Sandblasting of metals is a technology for highly effective cleaning of various surfaces using an abrasive material. It is used as preparatory work before anti-corrosion or paint and varnish treatment of the surface. This method allows you to remove paint, rust, and also degrease the workpiece. Widely used in various industries: metallurgy, automotive industry, metal structures, instrument making.

Types of sandblasting

There are several types of metal cleaning:

- Easy. This type of sandblasting involves surface cleaning: it removes traces of old paint and large pockets of corrosion. The effectiveness of the effect is comparable to treatment with a metal brush. Upon visual inspection there should be no obvious signs of corrosion or contamination.

- Average. More thorough sandblasting. After processing the metal, minor traces of rust remain - no more than 10% of the total surface area.

- Deep. Completely removes traces of any contaminants. The metal surface should look absolutely clean. This type requires significant consumption of abrasive substances.

There is also an international standard for the degree of surface preparation. Evaluation is carried out by visual inspection. There are four degrees:

- Sa 1. Light sandblasting of metal.

- Sa 1–2. Sandblasting without mirror effect of metal.

- Sa 2–2.5. Sandblasting until the metal is almost shiny.

- Sa 3. Complete sandblasting until the metal shines.

Additional Information. Most manufacturers of paint and varnish products require preliminary surface preparation. Sandblasting metal allows you to not only clean, but also degrease the painted area. Thanks to this, the technology in question is considered the most effective.

Indications for sandblasting teeth

Sandblasting teeth can remove any form of plaque that home cleaning cannot remove. This procedure is recommended for everyone. This dental service does not harm the condition of the enamel and does not damage fillings and implants. Cleaning with the device is absolutely harmless and safe, so it can be carried out by people of all ages, including children. This manipulation prevents the development of pathological processes in the oral cavity, allows you to make your breath fresh, and helps lighten the enamel.

The procedure is carried out, taking into account the patient’s characteristics, up to twice a year. The regularity of visiting the dental hygienist's office depends on the condition of the oral cavity.

Sandblasting must also be carried out before treating diseases. This procedure will enable the dentist to better assess the condition of the teeth and notice caries in the early stages. Sandblasting teeth will allow you to choose the most suitable color of the filling or implant to match the color of the enamel.

The essence and purpose of the technology

The operating principle of the technology is based on the interaction of the abrasive with the metal surface.

A compressor is used as a working mechanism, which creates the necessary pressure in the working system. Sand or other material used is captured by the air flow and thrown onto the work surface. The average operating pressure of the system is 8 atmospheres, and therefore the speed of particles supplied by pressure can reach 700–720 m/s. This indicator ensures thorough cleaning, and therefore experts consider sandblasting to be the best preparation for painting metal. By exposing the surface to abrasive particles, two goals are achieved:

- clean metal from contamination;

- give roughness.

The use of various materials allows you to focus on one or another action. The roughness of the plane increases the adhesive properties of paints and varnishes, which ultimately affects the service life of the coating.

Please note that maximum durability can only be achieved by deep sandblasting the metal surface. If you do not get rid of traces of corrosion, the lesion will develop even under a layer of paint.

Industrial enterprises use sandblasting of metal structures to remove rust and dirt. The cleaned metal surface allows for high-quality welding work.

Pros and cons of sandblasting

Compared to other processing methods, experts highlight a number of advantages:

- Performance. Sandblasting an area is much faster.

- Quality. The high speed of the abrasive ensures the removal of any contaminants from the metal. The adjustment range allows you to achieve the desired degree of cleaning. The impact on the metal does not reduce its properties and does not affect the thickness.

- Practicality. Models differ in different operating parameters and dimensions: from compact devices for a private garage to sandblasting units for industrial use.

- Versatility. Components and consumables for any type of work are available for sale.

VIEW Portable Sandblasting Machine on AliExpress →

With all the positive aspects, there are some disadvantages:

- Operator training. It is necessary to complete a special training course in order to master all the skills of high-quality and safe sandblasting work.

- Price. The use of sandblasting metal in industrial production requires significant financial investments. In addition, to carry out the work it is necessary to select a separate room and find qualified workers.

- Operation at home. The use of sand as an abrasive material is associated with certain difficulties: after completion of work, sand particles remain in the air, increasing the dust level. Without personal protective equipment, respiratory tract damage can occur.

Comparison with analogues

The blasting treatment method has more advantages than other methods. Chemical cleaning is not always applicable. The structural material being cleaned may react with reagents used as cleaning mixtures. This may lead to partial or complete destruction of the product.

Chemical cleaning of concrete surfaces is very difficult. It is difficult to achieve a uniform impact; after treatment, you need to rinse the surface with water and remove exfoliated concrete. If the layer is significantly contaminated, part of it is removed mechanically. If it is saturated with oil to its full depth, chemical cleaning of concrete is impossible in this case.

The sandblasting method is limited in use due to the possibility of injury to operating personnel, the need to carefully protect workers and equipment from dust and high noise levels. With a large volume of cleaning work performed, it is necessary to remove a significant amount of abrasive material. Processing brick with an abrasive leaves a roughness on the surface, and the glass loses its transparency, becoming dull.

Advantages of blasting technology:

- Safety

- low consumption of cleaning material

- versatility

- careful attitude towards the surface being cleaned

- high efficiency

- high service life of installations

- low amount of waste

- environmental neutrality

- mobility

- chemical neutrality

Main processing rules

High-quality cleaning of the treated surface is possible only if you select the equipment, components and consumables suitable for specific work correctly. Experience shows that to achieve a positive result, the following rules must be followed:

- The performance and pressure of the compressor should be sufficient for the selected sandblasting machine, and ideally have a power reserve of 20–30%.

- It is necessary to use large diameter air supply hoses - this will reduce pressure losses.

- Hose connectors and couplings must have the diameter of the supply hose.

- For large volumes of work, take care of the mobility of the unit.

- Use modern technological developments: remote control, moisture separator, high-strength boron carbide nozzles. The initial investment will pay off quickly.

- Do not skimp on personal protective equipment - this is the key to the sandblaster’s health.

Correctly selected equipment is half the battle. Don’t forget about training and advanced training of equipment operators.

Types of abrasives used

The first models of devices worked exclusively on sand.

This didn't last long. The technology of work involves the use of various materials for cleaning metal. Abrasive materials can be classified according to physical characteristics or origin. The first classification option is as follows:

- Hardness. The speed and intensity of metal processing depends on it.

- Fraction size. According to the laws of physics, large particles have greater impact force.

Important information! For uniform processing of metal, grain size is important. The use of a mixture containing fractions of different sizes leads to excessive consumption of abrasive.

- Form. The cleaning method depends on it. Round abrasive is effective in direct interaction with metal, and elongated fractions act by friction force. There is grain-shaped material. It has a polishing effect.

Based on their origin, abrasives are divided into the following groups:

- Natural. This includes special sand for sandblasting. During the development of technology, natural material was in great demand due to the lack of analogues. Desert and sea sands were especially valued. Modern safety requirements limit their use.

- Vegetable. Agricultural by-products. The seeds, husks or shells are processed and then used in production. The main quality of the material is its soft impact on the working area.

- Industrial. They are divided into three subcategories: metallic, non-metallic, waste from the metallurgical industry. The most famous abrasive of the first group is metal shot. Granulates and shot are made from almost all types of metal. They differ only in the size of the fraction. They are durable. Non-metallic abrasive is an industrial product. Features uniform grain size. It has high strength and excellent cleaning properties. A striking example is glass grain. The material from the last subcategory is obtained from waste slag. Has average characteristics. The main advantage is that industrial regions are able to supply this abrasive in large quantities.

Types of sandblasting equipment

Manufacturers offer two types of equipment for sandblasting metal:

- Mobile device. Compact dimensions allow the unit to be moved by one person. The scope of work is limited only by supplies of consumables. Safety equipment is required for operation. Within the operating range of the device, dusty air can pose a danger to people.

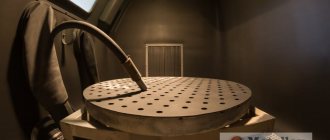

- Automatic sandblasting chamber. It is safe for the installation operator. The enclosed space allows you to collect abrasive after work. Requires a high-quality ventilation system. The dimensions of the processed parts are limited.

Review of sandblasting machines and cost

There are three types of mobile sandblasting machines, which differ both in operating principle and in price. Let's look at each type.

VIEW Sandblasting equipment on AliExpress →

Pressure type device

Its peculiarity is the method of supplying abrasive, which enters the metal surface through one channel with compressed air. It has good performance, but is dependent on the power of the compressor unit. Suitable for cleaning large surfaces. Widely used in industrial enterprises for repairing metal structures. The minimum cost of such units is $300. An installation with average performance costs about $1000.

Additional Information! On the Internet you can find a diagram of the design of pressure devices. An experienced welder can assemble the installation within a week.

Injection type device

Abrasive and air enter through separate channels. Because of this, the nozzle holder has an air and abrasive nozzle. It has low performance. This determines the scope of application of the devices - decorative processing of mirrors and other surfaces. The cost does not exceed $300.

Vacuum devices

They were developed as a type of pressure apparatus, but their design features separated them into a separate class. After contact with the metal, the abrasive is sucked into the device by vacuum. However, it reduces the kinetic energy of the particles, which affects power. Low productivity and high cost have led to the fact that such units are used very rarely.

Video – processing with Nordblast NB 28-2

The flow speed at the outlet of the Venturi pipe reaches 720 km/h. Increasing the speed of the mixture increases the amount of energy released by the particles. This greatly affects the efficiency of the cleaning process. The air mixture supply can be adjusted manually, separately from the compressed air supply from the compressor.

The installation uses a vibrator to maintain the soda in a powdery state and facilitate its absorption into the main line. The body and various parts of the Norddlast NB 28-2 are made of stainless steel and non-ferrous alloys. All materials are acid-resistant and protected from static electricity.

As an option, a supply air dryer with a moisture separator can be ordered. The reinforced design of wheels with rubber tires makes it easy to move the unit and place it in hard-to-reach places. Depending on the task and the object being processed, it provides for the use of glass granules and metal sand balls as cleaning materials. This allows it to be used as a sandblaster.

Using the Norddlast NB 28-2 you can clean rust, dirt, and old paint. It is especially in demand in the metallurgical industry for removing scale and slag from parts, in ship repair shops for cleaning the bottom of various ships, in auto repair centers for removing old paint from a car body. It is used for restoration work and odor removal.

What to look for when choosing a sandblasting machine

At the stage of selecting the necessary equipment, experts recommend paying attention to the following nuances:

- The dimensions and weight of the compressor are the key to comfortable movement around the work site.

- The manufacturer must produce the tank in accordance with the safety requirements for the manufacture of pressure vessels.

- A large number of hoses and fittings leads to a loss of performance of the device. For best performance, we recommend using sleeves with a diameter of at least one inch.

- The device must be adapted for all types of abrasive materials: from sand to cast iron shot.

- To ensure additional safety, you can purchase a unit with an additional safety valve that operates automatically.

- The volume of the container for storing consumables should be 60% of the capacity of the pressure vessel. A separate worker is required to service it.

- Pay attention to the volume of the pressure tank. When fully loaded, the abrasive should last at least 30 minutes. Material consumption is calculated based on the nozzle diameter and pressure force. The jet power does not affect the capacity.

- It is imperative to have a dosing mechanism that optimizes sand consumption.

- Shut-off valves are installed on the inlet and outlet lines.

- A large inspection hatch provides comfortable access to the loading area.

- When working with reusable materials, a special filter in the form of a sieve is installed on the loading funnel, which filters out grains of the wrong size.

- For long periods of work, use a compressor with a double tank.

Sandblasting machines entered the domestic market relatively recently, but users have already appreciated the convenience and performance of these devices when carrying out preparatory work on metal surfaces. If you have experience successfully using sandblasting technologies at home, share it in the comments section.

Description of the procedure

It is advisable to carry out this manipulation with the regularity recommended by the hygienist. Usually, the use of painkillers is not required, but if the teeth are sensitive, local anesthetics can be used.

Sandblasting hygienic teeth cleaning is not done with sand. It is based on the action of soda powder, which is neutral to teeth. The procedure is carried out by supplying a hydrocarbonate solution by sandblasting in the form of a jet of water under pressure. The flow is directed towards the gums and teeth. This manipulation is completely safe for tooth enamel. If unpleasant sensations arise, they pass in a minimum time.

READ ALSO: hygienic teeth cleaning: what is it and how is it done?

During the procedure, the tooth must be polished using special attachments made of rubber materials. Abrasive pastes are used together with them. The whole procedure is short in time and takes no more than 15 minutes.

Polishing is extremely necessary, since after cleaning the surface of the tooth becomes porous, and without it, dirt will easily get there. After all manipulations, the surface of the tooth is coated with varnish containing fluoride. Teeth cleaning is carried out in any dental clinic. During the period between cleaning procedures, it is necessary to maintain oral hygiene.