A blowtorch, as a device for performing a variety of repair and construction work, is still in wide demand. Their popularity is due to their compactness, ease of use, and, subject to proper operation, also safety. We will discuss below how to work with the lamp correctly and maintain it on time.

Device

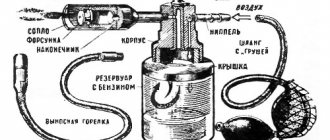

A gasoline blowtorch consists of the following components:

- A burner designed to use a specific type of fuel. For example, a gas blowtorch will have a different burner design than a device using liquid fuel.

- Fuel tank.

- Systems for supplying the combustible mixture to the burner.

- Manual fuel supercharger (pump).

- Shut-off and control device.

- Check valve (not available in all designs).

- Holding handle.

To achieve compactness, the booster pump is located directly in the tank. Before use, the user should pump the pump several times to create the required vacuum level: then the fuel will flow to the regulator.

The fuel supply system is extremely simple, and works on the principle of a locking needle: when such a needle moves in the cross section of the regulator, the pressure of the mixture changes, which determines a certain rate of fuel supply to the burner. Such pumping should be done periodically, as the external characteristics of the flame change. On the contrary, if work with the blowtorch is completed, then the pressure must be released. In modern devices, a check valve is used for this purpose; in lamps of an older design, the tank lid is simply opened slightly.

Some types of blowtorches are equipped with a remote burner, which is equipped with a long hose. In this case, an ordinary bulb made of gasoline and oil resistant rubber is used as a supercharger. A nipple inlet is used to connect the hose to the bulb and the tank body.

There is a valve on the end surface of the regulator, by opening which you can ensure the supply of gasoline mixture to the fuel-burning device. Under the pressure of the mixture, the regulator needle moves and opens access to the burner working space. From there the mixture enters the nozzle, is dispersed and ignited.

Pump repair

The blowtorch pump consists of a piston enclosed in a metal housing and a spool, which is installed at the end of the piston tube and operates on the principle of a check valve. It lets air into the body and does not let it back out.

At the end of the piston there is a leather cuff that pushes air when moving inside the lamp, and folds up to let air through when moving in the opposite direction.

This piece is simply a circle of leather sandwiched between two steel washers of different diameters. The upper washer is almost equal in diameter to the diameter of the cylinder, and the lower one is several millimeters smaller. Thanks to this, the cuff is able to pump air, folding only in one direction when necessary. To increase the service life of the cuff from repair to repair, it must be lubricated occasionally with thick lubricant.

Most often, the spool or cuff is faulty. Repairing a blowtorch pump will involve replacing them with serviceable ones. The best option for repairs would be to take working spare parts from a non-working old blowtorch, if possible. If you cannot find them, you will have to buy these parts.

How to use a blowtorch?

The safety of a gasoline blowtorch is also ensured by the fact that it is difficult to ignite the mixture directly in the burner, since the volatility of gasoline at ordinary room temperature is insufficient for ignition. Therefore, after checking the functionality of the device, the llama is pre-ignited. To do this, pour a little gasoline into a special cup and place it under the burner. The gasoline is set on fire, and when the flame begins to die out, the fuel supply valve is opened. Under the influence of internal pressure, the mixture leaves the nozzle nozzle, enters the zone of heated air containing gasoline vapor, heats up and spontaneously ignites. Then, using the control valve, the degree of extension of the needle in the burner is changed, which regulates the length and intensity of the torch.

The volatility and low density of gasoline provide sufficient conditions for its self-mixing. However, it is impossible to completely fill the tank with gasoline: it is necessary to ensure excess pressure of gasoline, which will be sufficient for its stable flow to the control device. In some designs, designed for lower values of excess pressure, not only a guide tube, but also a wick is provided for transporting gasoline.

The booster pump moves in rubber seals. To prevent them from becoming unusable ahead of time, the movements of the handle should not be sharp.

The duration of reliable operation of a blowtorch also depends on the type of mixture used to heat the lamp. For example, gasoline, even high-octane gasoline, contains organic compounds that, when burned, produce carbon deposits on the surface of the burner. Therefore, experts advise using ethyl alcohol for this purpose.

Lighting a gasoline blowtorch must be done outdoors, but without wind or drafts. If, after pumping and opening the tap, a vaporous mixture comes out of the nozzle, then its parameters are sufficient for ignition with a regular match or lighter. On the contrary, if liquid comes from the nozzle, then dispersing the mixture is not enough, and preheating it is required.

Handling old lamps

Old blowtorches that have not been used for a long time should first be inspected from the outside. During inspection, you need to check how easily all the valves and the tank lid open. The adjustment valve should turn easily.

After this, you need to check the housing for leaks. To do this, use a pump to pump air into a lamp that is not filled with fuel. Then, using a brush, apply a thick soap solution to all threaded connections and the faucet. You need to check it closed and open.

If all connections are tight and the pump is properly creating pressure in the housing, the tap performs its functions by opening and closing the burner, the lamp can be refilled and started.

Repair and performance check

If a gasoline blowtorch has not been used for a long time, then it is necessary to determine its suitability for work. To assess the quality of the device, perform the following steps:

- After igniting the torch, the degree of heating of the outer surface of the tank is set: if heating occurs evenly and gradually, then the parameters of the torch are stabilized, and the hum of the fire becomes uniform. The tank, however, should not be heated to temperatures exceeding 50 ° C.

- The nozzle tip is placed at a distance of 20...30 mm from the steel sheet: with a normal operating lamp, heating will be uniform, and as its duration increases, the flame will stabilize, which is explained by the reflection of the heat flow from the steel surface. If at the same time the flame disappears from time to time or goes out immediately, then the lamp cannot be used.

- Check the operation of the check valve: when the device is turned off, the mixture above the surface of the gasoline in the tank should bleed spontaneously.

- Check the operating pressure limits inside the tank with a pressure gauge. During normal operation of the lamp, these pressures should not exceed 0.3 MPa. Sudden fluctuations are a consequence of a malfunction in the fuel supply system to the regulator.

Restoring the pump

If hissing or other extraneous sounds appear during operation, you must immediately turn off the lamp, as the operation of the pump may be disrupted. In such a situation, it is necessary to restore a stable fuel supply. For repairs you will need tools:

- pliers;

- screwdriver.

- spring;

- lubricating oil.

Perform the following actions:

- Unscrew the plug located on the lid and remove the pump from the cylinder.

- Use a screwdriver to dismantle the spool on the valve.

- The element is cleaned of contaminants and the spring is replaced.

- The areas where the pump and housing meet are lubricated with engine oil.

- Assemble the lamp, following the reverse procedure for installing the pump.

What is the frequency of checking blowtorches?

A blowtorch is a source of increased danger, therefore, for its operation, adhere to the following rules:

- Do not use low-octane gasoline.

- Do not operate the device in the presence of leaks and a sharp increase in the temperature of the tank, as well as in an unsatisfactorily ventilated area.

- Do not refill the lamp during its operation or immediately after use.

- The lamp is inspected periodically.

The maintenance frequency is set as follows:

- In order to fully check hydraulic gasoline supply systems - at least once a year.

- In order to check the tightness and tightness of connections - at least once a month.

- To check the stability of the torch - each time before the next use, when the lamp body has completely cooled down.

The price of gasoline blowtorches is determined by their configuration, the developed thermal power and the volume of the fuel tank. It fluctuates in the range of 800... 1000 rubles.

The structure and principle of operation of a blowtorch

A blowtorch is a heating device with which a high temperature is obtained by flaming combustion of certain initial flammable substances. Such substances used during operation of the device are:

- petrol;

- alcohol;

- kerosene and some others.

A blowtorch will help you cope with a large number of tasks: heat a nut that cannot be unscrewed, heat up tar, etc.

The combustion products obtained during operation of the device form an elongated torch, and the temperature of the torch is very high.

The most common type is the gasoline blowtorch. In addition to this modification, blowtorches, in which the flame source is natural gas, have become widespread. This type of blowtorch differs from gasoline ones not only in the type of fuel burned during their operation, but also in design. The volume of tanks used for fuel in blowtorches can vary depending on the model of the device from 0.1 to 2 liters. The thermal power of these devices can vary in the range from 0.5 to 3 kW depending on the fuel supply. The lamp power is regulated using a special tap that opens the supply of the combustible substance.

Design of a gasoline blowtorch

In the design of a gasoline blowtorch, there are two main structural parts - a tank for storing fuel reserves and a burner.

An ejector is a device in which kinetic energy is transferred from one medium moving at a higher speed to another.

The burner is called an ejector. The ejector has a design that promotes the flow of air and decaying combustion products during the combustion process. The operating principle of this device is based on creating thrust due to fuel combustion.

A supply of fuel is poured into the tank, after which it is closed with a tight lid with a seal. The lid with a seal prevents fuel leakage during storage of the device, as well as during its operation. The tank for storing a supply of gasoline is equipped with a pumping device that allows air to be pumped into the tank to create excess pressure in it. Excess pressure contributes to the transportation of gasoline from the tank to the burner during operation of the device.

A typical device contains the following structural elements:

- fuel tank;

- handle for holding the device during operation;

- hermetically sealed fuel filler neck;

- pump with valve - to create excess pressure in the tank;

- siphon tube providing fuel supply to the evaporator;

- a needle valve used to regulate the fuel supply;

- evaporator;

- nozzle;

- ejector;

- nozzle cleaning device.

The fuel filled into the device tank is a consumable item. The smokiness of the flame and the clogging of the nozzle depend on the quality of the fuel used; in addition, the degree of explosion hazard that occurs during the use of the device depends on the quality of the fuel. For normal operation of gasoline devices, it is necessary to use special gasoline or gasoline with an octane rating of at least 80. If low-quality fuel is used, the device may require repairs.

The principle of operation of a blowtorch

The blowtorch can run on kerosene and gasoline.

After refueling the device, air is pumped into the tank using a pump, which creates increased pressure inside the fuel cylinder. Excessive air pressure forces fuel into the burner, where it burns and forms a flame. To ignite the burner and ensure stable operation, it must be preheated to a certain level. To carry out heating, a fuel cup is used, which is mounted under the burner. The capacity of one cup is usually enough to heat the burner to the desired temperature.

When a certain burner heating temperature is reached, the fuel supplied from the reservoir to the burner evaporates in the evaporator. Gaseous fuel enters the combustion area and forms a flame through a special nozzle. During the combustion of evaporated fuel, oxygen is sucked into the combustion area and the process is maintained.

During the process of heating the burner, air is not pumped into the tank for safety reasons, and the shut-off valve must be closed at this moment. The shut-off valve opens only after the burner and evaporator have warmed up. After opening the shut-off valve, the flame strength is adjusted. After finishing work with the device, turn it off by screwing in the shut-off valve.

REFUELING THE LAMP.

2.1. Fuel that is filled into a blowtorch must be cleaned of foreign impurities and water. 2.2. The use of gasoline or a mixture of gasoline and kerosene as fuel for a kerosene-powered lamp is prohibited. 2.3. Lamps running on pure gasoline are charged through a funnel with cotton wool or through a fine sieve to avoid small solid parts getting into the tank and clogging the capsule. 2.4. Lamp tanks must be filled with fuel to no more than 3/4 of its capacity. 2.5. Once work is completed, the lamp should be handed over to the technician every day.

Product Application Areas

About ten years ago, this device was used in every case where it was necessary to heat surfaces or metal. This product was very often used in production, since most often there was no replacement for it. A blowtorch is used in cases where heating is required in the absence of alternative sources of thermal energy or in the absence of the possibility of using modern technology.

A blowtorch is used for: heating a soldering iron tip, welding metal parts up to 1000 degrees, melting metal up to 900 degrees, for removing varnish, and when heating frozen pipes.

Most often this device is used in the following situations:

- if it is not possible to use an electric soldering iron during work, the device allows you to perfectly heat up both the solder and the soldering iron tip;

- if it is necessary to weld metal workpieces made of metals whose melting point is below 1000 degrees;

- if necessary, carry out the melting of metal having a melting point below 900 degrees;

- the tool is used when it becomes necessary to remove the varnish coating on the surface of objects made of metal;

- when heating and thawing frozen water in water supply and sewerage pipes;

- if it is necessary to carry out the operation of heating a car engine.

In some cases, a blowtorch is used to loosen bolts and other connections when disassembling them, if these connections are rusty. In addition, this device is used in agriculture during the slaughter of livestock for tarring animal skins.

Blowtorch Operating Instructions

Before using the device, you must read the instructions on how to use a blowtorch. You can use this device only after you have read the instructions.

The device can only be used outdoors. If there is an urgent need to use the device in a closed space, it can be used for a short time, followed by high-quality ventilation.

When using the device, you must strictly follow the operating instructions.

Failure to follow safety precautions when working with a blowtorch can lead to its explosion and other dire consequences.

- Before starting work, the device is refueled if necessary. The tank should be filled to three-quarters of its volume. An empty volume is required to create pressure during operation.

- Excessive pressure must be created in the tank using a pressure pump built into the device. To create pressure, you will need to perform up to 10 gentle pumping motions.

- After obtaining increased pressure, you need to pour fuel into the burner bath. It is best to use alcohol for this purpose, since this fuel does not produce a large amount of soot. The fuel poured into the bath is ignited to ensure initial heating of the burner evaporator. During the combustion of fuel in the bath, it is necessary to protect the device from drafts.

- After combustion of the fuel poured into the bath stops, the needle valve is opened. The fuel coming from the evaporator must be gaseous - if droplets are detected in the fuel flow, the procedure for heating the burner evaporator should be repeated.

- After receiving a jet of gaseous fuel, it is ignited. If necessary, the volume of incoming fuel can be adjusted using a needle valve. To speed up the process of complete heating of the burner, you can place the lamp against a metal sheet, and the distance from the sheet to the burner nozzle should be 2-3 cm.

- When carrying out work, monitor the state of the torch - you can increase or decrease it using a needle shut-off valve.

- If there is instability in the operation of the burner or combustion damping occurs, it is necessary to clean the nozzle with a needle specially designed for this purpose.

- After completion of work, the device torch is extinguished. Extinguishing the torch of the device is carried out by screwing the valve and lowering the needle. After the lamp has cooled, the air is bled from the tank.

Precautions required when working with a blowtorch

When working with a lamp, strict adherence to safety regulations is required. The fact is that violations of the rules for working with this device can provoke an explosion of the device. A blowtorch is a fire hazard. The fuel storage tank is located very close to the open flame of the torch.

When operating the device, the following rules must be observed:

- It is prohibited to operate the tool if fuel leaks or fuel vapors are detected in the structure;

- It is prohibited to use fuel during operation of a blowtorch that does not comply with the manufacturer’s recommendations;

- It is prohibited to operate the device for a long time, since the close location of the burner provokes heating of the fuel cylinder above 50 degrees Celsius;

- It is prohibited to use the device if a malfunction of the safety valve is detected;

- Do not fill the tank with fuel while the burner is burning;

- It is not recommended to use the device in enclosed spaces.

In addition, it should be said that failure to comply with almost any of the safety rules when working with a blowtorch can provoke an explosion and unpleasant consequences.

Following simple safety rules allows you to achieve the most efficient operation of the device during operation.

Lighting the lamp.

3.1. Before starting to use a blowtorch, you must check:

3.1.1. Is the valve that regulates the supply of fuel from the lamp cylinder to the burner completely unscrewed without loosening the pressure sleeve? If the control valve is unscrewed, it is PROHIBITED . 3.1.2. The tightness of the tank, /is there any leakage/, is there no gas leaking through the burner thread. 3.1.3. The tightness of the filler plug. 3.2. It is PROHIBITED to light blowtorches directly near oil-filled devices. 3.3. Filling or pouring fuel out of a lamp, disassembling and repairing a lamp, unscrewing a burner near an open flame, smoking, or adding fuel to a lamp that has not cooled down is PROHIBITED.