Electrode coating is one of the key factors on the basis of which the customer chooses a specific welding consumable for certain purposes. The only priority over the choice of coating is the material and the diameter of its rod. The final quality of the seam, the strength and durability of the connection will largely depend on what specific chemical composition coats the rod.

The most common types of electrode coatings are:

- Basic;

- Pulp;

- Rutile;

- Acidic;

- Mixed types;

- Other types of coating (products are marked with the index “P”).

Coatings shape a number of properties of the final products. And each type has its own strengths and weaknesses. But rutile electrodes for welding occupy a special position in the preferences of welders, regardless of their experience. What is the reason for this?

What is the difference between a rutile electrode and a basic one?

Electrodes with rutile coating appeared in the domestic industry relatively recently - they were developed in the USSR in the late 60s, and already in the 70s they became widespread. The material has become an alternative to base coat additives. When welding, the latter emit toxic fluoride compounds into the air, which are unsafe for the health of the welder, so they can only be welded outdoors or in a well-ventilated area.

This is because the coating of such rods contains potassium fluoride, and during operation toxic fluorine is released into the atmosphere. In contrast, rutile is a natural and chemically neutral material. Thanks to it, the content of harmful volatile compounds released into the air during manual arc welding is practically reduced to zero.

This opens up new opportunities for welding work: structures can be welded not only outdoors, but also indoors, without fear for health and the environment. At the same time, rutile itself conducts current well - the arc is instantly ignited and burns steadily, ensuring a high-quality weld.

Composition and features of the coating

Rutile is titanium dioxide, a mineral widely present in nature. The coating uses its concentrate, the share of which is about 50%. In addition to TiO2, the coating composition includes:

- feldspar (up to 25%) is a silicate mineral, along with rutile, it additionally stabilizes the arc combustion and forms a slag crust to protect the weld pool;

- ferromanganese (15%) – serves as a steel deoxidizer and an alloying element in the weld metal;

- magnesite (10%) – provides a protective gas environment for the weld pool;

- other elements (up to 3–5%) are usually alloying elements.

The proportion of components may vary depending on the brand of electrode. To increase work productivity, iron powder (marked as RZh) can be added to the coating. Rutile is often used in combination with cellulose or base coating to improve welding efficiency.

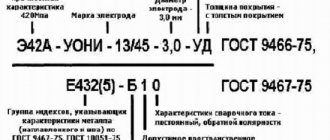

Marking

Depending on the manufacturer and the specific type of product, package markings may differ slightly. However, most rutile electrodes are labeled almost the same. Let's take a closer look at the example of marking MP-3 electrodes.

On their packaging you can see the following markings: E 46 – MR-3 – UD E 430 (3) - P26.

Let's look at everything in order:

- E46 - indicates the type according to GOST. This means that this model is designed for welding low-alloy and carbon steels. Tensile strength - 46 kgf/mm2.

- MP-3 is a brand from the manufacturer.

- U - indicates the purpose of the electrode. For welding carbon steels, tensile strength is 60 kgf/mm2.

- D is the coating thickness coefficient (thick).

- E - international marking. Indicates the type of electrode with a consumable coating.

- 43 - tensile strength (430 MPa).

- 0—relative elongation index (20%).

- (3) - temperature indicator -20°C. This is the minimum temperature at which the weld metal retains an impact strength of at least 34 J/cm2.

- P - type of coating. In our case - rutile.

- 2 - shows in what positions welding work can be carried out. This indicator means that you can cook in any direction except vertical “top to bottom”.

- 6 - for high-quality work you need to use a current of reverse polarity, constant. The open circuit voltage should be approximately 70V.

[ads-pc-2][ads-mob-2]

Advantages of rutile electrodes

We have already talked about one of the key advantages of such coating – environmental friendliness. When welding, a minimum of toxic and dangerous compounds for the welder are released into the air. This allows parts to be cooked in closed or poorly ventilated areas. There are other benefits too.

- Rutile is an excellent semiconductor, so ignition of an arc under the influence of current is usually instantaneous.

- You can weld on a wet surface and metal with traces of corrosion (up to 30% of traces of oxides from the total area of the welding zone). This is another advantage over core coated rods.

- The electric arc burns equally stably not only with direct current, but also with alternating current. This distinguishes rutile electrodes from additives with acid coating.

- With the correct welding technology, the appearance of intergranular cracks in the metal of the resulting weld, both cold and hot, is excluded.

- Rutile welding electrodes do an excellent job with tacks and short seams that require repeated ignition - the arc ignites perfectly and burns just as steadily.

- After welding, the seam is fine-scaled and smooth, and the slag crust is easily separated. If sanding of the seam is necessary, it is usually minimal.

The products are excellent not only for butt seams - most of them are suitable for welding overlap seams and fillet joints.

Disadvantages of rutile electrodes

Among the conditional disadvantages of electrodes with rutile coating (as with any other) is some limitation in use. They are used mainly for working with low-carbon and low-alloy steels. The use for welding structures made of steels with a high carbon content is excluded.

Before work, you must carefully adjust the power indicators. With increased voltage and current, the stability of the arc deteriorates, and there is a risk of deterioration in the quality of the weld. It should be taken into account that when welding in the lower position, the current value is usually reduced by 20%.

Also, before work, it is necessary to dry the rods and calcinate them - for the vast majority of products, calcination for an hour at a temperature of 140 to 200 ° C is recommended.

Features of operation

To make high-quality seams, you need to know the technique of working with ruthenium wire and apply it in practice.

Welding machine settings

This is a simple operation, but errors lead to excessive consumption of material and poor-quality metal welding.

Setting up a welding machine is a simple operation.

Before setting parameters on the device, you need to find out a few nuances:

- type of steel being welded;

- thickness of workpieces;

- depth and orientation in space of the connecting seam;

- electrical network capabilities.

Welding mode selection

This operation consists of setting the necessary parameters on an AC or DC device. The table shows the standards depending on the type of welding seam and the diameter of the rod:

| Diameter, mm | 2 | 2,5 | 3 |

| Current strength in lower position, A | 50-90 | 60-110 | 80-140 |

| Current strength in vertical position, A | 50-70 | 60-90 | 80-100 |

| Current strength in ceiling position, A | 70-90 | 80-100 | 100-130 |

We recommend reading: What are the types of electrodes for welding?

Calcination of consumables

The quality of the weld and ignition of the arc, sticking of the electrode and shedding of the coating depend on the amount of moisture in the rutile layer. To do this, the rods are pre-calcined.

For production control, a special log is kept indicating the date, operation number, type of product, temperature, signature of the person in charge.

Drying can be done in the following devices:

- in stationary furnaces with trays for electrodes and the ability to maintain a constant temperature from 60 to 500°C;

- in sealed thermal insulating cases when working outdoors;

- in special containers connected to a welding machine or household electrical network;

- in cabinets suitable not only for heating, but also for storing consumables.

The quality of the seam depends on the amount of moisture in the electrode.

At home they use the following devices:

- gas or electric oven;

- hot heating radiator (it is necessary to warm the electrodes for 2-3 days);

- with a construction hair dryer in an asbestos or other non-flammable pipe.

It is allowed to calcinate rutile electrodes no more than 3 times.

Where are they used?

Despite some limitations in use, rutile-coated electrodes are used in a wide range of jobs, including welding critical and critical structures.

- Installation and repair of water pipes. To carry out repairs, there is no need to completely drain the pipeline section - the ingress of water drops into the welding zone does not threaten the stability of the arc.

- Installation and repair of tanks.

- Construction of oil pipelines and gas mains.

- Connection of elements in water supply collectors.

- Laying distribution networks (generators and transformers).

They are also well suited for repair surfacing. They produce a strong and thick seam when restoring parts operating under conditions of intense abrasion and high abrasive loads.

Rutile coated electrodes – brands

There are dozens of domestic and foreign brands of electrical conductors with this coating on the market. We list the most widely used in Russia.

MP-3 - the brand is popular among both professionals and beginners, as it allows you to master welding techniques quickly enough. The material is suitable for joining parts of medium and large thicknesses. You can cook with both direct and alternating current; welding with short tacks is allowed. The surface of the parts must be clean; before welding, the rods must be calcined for an hour at a temperature of 150–180 °C.

OZS-4 - allow welding of products of medium and large thickness at elevated conditions. The surface may be damp or have traces of oxides. The recommended arc length is average, the current is alternating or constant of any polarity.

OZS-6 – have a rutile coating with iron powder, due to which they have increased productivity. Well suited when it is necessary to weld butt joints with large or irregular gaps.

OZS-12 – allows you to obtain a high-quality weld when working with oxidized surfaces. You can cook on both a short and long arc. Recommended for working with T-joints. Also among the advantages is the ability to weld at extremely low currents, including from a household network using rods of small (2–3 mm) diameter.

ANO-21 - have proven themselves when working with lap, corner and butt joints. They cope well with root seams of parts of large thickness (up to 5 mm). You can cook in any spatial position, which allows you to perform complex installation work directly on site. Welding on alternating and direct current of any polarity; traces of rust are acceptable on the surface.

ANV-29 - unlike the vast majority of rutile electrodes, allows the welding of high-alloy steels, in particular, chromium-molybdenum steels of the austenitic class (AISI-304 stainless steel, etc.).

Among foreign analogues, such brands as OK 46.00 (ESAB), Omnia 46 (Lincoln Electric), UTP 612 (Böhler Welding) and a number of others are widely in demand.

Rutile welding electrodes are produced by the Magnitogorsk Electrode Plant. MEZ products have long earned high praise from both experts and professionals, as well as those who use this material only in everyday life. All products have appropriate certificates and are accompanied by detailed instructions for use.

Material characteristics

You can get acquainted with them by looking at the table:

We recommend reading Composition of electrode coating

| Name | Unit | Meaning |

| Performance | g/min | 12-16 |

| Deposition factor | g/Ah | 11-15 |

| Consumption per 1 kg of deposited metal | kg | 1,4-1,7 |

Dimensions that electrodes can have:

| Diameter, mm | Length, mm |

| 2,0 | 300 |

| 2,5 | 300 |

| 3,2 | 350 |

| 4,0 | 350 |

| 5,0 | 450 |

| 6,0 | 450 |

Welding seam characteristics:

| Name | Unit | Meaning |

| Ultimate strength | MPa | 410-450 |

| Impact strength | J/cm² | 80-147 |

| Relative extension | % | 20-22 |

The production of rutile consumables for welding occurs in accordance with GOST 9466-75, 9467-75, as well as European and international standards ISO 2560, DIN 1913, AWS 5.1. Packages weighing 1, 2.5, 3 or 5 kg are available.