Scope of application of reinforced concrete drainage trays

Concrete drainage trays

Precast concrete trays are mainly used for constructing storm sewer channels on hard surfaces. Special drainage pipes are used to drain groundwater. Reinforced concrete gutters are used for the following purposes:

- storm drainage at city facilities: parks, highways, paths;

- wastewater disposal inside industrial workshops;

- laying a cable line;

- installation of hydraulic structures;

- pipeline laying.

As a rule, concrete trays are rarely used in private construction, since the soil tends to heave during the snowmelt season. This may cause the product to shift and even break.

Types of reinforced concrete trays

Reinforced concrete elements are classified according to the method of their installation: horizontal and vertical.

Types by purpose:

- C250. Designed for light loads. Used on small road surfaces, walking paths in the park.

- D400. They have a greater load than their predecessors. These are designed to drain storm water from busy roads and gas stations.

- E600. Used for large volumes of rainwater. More often they are installed in production and on highways.

- F900. The most powerful. Designed for storm drainage on the runway.

As for the sizes of reinforced concrete trays for storm drainage, their length is often 1 m. The internal diameter varies between 100-500 mm depending on the class of the product. The shape of reinforced concrete products is rectangular or round.

Durable concrete trays from

The Polytep company offers a catalog of concrete trays with a height of 60 and 95 millimeters for storm drainage. Our prices are favorable for individuals and legal entities in Moscow and the region. More than 25 years on the market have allowed us to patent the technology for manufacturing concrete trays for water drainage.

Our products are designed for installation on sidewalks and in places where there are restrictions on installation depth. To achieve maximum efficiency of water drainage, concrete drains should be installed in a “line”, and all seams must be treated with sealant. Water leaves the system through a relatively small hole (diameter 110 or 75 mm), which is located at the bottom. Concrete trays are completely unpretentious in maintenance - their inside is completely smooth, due to which dirt does not linger in the middle of the system.

Specifications

All reinforced concrete trays are produced in accordance with GOST, since high expectations are placed on them regarding strength and durability. For the manufacture of gutters, special reinforced concrete with a density of 2400 kg/m3 and cement grade M 250 are used. As a result, the finished product has the following characteristics:

- high strength to any mechanical stress, both static and dynamic;

- inertness to temperature changes;

- weight, which varies between 25-3000 kg;

- height of the gutter walls - 6-160 cm;

- waterproof;

- resistance to aggressive environments.

Due to the high mass of the product unit, it is necessary to use special equipment for installation.

Installation features

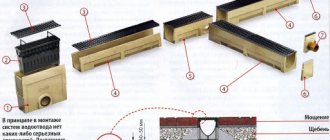

Laying of reinforced concrete trays is carried out in the following sequence:

- Dig a trench of the required size. The channel parameters must exceed the dimensions of the tray by 30 cm on each side and the height. In the future, this space will be filled with a concrete pad.

- The soil at the bottom of the trench is carefully compacted and a layer of sand 10-15 cm thick is poured onto it. It is also well compacted.

- A layer of concrete mortar 15 cm thick is poured onto the bedding. It is allowed to dry completely.

- Reinforced concrete gutters are laid on the dried base using special equipment. They are joined together, all joints are treated with bitumen sealant.

- The outer sides of the trays are filled with concrete mortar.

- The drainage channel is connected to the central storm drain; the top of the gutters is covered with protective cast iron or steel gratings.

When laying reinforced concrete trays, a slight slope towards the main receiver should be maintained. Then the water will be transported by gravity.

General requirements for installing drainage trays

Before installing the drainage system, the length of the route is calculated and, based on the obtained figure, the required number of elements is calculated. The installation instructions guarantee the durability and uninterrupted operation of the channel.

Installation of storm drains covered with asphalt, concrete, tiles

Main installation rules:

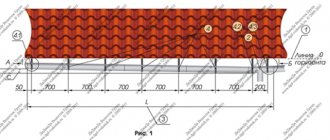

- The thickness of the concrete (grade B25) layer of the base and walls is 100 mm;

A crushed stone bedding 10 cm thick will significantly reduce the risk of product deformation due to soil swelling.

- The system is collected from the lowest point;

- The gutter slope must be at least 10 mm/1 linear. m;

- Connection to the sewerage system is made through a sand trap using a pipe d 110/160 mm or through a vertical drain;

Connecting the gutter to the sewer through a sand trap

- Seal the joints between the trays (sealant 010/based on MS polymer, bitumen mastic);

- At the turning points, the trays and lids are sawn and joined together;

The photo shows the connection diagram in the mustache.

- Asphalting is carried out with installed gratings, covered with fiberboard strips;

- Expansion joints 15–20 mm wide along the channel and vertical in 5 m increments;

- After installation, the grating should be 3–5 mm lower than the road surface.

The concrete base and walls of heavy trays are reinforced with reinforcing bars

Inspection/cleaning of sand traps is carried out up to 3 times monthly. Scheduled maintenance and cleaning of the drainage system at least 2 times a year.

How to lay a storm drain

The table shows the installation of drainage concrete trays near the terrace, but in the same way you can equip the paths at the entrance to the garage. Before laying the storm drain, a connection to the sewer system is made.

Installation diagram

| 1. Dig a ditch along the terrace. Its width should be wider than the gutter and exceed its height by 100 mm. This will make it possible to make a concrete base and strengthen the walls. | |

| 2. Prepare concrete for the base on which the trays will lie. | |

| 3. Apply sealant to the end of the tray. | |

| 4. Glue the end cap , carefully aligning it with the edge of the gutter. | |

| 5. Lay the first tray with a vertical drain , aligning the drain with the sewer pipe. | |

| 6. Install a sand catcher into the drain hole. | |

| 7. Lay subsequent trays , sealing them with sealant. | |

| 8. Glue the end cap at the end of the finished line. | |

| 9. Place and compact the concrete mixture on both sides of the assembled gutter. | |

| 10. Cover bare areas with soil. Lay the sod in the old place , you can lightly water it and trample it down. If the turf is several centimeters higher than the storm drain, it will shrink over time | |

| 12. Install the grilles . Do not walk near the gutter for several days until the concrete has completely hardened. |

Advantages and disadvantages

Reinforced concrete gutters have the following positive aspects:

- High resistance of the material to aggressive environments.

- Anti-corrosion properties.

- Long service life - 50 years or more.

- Resistance of concrete to temperature changes, including the effects of sub-zero temperatures. When subjected to repeated freezing and unfreezing, the material does not lose its performance properties.

- Inertness of concrete to mechanical stress. The exception is high-power targeted strikes.

- Environmental friendliness of products. Concrete does not emit fumes harmful to the environment.

- Ideal smoothness of the inner walls due to the addition of polymers to the solution during the manufacture of trays.

The relative disadvantages of reinforced concrete gutters include their weight. However, it can also be considered a plus. Because even heaving soil will not be able to move them from their place.

Drainage trays.

Characteristics.

Standard structures that are used in residential and industrial construction come in two types: drainage and rainwater.

For the construction of the railway, separate types of trays have been created: inter-track and inter-sleeper.

They differ from each other by the holes located on the sides of the products. It is through the holes in the structure that water enters and is removed from the railway tracks.

Advantages and disadvantages.

Pros:

- Service life is more than 50 years;

- Increased resistance to loads and damage;

- Contains only environmentally friendly materials;

- Withstand temperature changes;

- Resistant to corrosive formations.

Minuses:

- The weight of one structure can reach 50 kg;

- "Sensitivity" to transportation. If transportation rules are violated, cracks may form;

- During installation, all requirements specified by the manufacturer must be observed. If you make mistakes, the constructed structure may break down.

Application.

Trays are used for arranging drainage systems and other lines. They are used to get rid of water flows in a residential area, to preserve the integrity of the foundation, and to protect buildings from flooding.

Order and buy drainage trays at the PKF Stroygrupp reinforced concrete products plant

Cost of reinforced concrete trays

Prices for reinforced concrete drainage trays depend on the size and brand. Table of approximate prices:

| Tray brand | Length of the product | Product width | Product height | Tray weight | Price, rub.) |

| L-10-5 | 1000 mm | 500 mm | 230 mm | 200 kg | 950 rub. |

| L-1-7 | 1100 mm | 390 mm | 370 mm | 150 kg | 1100 rub. |

| LV-68-30 | 680 mm | 300 mm | 340 mm | 90 kg | 1780 rub. |

| L-300 | 2950 mm | 540 mm | 430 mm | 660 mm | 3200 rub. |

The cost of reinforced concrete trays may vary slightly depending on the region and the manufacturing company.

Dimensions of drainage trays. Let's figure out what's important

The sizes of drainage trays are varied. Similar products are used to collect and drain melt and storm water in surface drainage and are the main components. These products are elongated containers with a groove of rectangular, semicircular or square cross-section. And it is difficult to imagine a modern drainage system without these structures. Drainage trays differ not only in material, but also in size. What sizes of drainage trays are available today will be discussed in the article.

Typical sizes of drainage trays Before making a choice, you should familiarize yourself with the standard sizes. Among them: • DN; • external dimensions of the tray. DN gives the designation of the size of the hydraulic section in millimeters. European standards mean DN 100, 150, 200, 300, 400, 500. In the USSR, trays with indicators of 100, 110, 150, 160, 200, 300, 400, 500 were used.

The length of all drainage trays made of any material is 1000 m - this is the optimal length of the product, convenient for storage and transportation, convenient for calculations. The letter B defines the external width of the product. It varies from 116 to 650 mm. And the marking H means the depth of the structure (55 - 650 mm).

The width of the trays varies from 116 to 650 mm. The narrowest gutters are plastic. Thin plastic walls provide minimal width.

The widest and tallest ones are concrete. At these sizes, wide foundation walls are important.

The height of drainage trays varies from 55 to 650 mm.

Load classes of drainage trays In addition to standard sizes, load classes are distinguished. They will help you select the right products according to the requirements of the facility and avoid problems in subsequent operation. There are 6 classes of trays: • A15; • B125; • C250; • D400; • E600; • F900. The number indicates the maximum load capacity. Structures classified A15 can withstand loads of up to 1.5 tons. They are great for pedestrian areas, bike paths or courtyard areas. Products of the second type mean a maximum endurance of 12.5 tons. Garages, parking lots and similar facilities are the most common areas for their application. C250 structures are used for arranging sidewalks and service stations. Drainage trays D400, supporting up to 40 tons, are used for the construction of drainage on roads and gas stations. The fifth class (E600) can withstand loads of up to 60 tons, therefore suitable for installation on highways, transport terminals or warehouses. And finally, the last type is F900. These are the most durable structures known to date. After all, the maximum endurance is 90 tons. They are used at airports, places with high loads and other facilities.

If you are still wondering where to buy drainage trays at competitive prices, we are waiting for you at. We offer drainage products suitable for any facility and task. We work throughout Russia. Call and get advice on choosing the right products now!