One of the most common non-ferrous metals is aluminum; it is used both in pure form and as part of alloys. Various parts are made from duralumin, so welders often have to deal with this material. The complexity is due to the fact that in addition to aluminum, such an alloy also contains other metals, such as Cu, Mg, Mn. Welding duralumin is a complex technological process that requires some skills, so it will be difficult for a beginner to cope with it.

Welders often encounter aluminum.

What is duralumin

Duralumin consists of the following elements: aluminum - 93.5%, copper - 4.5%, magnesium - 1.5%, manganese - 0.5%. This composition determines the performance characteristics of the alloy. The main component affects the chemical activity of duralumin, so it quickly oxidizes in open air, resulting in the formation of a durable oxide film on the surface.

The given alloy composition is not constant, it can change. Not only the ratio of metals is important, but also the technology of heat treatment of duralumin.

Properties and weldability of duralumin

The difficulties of the welding process of duralumin are largely explained by its refractoriness. Compared to the main component, this composition is more dense, so it is less soft and flexible. During welding, electrodes are quickly consumed, and the fluidity of the alloy increases. You need to prepare for this before starting welding. Preliminary hardening of duralumin parts helps to eliminate this problem; it is performed at a temperature of +500°C.

Basic properties:

- density – 2.5-2.8 tons/m³;

- melting point – +650°C;

- Max fluidity – 250 MPa.

This material has high strength and relatively low weight, which makes it possible to make parts, mechanisms and structures from it that are used in various industries, the national economy and in everyday life.

Due to its high tendency to oxidize, duralumin is cooked at temperatures within +300°C, using a protective atmosphere of inert gases or flux.

This material is very refractory.

Welding process - difficulties in working with the material

An electric arc can be used to connect many types of iron. It has a fairly high combustion temperature, which makes it possible to melt plates of different thicknesses well and create reliable and airtight connections. But welding aluminum with an inverter is more difficult due to several specific features of this material.

The first difficulty is the hygroscopic properties of aluminum. The material is able to absorb surrounding moisture and accumulate in itself. This does not appear visibly on a cooled product, but will immediately become noticeable during welding. When the arc is ignited and the metal finds itself in a zone of elevated temperature, moisture begins to evaporate from its surface, inevitably entering the welding zone. This results in excessive spatter and interference with the seam. To prevent this phenomenon, preheating of the product with a burner at a temperature of 150-190 degrees is required. During the procedure, you can see the release of moisture on the surface.

Another difficulty is the oxide film that covers the entire product with a thin layer. It protects the metal from destruction in an acidic environment, but significantly interferes with welding with an inverter at home. The difficulty lies in the huge difference in melting temperatures. Aluminum material melts at 500 degrees, and its oxide at 2000 degrees. To eliminate this difference, it is necessary to clean the welding site with an iron brush, which gives access to the base metal.

Interaction with the surrounding air contributes to the formation of pores in the structure of the seam, which significantly reduces its sealing properties. Protection of the weld pool is carried out by supplying argon in the case of TIG, or by creating a gas cloud from the coated electrode when welding with an inverter at home.

Since pure aluminum is not used in products, other elements included in the alloy may be difficult to weld. Thus, grades Al2 and Al9 with a silumin content of 4 to 13% are considered to be weldable to a limited extent. The AMr1 and AMr6 brands have the same indicators, where manganese can be added from 2 to 6%. Duralumin D16 is difficult to weld.

Advantages and disadvantages

Among the advantages of this alloy, the following are noted:

- light weight, but duralumin parts can withstand high loads;

- welding work is performed using different technologies, their choice depends on the work conditions and other factors;

- preparing products does not require much labor and time;

- the necessary electrodes can always be purchased in specialized stores.

We recommend reading: How to cook aluminum with a semi-automatic machine

This process also has a number of disadvantages:

- the weld seam has low resistance to corrosion;

- after creating such a connection, the characteristics of the alloy deteriorate;

- To carry out work, you must have high qualifications, be careful and perform everything with high precision;

- to select electrodes, you need to know exactly the grade of the alloy;

- the high fluidity of duralumin creates difficulties when forming a welding bead;

- to perform the work efficiently, you have to use flux or shielding gas;

- the cost of consumables is high;

- When performing high-speed welding, it is difficult to organize quality control of the seam.

The seam may be subject to corrosion.

We carry out welding: stages of work

How to weld aluminum became clear after numerous attempts and experiments. Below are step-by-step steps to get a quality connection at home:

- If the plates to be welded have a thickness of more than 5 mm, then cutting of the edges is necessary. The standard is to cut the edges at 45 degrees, but other values are allowed. It is worth noting that the larger the cutting angle, the wider the weld seam will be. When the plate thickness is more than 7 mm, a technological gap of 2 mm is required between them. If the working object is a crack, then it must be widened with a cutting disc and a grinder, otherwise the seam will be superficial.

- The prepared product must be heated. Moisture is removed using a propane-oxygen flame. This can be a cutter or a regular can with a household torch. The surface must be heated to 150 degrees. This can be checked with a special apparatus or visually by the dry state of the material.

- After heating, the oxide film is quickly removed. A regular metal brush will do for this. It is important to remove the refractory layer at the beginning of the welding zone. The subsequent action will be exerted by the electrode, whose composition and temperature corrode the oxide, allowing welding to be performed.

- Tacks are placed on the prepared material to secure the sides to be welded. The root seam must be drawn evenly, filling the gap. The angle relative to the parts being welded is required to be 90 degrees. This is unusual for novice welders, or those who have only worked with carbon steel. But this way the molten metal will more accurately reach the joint. After the surface has cooled slightly, the slag is removed. This is quite difficult, so a sharp hammer is required.

- Subsequent layers of joint are applied to the level that fills the entire thickness of the material and creates a small bead over the joint.

- The seams are made with a short arc. Excessive increase in the gap can lead to arc breakage. At the end of the electrode, carbon deposits form in the form of a white layer. This is the protruding alkali. To continue welding, this dielectric must be removed.

When welding aluminum with an inverter, the electrode melts faster than when working with conventional steel, so training on a non-working surface will help your hand get used to maintaining a distance.

Requirements for welding

When welding parts made of duralumin, you must adhere to the following requirements:

- Flux is preliminarily applied to the joint and evenly distributed, this allows to improve the welding process;

- heating of the parts to be joined is carried out evenly, otherwise they may become deformed under the influence of temperature;

- after completion of the work, the created seam is heated for some time, do this until the metal cools down;

- After welding and cooling of the seam, it is cleaned of slag and checked for cracks, cavities, and damage.

Preparation before the welding process

To obtain a high-quality connection, the surface of the parts must be properly prepared before starting work. This will help remove the oxide film, which has a high density and melting point, which does not allow the arc to form stably, resulting in reduced connection reliability.

The preparatory process consists of the following stages:

- Cleaning the surface from corrosion, oil and other contaminants.

- To remove the refractory layer, use a metal brush and fine-grained sandpaper to do this. In production, the oxide film is most often removed by cathode sputtering; in this case, it is treated with ions, which allows you to quickly and efficiently clean the surface.

- Degreasing the surface. In this case, not only the remaining oil is removed, but also the remaining particles that during the welding process interfere with the quality of the work.

- Edge processing. If the thickness of the welded sections is more than 4 mm, their corners are beveled at an angle of 35°.

Before using the electrodes, they are heated at a temperature of +150°C, which helps remove excess moisture. After the preparatory work, it is recommended to start welding; within 3 hours this can be done no later than 24 hours, because a strong oxide film is formed again.

Getting rid of corrosion.

Household welding method without argon

The method is more often called soldering, because the process does not use electricity, but the connection of parts made of aluminum and its alloys is quite strong. You only need to have a portable gas burner, preferably with a large cylinder volume, and a wire with solder, for example, HTC-2000.

The process of joining parts or sealing cracks is simple. Heat the part to a temperature until the rod with solder begins to melt, fill the cracks with solder, and connect the surfaces. But do not forget to first clean the parts from the oxide film.

If you are a professional in aluminum welding processes and have something to add or argue, then join the discussion in the comments block.

Required welding equipment

To carry out welding work with duralumin parts, a standard electric arc welding machine and consumable electrodes are used, and this is also done using a gas torch. In production for such purposes they use:

- semi-automatic machines in which the wire is fed in a protective gas environment, they are designated DC MIG;

- welding equipment that works with non-consumable electrodes placed in an argon environment, they are designated AC TIG.

We recommend reading: How to weld aluminum yourself

For welding duralumin, equipment that supports operation with direct and alternating current is used. It must be inverter, compact, so that it can be transported. It is good when the machine is equipped with an oscillator for welding, and the length of the hose for connecting the torch is up to 3 m.

Duralumin welding technology

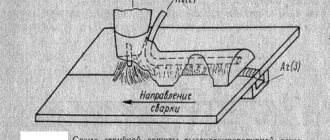

Although different equipment is used at home and in production for welding duralumin parts, the technology for carrying out the work is the same. The high fluidity of this material must be taken into account, so most often the work is performed in the lower position.

To avoid the formation of a large melt pool, the seam is made at high speed, and this will require high qualifications. At home, when using electric arc welding, you will not be able to obtain a high-quality connection. It will be porous, there will be residual stresses and cracks will appear.

Argon-arc

This technology involves the use of a non-consumable tungsten electrode that operates in a protective gas environment. Welding is performed using alternating current; modern machines have all the necessary settings, which helps simplify the process. Using this method helps to obtain a durable and high-quality seam, while the likelihood of corrosion will be minimal.

Semi-automatic

The use of a semi-automatic machine when welding duralumin is similar to how steel elements are connected using this method. The difference is that it is necessary to more carefully control the power of the arc and the advance of the wire, as well as increase its feed.

Types of welding of aluminum alloys

In industry, workshops and everyday life, three main methods of welding aluminum alloys are used:

- semi-automatic with wire feeding in an environment of protective inert gases - DC MIG;

- tungsten electrodes in an environment of protective inert gases AC TIG;

- coated electrodes without the use of inert gases - MMA;

- gas burner with coated electrodes without argon.

Each metal joining method has its own advantages and disadvantages and is designed for different applications.

Semi-automatic welding machines

Semi-automatic welding machines for aluminum operate in pulse mode. The high-voltage voltage pulse destroys the oxide film. Between pulses, the metal heats up, a drop flows into the weld pool and forms a high-quality seam.

In principle, a semi-automatic machine for aluminum does not differ from devices for welding ferrous metals, which some craftsmen use to weld silumin and duralumin. But technological features should be taken into account:

- aluminum and its alloys are not welded with direct current with negative polarity on the electrode, only with positive polarity;

- it is necessary to use a wire feeder with 4 rollers and a Teflon liner, otherwise the wire will get tangled;

- the wire feed speed should be 2-4 times higher than in machines for steel welding.

Semi-automatic machines for welding aluminum alloys are much more expensive than machines for ferrous metals, so sometimes it is cheaper to upgrade a regular welder for universal use.

The method is fast, but inferior in seam quality to arc welding.

Welding with tungsten electrodes

The tungsten arc welding method involves the use of an argon environment.

This method ensures the highest quality and most accurate seam creation. To prevent the formation of an oxide film, the process takes place in a protective atmosphere of an inert gas - argon. It is also possible to use other gases, such as xenon, krypton, nitrogen, but they are more expensive and their use can only be justified under special conditions.

Welding duralumin with a tungsten electrode using a three-phase arc increases work efficiency by 3-5 times and allows you to weld parts 3 cm thick in one pass. With a conventional connection, surfaces up to 0.3 cm thick can be welded in one pass.

Welding with coated electrodes without shielding gases

This welding method allows you to carry out work where the use of gases is not recommended or prohibited:

- hard-to-reach places;

- on the street;

- inside the tanks.

An electrode with an internal rod similar in composition to the metals being welded is coated with chloride and fluoride salts of sodium and potassium, and cryolite. During the evaporation process, the outer layer of the electrode creates a protective environment.

Welding with coated electrodes does not require bulky equipment or gas cylinders and is quite cheap.

Welding duralumin at home

Often there is a need to weld duralumin at home. If you have sufficient skills, you can get a relatively strong and reliable seam. They work using an electric arc apparatus and special consumable electrodes, which are sold in specialized stores.

Electrodes

Depending on the type of duralumin, the following types of rods alloyed with different metals are used:

- OZA-1 – titanium, copper;

- OZA-2 – aluminum with iron, titanium;

- OZANA-1, OZANA-2 – silicon, iron;

- OK96.10, OK96.20 – manganese, silicon, iron.

Electrodes for aluminum welding

Devices

There is insufficient current frequency in the household electrical network, therefore, in order to connect duralumin parts, it is necessary to use devices to increase this parameter.

You can perform welding work using an oxygen-acetylene torch. When it burns, a temperature is created that exceeds the melting point of duralumin. The use of this option leads to the oxidation of aluminum and the formation of an oxide film; to eliminate this drawback, work is performed in an argon environment.

It is more convenient to carry out welding using hydrogen-oxygen torches, which are also called plasma torches. They allow you to create a high-quality and durable seam that is less subject to deformation and corrosion.

Even with the necessary equipment, experience and knowledge, it is difficult to obtain a reliable welding connection of duralumin parts at home. If high demands are placed on the quality of the seam, then in such cases it is better to contact specialized organizations.

We recommend reading: How to weld aluminum yourself

Welding using a plasma heater.

Advantages

- If you strictly follow all the work technology, then in the end the seam will be smooth and of high quality, and the metal will be able to withstand heavy loads, while weighing very little.

- There are several methods for welding duralumin (argon welding, semi-automatic welding), you can choose the most optimal option, taking into account all the factors and conditions of the work.

- Finding electrodes is not difficult, since many interact well with such an alloy. For example: OZA-1, OK96.20, OZA-2, OZANA-1, OZANA-2,

- Any problem that arises during the welding process can be solved, but it is better to entrust the work to an experienced specialist.

Possible difficulties

If the parts to be welded are subject to static loads, then the work can be performed with consumable electrodes. When torsional loads are created at the weld site, welding is performed semi-automatically or using the argon arc method, because they provide a more reliable connection.

Duralumin melts quickly, so work must be carried out at high speed. When alloying components burn out, corrosion often forms at the weld site.

Problems arise when the equipment is configured incorrectly. Increased blowing of the welding zone does not allow the seam to form normally; in addition, the costs of this process increase. If the gas supply is insufficient, the metal in the work area foams and the tungsten electrode begins to burn.

Disadvantages

- As already noted, duralumin is characterized by low corrosion resistance, and after welding its technical characteristics become even lower.

- The process is complex, requiring care and precision, because... Any, even the slightest mistake can significantly affect the quality of the connection.

- Forming a weld bead is not easy because the metal is very fluid.

- In order to make the work process easier and so that welding takes less time, you need to use flux. It is applied to the surface of the part to be welded.

On a note! Flux is a substance that protects the area being welded from aggressive environmental influences and improves the quality of the connection.

- In order to obtain the most durable and reliable connection, you will have to resort to expensive types of welding, for example, welding duralumin with argon.

Additional Information

To create butt welds when working with products with a thickness of more than 3 mm, a tungsten electrode is often used. During welding, inert gas is supplied to the working area.

The use of a carbon electrode and acetylene gas welding does not allow creating a strong connection. A better result will be obtained using hydrogen-oxygen burners.

When working with a semi-automatic machine, it is important not only to correctly set the wire feed, but also the arc strength so that the parts being connected do not overheat. Correct adjustment to alternating current when performing argon welding with a tungsten electrode allows you to obtain high-quality connections.

In order to reliably connect duralumin products using welding, you must strictly adhere to the developed technologies, use serviceable equipment, have the necessary skills and follow safety regulations.

Difficulties of welding aluminum

The main difficulties encountered when welding aluminum.

During welding work, the work product heats up to a certain temperature and begins to change its color.

This happens with copper or iron - the most popular metals for the production of household items. Changing the shade helps the performer to correctly regulate the process, understand whether the heating is sufficient, determine whether the seam has been “sealed” or whether heat treatment needs to be continued. But aluminum does not change color .

Therefore, the welder cannot visually evaluate the result. The high thermal conductivity of this metal requires a limitation on the duration of thermal exposure. Exceeding the duration of exposure to high temperatures can lead to deformation, cracks, bulges and other defects.

The peculiarities of welding aluminum and its alloys are explained by a whole range of special properties that the metal has:

- The surface of this material is always covered with an oxide film , which has a high melting point - about 2000°C. The metal itself melts at 660°C.

- Drops molten aluminum

, formed during welding in the working area, are immediately covered with an oxide film, which prevents the formation of a continuous seam. To prevent this effect, it is good to use argon gas, which reliably protects the welded zone from interaction with air. - The high fluidity of aluminum in the molten state seriously complicates the formation of a weld pool. Therefore, the technology for welding aluminum requires the use of special linings that remove heat from the welding zone.

- Aluminum contains dissolved hydrogen , which tends to escape into the atmosphere. This promotes the formation of pores and crystallization cracks.

- Aluminum has a fairly high coefficient of linear expansion . Because of this, significant shrinkage occurs when the metal hardens.

- Due to the high thermal conductivity of this material, welding should be carried out using significant amounts of current.

- An important feature is that welding aluminum is often complicated by the fact that it is difficult for the performer to determine the brand of alloy from which the welded products are made. This complicates the choice of connection mode and method of its implementation.

burns on the back side

For household aluminum welding, MMA and TIG . Welding workpieces 5-7 mm thick. performed by direct current of reverse polarity. For thick-walled parts, preliminary preparation will be required. Welding aluminum with an electrode at home includes the following steps:

- thorough cleaning of workpieces from the oxide layer;

- degreasing is carried out using a solvent;

- to obtain a more durable and uniform connection, edges of products with a thickness of more than 5 mm. need to be removed at an angle of 45 to 65 degrees;

- the coating of electrodes for aluminum is characterized by active absorption of moisture, so calcination should be performed before welding;

- the surface to be welded must be heated to 250°C , which promotes more efficient melting of the oxide film;

- The current strength depends on the thickness of the walls of the product, the parameters of the seam, as well as the composition of the base metal.

Important! The weld seam should not be thick, otherwise it will be porous and cracked. Therefore, when working with massive parts, several passes should be made.

More detailed information is presented in the article “Welding aluminum with electrodes”.

Argon arc welding with a non-consumable electrode requires large financial costs. However, the quality of the seam is much better compared to the MMA connection. Home TIG welding technology includes the following operations:

- the device must be equipped with an oscillator (a device that ensures excitation and stability of the arc), which improves the parameters of welding and melting of the oxide layer;

- To avoid excess gas consumption, it is necessary to set the tungsten electrode to 5-6 mm. from the tip;

- argon is supplied at a flow rate of 5-8 l/min, after which current is supplied with a slight delay;

- after the formation of the weld pool, the welding wire melts progressively;

- welding is carried out using pulsed alternating current.

There are also general rules for welding aluminum that are recommended to be followed for any method:

- welding is performed from right to left ;

- the arc length should be 1.5-2.5 mm;

- the filler material is fed in short, progressive and reciprocating movements ;

- an angle of 90 degrees between the electrode and the wire

- It is not allowed to perform transverse vibrations with a tungsten electrode;

- Thin aluminum is welded with a copper or iron backing to dissipate heat and prevent burns.

burn-through

Is it worth trying?

Welding aluminum at home has a number of advantages :

- saving financial resources, this advantage is especially important for performers who have the necessary equipment at their disposal;

- instant results that can be checked immediately;

- the ability to use improvised means;

- no special requirements for seam quality.

However, it is worth noting the disadvantages :

- when welding aluminum at home, the performer will receive a connection of lower quality;

- sometimes difficulties arise when choosing filler material;

- at home it is difficult to use advanced technologies that are used in modern industries;

- it is more difficult to comply with safety regulations;

- electrodes may be stored in inappropriate conditions, they may become damp or deteriorate;

- lack of precise methods for quality control of the finished connection.