Experimental workshop of Viktor Leontyev. Miscellaneous metal science

Greetings, colleagues and gentlemen craftsmen. I will talk about an ancient method of measuring the temperature of steel objects by external signs. Nowadays, there are plenty of instruments for accurately measuring the temperature of various objects. Thermometers are used to measure temperatures by contact method. And to control heating at a distance, that is, without contact, pyrometers with various designs and technical characteristics are used.

And yet, those involved in metalworking must be able to determine the temperature of steel products. Let it be approximately, but quickly and without instruments.

Tarnish colors

When some metal alloys are heated to certain temperatures, oxide films on their surfaces can acquire different colors.

Such colors and their shades, characteristic of the temperatures that caused their appearance, are called tarnish colors.

The colors of tarnish appear more expressively on steels: carbon, alloy and stainless steel. We will observe the appearance of tarnish colors when a sheet of low-carbon steel is heated with a gas flame. I will call the designated place on the surface of the sheet, under which the heating source is located, the heating point. It is noticeable that the natural color of the steel at the heating point has changed to light yellow.

This means that the temperature of the material in this place has reached approximately 205 C. As the temperature increases further, the light yellow area appears to move away from the heating point. And its place has acquired a dark yellow color, with an inherent temperature of 240 C. The spot of general heating is expanding. The tarnish colors are arranged around the heating point in a characteristic order, indicating to what temperature the material was heated in the area occupied by each of them. With smoother heating, the color temperature areas will be expanded. As in this sample of medium carbon steel, on which we will continue to examine them. If we do not take into account the color shades observed in a very narrow arrangement, there are nine clearly defined color temperature regions, of which the region with the natural color of steel is not included. Next, one by one, a template will be applied to each of the nine color-temperature areas, the color and shade of which is most similar to the color of this area.

The template shows the temperature range and average value that is inherent in a given color of tarnish on the surface of carbon steel.

Once developed, tarnish colors do not disappear after cooling. Based on their presence, it is possible, for example, to determine that a part or tool was operated with certain violations, which led to its overheating. The colors of tarnish on alloy, stainless and heat-resistant steels are the same. However, they appear at higher temperatures, the values of which depend on the content of alloying elements.

Hardening knife steel at home

For simple carbon steels, even in artisanal conditions, satisfactory hardening can be done, the main thing is to arm yourself with the right knowledge.

Used tools, springs and files can be used as sources; Make sure there is no rust on them. A workpiece made from brand new melted metal is, of course, better, since parts that have served for a long time have a quality called fatigue, which reduces their strength. Although for high-quality materials it is enough to carry out annealing, which consists of heating the steel, holding it at a certain temperature and then slowly cooling it with a furnace or in sand at a speed of two to three degrees per minute. As a result of annealing, a stable structure is formed, free from residual stresses.

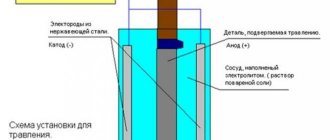

For both annealing and heating the part for hardening, you can use a homemade forge made from a pit lined with bricks, a blowtorch and a pipe. Ideally, of course, use a muffle furnace.

It’s easy to check at home whether the hardening has reached the required degree: you can run a file over the hardened product - if the hardening is not complete, the file will simply stick to the knife. Overheating can be checked in artisanal conditions by a strong blow of the workpiece against a hard object - a stone or a rail: the overheated blade shatters into pieces with such a blow.

Heat colors

As heating continues, the tarnished colors are replaced by incandescent colors.

Since heat is the glow of a material, an objective assessment of its darkest colors is possible only in the dark. And lighter ones, at least when darkened. The first color of heat visible to the eye is reddish-brown, meaning that the temperature of heat in the area of its manifestation is in the range of 530 – 580 degrees Celsius. Unlike tarnished colors, incandescent colors are not preserved when cooled, but change in the opposite order.

If scale has formed on the surface, its color returns to a light gray shade. When magnetic, iron-carbon alloys are heated above 768 C, their magnetic properties disappear. And they appear again after cooling below this temperature.

This phenomenon can be used as an additional means of temperature control. Heat colors reflect the heating temperature of not only metal bodies, but also non-metal ones. For example, products made of ceramics, graphite and others.

Annealing and hardening of duralumin

Duralumin is produced to reduce its hardness. The part or workpiece is heated to approximately 360°C, as during hardening, held for some time, and then cooled in air. The hardness of annealed duralumin is half that of hardened duralumin.

The approximate heating temperature of a duralumin part can be determined as follows. At a temperature of 350–360°C, a wooden splinter, which is passed along the hot surface of the part, becomes charred and leaves a dark mark. A fairly accurate temperature of the part can be determined using a small (about the size of a match head) piece of copper foil, which is placed on its surface. At a temperature of 400°C, a small greenish flame appears above the foil.

Method for measuring temperatures by tarnish and heat colors

The method of measuring temperatures by the colors of tarnish and heat has been successfully used since ancient times by metallurgists, blacksmiths, thermal experts, as well as representatives of other professions, including machine operators. To measure temperature using this method, tables are used that contain patterns of tarnish and heat colors with a description of their shades and an indication of the temperatures that lead to the appearance of each of them.

Craftsmen and specialists who have regular practice usually do not use tables. Because they know all the color shades and temperature values associated with their manifestations by heart. When there is no constant practice in this area, it is probably not worth relying on memory, especially color memory. By visual comparison from one table or another, a template is selected whose color is more similar to the color of the controlled area of the object. I would like to draw your attention to the fact that when comparing the colors of a template and an object, you should not expect them to be completely identical.

The similarity of their color shades is enough. And then we can assume that the temperature of a uniformly heated object is in the range of values indicated on the color template.

Often two adjacent colors appear on the surface of an object at once. It is not difficult to guess that the temperature of this object is between the average temperatures indicated on both templates. Compared to instrumental measurements, the accuracy of this method is, of course, lower. And yet, in many applications, for example, when performing not particularly important hardening or tempering, the accuracy of the color method is quite sufficient. As for cutting, when the distance of the cutting edge is controlled by the colors of tarnish on the moving chips, and at different points, there is probably no replacement for this old method. Enough tables with the colors of tarnish and heat have been published in the literature and on the Internet. Their interpretations differ in form and content, unfortunately, too. Unlike most of them, the colors used in this template video tutorial are computer matched to real heat colors and the tarnish colors of carbon steels. The names of color shades indicated on the templates are conditional. And their exact identification is possible using the so-called html color code indicated below.

Using this code entered into the search, the color of any of their templates can be easily found on the Internet. Ready-made tables with color templates for downloading to a mobile device or for printing can be downloaded from the project website. Possible causes of errors when measuring temperatures It must be taken into account that color perception is affected by the general illumination of the room, as well as its color, which can be natural, white or yellowish, coming from incandescent lamps. This applies to cases when trying to evaluate colors relying on memory. When measuring temperatures by tarnish colors, you need to understand that they reflect the temperature on the controlled surface. And this does not always correspond to the temperature of the entire mass of the heated object. If the task is to heat an object to a certain temperature, controlled by the color of the tarnish, it must be heated not through one point or surface, but evenly, from all sides. The uniformity of heating is also controlled by the colors of the heat. The same glow color at different points in any area of the object indicates its uniform heating. And vice versa. The scale that peels off from the hot base cools and heats up faster than the base mass, which distorts the actual color of the surface. This must be taken into account.