Print version July 31, 2021

When receiving orders for the manufacture of stainless steel tanks and containers, we are often asked questions about how one brand differs from another in terms of performance and durability. To dot all the i's, in this article we will look at the grades of stainless steel and their foreign analogues, and analyze their physical and chemical properties.

- Stainless steel concept

- Properties of stainless steel

- Classification of stainless steel grades

- Analogues of stainless steel grades

Stainless steel concept

Let's give a definition: stainless steel is a complex alloy steel that is resistant to rust in atmospheric conditions and corrosion in aggressive environments.1

Its resistance to corrosion differs from conventional carbon steels and therefore is widely used in the food industry, oil and gas and chemical industries for operation with highly aggressive environments and food products, since during storage, oxides and other substances do not form upon contact of the liquid and the surface of the container, which may affect the properties of the stored product.

What is stainless steel from a chemical point of view? — This is an alloy with a minimum mass fraction of chromium of 10.5% and a maximum mass fraction of carbon of 1.2%.2

In simple terms, stainless steel is made by adding alloying substances to iron in different proportions to obtain the required characteristics.

Thus, the main alloying element is chromium Cr. The alloys also additionally contain carbon C, nickel Ni, silicon Si, manganese Mn, titanium Ti, niobium Nb, cobalt Co, molybdenum Mo, vanadium V, sulfur S, phosphorus P, tungsten W, aluminum Al, copper Cu, cobalt Co.

Properties of stainless steel

How are corrosion-resistant properties achieved? — Thanks to the addition of additional chemical elements at the metal production stage, an oxide film is formed on the surface, which does not dissolve, but, on the contrary, protects the alloy itself from the effects of corrosion.

The main properties of stainless steel also include:

- high strength

- high quality welded joints

- plastic

- long service life with preservation of its properties

Nickel (nickel-based alloys) and iron-nickel (iron-nickel-based alloys) can be used as the base metal.

The introduction of various alloying elements adds certain properties to the original metal:

- chromium increases the corrosion resistance, hardness and strength of the alloy; reducing the linear expansion coefficient simplifies the welding process

- Nickel additionally increases viscosity, ductility, hardenability and reduces the coefficient of thermal expansion, which allows the use of a product made from such an alloy with sulfuric, hydrochloric and phosphoric acids

- manganese in a percentage of more than 1% helps to increase durability, hardenability, hardness and wear resistance (can be partially replaced with nickel)

- titanium increases the strength of steel and its density, which provides high corrosion-resistant properties

- molybdenum increases elasticity, anti-corrosion properties, increases tensile strength and resistance to high temperatures

- Niobium provides low corrosion in welded products

- vanadium increases the strength, density and hardness of the alloy

- tungsten increases hardness and reduces brittleness during heat treatment (tempering) due to the formation of hard carbide compounds with other elements

- silicon in a percentage of more than 1% increases heat resistance, elasticity, scale resistance and acidity, and also increases electrical resistance and strength with the same viscosity parameters

- cobalt helps to increase impact resistance and improve heat-resistant properties

- copper gives the alloy high resistance to atmospheric corrosion

- aluminum helps reduce metal aging and also increases impact strength and fluidity

CLASSIFICATION

1.1. Depending on the basic properties, steels and alloys are divided into groups:

- I - corrosion-resistant (stainless), resistant to electrochemical and chemical corrosion (atmospheric, soil, alkaline, acid, salt), intergranular corrosion, stress corrosion, etc.;

- II - heat-resistant (scale-resistant) with resistance to chemical destruction of the surface in gas environments at temperatures above 550 ° C, operating in an unloaded or lightly loaded state;

- III - heat-resistant, capable of operating under load at high temperatures for a certain time and at the same time possessing sufficient durability.

1.2. Depending on the structure, steel is divided into classes:

- martensitic - with the main structure of martensite;

- martensitic-ferritic - contain in the structure, in addition to martensite, at least 10% ferrite;

- ferritic - steels with a ferrite structure;

- austenitic-martensitic - the amount of austenite and martensite in the composition can be varied within wide limits;

- austenitic-ferritic - steels with more than 10% ferrite in the structure;

- austenitic - steels having an austenite structure.

The division of steels into classes according to structural characteristics is conditional and is made depending on the basic structure obtained by cooling the steels in air after high-temperature heating. Therefore, structural deviations cannot serve as a reason for rejection.

1.3. Depending on the chemical composition, alloys are divided into classes according to the main constituent element:

- iron-nickel alloys;

- Nickel-based alloys.

Classification of stainless steel grades

Depending on the composition of the alloy, the following groups of steels are distinguished:

- ferritic steels (also called chromium steels) contain more than 20% chromium and up to 0.15% carbon, due to which they have ductility, high resistance to highly aggressive environments and have good magnetic characteristics

- Austenitic (austenitic-ferritic and austenitic-martensitic) steels consist of up to 33% chromium and nickel

- martensitic and ferritic-martensitic contain up to 17% chromium and up to 0.5% carbon, have maximum resistance to various aggressive environments

Depending on the content of the alloying substance, certain alloys are used for various purposes and to work with various environments. Below is a list of steel grades that are most often used in the oil and gas and chemical industries.

| Steel marking | Steel type | Scope of application | Chemical composition |

| 12Х18Н10Т | austenitic chromium-nickel steels | for the manufacture of welded equipment in various industries | Cr 17-19 C up to 0.12 Si up to 0.8 Mn up to 2 Ni 9-11 S up to 0.02 P up to 0.0.5 Ti 5C-0.8 |

| 08Х18Н10Т | austenitic chromium-nickel steels | for the manufacture of welded products operating in environments of higher aggressiveness than steel grades 12Х18Н10Т and 12Х18Н9Т | Cr 17-19 C up to 0.08 Si up to 1 Mn up to 2 Ni 9-12 S up to 0.02 P up to 0.0.4 |

| 08Х18Г8Н2Т | chromium-manganese-nickel steels of the austenitic-ferritic class | for the manufacture of welded equipment operating in aggressive environments in the chemical, food and other industries | Cr 17-19 C up to 0.08 Si up to 0.8 Mn 7-9 Ni 1.8-2.8 S up to 0.025 P up to 0.0.35 Ti 0.2-0.5 |

| 08Х22Н6Т | chromium-nickel-molybdenum steels of the austenitic-ferritic class | for the manufacture of welded equipment in the chemical, food and other industries operating at temperatures not exceeding 300ºС | Cr 21-23 C up to 0.08 Si up to 0.8 Mn up to 0.8 Ni 5.3-6.3 S up to 0.025 P up to 0.0.35 Ti 5C-0.65 |

| 08Х18Н10 | austenitic chromium-nickel steels | for products subjected to heat treatment (hardening) | Cr 17-19 C up to 0.08 Si up to 0.8 Mn up to 2 Ni 9-11 S up to 0.02 P up to 0.0.04 Ti 5C-0.7 |

| 08Х17Н13М2, 08Х17Н13М2Т | chromium-nickel molybdenum steels of austenitic class | for technological equipment of the chemical industry | Cr 16-18 C up to 0.08 Si up to 0.8 Mn up to 2 Ni 12-14 S up to 0.02 P up to 0.035 Ti 5C-0.70 Mo 2-3 |

For reference Explanation of stainless steel grades: the name of the steel consists of alphabetic and numerical designations, in which the following are accepted: A (at the beginning of the grade) - sulfur, A (in the middle of the grade) - nitrogen, B - niobium, C - tungsten, D - manganese, D - copper, E - selenium, K - cobalt, M - molybdenum, H - nickel, P - phosphorus, P - boron, C - silicon, T - titanium, F - vanadium, X - chromium, C - zirconium, Yu - aluminum , Ch - REM (rare earth metals: lanthanum, praseodymium, cerium, etc.). The number after the letter indicates the average mass fraction of the alloying chemical element. The number before the letter indicates the mass fraction of carbon in hundredths. If the alloying element contains less than 1%, then the percentage is not indicated. For example: 12Х18Н10T is a stainless steel with a carbon content of 0.12%, 18% chromium, 10% nickel and less than 1% titanium.

Stainless steel 12Х18Н10Т

Substitutes

Substitute - steels 08Х18Г8Н2Т, 10Х14Г14Н4Т, 12Х17Г9А4, 08Х22Н6Т, 08Х17Т, 15Х25Т, 12Х18Н9Т.

Foreign analogues

| Germany DIN | Brand | X10CrNiTi18-9 |

| Number | 1.4541 | |

| USA (AISI, SAE, ASTM) | 321 | |

| France (AFNOR) | Z10CN18 | |

| UK (BS) | 320S31 | |

| Sweden (SS) | 2337 | |

| Italy UNI | — | |

| Japan | SUS321 | |

IMPORTANT!!! The possibility of replacement is determined in each specific case after assessing and comparing the properties of steels

Interpretation of steel 12Х18Н10Т

The number 12 indicates the average carbon content in hundredths of a percent, i.e. for steel 12Х18Н10Т this value is 0.12%.

The letter “X” indicates the chromium content of the steel. The number 18 after the letter “X” indicates the approximate amount of chromium in steel as a percentage, rounded to the nearest whole number, i.e. chromium content about 18%.

The letter “N” indicates the nickel content of the steel. The number 10 after the letter “N” indicates the approximate amount of nickel in steel as a percentage, rounded to the nearest whole number, i.e. Nickel content is about 10%.

The letter "T" indicates the titanium content of the steel. The titanium content in steel does not exceed 1.5%.

Type of delivery

Long products, including shaped steel: GOST 5949-75, GOST 2590-88, GOST 2879-88. Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78. Polished rod and silver steel GOST 14955-77, GOST 18907-73. Thick sheet GOST 7350-77. Thin sheet GOST 5582-75. Tape GOST 4986-79. Wire GOST 18143-72. Forgings and forged blanks GOST 25054-81, GOST 1133-71. Pipes GOST 9940-72, GOST 9941-72, GOST 14162-79.

Weldability

Steel 12Х18Н10Т is weldable without restrictions. Welding methods: RDS, ESW and KTS (Contact Spot Welding). Subsequent heat treatment is recommended.

Technological properties

Forging temperature, °C: beginning 1200, end 850. Sections up to 350 mm are cooled in air. Cutting machinability - Kv tv.spl = 0.85 and Kv b.st = 0.35 in the hardened state at HB 169 and σw = 610 MPa. Flock sensitivity - not sensitive.

Chemical composition, % (GOST 5632-2014)

| Steel | C | Si | Mn | Cr | Ni | Ti | S | P |

| 12Х18Н10Т | no more than 0.12 | no more than 0.80 | no more than 2.00 | 17,0-19,0 | 9,0-11,0 | 5,0-8,0 | no more than 0.02 | no more than 0.40 |

Application of 12Х18Н10Т

Purpose - parts operating up to 600 °C; welded machines and vessels operating in dilute solutions of nitric, acetic, phosphoric acids, solutions of alkalis and salts and other parts operating under pressure at temperatures from -196 to +600 °C, and in the presence of aggressive media - up to +350 °C.

Corrosion-resistant (stainless) steel is of the austenitic class and is mainly used as corrosion-resistant, but can also be used as heat-resistant and heat-resistant. In terms of heat resistance, it is close to steel 12Х18Н9Т.

It is used for the manufacture of welded equipment in various industries.

Approximate application as heat-resistant steel

Purpose: pipes, furnace fittings, heat exchangers, muffles, retorts, exhaust pipes and manifolds, spark plug electrodes. Recommended maximum temperature for long-term use (up to 10,000 hours), 800°C.

The temperature at which intense scale formation begins in air is 850°C.

Unstable in sulfur-containing environments. They are used in cases where nickel-free steels cannot be used.

Approximate application as heat-resistant steel

Exhaust system parts, pipes, sheet and section parts.

Recommended maximum application temperature is 600°C.

Service life - Very long.

The temperature at which intense scale formation begins in air is 850°C.

Application of steel 12Х18Н10Т for bodies, covers, flanges, membranes and valve assembly made from rolled products, forgings (stampings) (GOST 33260-2015)

| steel grade | ND for supply | Temperature of the working medium (wall), °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Long products GOST 5949. Sheets GOST 7350. Forgings GOST 25054. Pipes GOST 9940, GOST 9941 (made of 12Х18Н10Т) | -270 to 350 | For welded fittings operating in aggressive environments: HNO3, alkalis, ammonium nitrate, food media, special equipment media, ship fittings, cryogenic media, hydrogen sulfide-containing media; for membranes |

| St. 350 to 610 | For welded reinforcement assemblies in the absence of a requirement for resistance to intergranular corrosion |

Application of steel 12Х18Н10Т for fittings fasteners (GOST 33260-2015)

| Steel grade, according to GOST 1759.0 | Material standard or specification | Application options | |||||

| Bolts, studs, screws | Nuts | Flat washers | |||||

| Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | Ambient temperature, °C | Nominal pressure Pn, MPa (kgf/cm2) | ||

| 12Х18Н10Т | GOST 5632 | -196 to 600 | Not regulated | -196 to 600 | Not regulated | -196 to 600 | Not regulated |

The use of steel 12Х18Н10Т for the manufacture of spindles and rods (GOST 33260-2015)

| steel grade | ND for supply | Working environment temperature, °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Long products GOST 5949 | -270 to 350 | It is used for work in aggressive environments: nitric acid, alkalis, ammonium nitrate, food environments, environments of special equipment, shipbuilding, cryogenic equipment and hydrogen sulfide-containing environments. Used for welded joints |

| Long products GOST 5949 | St. 350 to 610 | Suitable for use in environments that do not cause intergranular corrosion |

Application of steel 12Х18Н10Т for bellows (GOST 33260-2015)

| steel grade | ND for supply | RD for the production of bellows | Working environment temperature, °C | Operating pressure Pp, MPa (kgf/cm2), no more | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Sheet GOST 5582. Tape GOST 4986, (for steel 1.4541) | GOST 21744, GOST 22388 | -260 to 550 | From 0.6 to 25.0 (from 6 to 250) | For water, steam, inert gases and cryogenic temperatures. For mildly aggressive environments - up to a temperature of 350°C. For corrosive environments - up to 150°C |

| Pipe GOST 10498 | -260 to 465 | From 0.15 to 3.10 (from 1.5 to 31.0) |

NOTE The table shows the limit values for temperatures and operating pressures. Specific combinations of application parameters (working pressure, axial stroke, temperature and full assigned life) are given in the regulatory documentation for bellows.

Application of steel 12Х18Н10Т for valve valve assembly

| steel grade | Working environment temperature, °C | Hardness | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | -100 to 300 | 155…170 HB | The functionality of the valve assembly is ensured by the presence of surfacing or other wear-resistant coating in the mating part |

Application of steel 12Х18Н10Т for helical coil springs

| steel grade | ND for supply | Application temperature, °C | Additional instructions for use |

| 12Х18Н10Т GOST 5632 | Wire | -253 to 400 | Safety, control valves, low-magnetic springs |

Application of steel 12Х18Н10Т for gaskets

| steel grade | Type of semi-finished product | Application temperature, °C | Additional instructions for use | |

| Name | ND for supply | |||

| 12Х18Н10Т GOST 5632 | Thick heat-treated sheets | GOST 7350 | -253 to 600 | Suitable for use in corrosive environments |

Resistance of steel 12Х18Н10Т to sulfide corrosion cracking

| Method of forming blanks | Name of parts |

| Forgings, stampings, rolled products | Body, bonnet, stem, spindle, valve seal parts, bellows end parts |

Maximum permissible temperature for the use of steel 12Х18Н10Т in environments containing ammonia

| steel grade | Temperature of application of steels, °C at partial pressure of ammonia, MPa (kgf/cm) | ||

| St. 1(10) to 2(20) | St. 2(20) to 5(50) | St. 5(50) to 8(80) | |

| 12Х18Н10Т | 540 | 540 | 540 |

Maximum permissible temperature for the use of steel 12Х18Н10Т in hydrogen-containing environments

| steel grade | Temperature, °C, at partial pressure of hydrogen, PH2, MPa (kgf/cm2) | ||||||

| 1,5(15) | 2,5(25) | 5(50) | 10(100) | 20(200) | 30(300) | 40(400) | |

| 12Х18Н10Т | 510 | 510 | 510 | 510 | 510 | 510 | 510 |

NOTE

- The parameters for using steels indicated in the table also apply to welded joints.

- The partial pressure of hydrogen is calculated by the formula: PH2 = (C*Pp)/100, where C is the percentage in the system; PH2—hydrogen partial pressure; Pp is the operating pressure in the system.

Relative erosion resistance coefficient of reinforcement parts made of steel 12Х18Н10Т

| Details of the flow part of the fittings | Part material | Erosion resistance coefficient relative to steel 12X18H10T | Maximum pressure drop at which there is no erosive wear, MPa |

| Body, pipes, rod, plunger (gate), seat | 12Х18Н10Т | 1,0 | 4,0 |

NOTE

- The coefficient of erosion resistance of a material is the ratio of the rate of erosive wear of the material to the rate of erosive wear of steel 12Х18Н10Т (taken as 1).

- Materials are erosion-resistant if the coefficient of relative erosion resistance Kn is at least 0.5 and the hardness of the material is HRC≥28.

Resistance of steel 12Х18Н10Т against crevice erosion

| Durability group | Point | Erosion resistance against steel 12X18H10T |

| Persistent | 2 | 0,75-1,5 |

Resistance of steel 12Х18Н10Т against impact erosion

| Toughness Point | NV no more | Materials |

| 5 | 150 | Austenitic chromium-nickel stainless steel grade 12Х18Н10Т |

Application of steel 12Х18Н10Т for the manufacture of main parts of nuclear power plant fittings

| steel grade | Type of semi-finished product or product | Maximum permissible temperature of use, °C |

| 12Х18Н10Т GOST 5632, GOST 24030 | Sheets, pipes, forgings, long products. Fasteners | 600 |

Characteristics

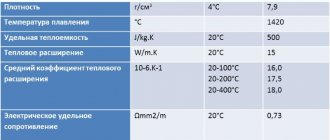

Density ρ at test temperature, 20 °C - 7900 kg/cm3

Thermal conductivity coefficient λ W/(m*K) at test temperature, °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 15 | 16 | 18 | 19 | 21 | 23 | 25 | 27 | 26 | — |

Electrical resistivity ρ, nOhm*m, at test temperature °C —

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 725 | 792 | 861 | 920 | 976 | 1028 | 1075 | 1115 | — | — |

Specific heat capacity c, J/(kg*K), at test temperature, °C

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 462 | 496 | 517 | 538 | 550 | 563 | 575 | 596 | — | — |

Thermal conductivity coefficient λ, W/(m*K), at test temperature, °C

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 15 | 16 | 18 | 19 | 21 | 23 | 25 | 27 | 26 | — |

Linear expansion coefficient α*106, K-1, at test temperature, °C

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 |

| 16,6 | 17,0 | 17,2 | 17,5 | 17,9 | 18,2 | 18,6 | 18,9 | 19,3 |

Modulus of normal elasticity E, GPa, at test temperature °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 198 | 194 | 189 | 181 | 174 | 166 | 157 | 147 | — | — |

Modulus of elasticity in torsional shear G, GPa, at test temperature °C

| Steel | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| 12Х18Н10Т | 77 | 74 | 71 | 67 | 63 | 59 | 57 | 54 | 49 | — |

Mechanical properties

| GOST | Delivery status | Section, mm | σ0.2, MPa | σb, MPa | δ5, % | ψ% |

| no less | ||||||

| GOST 5949-75 | Bar. Quenching from 1020-1100 °C in air, oil or water | 60 | 196 | 510 | 40 | 55 |

| GOST 18907-73 | Ground rod, processed to a specified strength | — | — | 590-830 | 20 | — |

| Cold-worked rod | Up to 5 | — | 930 | — | — | |

| GOST 7350-77 (transverse samples) | Hot-rolled and cold-rolled sheets: | |||||

| hardening from 1000-1080 °C in water or air | St.4 | 236 | 530 | 38 | — | |

| GOST 5582-75 (transverse samples) | hardening from 1050-1080 °C in water or air | Up to 3.9 | 205 | 530 | 40 | — |

| hard-worked | Up to 3.9 | — | 880-1080 | 10 | — | |

| GOST 25054-81 | Forging. Quenching from 1050–1100 °C in water or air | Up to 1000 | 196 | 510 | 35 | 40 |

| GOST 18143-72 | Heat treated wire | 1,0-6,0 | — | 540-880 | 20 | — |

| GOST 9940-81 | Seamless hot-deformed pipe without heat treatment | 3,5-32 | — | 529 | 40 | — |

Mechanical properties at elevated temperatures

| tsp, °С | σ0.2, MPa | σa, MPa | δ5, % | ψ% | KCU, J/cm2 |

| 20 | 225-315 | 550-650 | 46-74 | 66-80 | 215-372 |

| 500 | 135-205 | 390-440 | 30-42 | 60-70 | 196-353 |

| 550 | 135-205 | 380-450 | 31-41 | 61-68 | 215-353 |

| 600 | 120-205 | 340-410 | 28-38 | 51-74 | 196-358 |

| 650 | 120-195 | 270-390 | 27-37 | 52-73 | 245-353 |

| 700 | 120-195 | 265-360 | 20-38 | 40-70 | 255-353 |

Note.

Hardening from 1050-1100 °C in air.

Mechanical properties during long-term strength testing (GOST 5949-75)

| tsp, °С | Creep limit, MPa, not less | Creep rate, %/h |

| 600 | 74 | 1/100000 |

| 650 | 29-39 |

| tsp, °С | Long-term strength limit, MPa, not less | τ, h |

| 600 | 147 | 10000 |

| 650 | 78-98 |

Impact strength KCU

| Delivery status | KCU, J/cm2, at temperature, °C | ||

| +20 | -40 | -75 | |

| Strip 8×40 mm | 286 | 303 | 319 |

Note.

Fatigue limit σ-1 = 279 MPa at n = 107.

Sensitivity to aging embrittlement

| Time, h | Temperature, °C | KCU, J/cm2 |

| Ref. comp. | Ref. comp. | 274 |

| 5000 | 600 | 186-206 |

| 5000 | 650 | 176-196 |

Heat resistance

| Wednesday | Temperature, °C | Strength group or score |

| Air | 650 | 2-3 |

| 750 | 4-5 |

Find out more

Structural alloy steel 38ХА…

Steel 09G2S - structural low-alloy...

Steel 40Х13 is corrosion-resistant…

Corrosion resistant, heat resistant, heat resistant, wear...