Characteristics of steel grade 09GSF

09GSF - Structural alloy steel with increased corrosion resistance and cold resistance. Can be welded without restrictions, welding methods: manual arc welding, automatic submerged arc welding and gas shield, AF, MP, ESh and CT. If there is a significant amount of welding, a subsequent tempering is recommended. There is a tendency to temper brittleness. It has found its application for the manufacture of pipe blanks and seamless hot-deformed oil and gas pipeline pipes with increased corrosion resistance and cold resistance, intended for use in gas transporting systems, oil and gas pipeline systems, technological field pipelines transporting oil and petroleum products, as well as in systems for maintaining reservoir pressure in the northern climate zone at ambient temperatures from -60°C to +40°C, temperature of transported media from +5°C to +40°C and operating pressure up to 7.4 MPa; for the production of electric-welded expanded straight-seam pipes with increased corrosion resistance and cold resistance, used for gas pipelines, process and field pipelines for operating pressures up to 7.4 MPa, transporting oil and petroleum products, for pipelines for maintaining reservoir pressure in any climatic zones. The pipes differ from conventional oil and gas pipelines in accordance with GOST 8731, GOST 8732, by increased cold resistance, increased resistance to general and pitting corrosion, resistance to sulfide corrosion cracking and the formation of hydrogen cracks.

Steel 09G2S - low-alloy structural steel for welded structures

Steel substitutes:

- 09GS,

- 09G2DT,

- 09G2T,

- 10G2S

Foreign analogues:

- TSt E 355 (1.0566) - Germany DIN

- A590 AZ, A 36-207 - France (AFNOR)

IMPORTANT!!! The possibility of replacement is determined in each specific case after assessing and comparing the properties of steels

Type of delivery

Long products, including shaped steel: GOST 19281-73, GOST 2590-88, GOST 2591-88, GOST 8239-89, GOST 8240-89. Thick sheet GOST 19281-89, GOST 5520-79, GOST 5521-93, GOST 19903-74. Thin sheet GOST 17066-80, GOST 19903-74, GOST 19904-74. Strip GOST 103-76, GOST 82-70.

Forgings and forged blanks GOST 1133-71.

Purpose

Parts of apparatus and vessels operating at temperatures from -70°C to +475°C under pressure.

In steam and hot water pipelines - parts made of sheet metal - up to a temperature of 450°C, pipes - up to a temperature of 425°C, in boilers - sheet parts operating at temperatures up to 450°C, in all cases without pressure limitation. Fasteners in boilers and pipelines are used up to temperatures of 425°C and pressures of up to 10 N/mm2.

Steel grade 09G2S must be tested for tension at elevated temperatures.

As a result of such tests, the yield strength at 320 °C for sheets of steel grade 09G2S with a thickness of 60 mm and more should be at least 18 kg/mm2

Interpretation of steel 09G2S

The two-digit number 09 indicates the approximate carbon content in steel in hundredths of a percent, i.e. The carbon content in steel is approximately 0.09%.

Beech G means that the steel contains manganese in an amount of about 2%.

The letter C means that the steel contains silicon.

Chemical composition, % (GOST 19281-2014)

C, carbonMn, manganeseSi, siliconP, phosphorusS, sulfurCr, chromiumNi, nickelCu, copperAs, arsenicN, nitrogenmore

| 0,12 | 1,3-1,7 | 0,5-0,8 | 0,035 | 0,040 | 0,30 | 0,30 | 0,30 | 0,08 | 0,008 |

Application of steel 09G2S for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| steel grade | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| Sheets GOST 5520, categories 7, 8, 9 depending on the wall temperature | -70 to 200 | For welded components of reinforcement operated in a macroclimatic region with a cold climate | |

| Category 6 | -40 to 200 | ||

| Categories 3, 5 | -30 to 200 | ||

| Category 12, 17 | -40 to 475 | ||

| Category 15, 17 | -70 to 475 | ||

| Sheets GOST 19281, category 3 | -30 to 200 | ||

| Category 4 | -40 to 200 | ||

| Category 12 | -40 to 475 | ||

| Categories 7, 15 | -70 to 200 |

Application of steel 09G2S for reinforcement fasteners (GOST 33260-2015)

| Steel grade, according to GOST 1759.0 | Standard or specification for material | Application options | |||||

| Bolts, studs, screws | Nuts | Flat washers | |||||

| Ambient temperature, °C | Nominal pressure, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure, MPa (kgf/cm2) | ||

| 09G2S | GOST 19281 | -70 to 425 | 16 (160) | -70 to 425 | 16 (160) | -70 to 450 | Not regulated |

Maximum permissible temperatures for the use of 09G2S steel in environments containing ammonia

| steel grade | Steel application temperature, °C at ammonia partial pressure, MPa (kgf/cm2) | ||

| St. 1(10) to 2(20) | St. 2(20) to 5(50) | St. 5(50) to 8(80) | |

| 09G2S | 300 | 300 | 300 |

NOTE The conditions of use are established for a corrosion rate of the nitrogen layer of no more than 0.5 mm/year.

Maximum permissible temperature for using 09G2S steel in hydrogen-containing environments

| steel grade | Temperature of steel application, °C at partial pressure of hydrogen, MPa (kgf/cm2) | ||||||

| 1,5(15) | 2,5(25) | 5(50) | 10(100) | 20(200) | 30(300) | 40(400) | |

| 09G2S | 290 | 280 | 260 | 230 | 210 | 200 | 190 |

Yield strength σ0.2 (GOST 5520-79)

| σ0.2, MPa, at test temperature, °C | |||

| 250 | 300 | 350 | 400 |

| 225 | 195 | 175 | 155 |

Mechanical properties

| GOST | Delivery status | Section, mm | σ0.2, MPa, | σв, MPa, | δ5 (δ4), % |

| no less | |||||

| GOST 19281-2014 | Long and shaped rolled products | To 10 | 345 | 490 | 21 |

| GOST 19281-2014 | Sheet and strip (transverse samples) | From 10 to 20 incl. | 325 | 470 | 21 |

| From 20 to 32 incl. | 305 | 460 | 21 | ||

| St. 32 to 60 incl. | 285 | 450 | 21 | ||

| St. 60 to 80 incl. | 275 | 440 | 21 | ||

| St. 80 to 160 incl. | 265 | 430 | 21 | ||

| GOST 19281-2014 | Sheet after quenching and tempering (transverse samples) | From 10 to 32 incl. | 365 | 490 | 19 |

| From 32 to 60 incl. | 315 | 450 | 21 | ||

| GOST 17066-94 | Hot rolled sheet | 2 — 3,9 | — | 490 | (21) |

Mechanical properties at elevated temperatures

| tsp., °C | σ0.2, MPa | σв, MPa | δ5, % | Ψ, % |

| 20 | 300 | 460 | 31 | 63 |

| 300 | 220 | 420 | 25 | 56 |

| 475 | 180 | 360 | 34 | 67 |

Note : Normalization at 930-950 °C.

Mechanical properties depending on tempering temperature

| tref., °C | σ0.2, MPa | σв, MPa | δ5, % | Ψ, % |

| 20 | 295 | 405 | 30 | 66 |

| 100 | 270 | 415 | 29 | 68 |

| 200 | 265 | 430 | — | — |

| 300 | 220 | 435 | — | — |

| 400 | 205 | 410 | 27 | 63 |

| 500 | 185 | 315 | — | 63 |

Impact strength KCU

GOST Delivery conditionSection, mmKCU, J/cm2, at temperature, °C+20-40-70

| GOST 19281-89 | Long and shaped rolled products | From 5 to 10 From 10 to 20 incl. From 20 to 100 incl. | 645959 | 393434 | 3429— |

| Leaf and strip | From 5 to 10 From 10 to 160 incl. | 6459 | 3934 | 3429 | |

| Sheet after quenching and tempering (transverse samples) | From 10 to 60 | — | 49 | 29 |

Technological properties

Forging temperature, °C: beginning 1250, end 850. Weldability - weldable without restrictions. Welding methods: RDS, ADS submerged and gas shielded, ESW.

Cutting machinability - Kv tv.spl = 1.0 and Kv b.st = 1.6 in the normalized, tempered state at σв = 520 MPa.

Tendency to temper brittleness - not prone.

Flock sensitivity - not sensitive.

Chemical composition of steel 09GSF

| Standard | C | S | P | Mn | Cr | Si | Ni | Cu | N | As | Al | V | Mo | Zn | Sn | Sb | Pb | Bi | Nb |

| TU 1383-010-48124013-03 | up to 0.12 | up to 0.005 | up to 0.018 | up to 0.7 | up to 0.3 | up to 0.7 | up to 0.3 | up to 0.3 | up to 0.008 | up to 0.01 | 0.02-0.05 | 0.04-0.12 | — | up to 0.001 | up to 0.001 | up to 0.001 | up to 0.001 | up to 0.001 | — |

| TU 1381-116-00186654-2013 | up to 0.13 | up to 0.005 | up to 0.015 | up to 0.7 | up to 0.3 | up to 0.7 | up to 0.3 | up to 0.3 | up to 0.01 | — | 0.02-0.05 | 0.04-0.12 | up to 0.2 | — | — | — | — | — | up to 0.04 |

| TU 39-0147016-123-2000 | 0.07-0.12 | up to 0.01 | up to 0.02 | 0.5-0.8 | up to 0.3 | 0.5-0.8 | up to 0.3 | up to 0.3 | up to 0.012 | — | 0.02-0.05 | 0.04-0.12 | — | — | — | — | — | — | 0.015-0.06 |

| TU 14-158-116-99 | 0.07-0.12 | up to 0.01 | up to 0.02 | 0.5-0.8 | up to 0.3 | 0.5-0.8 | — | — | — | — | 0.02-0.06 | 0.08-0.15 | — | — | — | — | — | — | — |

According to TU 1383-010-48124013-03, to ensure fine grain size and nitrogen binding into nitrides and carbonitrides, it is allowed to introduce titanium and niobium in amounts of no more than 0.030% and 0.040%, respectively. It is allowed to alloy steel with chromium and molybdenum in amounts not exceeding 0.40% and 0.30%, respectively. To globularize non-metallic inclusions, steel is deoxidized with silicocalcium or cerium. Total Nb+V+Ni content ≤ 0.15%.

According to TU 39-0147016-123-2000, the introduction of titanium up to 0.030% is allowed.

According to TU 1381-116-00186654-2013, the chemical composition is given for steel grade 09GSF. The mass fraction of calcium in steel should be no more than 0.0050% (50ppm). To globularize inclusions, steel is treated with calcium-containing materials. Alloying of steel with rare earth metals is allowed. The Ca/S ratio is not less than 1, deviation from the regulated Ca/S ratio is allowed, provided that compliance with the requirements of the specifications for corrosion characteristics is ensured. It is allowed to add titanium to obtain a mass fraction in steel of no more than 0.030%. The steel must be subjected to vacuum degassing: the mass fraction of hydrogen in liquid steel after degassing should be no more than 2.5 ppm. The mass fraction of hydrogen is taken according to the document on the quality of rolled sheets. When the hydrogen content is more than 2.5 ppm, the slabs must be subjected to anti-floken treatment (APT) in heated or unheated rings. Mass fraction of Nb+V no more than 0.15%. Permissible deviations in chemical composition: carbon +0.010%, manganese +0.020%, silicon ±0.050%, sulfur +0.0010%, phosphorus +0.0030%, aluminum +0.010%, copper +0.050 %, for nickel +0.050, for chromium ±0.050%, for vanadium +0.020%, for nitrogen +0.0010%. The carbon equivalent value should not exceed 0.43, and the cracking resistance parameter Pcm should not exceed 0.24.

According to TU 14-158-116-99, the chemical composition is given for steel grade 09GSF. The total aluminum content in steel should be in the range of 0.02-0.06%. It is allowed to introduce titanium in amounts up to 0.030%. Other requirements and deviations are in accordance with the requirements of TU 14-1-1921 and GOST 19281. The carbon equivalent is determined in each heat and should not exceed 0.43%

How to distinguish steel 3 from 09g2s

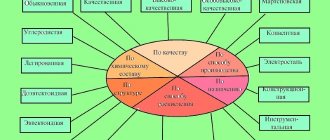

High strength steel grades

Steel is one of the most important materials that is used in almost all industries. Depending on the application, high-strength steel has different requirements. Steel grades differ in structure, chemical composition and in their properties (physical and mechanical).

Steel is a deformable alloy of iron with carbohydrate (no more than 2 percent) and admixtures of other elements: manganese, silicon, phosphorus. Special requirements are placed on high-strength fasteners. Therefore, to obtain steel that will ideally meet all characteristics, special impurities are added - alloying elements.

These are chromium, tungsten, vanadium, titanium, manganese or silicon.

Steel 20

Quality carbon structural steel

pipes for superheaters, manifolds and pipelines of high-pressure boilers, sheets for stamped parts, cemented parts for long and very long service at temperatures from -40 to 350 degrees.

STEEL GRADE 3

Regular quality carbon steel. This type of steel is in greatest demand in construction. The reason for this popularity is manufacturability, durability and an attractive price.

Another advantage of this alloy is the ability to make products from it that can withstand heavy loads and have good impact resistance. Steel 3 is produced according to GOST 380-94, according to which steel is marked with the letters “St” with a serial number from 0 to 6.

The higher this number, the greater the amount of carbon contained in the steel. This means better strength, but worse plastic characteristics. Steel 3 welds well, is non-flocene sensitive, and is not prone to temper brittleness.

Steel 3 contains: carbon – 0.14-0.22%, silicon – 0.05-0.17%, manganese – 0.4-0.65%, nickel, copper, chromium – no more than 0.3%, arsenic no more than 0.08%, sulfur and phosphorus - up to 0.05 and 0.04%. The amount of these components in the St3 alloy is not allowed above the specified values. The basis of steel is ferrite.

Its characteristics do not allow it to be used in its pure form. To improve the strength of ferrite, steel is saturated with carbon, chromium, nickel, silicon, manganese are added (alloyed) and additional thermal hardening is carried out.

Steel 3 withstands a wide temperature range under variable loads. It welds well, is stamped in cold and hot conditions, and is drawn. Can be used without heat treatment.

Weldability of steel 3

Without restrictions - welding is performed without heating and without subsequent heat treatment. In steel classified as good, the carbon content is less than 0.25%. They are welded without the formation of hardening structures and cracks in a wide range of welding conditions. Application temperature

Steel application temperature 3

The minimum application temperature (the temperature of the coldest five-day period in the region) is minus 30. The maximum application temperature is plus 300.

STEEL GRADE 35

High quality medium carbon steel. This type of steel is used for parts that require high ductility and impact resistance.

High-quality carbon steels of type 35 are manufactured according to GOST 1050-88 and are marked with two-digit numbers that indicate the average carbon content in hundredths of a percent. For example, steel 35 (0.35%).

It has high strength (σв = 640...730 MPa, σ0.2 = 380...430 MPa) and relatively low ductility (δ = 9...14%, ψ = 40...50%).

In addition, this type of steel is not susceptible to medium stress, is resistant to deformation and wear, and is not subject to cracking and corrosion. Therefore, steel 35 is used in the production of high-strength fasteners and flange connections. Temperature range: -40 to +450 degrees Celsius

35 steel has limited weldability. Methods of welding RDS, ADS submerged arc and gas shield, ESW. We recommend heating and subsequent heat treatment. CTS without restrictions.

Mechanical properties of steel 09GSF

| Type of delivery | Section, mm | sТ|s0.2, MPa | σB, MPa | d5, % | KCU, kJ/m2 | H.R.C. | HRB | HV, MPa |

| Rolled sheets for pipes according to TU 1381-116-00186654-2013. Transverse samples. KCU-60°С/KCV-40°С | ≥375 | 510-610 | ≥23 | ≥580/590 | — | — | — | |

| Seamless hot-deformed oil and gas pipeline pipes with increased corrosion resistance and cold resistance as delivered according to TU 1383-010-48124013-03 (mechanical properties of pipe metal and KCV-40 °C are indicated) | — | ≥350 | ≥510 | ≥20 | ≥784 | — | ≤92 | — |

| Pipes according to TU 1381-116-00186654-2013. Transverse samples. Column KCU indicates KCV-60°С/KCV-20°С | ≥350 | 510-630 | ≥20 | ≥392/392 | ≤22 | — | ≤250 | |

| Electric-welded straight-seam steel pipes with increased corrosion resistance and cold resistance for gas and oil pipelines according to TU 14-158-116-99. Transverse samples. Column KCU shows KCV values at different test temperatures KCV-20°С/KCV-40°С/KCV-60°С | ≥363 | 510-630 | ≥20 | ≥392/392/392 | — | — | — | |

| Electric-welded straight-seam oil and gas pipes in delivery condition according to TU 39-0147016-123-2000. Transverse samples. The KCU column indicates the value KCU-60 °C | 530-1020 | ≥350 | 510-630 | ≥20 | ≥392 |

Stainless steel

Stainless steel is an alloy type of steel. Depending on the type and brand, stainless steel can be used in a wide variety of fields from the food and chemical industries to construction and architecture.

Stainless steel is divided into three main types:

Corrosion resistant

Heat resistant

· Heat resistant

This type of steel acquires stainless properties by adding chromium. Moreover, the corrosion resistance of the alloy directly depends on the percentage of chromium.

The reason for corrosion resistance is a thin film of insoluble acids that forms during the smelting of chromium-containing metals.

Thus, steel with a chromium content of up to 17% is resistant to corrosion under normal conditions, without exposure to aggressive environments and high temperatures. This type of stainless steel is used in the food industry, some types of light industry, for the manufacture of medical instruments, etc.

Steel with a chromium content of more than 17% is more stable and can withstand high temperatures and various aggressive environments without oxidizing even in strong solutions (up to 50%) of acids.

Stainless steel is extremely resistant to the atmosphere and is the best option for capacitive equipment located in open areas, including in climatic conditions with high humidity.

Stainless steel grade 12x18n10t

Stainless steel 12x18n10t is a high-carbon, corrosion-resistant, non-magnetic structural steel of the austenitic type with the addition of titanium.

In the chemical composition of stainless steel 12x18n10t, in addition to the components required for stainless steel - nickel and chromium, there is also titanium (the element content of less than 1.5% is not indicated in the steel marking).

Stainless steel 12x18n10t has good weldability. After the welding process, it is recommended to post-process the seams. Steel 12x18n10t is resistant to intergranular corrosion after welding.

In mildly aggressive environments, it is allowed to operate parts made of steel 12x18n10t in the temperature range from -196°C to +600°C without changing the properties of the steel. In an aggressive environment, the upper temperature threshold is reduced to +350°C.

Stainless steel 12x18n10t can be used in any area of production. It is mainly used for the manufacture of machine parts and mechanisms operating at temperatures up to 600°C. Steel 12x18n10t (technical stainless steel) is suitable for the construction of welded structures (tanks, pipelines, etc.) in contact with weak solutions of acetic and phosphoric acids, as well as in interaction with alkaline solutions and solutions of acidic salts.

The closest analogue of steel 12x18n10t in terms of chemical composition and physical properties is AISI 321 stainless steel.

Steel 09GSF Moscow and Moscow region

Steel has a wide range of applications in mechanical engineering, manufacturing, construction, shipbuilding, aircraft manufacturing and many other industries. There are many grades of steel, most of them are made to order, there are grades that are constantly in stock due to regular demand. The Resurs company sells 09GSF steel directly from the manufacturer. With constant demand, we are ready to offer mutually beneficial terms for the supply of many grades of steel. Including 09GSF.

The favorable price for the 09GSF brand is determined by the minimum markup and the absence of intermediaries. We take full responsibility for the supplied material and guarantee the quality of delivery. The cost of products is determined by warehouse and logistics costs; we have the ability to supply steel directly from the manufacturer’s plant, this allows our clients to run their business stably.

How to distinguish steel 3 from 09g2s - Metalist's Handbook

Steel 09g2s is a very popular steel, used both in construction and in many industries. There are domestic and foreign analogues of this type. It is most often used for the manufacture of pipes, rolled metal and welded metal structures, the temperature range of which is from -70 to 4250C9 with permissible loads on them).

Steel 09g2s 12: decoding

Understanding how labeling is formed allows you to clearly understand what product the manufacturer represents, as well as its main features. For those who are interested in details about 09g2s, the breakdown of steel is as follows:

- 09 – quantitative fraction of carbon content in the alloy (0.09%);

- G2 is manganese and its part in the entire volume fluctuates around 2% (the exact figure ranges from 1.3 to 2%);

- C - denotes silicon, the absence of numbers after the symbol indicates that it is less than 1%.

Thus, the decoding of 09g2s clearly looks like this:

| Element | , % |

| C (carbon) | up to 0.12 |

| Si (silicon) | 0,5 – 0,8 |

| Mn (magnesium) | 1,3- 1,7 |

| Ni (nickel) | up to 0.3 |

| S (sulfur) | up to 0.04 |

| P (phosphorus) | up to 0.035 |

| Cr (chromium) | up to 0.3 |

| N (nitrogen) | up to 0.008 |

| Cu (copper) | up to 0.3 |

| As (arsenic) | up to 0.08 |

| Fe (iron) | 96-97 |

As can be seen from the table, the interpretation of steel 09g2s is not limited to only three alloying components. In addition to carbon, silicon and manganese, it is supplemented by the following elements: nickel, sulfur, phosphorus, chromium, nitrogen, copper, etc. The percentage component of alloying metals is no more than 1-2 total%.

Marking 09g2s on a steel sheet

Also, for steel 09g2s, not only the alloying level is taken into account, but also other factors. Here are just a few of them that are significant for a particular case:

- constructiveness (purpose);

- eutectoid (structure: hexagonal, cubic, etc.; changes after hardening, etc.);

- production method (open hearth, conventional or electric steel);

- chem. steel composition 09g2s (in this case low-alloy).

As a result, analogues appear in relation to which questions like the following are often asked: is 345 steel 09g2s ? The designation C345 was introduced for builders , where the numbers do not indicate the chemical composition of the material, but its important property - the yield strength; for steel 09g2s it corresponds to the construction standards C345, which is reflected in a number of GOSTs (27772-88).

Below, several classic options are considered, including when one grade of steel corresponds to several strength classes.

Technical characteristics: subtleties of using reference manuals

The properties of 09g2s steel are largely determined by the chemical composition of the alloy, its specific parameters, which today are quite accurately calculated by metallurgists.

Steel grade 09g2s has the following critical points :

- Ac1 = 732, when austenite transforms into pearlite during cooling processes;

- Ac3(Acm) = 870 (s – from French chauffage/heating) the end point of cementite dissolution;

- Ar3(Arcm) = 854 (refroidissement – cooling) the beginning of the release of Fe3C;

- Ar1 = 680 hypoeutectoid steel, corresponds to ferrite precipitation

The symbols are classic, numbers 1 and 3 indicate the numbers of points on the graph. The symbols cm usually mark hypereutectoid steels.

If we talk about other features of St 09g2s, the following characteristics are noted: easy weldability of the material . For this purpose, RDS, ADS under flux and gas protection are used. Only products that have undergone chemical-thermal treatment cannot be welded.

The mechanical properties of steel 09g2s are tabular values that were developed by a number of GOST standards and describe the material at room temperature, as well as for its other states.

Among the important mechanical properties of 09g2s steel are the following:

- Yield strength for permanent deformation, measured in MPa;

- Relative values of elongation at break and contraction;

- Impact strength (use under load is one of the main applications);

- Brinell hardness (HB).

Strength class of steel 09g2s: the table for the list of grades includes the one indicated, which, as already noted, corresponds to C345 . This also includes a number of other brands.

Thus, steels that are different in chemical composition and even in the method of producing steel can have the same strength class.

This data can be found for 09g2s according to GOST 19281-2014; the characteristics of the alloys are presented in convenient tables that are easy to navigate. You can view (download) GOST 19281-2014 here .

But the opposite situation is also possible. For example, for 09g2s GOST 19281-89 and grade 16GS there is data on strength classes 265 and 296.

The same GOST describes the types of rolled metal:

- Varietal, round, shaped with various sections (including circle 09g2s).

- Wideband profiles with a certain thickness of products.

Large diameter circles steel 09g2s

Similar information is provided for other brands.

The density of steel 09g2s fluctuates, somewhere around the 7800 kg/m3 mark. But alloying elements can either increase the specific gravity or reduce it. Tungsten tends to be the first. The second is achieved by adding: cobalt, nickel, copper.

The hardness of steel 09g2s can be determined by Brinell, Rockwell, Vickers, etc. the choice of system is determined by the type of products for which parameter determination is required. It is also important when choosing a welding method; the hardness of the steel at the weld should remain fairly high.

Most of the listed parameters can be found in TU 14 3 1128 2000 for steel 09g2s, as well as for other grades. The technical specifications describe the requirements for the materials from which pipes are made for servicing gas fields and other areas of the industry.

The permissible stress for steel 09g2s is calculated depending on the following values:

- strength class and grade;

- temperatures at which it will be operated;

- thickness, sometimes configurations (circle, sheet, etc.).

Existing 09g2s analogues are foreign (European, Asian, others), most similar in mechanical and technical properties to the specified brand. However, the chemical composition can vary greatly. The Bulgarian version of this brand has the closest configuration.

Steel 09g2s: characteristics and application

The main areas of use of this brand: sheet and shaped products. For hot-rolled strip, GOST 103-2006 standards are used, but steel circles are in accordance with GOST 2590-2006.

As already noted, steel 09g2s and analogues are easy to weld. The characteristics already listed allow the use of this material for products that require high wear resistance: beams, channels, corners.

Brand 09g2s, its technical characteristics, are necessary in the creation of vehicles, construction, oil and chemical industries.

A wide temperature range allows the material to be used where severe deformations occur over a long service life.

At the same time, the limiting temperature of -70 degrees facilitates the use of products made from St. 09g2s in harsh climatic conditions.

Steel 09g2s is used in the construction of RVS for storing petroleum products in the North

Steel 09g2s-15 also fits this description well. It is used for all of the above points. It only remains to add that in addition to welding, installation can be carried out using bolted connecting elements.

The metal's resistance to chemical influences makes it interesting in the relevant industry. At the same time, high mechanical qualities are used for the construction of bridges, roads, port stations, etc.

The 09g2s-12 brand is also popular among builders. It also has stable plastic properties. It is distinguished by a special chemical composition, which includes arsenic. Used for the manufacture of pipeline fittings. Cannot be used in the food industry.

In the north of Russia, many kilometers of pipelines were built using just this brand. There, more than anywhere else, frost resistance and easy weldability of products are useful. This allows you to create complex, at the same time socially significant objects (metal structures) from 09g2s and analogues.

At the same time, for cities with a temperate or continental climate, steel 09g2s according to GOST standards of various numbers is suitable for beautifying streets. Square pipe is extremely popular as fencing, posts for billboards, installation of mobile trading platforms, and much more. For the same purposes, the rectangular configuration of products is used.

Steel 09g2s, the characteristics of which have already been discussed in some detail in this presentation, is of interest to welders, regardless of the method of performing work. Flanges made of this material are especially popular. Features of the work are described in GOST 19281-73. The craftsmen are quite welcoming to the news about the need to work with this brand.

The boiler tank itself is made of steel 09g2s

Steel 09g2s with different strength classes can be used for the production of steam boilers, as well as equipment used in the agricultural complex. Details about the requirements for steel 09g2s in GOST-5520 79.

An additional reason for using alloys of this brand is high efficiency, achieved not only due to low cost of production. The ease and speed of construction of buildings, structures, installation of equipment also allows you to optimize the costs of enterprises in various industries.

Steel grade 09G2S

Steel grade 09g2s is a low-alloy structural steel. In addition to manganese and silicon, the composition also includes sulfur, nickel, phosphorus, chromium, nitrogen, copper and other impurities. They are not indicated in the name due to their very low content, which is not critical for mechanical and chemical properties.

Unlike the previous brand, this quality class is defined as high. It cooks just as well, however, with some peculiarities: when electric welding, it is necessary to choose the correct current, and the resulting product is usually subjected to subsequent hardening.

This steel is used to make sheet and shaped metal products, which are used in construction and the production of parts, welded pipes, metal structures, various parts and components in mechanical engineering.

An important feature of this brand is its resistance to negative temperatures: products made from 09G2S can be used in the range from -70 to +425 degrees. Therefore, it is used for use in regions with difficult climatic conditions.

We offer rolled metal from different grades of steel. At your request, we will cut it into sheets or dissolve it into strips of the required size. All the steel that comes to us is made by the best manufacturers in the country, so you don’t have to worry about its quality.

Source

Steel grades st3PS/SP and 09G2S

What is the difference between steel grades st3PS/SP and 09G2S

Knowing and being able to distinguish steel grades is necessary for everyone involved in the production of metal products of any purpose and type. In this article we will look at two types of steel and determine what their indices mean and how this affects their scope of application.