silicates, and rutile are added as additives. Ferromanganese is used as a deoxidizing agent.

Figure 1 - Cellulose electrodes

Cellulose electrodes are designed for welding low-carbon steels of medium and high alloying. They are used for pipelines operating at high temperatures. Welding and technological properties allow welding seams in any spatial position, including vertically from top to bottom. The formation of a root bead eliminates the need for processing from the reverse side.

For cellulose coatings, the calcination temperature is important. It should not exceed 120 ⁰C, otherwise the organic substances of the coating will begin to decompose. When exposed to humid air for a long time, cellulose absorbs water, which impairs the quality of welding.

Acid coating of electrodes

The acid coating (designated according to GOST 9466-75 by the letter “A”) is created on the basis of materials of ore origin. Oxides are used as slag-forming components, and organic components are used as gas-forming components. When the coating melts, a large amount of oxygen is released in the molten metal and in the arc burning zone. Therefore, a lot of deoxidizers - manganese and silicon - are added to the coating.

Advantages of acid coating electrodes:

- low tendency to form pores when extending the arc and when welding metal with scale and rusty edges;

- high welding productivity due to the release of heat during oxidation reactions;

- Stable arc burning when welding with direct and alternating current.

The disadvantages of this coating include reduced ductility and impact toughness of the weld metal, which is associated with the impossibility of alloying the weld due to oxidation of alloying additives. Due to the absence of calcium in the coating, the weld metal contains sulfur and phosphorus, which increase the likelihood of the formation of crystallization cracks. One of the main disadvantages of this coating is the release of a large amount of harmful impurities due to the increased content of manganese and silicon compounds in aerosols. Therefore, acid-coated welding electrodes are rarely used in recent years.

The scope of application of acid-coated electrodes is welding of non-critical structures made of low-carbon steels.