Chemical composition

All alloys are characterized by their specific chemical composition. Established standards determine the concentration of all elements within a certain range. Among the features of the chemical composition of C 255, we note the following points:

- Most of the composition is iron, about 97%. This element is part of almost all alloys.

- Carbon determines the hardness and strength of the metal, as well as its brittleness and degree of weldability. The C255 steel in question contains about 0.22% carbon. Too high a carbon concentration leads to brittleness of the structure and problems with weldability. However, a decrease in the amount of this chemical in the composition causes a decrease in the hardness and strength of the structure. It is important not only how much carbon is in the composition, but how evenly it is distributed throughout the structure. Uneven carbon distribution results in poor performance.

- Manganese is included in the composition of many metals, in this case it is about 0.65%.

- Silicon largely determines the basic operational properties, its concentration is from 0.15 to 0.3%. Silicon also affects strength and weldability, hardness and other important characteristics.

- Copper, nickel and chromium each account for 0.3%. A low chromium concentration means that the surface can become corroded. Prolonged exposure to precipitation and certain chemicals leads to corrosion. Excessive use with such damage to the metal leads to a decrease in the strength of supporting structures and a deterioration in decorative qualities.

Sulfur and phosphorus are also included in the composition in small quantities. These substances impair the performance of C255 steel, for example, strength.

Compound

The chemical composition and ratio of components in steel grade C255 are regulated by GOST 27772-88. According to it, the alloy contains:

- 0.22% carbon, the indicators of hardness and fragility depend on its quantity and uniformity of distribution in the structure;

- 0.65% manganese, GOST allows an increase in its mass fraction to 0.85%;

- from 0.15 to 0.30% silicon, it is necessary to improve the performance properties of the material;

- 0.3% copper and nickel each, a small amount of these elements does not have a noticeable effect on the properties;

- chromium – 0.3%, low content of the element indicates the metal’s susceptibility to corrosion under certain conditions;

- up to 0.02% residual aluminum;

- 0.04-0.05% sulfur and phosphorus, impurities of which are inevitable in the composition of the alloy.

In some deposits there are ores containing arsenic, but its concentration does not exceed 0.12%.

Mechanical properties

The main characteristics of steel C255 can be found in specialized literature. Some qualities depend on the ambient temperature and some other factors. The mechanical properties of the alloy are as follows:

- The yield strength of steel C255 is 255 MPa.

- Tensile strength 360 MPa.

- The relative elongation of the workpiece is 25%.

If necessary, the performance characteristics of C255 steel can be improved by heat and other types of treatment. The most common methods used are surface hardening and tempering:

- In the first case, the surface hardness is increased. Exposure to high temperatures causes the metal structure to rearrange and become denser. To carry out hardening, special equipment is used that heats the workpiece to the required temperature. Cooling involves the use of a water or oil bath. In order to reduce the likelihood of scale and other defects, oil is used to cool the workpiece, as it ensures a uniform decrease in temperature.

- Tempering involves reducing internal stresses, which can cause surface or internal defects. This method of heat treatment involves heating to a lower temperature, but the temperature is increased and decreased gradually. Due to this, the main operational characteristics of C255 steel are increased.

Hardening and tempering in most cases is carried out when the workpiece is small in size. Massive products are difficult to process, since heating them requires large specialized equipment.

The alloy in question is characterized by excellent mechanical properties, but it is not resistant to corrosion. That is why the structures being created require protection from moisture and some other chemicals. In most cases, the surface is double-painted with waterproof paint when the base is first primed. To significantly increase the protection of the structure, hot-dip galvanizing is carried out, since zinc can withstand exposure to moisture and chemicals.

Application area

The steel grade in question, C255, is used to create metal structures that belong to the first group.

This group is characterized by welded elements used in particularly difficult operating conditions.

The following load may be placed on the structures being created:

- Dynamic – gradual increase and decrease in pressure. To withstand dynamic loads, the metal must have ductility.

- Moving – changing the point of pressure concentration. Such an impact can lead to the destruction of load-bearing elements.

- Vibration - a similar effect is inherent in bridges and other load-bearing structures. Vibration can lead to deformation of the weld and fasteners.

Steel 255 is found in the structures of bridges, overpasses, stairs and other load-bearing structures that are subject to high loads. In some cases, it is allowed to use metal in the manufacture of critical mechanisms in the engineering industry.

Alloy analogues

Based on their chemical composition and mechanical properties, several similar alloys are distinguished. An analogue of steel C255 can be of domestic and foreign origin. Similar domestic brands are as follows:

- 18sp, 18Gsp and 18Gps.

- VSt3sp5 and VSt3ps6.

- St3Gps and St3Gsp.

Foreign analogues are manufactured taking into account the ISO 630 standard. This group includes the following standards:

- Fe 360-C (E 235-C).

- Fe 360-B (E 235-B).

- Fe 360-D (E 235-D).

Some analogues can be improved by thermal and chemical treatment. All alloys are characterized by high weldability and machinability.

Analogs of steel grade C255

Carbon steel C255 according to GOST 27772-88 corresponds to the following grades of steel:

- St3Gps and St3Gsp according to GOST 380 (Appendix 1 GOST 27772-88)

- VSt3sp5, VSt3Gps5 and VSt3ps6 (rolled sheets with a thickness of over 20 to 40 mm, shaped - over 30 mm) according to GOST 380-71, VSt3sp5-1 and VSt3Gps5-1 according to TU 14-1-3023–80 and 18sp, 18Gps, 18Gsp GOST 23570–79 (Table 51b appendix 1 SNiP II -23-81)

- E 235-B (Fe 360-B), E 235-C (Fe 360-C) and E 235-D (Fe 360-D) according to ISO 630:1995 (Appendix A GOST 380-2005)

We manufacture the following standard metal products:

Flight stairs, platforms, stepladders and their guards according to series 1.450.3-7.94.2:

Flight stairs, landings, stepladders and their railings according to series 1.450.3-3.2:

Steel stepladders for wells according to:

Steel marking 255

When marking C255 steel, certain standards are used that allow you to quickly determine the basic properties of the metal. Decryption is carried out as follows:

- The first letter C indicates that the metal is applicable in construction.

- The numbers used for marking indicate the fluidity of the finished product, which is measured in N/mm 2.

- Often the markings are applied to the surface of the workpieces with yellow insoluble paint.

Download GOST 27772-88

For this brand, the requirements of GOST 27772-88 apply. They determine the possibility of using the material in the manufacture of angles, bent profiles and channels, and I-beams. The cross-sectional thickness of the manufactured elements must be no less than 4 mm and no more than 30 mm.

You may also be interested in the following articles:

Steel 10 (carbon quality) Steel 35 structural carbon quality

Steel grade C225 is used for the production of sheet and profile metal products intended for installation and assembly of critical metal structures with bolted, riveted, welded and seam joints. The brand is most popular and in demand in the construction industry, which has no restrictions when performing welding work.

Explanation of markings

When deciphering the C255 steel grade, it should be taken into account that:

- the sign “C” in front of the numbers indicates the main purpose of the steel – use in construction;

- “255” is the value of the yield strength of rolled metal, the sign is applied to the surface of the metal.

Products are manufactured in accordance with GOST in the form of:

- sheet and profile products;

- corners and I-beams;

- special channels;

- smooth and diamond-corrugated sheets;

- bent profiles of various configurations.

All rolled products are manufactured in accordance with technical requirements - with a section thickness of elements of no less than 4 mm and no more than 30 mm.

Russian structural alloys of ordinary quality of carbon categories are recognized as analogues of steel grade C255 according to GOST 27772-88. They represent variations of the St3 brand, which differ:

- carbon content;

- strength indicator;

- degree of deoxidation – ps and sp.

Decoding steel C255

Marking C means that this steel is intended for use in construction, and the number 255 determines the yield strength of the finished steel in N/mm 2. It is applied to the metal surface with yellow insoluble paint.

GOST

Requirements for metal must comply with GOST 27772-88, which defines technical conditions for the production of rolled products for metal structures in construction. In accordance with the state standard, the following are made from steel C255: angles, I-beams, channels, bent profiles of various configurations, as well as smooth and corrugated metal sheets. The cross-sectional thickness of rolled elements cannot be more than 30 mm and less than 4 mm.

Compound

The mass fraction of the elements that make up this steel is given in the table of the state standard:

- about 97% iron (Fe);

- 0.22% carbon (C);

- 0.65% manganese (Mn);

- 0.15-0.3% silicon (Si);

- 0.3% chromium (Cr), nickel (Ni) and copper (Cu);

- 0.2% aluminum (Al);

- 0.05% sulfur (S);

- 0.04% phosphorus (P).

When using ores from individual deposits, an increased manganese content of 0.2% and the presence of arsenic are allowed, but not more than 0.12%.

Analogues of steel C255

Based on the chemical composition and mechanical properties, the state standard defines the following domestic brands as analogues of C255:

- VSt3sp5, VSt3ps5 and VSt3ps6;

- St3Gps and St3Gsp;

- 18sp, 18Gps and 18Gsp.

Among the foreign analogues for ISO 630 standardization, the following should be mentioned:

- Fe 360-B (E 235-B)

- Fe 360-C (E 235-C)

- Fe 360-D (E 235-D).

steel grade, analogues, explanation, characteristics

In the production of metal structures, C245 steel is a low-carbon grade used for building structures.

Chemical composition

Steel consists of approximately:

- 98% iron,

- 0.2% carbon,

- 0.65% manganese,

- from 0.05 to 0.015% silicon,

- up to 0.3% chromium, nickel and copper combined.

The presence of up to 0.05% sulfur, 0.04% phosphorus and 0.08% arsenic is allowed.

Decoding steel C245

In the designation of steel, the letter C means “construction”, the numbers 245 are the yield strength (T) in megapascals (MPa). In more conventional units σT = 24.5 kg/sq. mm.

Among other parameters characterizing the mechanical properties of steel, we note the tensile strength = 370 MPa (37 kg/sq. mm).

Weldability

To assess weldability, use the criterion of carbon equivalent, calculated by the formula

Se=C+G/6+X/5+(N+D)/15, where C, G, X, N, D – the amount of carbon, manganese, chromium, nickel and copper as a percentage in the composition of the steel or alloy.

For C245, the equivalent carbon is below 0.25%, which means good weldability. The weld seam is not prone to the formation of hot and cold cracks. Parts can be welded by any method without additional measures - preheating, forging the heat-affected zone, etc.

Plastic

Plastic qualities, i.e. the ability to deform in a cold state without signs of destruction, are characterized by the relative elongation of the sample at break and the size of the yield area.

Steel C245 has a relative elongation at break, i.e., the elongation of the sample relative to the initial size after fracture, of 25%.

The length of the yield plateau, i.e. the change in relative elongation at which the stress does not change, is at least 2.5%.

This indicates the possibility of bending and stamping thin sheets of steel. For thick ones, local heating should be used to avoid cracks.

To understand the difference in the deformation capacity of thin and thick sheets, you should refer to the course on strength of materials. When bending a sheet, the difference in changes in the dimensions of the outer and inner sides will be greater, the greater the thickness. This means that for a thick sheet, the relative deformation will be greater and the probability of destruction - the appearance of cracks - will be higher.

With increasing temperature, the yield strength of the metal decreases, and the yield area increases. Therefore, to deform a thick steel sheet, it must be heated or the bend radius increased.

Corrosion resistance

Alloying components—silicon, copper, etc.—slightly increase the corrosion resistance of steels.

C245 has moderate oxidation resistance. It is sufficient for inter-operational storage of workpieces, as well as for operation inside dry rooms without additional protection. In other cases, paint and varnish coatings corresponding to the operating conditions of the structure should be applied.

Analogs

According to GOST 27772-88, steel grade C245 corresponds to:

- St3ps5 and St3sp5 according to GOST 380 and GOST 535 (Appendix 1 GOST 27772-88)

- VSt3ps6 according to GOST 380-71 (Table 51b appendix 1 SNiP II-23-81)

- VSt3ps6-1 according to TU 14-1-3023–80 (Table 51b, Appendix 1, SNiP II-23-81)

- 18ps according to GOST 23570–79 (Table 51b appendix 1 SNiP II-23-81)

- E235-B, E235-C, Fe 360-B and Fe 360-C according to ISO 630:1995 (Appendix A GOST 380-2005)

Application

Grade C245 is used for the production of sheet and shaped rolled products - equal and unequal angles, channels, T-beams, I-beams. Rolled steel is used in the production of metal structures for various purposes. Due to their good weldability, welded joints are widely used in their production.

Particularly critical structures operating under conditions of constant increased vibration loads are required to be connected with rivets or other methods that prevent the spread of possible cracks.

As analogues of steel grade C245 we can name steel St.3ps, steel St.3sp, which are similar in mechanical properties and chemical composition. It should be noted that a mandatory requirement is the complete or partial completion of deoxidation of steels before the process of casting into molds. This is indicated by the letters ps and sp in the designation of brands.

Low-alloy structural steel C245 has properties that meet the requirements for metal structures for general use.

It can be welded well by all types of welding without additional measures to reduce red and blue brittleness.

The steel has average corrosion resistance. This requires the use of protective paint and varnish coatings for metal structures made from the described steels used outdoors.

Rating: 0/5 — 0 votes

Types of processing and application

The amount of carbon and alloying additives in the chemical composition of C255 steel allows the use of any types of welding to connect parts and structural elements. Thermal, laser, hydraulic and mechanical processing technologies can be used for cutting rolled products and cutting sheets. It is noted that drilling, milling and threading are quite simple.

In construction, rolled steel C255 is used for the installation of metal structures of group 1, which includes welded elements designed to work in particularly difficult conditions. Including under vibration, dynamic and moving loads. The first group includes structural elements of bridge spans, supports for power lines, crane beams, load-bearing trusses, overpasses, stairs and others.

It is allowed to use rolled steel grades in other types of industrial production except construction. For example, for the manufacture of housings and load-bearing elements in mechanical engineering.

This page shows the technical, mechanical and other properties, as well as the characteristics of steel grade C255.

Classification of material and application of grade C255

Grade: C255 Material classification: Steel for building structures Application: production of rolled products intended for building steel structures with welded and other connections

Chemical composition of material C255 in percentage terms

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to 0.22 | 0.15 — 0.3 | up to 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.012 | up to 0.3 |

Mechanical properties of C255 at a temperature of 20 o C

| Assortment | Size | Eg. | s in | s T | d 5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Sheet, GOST 27772-88 | 2 — 3.9 | 380 | 255 | 20 | ||||

| Sheet, GOST 27772-88 | 4 — 10 | 380 | 245 | 25 | ||||

| Sheet, GOST 27772-88 | 10 — 20 | 370 | 245 | 25 | ||||

| Sheet, GOST 27772-88 | 20 — 40 | 370 | 235 | 25 |

Technological properties of C255

Purpose and application

Steel of this grade is intended for building structures; it is specially produced for use in the construction of steel structures with welded and other connections.

This brand contains all the necessary additives for long-term operation of structures. This brand is also used in the production of hot-rolled products - channels, including special ones, I-beams, angles, sheets, wide-band universal rolled products and bent profiles. The metal is also used in other industries.

In terms of quality, all grades of steel can be of ordinary quality, high quality, high quality and high quality. Based on their chemical composition, they are divided into carbon and alloyed. Quality refers to the combination of properties that are created during the steel manufacturing process. These include chemical composition, uniformity of metal structure, mechanical properties and manufacturability.

Physical and mechanical properties

All characteristics and physical properties at different temperatures and other conditions:

- hardness - HB 10-1 = 131 MPa;

- specific gravity - 7700-7900 kgf/m2

At a temperature of 20°C, steel grade C245, assorted sheets with dimensions of 2-3.9 mm, has the following mechanical properties at a temperature = 20°C:

- temporary tensile strength (tensile strength limit) - 370 MPa;

- proportionality limit (yield strength with residual deformation) - 245 MPa;

- relative elongation of the material after rupture - 20%;

- steel sheet measuring 4-10 mm has almost similar mechanical characteristics, differing only in one indicator - relative elongation after break, it is 25%.

Chemical and technological properties of steel C245

The chemical composition of steel grade C245 is given as a percentage according to GOST 27772-88

- Carbon - up to 0.22%.

- Manganese - no more than 0.65%.

- Silicon - within 0.05-0.15%.

- Sulfur - up to 0.050%.

- Phosphorus - within 0.040%.

- Chromium, nickel and copper - up to 0.30%.

- Arsenic - up to 0.08%.

The chemical composition of the finished alloy is guaranteed by the manufacturer; steel processing is allowed with synthetic slags, argon blowing, evacuation, and modification of the metal with rare earth elements and calcium. They are introduced into it by calculation - up to 0.05% of rare earth elements and within 0.02% of calcium.

- Weldability - no restrictions.

- Flock sensitivity - not sensitive.

- The tendency to temper brittleness has not been established.

All technological properties of steel accurately reflect the tendency of a given grade to certain deformations that finished products will experience under certain conditions. This is due to technological processing or operating conditions of the metal.

The relatively low cost of production allows us to produce various grades of steel in large and small batches. A number of properties, such as manufacturability, chemical composition, mechanical properties, have helped this material become the main one in the production of tools, devices, mechanical engineering and the construction of metal structures. Such valuable properties and qualities of the metal ensure trouble-free operation of finished products.

Other brands in this category:

Please note that this information about the C255 brand is provided for informational purposes. The parameters, properties and composition of the actual C255 grade material may differ from the values given on this page. More detailed information about the C255 grade can be found on the information resource Brand of steel and alloys. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation!

Brand: C255 Class: Steel for building structures Use in industry: production of rolled products intended for building steel structures with welded and other connections Weldability of the material: without restrictions.

Steel grade C255 is one of the most popular and in demand in the construction industry, as it is endowed with excellent strength characteristics and has no restrictions in weldability. It is supplied to sites in the form of rolled products (including shaped pieces) for subsequent use as part of all kinds of metal structures (connection - welding or any other).

S285

| Brand: | S285 |

| Substitute: | St3sp, St3Gps, St3Gsp |

| Classification: | Steel for building structures |

| Application: | production of rolled products intended for building steel structures with welded and other connections |

| Foreign analogues: | Known |

Chemical composition in % of material C285

GOST 27772-88

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to 0.22 | 0.15- 0.3 | up to 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.012 | up to 0.3 |

| Note: Manganese content up to 0.85% is allowed |

Technological properties of material C285.

| Weldability: | no limits. |

Mechanical properties at T=20oC of material C285.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Sheet, GOST 27772-88 | 2-3.9 | 390 | 285 | 17 | ||||

| Sheet, GOST 27772-88 | 4-10 | 390 | 275 | 24 | ||||

| Sheet, GOST 27772-88 | 10-20 | 380 | 265 | 23 |

Foreign analogues of material C285 Attention! Both exact and closest analogues are indicated

| USA | Germany | Japan | France | England | European Union | Italy | China | Sweden | Poland | Czech | Austria |

| — | DIN,WNr | JIS | AFNOR | B.S. | EN | UNI | G.B. | SS | PN | CSN | ONORM |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, |

| sT | - Proportional limit (yield limit for permanent deformation), |

| d5 | - Relative elongation at break, |

| y | -Relative narrowing, |

| KCU | -Impact strength, [kJ/m2] |

| HB | - Brinell hardness, |

| Physical properties: | |

| T | -Temperature at which these properties are obtained, |

| E | -Elastic modulus of the first kind, |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, |

| Weldability: | |

| no limits | -welding is performed without heating and without subsequent heat treatment |

| limited weldability | -welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | - to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding-annealing |

C285-Steel for building structuresC285-chemical composition, mechanical, physical and technological properties, density, hardness, application

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells C285 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, C285 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Material C285 buy in Chelyabinsk

Individual cost is built through personal communication with each potential customer. Managers take into account the volume of the transaction, offer discounts to regular customers and maintain an open dialogue. As a result, even when controversial situations arise, we are able to find a compromise and come to a solution that satisfies both parties.

Delivery

Logistics work is included in the package of our professional services. We constantly improve our knowledge, acquire the latest equipment, so that the cargo is delivered anywhere in Russia.

The presence of our own railway sidings significantly increases the speed of shipment and subsequent delivery. Having such resources, we guarantee delivery of cargo of any volume and dimensions. This professional approach makes us leaders in the metal products market.

Steel S255: chemical composition and GOST standards for rental

Carbon steel C255 (carbon share is about 0.2%) is produced in accordance with GOST 27772-88, which determines the following composition of the chemical elements of the steel alloy:

- Fe – about 97%

- C – up to 0.22%

- Mn – up to 0.65%

- Si – 0.15-0.3%

- Ni – up to 0.3%

- Cr – up to 0.3%

- Cu – up to 0.3%

- S – up to 0.05%

- P – up to 0.04%

- N – up to 0.012%

Hot rolled shaped steel C255:

- GOST 8509 – equal angle angle

- GOST 8510 – unequal corner

- GOST 8239, 26020 – I-beam

- GOST 8240 – channel

- GOST 19425 – I-beam and special channel

In addition, carbon steel 255 is used for the production of rolled products:

- GOST 19903 – sheet

- GOST 82 – universal broadband

- GOST 8568 – sheet metal with lentil and rhombic corrugation

Bent profiles are also made from steel of this grade: according to GOST 7511, 8278, 8281, 8282, 8283, 9234, etc.

S255

S255 Chelyabinsk

| Brand: | S255 |

| Substitute: | St3Gps, St3Gsp |

| Classification: | Steel for building structures |

| Application: | production of rolled products intended for building steel structures with welded and other connections |

| Foreign analogues: | No data |

Chemical composition in % of material C255

GOST 27772-88

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to 0.22 | 0.15- 0.3 | up to 0.65 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.012 | up to 0.3 |

| Note: Manganese content up to 0.85% is allowed |

Technological properties of material C255.

| Weldability: | no limits. |

Mechanical properties at T=20oC of material C255.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| Sheet, GOST 27772-88 | 2-3.9 | 380 | 255 | 20 | ||||

| Sheet, GOST 27772-88 | 4-10 | 380 | 245 | 25 | ||||

| Sheet, GOST 27772-88 | 10-20 | 370 | 245 | 25 | ||||

| Sheet, GOST 27772-88 | 20-40 | 370 | 235 | 25 |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, |

| sT | - Proportional limit (yield limit for permanent deformation), |

| d5 | - Relative elongation at break, |

| y | -Relative narrowing, |

| KCU | -Impact strength, [kJ/m2] |

| HB | - Brinell hardness, |

| Physical properties: | |

| T | -Temperature at which these properties are obtained, |

| E | -Elastic modulus of the first kind, |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, |

| Weldability: | |

| no limits | -welding is performed without heating and without subsequent heat treatment |

| limited weldability | -welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | - to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding-annealing |

C255-Steel for building structuresC255-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

Material S255 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells C255 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, C255 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Material C255 buy in Chelyabinsk

Individual cost is built through personal communication with each potential customer. Managers take into account the volume of the transaction, offer discounts to regular customers and maintain an open dialogue. As a result, even when controversial situations arise, we are able to find a compromise and come to a solution that satisfies both parties.

Delivery

Logistics work is included in the package of our professional services. We constantly improve our knowledge, acquire the latest equipment, so that the cargo is delivered anywhere in Russia.

The presence of our own railway sidings significantly increases the speed of shipment and subsequent delivery. Having such resources, we guarantee delivery of cargo of any volume and dimensions. This professional approach makes us leaders in the metal products market.

Application of steel grade C255

Builders distinguish 4 groups of building metal structures, classified according to the degree of their responsibility and the conditions of their operation. The most demanding is the first group, which includes welded structures forced to work in particularly difficult conditions, including those exposed to fairly large vibration, dynamic and moving loads. In this case, it is allowed to use only the steel grade C255 we are considering, as well as C285, C345 or C375.

The first group includes such structures as elements of bridge spans, power transmission line supports, crane beams, unloading and bunker overpasses, transport galleries, trusses, etc.

Material S255 Chelyabinsk

When choosing products sold by our company, you can always count on high quality, including when purchasing C255 material . This confidence is underlined by years of experience and qualified personnel. Mutually beneficial cooperation and respect towards the customer are the main criteria of our work.

The buyer can choose C255 material based on his needs. All necessary parameters, scope of use, dimensions, as well as individual characteristics are taken into account. Thus, during subsequent production, construction or other purposes, the customer minimizes waste as much as possible, saving money and his own time.

Each material, made in accordance with generally accepted rules, has the declared characteristics. In addition to sales, our company is ready to perform product testing. All activities are carried out using high-precision equipment, and the data is generated in a clear, accessible format.

Thanks to extensive experience and cooperation with leading manufacturing plants, delivery of large volumes is available to customers. The cargo is delivered, including, regardless of size and shape, this is taken into account due to the specifics of the metallurgical sector.

A huge assortment can make it difficult to choose goods and services. Therefore, we constantly improve the qualifications of our staff, who can provide advice on both technical and financial issues.

Prices for steel sheets

In APEX metal you can buy sheet steel 3 in sheets and rolls at a low price:

- for use in construction

- manufacturing of general purpose products, pipes, bent profiles

Depending on the purpose, steel sheet 3 is produced from grades with different chemical compositions and properties in accordance with GOST 380, GOST 19281, GOST 27772, TU.

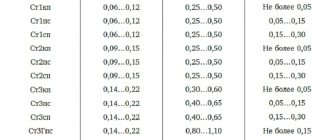

- Thin-sheet and thick-sheet hot-rolled products are made from steel Z of ordinary quality with a chemical composition that must meet the requirements of GOST 380:

| steel grade | Mass fraction of chemical elements, % | |||||||||

| C | Mn | Si | S | P | N | Cr | Ni | Cu | As | |

| St3kp | 0,14. 0,22 | 0,30. 0,60 | 0,05. 0.07 | up to 0.05 | 0,04 | 0,012 | up to 0.30 | up to 0.30 | up to 0.30 | up to 0.08 |

| St3ps | 0,14. 0,22 | 0,40. 0,65 | 0,05. 0,15 | |||||||

| St3sp | 0,14. 0,22 | 0,40. 0,65 | 0,15. 0,30 | |||||||

| St3Gps | 0,14. 0,2 | 0,80. 1,10 | 0,05. 0,15 | |||||||

| St3Gsp | 0,14. 0,2 | 0,80. 1,10 | 0,15. 0,30 | |||||||

- Thick-sheet hot-rolled sheets of high strength steel 3 with a basic chemical composition in accordance with GOST 19281 are produced with regulated or controlled rolling with accelerated cooling to ensure the following strength classes:

- Hot-rolled sheets GOST 27772, intended for the manufacture of welded and other building structures:

General concept

The modulus of elasticity (also known as Young's modulus) is one of the indicators of the mechanical properties of a material, which characterizes its resistance to tensile deformation. In other words, its value shows the ductility of the material. The greater the elastic modulus, the less any rod will stretch, all other things being equal (load magnitude, cross-sectional area, etc.).

In the theory of elasticity, Young's modulus is denoted by the letter E. It is an integral part of Hooke's law (the law on the deformation of elastic bodies). Connects the stress arising in the material and its deformation.

According to the international standard system of units, it is measured in MPa. But in practice, engineers prefer to use the dimension kgf/cm2.

The elastic modulus is determined experimentally in scientific laboratories. The essence of this method is to tear dumbbell-shaped samples of material using special equipment. Having found out the stress and elongation at which the sample failed, divide these variables by each other, thereby obtaining Young's modulus.

Let us immediately note that this method is used to determine the elastic moduli of plastic materials: steel, copper, etc. Brittle materials - cast iron, concrete - are compressed until cracks appear.

Additional characteristics of mechanical properties

The modulus of elasticity makes it possible to predict the behavior of a material only when working in compression or tension. In the presence of such types of loads as crushing, shear, bending, etc., additional parameters will need to be introduced:

- Stiffness is the product of the elastic modulus and the cross-sectional area of the profile. By the value of rigidity, one can judge the plasticity not of the material, but of the structure as a whole. Measured in kilograms of force.

- Relative longitudinal elongation shows the ratio of the absolute elongation of the sample to the total length of the sample. For example, a certain force was applied to a rod 100 mm long. As a result, it decreased in size by 5 mm. Dividing its elongation (5 mm) by the original length (100 mm) we obtain a relative elongation of 0.05. A variable is a dimensionless quantity. In some cases, for ease of perception, it is converted to percentages.

- Relative transverse elongation is calculated similarly to the point above, but instead of length, the diameter of the rod is considered here. Experiments show that for most materials, transverse elongation is 3-4 times less than longitudinal elongation.

- The Punch ratio is the ratio of the relative longitudinal strain to the relative transverse strain. This parameter allows you to fully describe the change in shape under the influence of load.

- The shear modulus characterizes the elastic properties when the sample is exposed to tangential stresses, i.e., in the case when the force vector is directed at 90 degrees to the surface of the body. Examples of such loads are the work of rivets in shear, nails in crushing, etc. By and large, the shear modulus is associated with such a concept as the viscosity of the material.

- The bulk modulus of elasticity is characterized by a change in the volume of the material for uniform, versatile application of load. It is the ratio of volumetric pressure to volumetric compressive strain. An example of such work is a sample lowered into water, which is subject to liquid pressure over its entire area.

Read also: Internet wire crimp colors

In addition to the above, it should be mentioned that some types of materials have different mechanical properties depending on the direction of loading. Such materials are characterized as anisotropic. Vivid examples are wood, laminated plastics, some types of stone, fabrics, etc.

Isotropic materials have the same mechanical properties and elastic deformation in any direction. These include metals (steel, cast iron, copper, aluminum, etc.), non-laminated plastics, natural stones, concrete, rubber.

Construction steel grades - analogues and replacement

One of the important characteristics of construction rolled steel 3 is its resistance to brittle fracture. To confirm these properties, samples of steel sheets undergo impact bending tests at decreasing temperatures.

The level of resistance to brittle fracture of rolled sheets in accordance with GOST 27772 is guaranteed by the required value of impact strength (KCU - when tested for impact bending with a U concentrator). For steels smelted according to EN standards, this value is the fracture coefficient (KV).