What is fiber fiber

Concrete has specific characteristics that define it as a brittle substance with a heterogeneous structure. Its ultimate deformation value is much lower than, for example, glass, steel or polymer composites.

To increase elasticity, it became necessary to use fibrous additives (fiber) as micro-reinforcement for concrete structures. This feature has found wide application in the technology of construction processes, such as the preparation of cement mixtures, the production of high-strength materials, etc.

Fiber is a material in the form of lengths of threads or narrow strips of organic or inorganic origin. The mechanical characteristics of fiber-reinforced concrete depend on the number and arrangement of fibers in the solution.

The method of dispersed reinforcement of concrete provides for arbitrary and directional orientation of the fibers.

Directional involves the use of thin continuous threads, woven and non-woven meshes, strands and other similar materials. Free (free) occurs when using rolled materials in the form of mats, canvases, veils.

Advantages and disadvantages

The use of fiber has significant advantages over traditionally reinforced concrete.

As mentioned above, this element is used as a reinforcing substance. The type of mixture has absolutely no effect on the final result. The main condition is uniform distribution over the entire surface. Fiber should be used for the following reasons:

- new qualities are added to concrete, the surface becomes monolithic;

- reinforcement will be successful due to the fact that the mixture is easily absorbed by concrete and concrete mixtures;

- the outer and inner layers in concrete will acquire new stability values and will be able to withstand a greater number of loads;

- the material is very economical;

- fiber prevents the appearance of lumps/bubbles;

- rapid distribution throughout the mixture (taking into account even low consumption);

- aesthetics (the fibers disappear immediately after the solution hardens);

- the element is unique and suitable for strengthening absolutely any solution;

- the possibility of cracking is 10%;

- profitability (fiber is sold in construction stores of different price categories, but at the same time it is inexpensive);

- no serious time investment;

- anti-corrosion effect.

No shortcomings of this material have been identified. It can be added to a variety of solutions to strengthen materials without causing any harm to them.

Return to contents

Main components of the supplement

The technology for manufacturing additives depends on the type of reinforcing components used. Not all fibers meet the requirements for reinforcement cages.

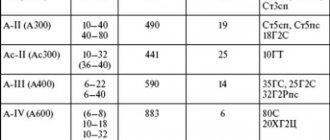

Metallic and non-metallic threads of different lengths and cross-sections are used as fibers:

- In terms of construction, the greatest effect is obtained from the use of steel fibers, the deformability modulus of which is 6 times higher than that of concrete.

- The use of polypropylene can reduce the risk of cracking during plastic shrinkage of mixtures by 60-90%.

- Glass fiber has low alkali resistance and is used only for preliminary reinforcement in the manufacture of gypsum products or wall blocks made of cellular concrete.

- Basalt fiber is resistant to alkaline processes. The elastic modulus is 15-20% higher than that of glass fibers.

- Asbestos fibers are neutral to the aggressive effects of cements and are characterized by high strength and fire resistance.

A rational choice of additives for concrete reinforcement makes it possible to obtain products that are resistant to mechanical loads.

Fiberglass has low alkali resistance.

Advantages of mortar with fiber fiber

Advantages of using fiber fiber

- During plastic shrinkage, it reduces the formation of cracks and the release of water;

- Reduces the hardening time of the solution;

- Increases resistance to fire;

- Reduces the likelihood of penetration of chemicals and moisture;

- Increases resistance to freezing or thawing;

- Increases resistance to mechanical stress and abrasion;

- Cost-effective relative to steel mesh that controls cracking;

- The strength of concrete increases;

- Concrete is more resistant to anti-icing salts;

- Prevents the solution from separating.

Advantages

The widespread use of fiber-reinforced concrete is due to the fact that its physical and mechanical properties are several times better than those of traditional materials. At the same time, the performance characteristics of the products comply with the standards.

Strengthening the screed

To strengthen coatings, it is recommended to use steel fibers with a length of 35-75 mm and a diameter of 0.3-1.0 mm. Heavy concrete of class B25-B35 with a coarse aggregate size of no more than 20 mm is chosen as a cement matrix.

The use of dispersed reinforcement with steel fibers will enhance the performance properties, strengthen the top layer of the base, increase wear resistance, bending strength, crack resistance and durability of the structure.

Prevention of defects

The occurrence of defects in concrete pavements is associated with a violation of the technological process. This is explained by thoughtless savings, non-compliance with the norms and rules provided for this type of structure. Such negligence leads to the appearance of cracks, chips, and potholes on the surface.

As practice has shown, the most effective means for preventing and eliminating defects that have arisen are repair solutions reinforced with various types of fibers. The use of steel or polypropylene fiber makes it possible to avoid the delamination of mixtures during the laying period, and subsequently premature wear and destruction of coatings.

Improved adhesion and water resistance

The water resistance of concrete can be improved using dispersed reinforcement. Since the properties of fiber-reinforced concrete depend on the characteristics of the fibers used, by choosing a material with the necessary characteristics, you can successfully solve the problem.

For example, the use of steel and basalt fibers will increase the water resistance of products several times. To obtain better adhesion of fibers to the cement matrix and uniform distribution of fibers, it is necessary to correctly select the optimal length and diameter of the segments used.

Cost-effective and anti-corrosion properties

The use of fiber for reinforced concrete structures, when part of the frame is replaced with dispersed fibers, allows one to obtain tangible benefits, since the price of modifiers is much lower than the cost of rod reinforcement.

Another big advantage of using steel fiber is that it is protected from corrosion by a dense cement coating.

With proper use of additives, you can obtain an economically useful product with improved performance properties.

How to choose fiberglass for screed?

When choosing the material in question, you should take into account not only its price per kilogram, but also the consumption of fiber fiber of one type or another per cubic meter of solution. Steel fibers will consume the most weight, and polypropylene fibers the least. At the same time, the steel version is much cheaper than the polymer one. And fiberglass and basalt are somewhere in between.

Popular material manufacturers

If, when deciding how to choose plastic windows, you have to analyze the thermal conductivity and number of chambers of various proposals, then with fiberglass the main thing is the consumption per 1 m3 and the price per 1 kg. Moreover, these two figures must be considered together, and not separately.

Based on the combination of characteristics and final cost, in most cases it is recommended to choose polypropylene fiber. It is expensive, but is consumed in the smallest volumes per cubic meter of solution. But if you need a reinforcing material for a thin layer or one without much strength, then you should take basalt fiber at a lower price. However, a lot here depends on the required properties and thickness of the subfloor.

Types of fiber fiber for concrete and its properties

The introduction of modifiers in the form of fibers into concrete helps to improve operational and performance characteristics. The mechanical properties of fiber reinforced composite materials depend on the type of additive, volume and size of the elements.

Steel fiber

Metal fibers used as reinforcement cages are produced by various methods:

- electromechanical;

- mechanical;

- from molten metal by molding.

The most widespread are mechanical methods, using which the following types of materials are obtained:

- Wire fibers, which are pieces of thin wire 10-50 mm long.

- Sheet fibers are produced by milling a thin sheet of metal.

- Ultra-thin ones are made by melt extrusion and subsequent drawing through diamond filters.

Steel fiber.

Advantages of dispersed reinforcement with metal fibers:

- resistance to dynamic and static loads increases;

- crack resistance;

- wear resistance;

- seismic resistance;

- frost resistance.

With a fiber content of 0.5% or more, the workability of the mixtures increases. With an increase in the volume of the additive in the range of 02-0.8%, an improvement in tensile-compressive strength is observed.

Glass fiber

This group of additives is produced from silicate materials and molten volcanic rocks. Glass fiber has a length of 20-40 mm and a diameter of 10 microns. Its main feature is its high tensile-compressive strength (1500-3000 MPa). The elastic modulus of such modifiers is several times higher than that of concrete.

For cement matrices, glass threads woven into bundles are used. The harness is divided into segments of equal length, the exact dimensions of which are specified by the technological map.

Asbestos fiber

To reinforce concrete, sections of fibers, veils, canvases and materials in the form of non-woven meshes are used.

Asbestos fibers have the following qualities:

- high strength (300 kgf/mm²);

- fire resistance (up to 1500 °C);

- resistance to alkaline environments (9.0-10.1 pH);

- low electrical and thermal conductivity (0.045-0.065 W/m∙K);

- durability.

When reinforcing concrete, sections of fibers and materials in the form of non-woven meshes are used.

The tensile strength of asbestos fiber exceeds the similar properties of steel.

Basalt fiber

Basalt fiber is equal length pieces obtained from molten natural stone of volcanic origin.

The introduction of additives improves the following indicators:

- crack resistance - 2 times;

- frost resistance - up to 500 cycles;

- impact resistance - 5 times;

- elastic modulus - by 30-40%;

- by 20-50% - compressive strength;

- waterproof - 50%.

Basalt fibers provide high adhesion to the cement matrix, do not corrode and do not ignite under the influence of open fire.

Polypropylene fiber

Polypropylene fiber is an alkali-resistant material, compatible with cement and gypsum binders.

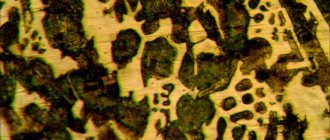

It is a synthetic fiber with a diameter of 0.02-0.038 mm. Fiber is made from polypropylene film by cutting and twisting into bundles. The tourniquet is divided into segments 0.3-0.5 mm long. In the concrete solution, the weave opens up and creates a network structure.

The use of polypropylene fiber allows you to:

- increase water resistance;

- frost resistance;

- tensile bending strength;

- increase fatigue and impact strength;

- heat resistance;

- wear resistance;

- improve the quality of the base of concrete products;

- strengthen the ability to withstand alternating loads;

- prevent mixtures from separating.

Polypropylene fiber reduces the risk of cracking by 60-90% and reduces shrinkage of concrete.

What is fiber for concrete or mortar?

First, let’s define the concept of what fiber fiber is. The name itself consists of 2 identical words, only one is English, the other Russian. “Fiber” is translated from English as fiber. Fiber for concrete is thin threads made from different materials. They have different lengths, thicknesses, and cross-sections.

Helpful information:

- Plasticizer for concrete: types and applications

- DIY concrete countertop

- Anchors for concrete

- Liquid glass for concrete

- Ironing of concrete surface

- How much does a cube of concrete weigh?

Why were they invented? Previously, and even now, during serious construction, the flexibility and strength of the monolith is increased by metal structures and meshes. This is a very costly and time-consuming undertaking. Therefore, to speed up the process, they came up with adding fine fibers directly to the mixture. They also form a mesh and play the role of micro-reinforcement. With the correct addition of fibers, concrete becomes more flexible, does not shrink strongly and does not crack.

Let's take a closer look at the process that occurs when cement hardens. It looks like this. Thin threads are located in the solution at different angles, intersecting, creating a mesh. This mesh prevents the components of the cement-sand mixture from changing their position. Sand grains do not settle to the bottom, and small particles of cement do not migrate to the surface. When the mixture sets, the fibers glue the particles of the mortar together, hold them in place and prevent the appearance of cracks during shrinkage.

Concrete to which microfiber is added is called fiber-reinforced concrete.

When advertising their product, manufacturers of the reinforcing additive attribute to it the following positive properties:

- Unlike metal reinforcement, which creates increased strength due to its design, microfiber fibers create a three-dimensional mesh and strengthen the monolith itself. Therefore, this additive is used to produce not only floors, foundations, but even just concrete blocks.

- Fiber fibers improve concrete strength, flexibility and vibration resistance so well that this additive is used for masonry mortar in earthquake-prone areas. They are also used for the construction of military, industrial facilities, and railway sleepers.

- Microfibers, which consist of synthetic material, do not enter into chemical reactions. Therefore, aggressive liquids cannot affect the strength of the structure. Villi also fill the pores. This makes the concrete waterproof and resistant to temperature changes.

- Reinforcing threads make the surface resistant to abrasion. This quality is used for the construction of surfaces with increased traffic load.

- Fiber fiber promotes faster hardening of the cement composition. This quality is used in the production of casting molds. In addition, defects and damage to products during transportation are reduced.

- Microfibers increase the plasticity of the solution and reduce cement consumption by 20%. The good flexibility of the solution allows you to make a screed with a small amount of water. A large number of fibers, on the contrary, makes the cement less pliable. In this case, it is recommended to add plasticizers.

- Decorative products made from fiber-reinforced concrete retain their attractive appearance for a long time and do not chip or crack.

As you can see, fiber fiber is simply an elixir of strength for concrete. If not for one “But”. You need to know exactly what type of fiber is needed for a particular application, and how much to add. Excessive consumption can only ruin everything. A large amount of polypropylene fiber reduces the strength grade. And buying a fake generally helps to waste all your money. The point here is this. High-quality fibers are treated with an anti-clumping compound. Thanks to this, the fibers are distributed almost individually inside the monolith. But the fake rolls into lumps, and there is no talk of any three-dimensional mesh.

Perlite: what is it and insulation characteristics

Scope of application

The choice of technical solutions for dispersed reinforcement depends on the type of fibrous materials used.

For example, basalt fiber is wear-resistant, therefore suitable for strengthening structures used in places with increased requirements for mechanical stress:

- production sites;

- industrial floors;

- pedestrian paths with heavy traffic, etc.

The resistance of basalt fiber to chemical factors and seismic resistance allows its use in the following areas of residential and industrial construction:

- during the construction of hydraulic structures;

- in bank protection works;

- when constructing earthquake-resistant structures;

- explosive objects;

- in the production of chemically resistant reinforced concrete pipes for transporting aggressive liquids.

Basalt fiber is widely used in various areas of residential and industrial construction.

Basalt fiber is an indispensable component in the production of aerated concrete, foam concrete and other products made from cellular concrete, and also serves as a structure-forming material in the manufacture of shaped products for small architectural forms.

Steel fiber reinforced concrete is used in the construction of structures that require increased strength:

- Monolithic structures: highways, industrial floors, screeds, etc.

- Dams, breakwaters, irrigation canals, tanks for liquids, tunnels.

- Defensive structures.

- Reinforced concrete structures: production of prefabricated foundations, piles, wall panels, beams, columns, pipelines.

- Construction of road, airfield and sidewalk coverings.

The use of polypropylene fiber is recommended when performing the following types of work:

- installation of industrial floors and screeds;

- construction of external walls, insulation based on cellular concrete blocks;

- production of piece decorative products (paving slabs, borders);

- preparation of mortars, shotcrete mixtures, plasters.

Asbestos fibers are used to reinforce materials with low elasticity:

- roofing wavy and flat coverings;

- free-flow and pressure pipes;

- strengthening modifying additives for the top layer of concrete;

- decorative facade slabs;

- repair compounds, asphalt mixtures.

Glass fiber is used for the construction of houses, sewer wells, etc. However, the insufficient resistance of the fibers to the effects of the hydrating cement environment limits its use.

Application of polypropylene fiber

The material is relevant for a wide variety of objects. For example, 100% polypropylene fiber SikaFiber® PPM-12 reliably reinforces screeds, blind areas, and plasters.

The material is convenient to use. The fiber for the solution is supplied in a special bag. The additive can be added at any stage - to dry ingredients or into a liquid mixture. No special equipment is needed; a regular concrete mixer will do.

Fiber fiber for floor screed, wall plaster and other structures is superior in convenience to traditional reinforcement methods.

Compared to metal mesh and steel rods, the fibers are evenly distributed throughout the solution. This reduces the number of internal shrinkage microcracks, and also prevents delamination and rapid abrasion of the outer layers.

To effectively strengthen concrete, you need to use materials from reliable manufacturers. Sika polypropylene fiber has passed laboratory tests and has European certificates - with such an additive, a concrete structure or product will serve for years even in extreme conditions.

Mixing Methods

Do-it-yourself production of concrete structures using the dispersed reinforcement method involves 3 main stages:

- Preparation of fiber reinforcement.

- Preparation of the composite.

- Molding of products.

When using modifiers, the hardness of mixtures increases. As a result, concrete loses its mobility and becomes difficult to place.

Adding polypropylene

An indispensable condition for obtaining compositions with high strength and stability is a uniform supply of fiber fiber into the concrete mixer.

Work order:

- First, filler, crushed stone or gravel is added.

- Then sand is poured in and mixed dry.

- Without turning off the concrete mixer, the required volume of polypropylene fibers is introduced.

- Cement and water with plasticizers dissolved in it are added.

- Continue stirring until a homogeneous mixture is obtained.

Introduction of basalt

To achieve good adhesion and the required reinforcement effect, the optimal diameter and length of the fibers are selected.

Instructions for making basalt fiber reinforced concrete:

- Sand and crushed stone are poured into a concrete mixer.

- Add the required amount of additive and mix.

- When the unit is turned on, pour water into the mixer.

- Cement is added.

- Continue kneading until the desired consistency is obtained.

If products are prepared on the basis of gypsum or cement-sand mortar, then reinforcement is performed last.

Application of fiber fiber depending on length

Fiber fibers have a diameter of 20 - 30 microns (micrometers):

18 millimeters long

. Material of this size is used for especially heavy types of concrete, for the preparation of which large and medium-sized filler (crushed stone, sand, gravel) is used. This solution is used for the construction of hydraulic structures, road surfaces and bridges.

12 millimeters long

. This fiber fiber is used for the manufacture of concrete floor slabs, self-leveling concrete floors, foam concrete, hydraulic structures, heavy and light concrete, and some types of gypsum mixture.

6 mm long

.

This fiber is intended for use in grouting, masonry, cement-sand, plaster and installation and repair mortars. Fiber fiber of this size is also used in the production of gypsum solutions and dry mixes.

Thanks to the addition of polypropylene fiber, within six hours after laying the semi-dry screed, the risk of microcracks is reduced. Further, when the screed hardens and the shrinkage process begins, thanks to the fiber fibers, cracks do not have the opportunity to grow, thereby preventing the appearance of larger cracks. Finally, in the last stage of construction, uniform dehydration is ensured by the fibers, thereby reducing the stress of the concrete from the inside.

Mixing technology

To combine fiber with concrete, gypsum and any other mixture, you need a concrete mixer and water. There are two mixing technologies. The first is prepared as follows:

- Dry material is poured into the concrete mixer: cement, sand, crushed stone and fiber fibers.

- Water is added in accordance with the manufacturer's instructions indicated on the packaging. It is not recommended to violate the proportions, since a composition that is too thick is difficult to work with, and if it is too liquid, it shrinks.

- The process of mixing the solution takes 10-15 minutes. To increase the elasticity of the mixture, plasticizers can be added.

- The mixture is left for half an hour. After this, you can begin construction and repair work.

If you need to prepare a small amount of mortar, you can use a construction mixer.

As for the second mixing technology, it consists of the following steps:

- A dry mixture of cement and sand is prepared.

- Pours into the mold.

- The required amount of microfiber is added.

- After the fibers are evenly distributed, water is added.

Fiber can be added to the solution at any stage of preparation.