When it comes to Lego bricks, it is very difficult to separate the seeds of popularization of a new product from its actual working qualities. Even the term itself, using the name of a famous toy company, does its best to simplify concepts, which is not always beneficial. Especially when it comes to professionals or advanced amateurs.

To slightly dispel the childish image of a wonderful construction product, let’s call a spade a spade.

Thus, the term Lego brick, literally translated from English, sounds more detailed and complete - interlocking brick, which means mutually interlocking bricks, interlocking brick, that is, a brick with a lock.

Now, when discussing and searching for information regarding price, characteristics and application technologies, the possibilities are significantly expanding, especially for those who decide to make Lego bricks with their own hands.

Features of Lego bricks

A business idea such as the production of Lego bricks is profitable , because it is a high-quality and durable hyper-pressed material intended for cladding and construction.

Thanks to its unique shape, similar to Lego bricks, it allows for quick and convenient masonry, does not require plastering and creates a smooth surface .

To work with such bricks, you do not need cement or other solutions. To connect and firmly fix it during laying, a special adhesive mass is used, which is sold in convenient tubes and is used sparingly.

Optional equipment

In addition to the machine, to ensure continuous operation , for the variety of products, to speed up the production process, it is necessary to purchase additional equipment:

- In order to make bricks of different shapes and sizes, it is necessary to purchase matrices. appearance will largely depend on its quality . Look at the surface, it should not have any roughness or burrs. The matrices are made of wear-resistant steel, the wall thickness should be 6-8 mm. Using a variety of matrices, you can produce single, double or one-and-a-half bricks. You can also diversify the resulting shapes: in the form of rails, with 2 or 4 holes , in the form of a cube or parallelepiped. For small production, it is enough to have about 3-5 molds ; in order to expand the range on the market, it is best to have more than 6 pieces.

- To facilitate the process of preparing the mixture, you can purchase automatic mortar mixers. The price for them is quite high - from 60 thousand rubles. Pay attention to the blades, they must be of high quality and withstand heavy loads, the larger the blade area, the better.

- Shipping tapes . They are designed to supply bulk materials to the mixer or to deliver the finished mixture to the machine hopper. They can be vertical or horizontal. Cost about 100,000 rubles.

In addition to the equipment listed, you will need some tools , which you cannot do without during work:

- pallets for storing products;

- shovels for filling dry materials;

- containers for cement, water and other materials;

- brushes for cleaning the hopper, transport belt, tray from excess mixture.

Most machines do not require a large number of maintenance personnel; the most common ones can be operated by one person. But in order to increase productivity , it is necessary to attract two workers. So, one will work with the machine , and the second will ensure continuous supply of the mixture to the machine. Involving more people will be unjustified .

Block types

Lego bricks come in two types. Both types are common and well known in the building materials market:

- Type 1 – Facing brick with two technological holes. The structure involves holes with a protrusion on the top of the block and a similar connector on the bottom. With this design, bricks are attached to one another, and with the addition of glue they create a flat, durable surface.

- Type 2 – These blocks have an unusual design. The brick consists of 3 parts: two outer parts are at the same level and one middle part protrudes 4 cm. The block also has a similar hole for fastening from below.

Registration of a business for the production of Lego bricks

The production of Lego bricks as a business is subject to mandatory registration. To carry out such activities, it is enough to register an individual entrepreneur .

To submit an application, you will need a package of documents consisting of a copy of your passport, a receipt for payment of the state fee and a completed application form in form P21001 .

When registering, you will need to indicate the following OKVED :

- 26.40 — Production of bricks, tiles and other building products from baked clay.

- 52.46.72 — Retail trade in bricks.

- 6.61 — Production of concrete products for use in construction.

- 51.53.24 — Wholesale trade of other building materials.

When submitting an application, do not forget to indicate the simplified tax system , since by default your organization will be assigned a general tax system.

Select the most suitable tax object for you. The simplified tax system provides for 2 options: 6% of income, or 15% of the difference between income and expenses of your organization.

How to start a Lego brick making business - where to start

Any business starts with an idea and financial calculations.

After that we open production.

Step 1. Register a business

Before starting a business, they choose the form of the new organization. LLCs and individual entrepreneurs produce products in the same way, but each type of business has its own characteristics.

Let's highlight the main ones:

- Individual entrepreneurs keep simplified records and pay less state fees . Such an organization is a company of one specific person. Other founders cannot be accepted into it. Personal savings or property of the citizen who organized the individual entrepreneurs are accepted to correct the financial mistakes of the organization.

- The LLC maintains full reporting . The time frame for registering a company is 2.5 months. The organization is owned by 1-50 people. The company is responsible for financial failures only with its property (authorized capital).

Please note: IP cannot be sold. In this form, organizations sell only material assets (equipment, raw materials, finished products). A business with a full package of documents for the company can only be sold by an LLC.

Step 2. Select a room

A big plus of Lego production is the minimum space requirements for the production line. Small machines are placed on a construction site, in a garage, in a personal garden, etc.

When launching a line with a capacity of more than 600,000 units/year, a workshop will be equipped.

Basic requirements for production premises:

- area more than 100 m² (including premises for storing raw materials and finished products);

- the height of the ceilings is calculated as the height of the equipment + the increase in loading (for overhead supply of raw materials);

- existing communications (electricity, water, heating);

- good ventilation.

Locate your production in an industrial zone, close to the private sector. This is the most economical way to produce building materials.

Step 3. We purchase raw materials and equipment

Having determined the enterprise's budget, they proceed to the purchase of machines and additional equipment.

Basic parameters for choosing a machine:

- productivity (manufactured quantity per cycle/day/month/year);

- time of one cycle;

- pressure;

- number of matrices;

- mold thickness;

- operating mode (manual, automatic).

Without good equipment, the quality of products will be low. Study the offers on the market in detail and compare them with your requirements.

When choosing between a machine that presses bricks faster and compresses the mold more strongly, choose the latter. It is better to produce fewer products that customers will buy than to produce mountains of defects.

Environmentally friendly raw materials are available in all regions.

To select it, evaluate:

- customer preferences;

- price of the main material;

- the cost of binders, plasticizers and dyes;

- availability;

- quality.

The production line is designed for repeated changes of raw materials and recipes. At the preliminary stage, several options for the source material (filler) are selected: sand, clay, dolomite, marble chips, slag, etc.

Advantages and disadvantages of Lego bricks

Lego bricks are easy to make and have a number of advantages:

- Lightness of blocks due to technological holes;

- Through holes can be used for communications;

- No need for firing;

- Moisture resistance;

- Heat resistance;

- Simplicity and speed of laying;

- Possibility of producing blocks of various textures and colors;

- Environmental friendliness of the building material;

- Dry masonry;

- Beautiful appearance.

Flaws:

- Low heat retention;

- Low hardening speed in the absence of steam treatment;

- High hygroscopicity of the material.

Room

To set up the production of Lego bricks with your own hands, a small room or garage may be suitable . In this case, mini installations with a small output are suitable as equipment.

For full operation, you will need water supply, sewerage and a 380V electrical network. The area of the room should be about 50 sq.m. , and the height is at least 3.5 m. In order to produce high-quality building materials, it is important to avoid sudden temperature fluctuations in the workshop and maintain it at a level of at least 5 degrees.

Make sure there is good ventilation and cleanliness in the room. Don't forget to allocate space for storing finished goods. You will also need convenient access to your workshop.

Production process

The main raw material for the manufacture of building materials is a mixture based on cement, clay, fillers, which use sand and various screenings (for example, crushed stone screenings or waste from sawing limestone rocks), and water. Additionally, plasticizers can be added to the composition to improve density and strength, and coloring pigments to improve the aesthetic characteristics of the product. There is no ideal recipe for making the mixture, just as there is no GOST or any other special regulatory documents for the production of bricks.

Interesting: Danish builder Ole Kirk Christiansen, who is credited with developing the brick with locking elements, never managed to patent his invention. The special tenons were considered an additional technical function of the brick and the patent was refused.

Lego bricks have been manufactured in our country since 2021. When producing it, manufacturers are guided by the requirements of GOST 6133-99 “Concrete wall stones” and GOST 7025-91 “Ceramic and silicate bricks and stones.” In order to compete with manufacturers of traditional wall building materials, it is recommended to undergo the certification procedure and obtain documents confirming compliance with the requirements of these GOSTs. The technological chain for the production of Lego bricks consists of the following stages:

- preparation of the raw material mixture - sifting, grinding, kneading cement, sand and screenings with the addition of water in a special bin

- molding and pressing of the product. The raw material mixture enters the molding chamber, where a blank is made using a matrix, which is then pressed under high pressure and pulled out by a special device.

- brick ripening within three days

The production of Lego bricks is based on the method of hyperpressing or cold welding. Under the influence of high pressure, fine particles are soldered together. In this case, additional heating from external heat sources is not required. It is important to keep in mind that after maturation, the building material cannot be used immediately. It should take from 7 to 28 days for it to gain strength. Otherwise, the products may become deformed and cracks may form on them.

Equipment

The construction equipment market offers a wide selection of equipment for making Lego bricks. Here you will find both large lines and mini installations for organizing a workshop in a small room.

The price of equipment for the production of Lego bricks depends on the power, output and pressure that is exerted on the raw materials when forming the block.

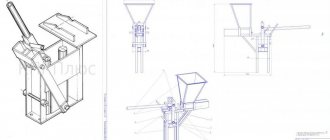

From the equipment you will need a crusher, a vibrating sieve, a mixer, a hopper, a dispenser, a hyperpress, a mold for the production of Lego bricks and a steaming chamber.

Usually , in order to produce Lego bricks at home, an entrepreneur purchases a mini installation. Such a machine contains everything you need for the production process, except for the steaming chamber, which can be purchased separately, built independently, or completely dispensed with.

The best equipment for making Lego bricks

We will look at the best installations that are suitable for organizing a mini production of Lego bricks.

Below are both cheaper mechanical (manual) and hydraulic (semi-automatic) machines , the price of which is an order of magnitude higher. These installations are produced in many cities of Russia. You can buy a machine for producing Lego bricks in Saratov, Krasnodar, Kirov, Blagoveshchensk, etc.

1. Hydraulic machine “Lego 180” – $2,540, manufactured by TekhTron LLC, Kirov; Allows you to make bricks with dimensions: length - 250 millimeters, width - 125 millimeters, height - 65-90 mm. The weight of the block depends on the raw materials used - 3.5 - 4 kg.

Specifications:

- Dimensions: 150 by 65 by 120 centimeters;

- Weight: 202 kilograms;

- Motor: 3 phase, 380V;

- Productivity: 180 pieces per hour, 1440 pieces per shift (3.8 m3);

- Pressure on the product: 8-10 tons (adjustable).

2. Mechanical machine “Lego 120” - cost 680 dollars, produced by TechTron LLC, Kirov. Allows you to produce bricks with the following parameters: length - 250 mm, width - 125 mm, height - 65-90 mm. The weight of the block depends on the raw materials used, from 3.5 kg.

Specifications:

- Dimensions: 160 x 50 x 110 cm;

- Weight: 89 kg;

- Productivity: 120 pieces per 1 hour, 960 pieces/shift (2.5 m3);

- Product pressure: About 2 tons.

3. A mechanical machine worth $630, manufactured by Stanki-Saratov LLC, Saratov. Allows you to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Dimensions: 20 x 50 x 14 cm;

- Weight: 99 kilograms;

- Hopper volume: 40 liters;

- Productivity: up to 1000 pcs/shift;

- Pressure: 2 tons.

4. Hydraulic machine for Lego bricks SGU-2000 – $2,370, manufactured by Ferrum LLC, Kirov. Allows you to make bricks with dimensions: length - 250 mm, width - 125 mm, height - 65 mm.

Specifications:

- Occupied area – 3 sq. m.;

- Productivity: up to 130 pcs/hour;

- Product pressure: 20 tons;

- Power consumption – 7.5 kW;

- 12 month warranty

5. Hydraulic machine for making Lego bricks – $6,360, manufactured by ImportTechKom-Invest LLC, Blagoveshchensk. Allows you to make bricks with dimensions: length - 300 mm, width - 150 mm, height - 100 mm / length - 250 mm, width - 125 mm, height - 75 mm.

Specifications:

- Machine type: hydraulic;

- Productivity: up to 1900 pcs. per shift;

- Size: 350*500*1000 millimeters;

- Pressure: 80 - 100 kN;

- Weight: 450 kg.

6. Hydraulic machine 5BRICKS40S – $4,650, manufactured by GlobImport LLC, Krasnodar. Allows you to produce bricks with the following parameters: length - 250 mm, width - 125 mm, height - 75 mm.

Machine parameters:

- Hydraulic machine;

- Productivity: 200 bricks in 1 hour;

- The kit includes equipment for the manufacture of 3 types of products;

- Dimensions - 0.94 x 0.65 x 1.45 m;

- Hopper volume – 95 l.;

- Weight: 198 kg.

Raw materials for production

The standard dimensions of Lego bricks are 125 mm wide, 250 mm long, and height is from 65 to 90 mm. Depending on the composition, the weight of one Lego brick can vary from 3.5 to 4 kg. One cube of a single Lego brick with a height of 65 mm contains 500 bricks, and to produce such a volume, 220 kg of cement mixture and 1.6 tons of screenings are required. The same amount of raw materials will be required to produce one cube of one-and-a-half bricks with a height of 90 mm, the number of finished products will be 357 bricks.

Each manufacturer can change the composition of the brick at its discretion, but there are several established recipes:

- 90% clay, 10% cement, water;

- 30% sand, 55% clay, 10% cement, water;

- 90% screenings of various fractions, 10% cement, water.

Lego bricks made using fine fraction screening will be of higher quality, however, this fraction is less popular with suppliers, so it is worth planning purchases in advance. An exclusive supply agreement may have to be entered into. In fact, when producing screenings of large fractions, in the absence of consumers, small screenings, which are sometimes called dust, are considered waste. Therefore, finding a supplier with affordable prices will not be difficult.

Lego brick manufacturing technology

The correct technology for producing Lego bricks is the key to a quality product. Using mini installations, you can produce about 1000 blocks per shift.

Stage No. 1: Preparation of raw materials

Raw materials for the production of Lego bricks include environmentally friendly materials such as lime, shell, marble and dolomite screenings, cement, water, sand, dyes and plasticizers. The production of Lego bricks in the southern regions of Russia may allow the use of clay, but it should be remembered that when the air temperature drops to minus 20 degrees, such bricks will most likely crack.

Stage No. 2: Mix for the production of Lego bricks

Typically, the mixture includes a base, a binder and water. The base is sand, clay or screenings; it is recommended to use cement to bind the material, and water is needed for kneading, additional binding and obtaining a homogeneous mass.

- 1 composition option: 87% clay, 10% cement, 3% water and dye.

- Composition option 2: 53% sand, 33% clay, 10% cement, 4% water and dye.

- Composition option 3: 40% dolomite screenings, 40% crushed limestone screenings, 15% cement, 5% water and dye.

- Composition option 4: 85% screenings of crushed limestone (or any other), 10% cement, 3% water, 2% plasticizers and dye.

To avoid problems when using pigment, dilute it in water before adding it to the mixer.

Stage 3: Production process

The manufacturing process depends on what equipment you use to make Lego bricks. The mini installation allows you to mix, dose and form blocks. The production process is structured as follows:

- The operator loads the components into the mixer;

- Intensive mixing of the composition occurs;

- The Lego brick mixture is transported via a conveyor belt to the hopper;

- The composition is dosed and entered into a special matrix made of high-quality steel;

- The mixture is evenly distributed in the mold under the influence of vibration;

- The brick is given its final shape by pressure and vibration.

Stage No. 4: Strengthening

To speed up production and improve the quality of the final product, the brick is steamed in a special chamber. At temperatures up to +70 degrees, it gains final strength in 7-8 hours. In the absence of a steaming chamber, the hyperpressed Lego brick must be aged at a temperature not lower than +15 degrees for two days. The strength of such a block will not be high - about 40-50%. To obtain the greatest strength in the absence of steam treatment, the brick should lie for 20-25 days.

It should be remembered that the determining factor influencing the final strength of the product is the pressure exerted during molding. Small installations have a press for the production of Lego bricks, which is capable of exerting a pressure of about 3 tons, while to obtain a high-quality durable block a pressure of at least 50 tons is required. Pay attention to this indicator when choosing equipment.

Features of the material

Externally, this material has many similarities with the elements of the children's construction set of the same name. The shape features have a positive effect on the installation and strength of the finished object.

Lego brick has a number of positive qualities:

- increased strength;

- reliable heat and noise insulation;

- ease of installation and maintenance after installation;

- environmental friendliness;

- increased resistance to weather conditions.

Each brick has a pair of holes protruding above the surface. It plays the role of a lock, providing additional fixation and strength of the structure. The channels that are formed during installation are often used as highways for cables and infrastructure nodes. Bricks should be fastened with facade glue, and not with the usual mixture of sand and cement.

Back to contents

Mixture composition

There are several formulations. The specific number of components is determined by their characteristics. The basis of any mixture is a combination of 85% filler and 15% PC500 cement. The filler can be:

- crushed stone screening is the best choice for Russia in order to comply with frost resistance requirements;

- a mixture of clay, limestone screenings;

- waste from stone crushing and sawing industries.

Important note: clay negatively affects the frost resistance of the finished product.

The technology for producing Lego bricks does not involve firing. On average, the production of 500 pieces will require 220 kg of cement, as well as 1600 kg of screenings. Taking this into account, we can derive the approximate cost of one brick - 4 rubles.

Back to contents

Lego brick dimensions

Matrices allow you to form blocks of various sizes. The standard parameters of such a block are : length - 250 mm, width - 125 mm, height - 65 mm.

Despite the existence of such a standard, bricks whose size differs from those indicated are also in demand.

On the construction equipment market you can find matrices for making bricks with the following parameters: length - 300 mm, width - 150 mm, height - 100 mm, or blocks close to the standard: length - 250 mm, width - 125 mm, height - 75 mm.

There are also machines for the production of Lego bricks, which provide the ability to produce several types of bricks; you just need to change the shape. This is convenient, since an entrepreneur can expand his range not only due to textures and colors, but also due to sizes, without purchasing additional equipment.

Lego bricks: composition of the mixture

In this regard, there are several varieties. Lego bricks can be made from the following compositions:

- Clay-cement. Components such as clay (90%), cement (8%) and water are used here.

- Composition based on various screenings. This also includes screenings (85-90%), cement (8%) and water.

- Clay-sand. This includes four components: sand (35%), clay (55%), cement (8%) and water.

When planning production, the availability of raw materials should be taken into account. This is an important condition. Bricks produced by pressing require raw materials with a fine fraction. This must be taken into account to achieve the required strength. Lego bricks obtained from screenings have the highest strength characteristics.

The content of a large amount of sand in the product contributes to the deterioration of the strength indicator due to the presence of large sand fractions.

The production of products such as Lego bricks, reviews of which indicate their reliability and efficiency, requires special molding dies. With their help, a surface is created with the required smoothness and with certain parameters of given geometric dimensions. For the full production of these products, you must have the entire set of matrices that allow you to obtain halves of these bricks and fitting products. They are used for finishing work.

Lego brick production staff

When purchasing equipment, you may find that this machine, although intended for use at home, still requires two and sometimes three workers.

If you use a small manual machine to produce Lego bricks, then you can handle the production of the product yourself, but in this case there can be no talk of high output.

Entrepreneurs noted that the most convenient distribution of labor is to allocate workers to the following areas:

- The worker responsible for screening the mixture;

- A worker making a mixture;

- Machine operator.

Lego brick production technology

The manufacturing process of this product includes several stages. Namely, carrying out:

- preparatory work;

- molding;

- pressing bricks;

- storage of finished products with appropriate aging for a certain time.

Next, let's look at each stage in more detail. Preparatory work includes the delivery of the required raw materials, their sorting and preparation of the required mixture for molding.

In order to increase productivity, it is recommended to use additional equipment that will allow you to bring the components to the required fraction (if necessary) by sifting and mix the raw material additives. If there are large volumes, the finished mixture is fed into the receiving hopper of the equipment using a conveyor. Then, the required volume of the substance is sent to the matrix for formation using a dispensing device. This is done automatically with the help of an operator. After this, the dispenser returns to the space below the bunker. Then the valve is opened, which supplies oil to the press. After this, the mixture is compressed for a certain time. Next, using a pusher, the finished brick is pulled out and transferred to a temporary warehouse area, where the resulting products must be stored for three days. After this, the products can be shipped to the consumer. The period of time before starting to use the product must be at least 21 days.

Profitability of production

Let's calculate profitability and find out how profitable the production of Lego bricks is as a business.

Investments

- Hydraulic machine for the production of Lego bricks “Lego 180” – $2,540;

- Shovels, wheelbarrows, gloves and other auxiliary tools – $250;

- Pallets and storage film - $85.

Total: $2,875.