The beginning of the history of iron

In the third millennium BC. e. people began to mine and learned to process bronze and copper. They were not widely used due to their high cost. The search for new metal continued. The history of iron began in the first century BC. e. In nature, it can only be found in the form of compounds with oxygen. To obtain pure metal, it is necessary to separate the last element. It took a long time to melt the iron, since it had to be heated to 1539 degrees. And only with the advent of cheese-making furnaces in the first millennium BC did they begin to obtain this metal. At first it was fragile and contained a lot of waste.

With the advent of forges, the quality of iron improved significantly. It was further processed in a blacksmith, where the slag was separated by hammer blows. Forging has become one of the main types of metal processing, and blacksmithing has become an indispensable branch of production. Iron in its pure form is a very soft metal. It is mainly used in an alloy with carbon. This additive enhances the physical property of iron, such as hardness. The cheap material soon penetrated widely into all spheres of human activity and revolutionized the development of society. After all, even in ancient times, iron products were covered with a thick layer of gold. It had a high price compared to the noble metal.

Use of iron in construction. Interesting Facts.

Iron occurs naturally in rocks (ores) containing iron oxides. Since the Iron Age.

Iron comes into use very early, in the form of parts that hold the main materials (wood, stone), and then for decorative elements. Only in the 19th century, with the industrial revolution, did it become a fundamental component of new construction. The 20th and 21st centuries are intensifying this trend and massively using iron and steel.

Antiquity Production In ancient times and until the late Middle Ages, iron was mined by heating layered layers of iron ore and wood or charcoal. In these "furnaces" the resulting temperatures are not very high and the metal becomes pasty. It is then pounded by a blacksmith to get rid of its impurities.

Therefore, iron remains produced in small quantities, which is used to make small items (weapons, tools...). They are sometimes used during construction, but only for small parts: staples, chains, anchors... which allow you to hold the stones together. In Ancient Greece, metal rods could strengthen the structure of marble temples. This method of stitched stone or "army stone" survived into the 19th century.

Mythology In Greek mythology, Hephaestus is the god of fire, iron, and therefore Kuznetsov. The son of Jupiter, king of the gods, and Juno, his wife, he is born and immediately rejected by his mother, who casts him from the top of Olympus, the mountain of the gods. His fall ends in the sea, where he is rescued and collected by Thetis and Eurinomia, daughters of the ocean. For nine years he lives in a cave and learns to forge, thanks to the fire of the volcano, buckles, staples and jewelry.

Middle Ages In the Middle Ages, iron beams served as reinforcement for wooden frames of houses, especially urban houses with several floors.

But iron is also needed in metalworking or for making certain items such as harrows (bars to protect gates), strong locks, or bars that protect openings.

Iron is well used in the construction of cathedrals and Gothic churches. It is estimated that each building accounts for several tens of tons. This material comes in several forms: simple brackets between stones or framed supports and pegs; metal beams strengthening stone structures or wooden structures; stained glass barlotiers: iron bars that hold stained glass panels in place when being laid. By some estimates, almost 50% of the iron in cathedrals is used in stained glass; consolidation structures called "chains": linking iron bars that wrap around part of a building and stop lateral shocks that could cause it to collapse. In the Amiens Cathedral, which was threatening to collapse, such a chain was urgently installed. Smaller systems of chains, buried in the masonry or apparent, may also surround the towers.

Thus, metal artisans, blacksmiths, and mechanics were ubiquitous at the construction of cathedrals, who sometimes mistakenly believe that they were made only of stone and wood.

Renaissance Blast furnace technology, which allows high temperatures, has existed in China since the 5th century. But in the West, before the beginning of the 15th century, still modest-sized blast furnaces should appear in combination with a water mill driving bellows (“hydraulic bellows”). This device allows you to obtain metal in liquid form, easily molded: this is cast iron (a molten mixture consisting of iron and carbon).

From the Renaissance to the 18th century: iron becomes decorative Since the Renaissance, iron is no longer used only as a defense aimed at strengthening wood or stone. It becomes a full-fledged decorative element used for balusters, stair railings or balconies, balconettes, railings and even sometimes for columns. In the 18th century, the Baroque style emphasized ironwork. The 19th century is the golden age of iron in construction, thanks to advances in iron and steel.

Production Now the ore is smelted with coal in blast furnaces, which allow it to reach high temperatures and produce in large quantities. In 1807, 300 furnaces produced 450,000 tons of pig iron in France.

Depending on the level of carbon, we get different products: Cast Iron: The raw product of a blast furnace, it is hard and brittle. It can be cast into any desired shape. It resists bending poorly, but withstands pressure well, namely compression: this is why cast iron is widely used for columns and decorative elements.

Iron: It is obtained by degassing (removing some of the carbon) from cast iron, which helps make it more tensile and malleable. Iron is used in the form of beams for frames and structures because of its relatively high strength.

Steel: Steel is a metal alloy consisting of carbon and iron, obtained by refining pig iron (Bessemer process, 1856). The substance is processed in blast furnaces: iron ore and coke are brought to a temperature of 1500°. The coke is burned, and the iron is charged with carbon: cast iron is obtained. The cast iron, then in a liquid state, is poured onto the metal where the carbon is eventually removed. This results in steel that can be enriched with nickel, chromium or something else depending on its use (construction, automotive, etc.). Steel is primarily intended for mechanical engineering and weapons. Little used in construction before 1890, but it is a very hard, durable and ductile material (that can deform without breaking).

Standardization of metal elements: the example of the “Polonceau truss” Melted into molds sold from a catalogue, the parts required for the construction of metal structures are standardized. In 1836, engineer Camille Polonceau invented a triangular piece of iron and wood, followed by steel and cast iron sections, known as the “Polonceau truss” for the frame of a small hangar. This very light piece is resistant to the pressures exerted in the frame. It is used at many stations.

Qualities of metal in construction It resists fire well. Since 1830, all the attics of Parisian theaters have been made of iron due to the constant fire hazard posed by candle and then gas lighting. He's tough. Its strength is much higher than that of wood or stone. It does not rot, that is, it does not rust, unless, of course, it is well treated with special compounds.

Using metal directly on construction sites The industrialization of iron production really began around 1840-1850. This leads to thoughts about the renewal of construction technologies and gradually promotes the use of iron and cast iron on new construction sites.

But iron architecture is not imposed on all buildings at the same time. Cast iron columns, which allow large spaces to be opened up without walls, are used in train stations, factories, covered markets or department stores... The first building to show off its metal structure is a factory located in the Parisian region, and not in the very center of Paris: the Meunier chocolate factory in Noisiel , built in 1871.

Metal floors first appear in theaters when orders prohibit them from being built of wood to avoid fire hazards. Many bridges are also built of metal or using a mixed stone-metal technique. The Pont des Arts in Paris is the first French bridge built of cast iron.

It was only in the last third of the 19th century that iron architecture conquered more prestigious buildings such as museums or libraries. The 1889 World's Fair, with the Eiffel Tower at its center, serves as a trigger. However, some buildings remain hidden behind stone siding, which gives the building a more classical appearance, such as the exterior façade of the Grand Palace. The interior, on the other hand, shows off its iron and glass structure.

A particular event probably accelerated the adoption of metal in the construction industry: the Parisian Carpenters' Strike, which lasted for many months in 1845. Deprived of wood, contractors used iron to complete the construction they had begun, thereby helping to popularize what was still an exceptional material.

Iron and glass Iron's ally in construction is glass, which smoothly “fills” light metal structures. Then came shopping galleries illuminated by daylight, gigantic greenhouses similar to those in the garden of plants in Paris. The most impressive example of this association is London's Crystal Palace, site of the 1851 World's Fair.

Iron is invested in private homes Iron architecture appears primarily in public or industrial buildings. Private buildings and houses mostly use iron for their balconies or sometimes for their entrance doors. But in 1882, a decree was issued allowing Paris to have structures protruding a maximum of 80 cm from a height of 5.75 m. This provision met the expectations of builders dissatisfied with the monotony of Ottoman alignments. Then, buildings with "bow-windows" (or oriels) are born, which bring clarity and extra space. Lightweight and not cluttering up space, iron is well suited for the manufacture of such façade elements, which can be of various shapes: rectangular, curved...

Inspired by Art Nouveau With Art Nouveau, which originated at the end of the 19th century, iron is naturally imposed in this flow, which seeks to renew the aesthetics of various fields (applied arts such as furniture, painting, architecture...).

Art Nouveau is inspired by the forms of nature, especially the sinuous, asymmetrical lines of plants. It is then widely used in decorations (ramps, ironwork, stained glass) which extend the steel structure of buildings. This style amazes with its brightness and originality. It is adopted in many residential buildings and private homes.

The birth of skyscrapers The construction of the first high-rise buildings was made of cast iron, with stone facades. This is a very heavy combination, where stone and metal are load-bearing, but, alas, they do not allow you to overcome 17 floors. The first skyscraper, in 1885, is the Home Insurance Building, built in Chicago. Its structure is steel; its stone wall is a “curtain” that creates the whole but does not support it.

Transport services in modern construction

Now, in modern construction, a huge amount of iron materials are used, which are installed using special construction equipment. It is also important to move people in space to perform their tasks and work, including for the construction of objects.

If you need to rent special equipment, look here: https://dcs-rent.ru/arenda-avtokrana

If you want to travel comfortably in a car throughout Russia, then AutoSpetsService LLC can organize full-cycle transport services throughout Russia; more information here.

Iron in nature

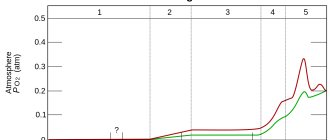

The lithosphere contains more aluminum than iron. In nature, it can only be found in the form of compounds. Ferric iron, reacting, turns the soil brown and gives the sand a yellowish tint. Iron oxides and sulfides are scattered in the earth's crust, sometimes there are accumulations of minerals, from which the metal is subsequently extracted. The content of ferrous iron in some mineral springs gives the water a special taste.

Rusty water flowing from old water pipes is colored by the trivalent metal. Its atoms are also found in the human body. They are found in hemoglobin (iron-containing protein) in the blood, which supplies the body with oxygen and removes carbon dioxide. Some meteorites contain pure iron, sometimes whole ingots are found.

Iron atom and molecule. Iron formula. Structure of the iron atom:

Iron (lat. Ferrum) is a chemical element of the periodic system of chemical elements of D.I. Mendeleev with the designation Fe and atomic number 26. It is located in the 8th group (according to the old classification - a secondary subgroup of the eighth group), the fourth period of the periodic system.

Iron is a metal. Belongs to the group of transition metals. Refers to ferrous metals .

As a simple substance , iron under normal conditions is a malleable, viscous metal of a silvery-white color with a grayish tint with high chemical reactivity. Iron itself is usually called its alloys with a low impurity content (up to 0.8%), which retain the softness and ductility of pure metal. In practice, alloys of iron with carbon are more often used: steel (up to 2.14 wt.% carbon) and cast iron (more than 2.14 wt.% carbon), as well as stainless (alloy) steel with additions of alloying metals (chrome, manganese, nickel and etc.).

The iron molecule is monatomic.

Chemical formula of iron is Fe.

The electronic configuration of the iron atom is 1s2 2s2 2p6 3s2 3p6 3d6 4s2. The ionization potential (first electron) of the iron atom is 762.47 kJ/mol (7.9024681(12) eV).

The structure of the iron atom. The iron atom consists of a positively charged nucleus (+26), around which 26 electrons move in four shells. In this case, 24 electrons are in the internal level, and 2 electrons are in the external level. Since iron is located in the fourth period, there are only four shells. First, the inner shell is represented by the s-orbital. The second – the inner shell is represented by s- and p-orbitals. The third - inner shell is represented by s-, p- and d-orbitals. The fourth - outer shell is represented by the s-orbital. At the internal energy level of the iron atom, the 3d orbital contains two paired and four unpaired electrons. At the outer energy level of the iron atom, the s orbital contains two paired electrons. In turn, the nucleus of an iron atom consists of 26 protons and 30 neutrons.

The radius of the iron atom (calculated) is 156 pm.

The atomic mass iron atom is 55.845(2) a. eat.

Iron , one of the most common metals in the earth's crust, ranks fourth. The iron content in the earth's crust is 6.3% (by weight). In this indicator, iron is second only to oxygen, silicon and aluminum.

Iron, atomic properties, chemical and physical properties

What physical properties does iron have?

It is a ductile silver-white metal with a grayish tint and a metallic sheen. It is a good conductor of electric current and heat. Due to its ductility, it lends itself perfectly to forging and rolling. Iron does not dissolve in water, but liquefies in mercury, melts at a temperature of 1539 and boils at 2862 degrees Celsius, and has a density of 7.9 g/cm³. A peculiarity of the physical properties of iron is that the metal is attracted by a magnet and, after the cancellation of the external magnetic field, retains magnetization. Using these properties, it can be used to make magnets.

Physical properties of metals

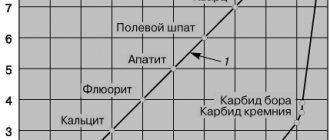

Hardness

All metals (except mercury and, conditionally, francium) are in a solid state under normal conditions, but have different hardnesses. The table below shows the hardness of some metals on the Mohs scale.Hardness of some metals on the Mohs scale:

| Hardness | Metal |

| 0.2 | Cesium |

| 0.3 | Rubidium |

| 0.4 | Potassium |

| 0.5 | Sodium |

| 0.6 | Lithium |

| 1.2 | Indium |

| 1.2 | Thallium |

| 1.25 | Barium |

| 1.5 | Strontium |

| 1.5 | Gallium |

| 1.5 | Tin |

| 1.5 | Lead |

| 1.5 | Mercury(tv) |

| 1.75 | Calcium |

| 2.0 | Cadmium |

| 2.25 | Bismuth |

| 2.5 | Magnesium |

| 2.5 | Zinc |

| 2.5 | Lanthanum |

| 2.5 | Silver |

| 2.5 | Gold |

| 2.59 | Yttrium |

| 2.75 | Aluminum |

| 3.0 | Copper |

| 3.0 | Antimony |

| 3.0 | Thorium |

| 3.17 | Scandium |

| 3.5 | Platinum |

| 3.75 | Cobalt |

| 3.75 | Palladium |

| 3.75 | Zirconium |

| 4.0 | Iron |

| 4.0 | Nickel |

| 4.0 | Hafnium |

| 4.0 | Manganese |

| 4.5 | Vanadium |

| 4.5 | Molybdenum |

| 4.5 | Rhodium |

| 4.5 | Titanium |

| 4.75 | Niobium |

| 5.0 | Iridium |

| 5.0 | Ruthenium |

| 5.0 | Tantalum |

| 5.0 | Technetium |

| 5.0 | Chromium |

| 5.5 | Beryllium |

| 5.5 | Osmium |

| 5.5 | Rhenium |

| 6.0 | Tungsten |

| 6.0 | β-Uranium |

Melting temperature

The melting points of pure metals range from −39 °C (mercury) to 3410 °C (tungsten). The melting point of most metals (except alkali) is high, but some metals, such as tin and lead, can melt on a regular electric or gas stove.

Density

Depending on their density, metals are divided into light (density 0.53 ÷ 5 g/cm³) and heavy (5 ÷ 22.5 g/cm³). The lightest metal is lithium (density 0.53 g/cm³). It is currently impossible to name the heaviest metal, since the densities of osmium and iridium - the two heaviest metals - are almost equal (about 22.6 g / cm³ - exactly twice the density of lead), and it is extremely difficult to calculate their exact density: for To do this, the metals must be completely purified, because any impurities reduce their density.

Plastic

Most metals are ductile, meaning metal wire can be bent without breaking. This occurs due to the displacement of layers of metal atoms without breaking the bond between them. The most ductile are gold, silver and copper. Gold can be used to make foil 0.003 mm thick, which is used for gilding products. However, not all metals are ductile. Wire made of zinc or tin crunches when bent; When deformed, manganese and bismuth hardly bend at all, but immediately break. Plasticity also depends on the purity of the metal; Thus, very pure chromium is very ductile, but, contaminated with even minor impurities, it becomes brittle and harder. Some metals, such as gold, silver, lead, aluminum, osmium, can grow together, but this can take decades.

Electrical conductivity

All metals conduct electricity well; this is due to the presence in their crystal lattices of mobile electrons moving under the influence of an electric field. Silver, copper and aluminum have the highest electrical conductivity; for this reason, the latter two metals are most often used as wire materials. Sodium also has very high electrical conductivity; in experimental equipment, attempts are known to use sodium conductors in the form of thin-walled stainless steel pipes filled with sodium. Due to the low specific gravity of sodium, with equal resistance, sodium “wires” are much lighter than copper and even somewhat lighter than aluminum.

Thermal conductivity

The high thermal conductivity of metals also depends on the mobility of free electrons. Therefore, the series of thermal conductivities is similar to the series of electrical conductivities, and the best conductor of heat, as well as electricity, is silver. Sodium also finds use as a good conductor of heat; It is widely known, for example, that sodium is used in valves of automobile engines to improve their cooling.

The lowest thermal conductivity is found in bismuth and mercury.

Color

The color of most metals is approximately the same - light gray with a bluish tint. Gold, copper and cesium are yellow, red and light yellow, respectively.

Chemical properties

Iron has the following properties:

- in air and water it easily oxidizes, becoming covered with rust;

- in oxygen, the hot wire burns (and scale is formed in the form of iron oxide);

- at a temperature of 700–900 degrees Celsius, it reacts with water vapor;

- when heated, reacts with non-metals (chlorine, sulfur, bromine);

- reacts with dilute acids, resulting in iron salts and hydrogen;

- does not dissolve in alkalis;

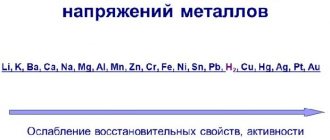

- is capable of displacing metals from solutions of their salts (an iron nail in a solution of copper sulfate becomes covered with a red coating - this is the release of copper);

- In concentrated alkalis when boiling, the amphotericity of iron is manifested.

Metal structure

Crystal structure of alloys

Vacancy in the crystal lattice

Dendrite formation

See also: Metallurgy

No metal can be prepared in an absolutely pure state. Technically “pure” metals can contain up to several percent impurities, and if these impurities are elements with low atomic weight (for example, carbon, nitrogen or oxygen), then in terms of atomic percentages the content of these impurities can be very large. The first small amounts of impurities in the metal usually enter the crystal in the form of a solid solution. There are two main types of solid solutions:

- first, when the impurity atoms are much smaller than the solvent metal atoms, the dissolved atoms are located in the solvent lattice along interstices, or “voids.” The formation of such solid solutions—interstitial solid solutions—is almost always accompanied by expansion of the solvent lattice, and in the vicinity of each dissolved atom there is a local distortion of the lattice;

- second, when the atoms of the impurity and the solvent have approximately the same sizes, a substitution solid solution is formed, in which atoms of the dissolved element replace atoms of the solvent, so that atoms of both types occupy places at the sites of the common lattice. In such cases, there is also a distorted region around each dissolved atom, and whether the lattice expands or contracts depends on the relative sizes of the solvent and solute atoms.

For most metals, the most important elements forming interstitial solid solutions are hydrogen, boron, carbon, nitrogen and oxygen. The presence of dislocations always leads to the appearance of abnormally large or small interatomic distances. In the presence of impurities, each dislocation is surrounded by an “atmosphere” of impurity atoms. Impurity a dislocations, because as a result of the movement of dislocations a new configuration with increased energy will be formed. The boundaries between crystals are also regions with anomalous interatomic distances and, therefore, also dissolve impurity atoms more easily than undistorted regions of crystals.

As the impurity content increases, dissolved atoms enter the bulk of the crystal, but there is still an excess of impurities along the grain boundaries and around dislocations. When the impurity exceeds the solubility limit, a new phase appears, which can be either a solute, an intermediate phase, or a compound. In such cases, the boundaries between phases can be of two kinds. In general, the crystal structure of impurity particles is too different from the structure of the solvent metal, so the lattices of the two phases cannot transform into one another, forming a continuous structure. In such cases, layers with an irregular (distorted) structure are formed at the phase boundaries. The formation of boundaries is associated with the appearance of free surface energy, but the deformation energy of the solvent lattice is relatively small. In such cases, they say that these particles are released incoherently.

In some cases, the interatomic distances and the crystal structure of the solvent metal and impurity particles are such that some planes can be connected to each other, forming a continuous structure. Then they say that the particles of the second phase are released coherently and, since the conjugation of the lattices is never absolutely precise, a highly stressed region is formed around the boundary. In cases where the deformation energy is too high for this, neighboring crystals can come into contact in such a way that regions of elastic deformation appear in the boundary layers, and dislocations appear at the interface itself. In such cases, the particles are said to be released semi-coherently.

As the temperature increases, due to an increase in the amplitude of atomic vibrations, a defect in the crystal lattice, which is called a vacancy or “hole,” can form. Diffusion of vacancies is one of the mechanisms of dislocation formation.

As a rule, metal crystallization occurs by supercooling with the formation of a dendritic structure. As they grow, dendritic crystals come into contact, and various structural defects are formed. In most cases, the metal hardens so that the first batch of crystals contains fewer impurities than subsequent ones. Therefore, as a rule, impurities are concentrated at grain boundaries, forming stable structures.

Feature properties

One of the physical properties of iron is ferromagneticity. In practice, the magnetic properties of this material are often encountered. This is the only metal that has such a rare feature.

Under the influence of a magnetic field, iron is magnetized. The metal retains its formed magnetic properties for a long time and remains a magnet itself. This exceptional phenomenon is explained by the fact that the structure of iron contains a large number of free electrons that can move.

Reserves and production

One of the most common elements on earth is iron. In terms of content in the earth's crust, it ranks fourth. There are many known ores that contain it, for example, magnetic and brown iron ore. The metal is produced in industry mainly from hematite and magnetite ores using the blast furnace process. First, it is reduced with carbon in a furnace at a high temperature of 2000 degrees Celsius.

To do this, iron ore, coke and flux are fed into the blast furnace from above, and a stream of hot air is injected from below. A direct process for obtaining iron is also used. The crushed ore is mixed with special clay to form pellets. Next, they are fired and treated with hydrogen in a shaft furnace, where it is easily restored. They obtain solid iron and then melt it in electric furnaces. Pure metal is reduced from oxides using electrolysis of aqueous salt solutions.

Getting iron

Pure iron is obtained by reduction from oxides (pyrophoric iron), electrolysis of aqueous solutions of its salts (electrolytic iron), and decomposition of iron pentacarbonyl Fe(CO)5 when heated to 250°C. Particularly pure iron (99.99%) is obtained using zone melting. Technically pure iron (about 0.16% of impurities of carbon, silicon, manganese, phosphorus, sulfur, etc.) is smelted by oxidizing the components of cast iron in open-hearth steel-smelting furnaces and oxygen converters. Welding or brick iron is obtained by oxidizing the impurities of low-carbon steel with iron slag or by reducing ores with solid carbon. The bulk of iron is smelted in the form of steel (up to 2% carbon) or cast iron (over 2% carbon).

Benefits of Iron

The basic physical properties of the iron substance give it and its alloys the following advantages over other metals:

- They have hardness and strength while maintaining elasticity. These qualities are not the same for different alloys and depend on alloying additives, production methods and heat treatment.

- A wide variety of cast iron and steels allow them to be used for any needs in the national economy.

- The high magnetic properties of metal are indispensable for the manufacture of magnetic cores.

- The feasibility of light mechanical processing, due to the physical properties of iron, makes it possible to obtain sheets, rods, beams, pipes, and shaped profiles from its alloys.

- The significant malleability of the material allows it to be used for decorative products.

- Low cost of alloys.

Flaws

In addition to a large number of positive qualities, there are also a number of negative properties of the metal:

- Products are susceptible to corrosion. To eliminate this undesirable effect, stainless steels are produced by alloying, and in other cases, special anti-corrosion treatment is carried out on structures and parts.

- Iron accumulates static electricity, so products containing it are subject to electrochemical corrosion and also require additional processing.

- The specific gravity of the metal is 7.13 g/cm³. This physical property of iron gives structures and parts increased weight.

Composition and structure

Iron has four crystalline modifications that differ in structure and lattice parameters. For the smelting of alloys, it is the presence of phase transitions and alloying additives that is of significant importance. The following states are distinguished:

- Alpha phase. It lasts up to 769 degrees Celsius. In this state, iron retains the properties of a ferromagnet and has a body-centered cubic lattice.

- Beta phase. Exists at temperatures from 769 to 917 degrees Celsius. It has slightly different lattice parameters than in the first case. All physical properties of iron remain the same, with the exception of magnetic ones, which it loses.

- Gamma phase. The lattice structure becomes face-centered. This phase appears in the range of 917–1394 degrees Celsius.

- Omega phase. This state of the metal appears at temperatures above 1394 degrees Celsius. It differs from the previous one only in the lattice parameters.

Iron is the most sought after metal in the world. More than 90 percent of all metallurgical production falls on it.

Application

People first began to use meteorite iron, which was valued higher than gold. Since then, the scope of this metal has only expanded. The following are the uses of iron based on its physical properties:

- ferromagnetic oxides are used for the production of magnetic materials: industrial installations, refrigerators, souvenirs;

- iron oxides are used as mineral paints;

- ferric chloride is indispensable in amateur radio practice;

- Ferrous sulfates are used in the textile industry;

- magnetic iron oxide is one of the important materials for the production of long-term computer memory devices;

- ultrafine iron powder is used in black and white laser printers;

- the strength of the metal makes it possible to manufacture weapons and armor;

- wear-resistant cast iron can be used to produce brakes, clutch discs, and parts for pumps;

- heat-resistant – for blast furnaces, thermal furnaces, open-hearth furnaces;

- heat-resistant – for compressor equipment, diesel engines;

- high-quality steel is used for gas pipelines, casings of heating boilers, dryers, washing machines and dishwashers.