Cross wedge rolling of billets

The essence of the cross-wedge rolling process is as follows: a piece workpiece, usually separated from the rod, is laid across the lead-in part of a stationary tool (Fig. 1).

A movable tool with a similar profile, moving parallel to the stationary one, is inserted into the workpiece, causing it to rotate. Both tools have inclined side edges, which force excess metal to move towards the ends, thereby lengthening the workpiece. The position of the inclined side face in space is determined by the angles of inclination α and sharpness β. Continuously rolling along the stationary tool, the workpiece approaches the shape of the finished product. At the final stage, excess metal from the finalized product is trimmed with knives installed on both sides of the tool. Then it is removed, and the movable tool returns to its original position. The processing cycle of 3–10 s is repeated with the subsequent workpiece.

Figure 1 – Scheme of cross-wedge rolling

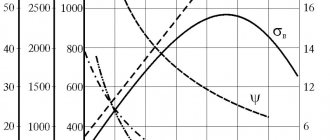

Deformation forces are represented by three components: rolling force Px, axial force - Ru and compressive force - Pz. The rolling force Px determines the drive power of cross-wedge rolling mills. The axial force Py characterizes the magnitude of tensile stresses arising in the rolled workpiece, which should not exceed the yield strength of the rolled material in order to avoid stretching or rupture of the rod.

The compressive force Pz exerts a thrust effect on the rolling stand. To prevent this from affecting the accuracy of the product, it is necessary to ensure sufficient rigidity of the stand, and the magnitude of the elastic deformations of the stand must be significantly less than the tolerances of the rolled products.

The intensity of shape change during rolling is characterized by the degree of compression

where D is the diameter of the original workpiece; d is the diameter of the workpiece after rolling in the section under consideration.

The main technological parameters of a wedge tool when rolling cylindrical sections are the angles of inclination of the side face α and the tip angle β. As the angle α increases, the length of the deformation zone and the required rolling force Px decrease.

However, this increases the axial force Py, which at a certain compression value can cause rupture of the workpiece.

Angle β determines the speed of propagation of the deformation zone along the axis of the workpiece, the length of the tool, the maximum achieved degree of compression per pass and significantly influences the power mode of the rolling process. The correct choice of angles α and β and degree of compression δ regulates the process in a stable mode, eliminating slippage of the workpiece. These parameters significantly affect the power, kinematic parameters, process efficiency, and stress-strain state.

There are several schemes of cross-wedge rolling and corresponding mill designs (Fig. 2). Each of these schemes has both certain advantages and disadvantages, and therefore there has been some specialization in their use. Thus, the single-roll rolling scheme (Fig. 2 a) does not provide significant compression, since the torque is applied to the workpiece only in one area. In addition, the expansion forces lead to bending of the workpiece. All this limits the technological capabilities of this rolling scheme.

Twin-roll rolling (Fig. 2 b, c) is used in mass production and is characterized by extremely high productivity, but at the same time the very high cost of tools and the complexity of debugging processes. In two-roll mills, the workpiece is held in the working area by guide wires or centers. Due to the friction of the workpiece along the guides, its individual protrusions can distort their shape and reduce the accuracy of the product. The use of centers leads to excessive consumption of metal, since areas on the workpiece in contact with the centers, as a rule, are subject to subsequent cutting.

The advantage of single-roll and two-roll mills is the ability to roll products from rods, which is most effective when rolling short workpieces. The fact is that when rolling from a rod, piece blanks turn out to be too short and their transportation is difficult to automate. In addition, the share of end waste in the billet volume becomes so significant that the profitability of rolling is sharply reduced. Roller mills are also successfully used when rolling asymmetrical parts, since this eliminates the need to equalize rolling conditions in different parts of the workpiece.

Three-roll mills (Fig. 2d) create a qualitatively different stress state in the deformation zone and significantly reduce the likelihood of metal destruction in the axial zone of the workpiece, which can be accompanied by transverse rolling. When rolling with three rolls, 1.5 times more torque can be transmitted to the workpiece (three contact pads instead of two), which makes it possible to significantly intensify the rolling process. The disadvantage of this scheme is the small diameters of the rolls and limited compression, since when they come together the rolls rest against one another, which significantly limits the technological capabilities of the mills.

Roller-segment mills (Fig. 2e) are extremely simple and provide maximum process productivity due to the fact that the loading and removal of workpieces is carried out without stopping the rotation of the roll. The disadvantage of the mills is the complexity of manufacturing and debugging tool segments and the lack of adjustment of the distance between the roll and the segment, which negatively affects the accuracy of the product. The mills work with piece workpieces.

Figure 2 – Schemes of cross-wedge rolling mills: a – single-roll; b – two-roll; c – two-roll with screw gauges; g – three-roll; d – roller-segment; e – two-segment; g – rolling with two movable plates; h – rolling with movable and fixed plates; and – rolling with two discs

Two-segment mills (Fig. 2 e) are characterized by low productivity and are mainly used for rolling splines and gear teeth, but can also be used for cross-wedge rolling of shafts. The disadvantages of mills also include the limited length of the tool.

Mills with two movable plates (Fig. 2g) are distinguished by the ease of manufacturing and repair of complex and high-precision tools, which ensures high accuracy of products and ease of debugging of new technological processes. The disadvantage is the low productivity of the process due to two stops of the plates (for loading and removing workpieces) and idle return stroke.

Mills with movable and fixed plates (Fig. 2 h) have the above advantages and at the same time do not require stops to load and remove the workpiece. Schemes have been developed that make it possible to use the reverse motion of the movable plate for rolling. In addition, by moving the stationary plate and the position of the tool on it, it is possible to automatically adjust the diametrical and linear dimensions and thereby increase the accuracy of the rolled parts.

The disadvantage of these mills is the impossibility of rolling from a rod and, therefore, the unprofitability of producing short workpieces, the length of which does not exceed 1–1.5 times its diameter.

The operation of the listed mills in industrial conditions determined the appropriate areas of use for each design. Thus, roller-segment mills are most effective in mass production when rolling blanks for subsequent stamping; mills with flat plates – in the production with frequent changeovers of a large range of high-precision parts of complex configurations; Rolling mills occupy an intermediate position: they are most effective when rolling one or two products, especially short ones, with relatively low requirements for their accuracy.

The rolling scheme with two disks is not used in industry (Fig. 29 i), which is caused by the complexity of manufacturing a wedge tool.

Of all the considered concepts of cross-wedge rolling, the two-roll and flat wedge ones are the most widely used, on the basis of which corresponding types of equipment have been created that allow rolling workpieces with a diameter of 0.5-130 mm and a length of 5-630 mm.

The configuration of the resulting products is very diverse (Fig. 3). It includes cylindrical, conical, spherical and other shapes, all kinds of grooves and protrusions. Diameter differences can be significant; a fourfold reduction is allowed. If a bar with a square or hexagonal cross-section is used as the initial workpiece, then these elements can be saved without changing the workpiece.

Figure 3 – Products obtained by cross-wedge rolling for subsequent stamping (a) and machining (b)

Transverse wedge rolling can be used in the technological process for the production of intermediate profiled workpieces for subsequent precision stamping or other plastic deformation processes, as well as for finishing machining.

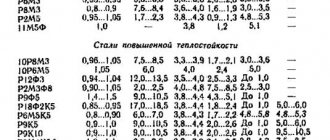

Almost all structural steels, a number of tool steels and heat-resistant materials, as well as non-ferrous alloys based on copper and aluminum can be subjected to cross-wedge rolling. The accuracy of rolled products is comparable to the accuracy of parts produced on automatic lathes. Agricultural machinery parts are produced without further machining. In other cases, final sanding is used. The wear resistance and fatigue strength of parts increases.

It is advisable to use cross-wedge rolling in the manufacture of parts with a production program of more than 10,000–25,000 pieces. per year, i.e. for large-scale and mass production. The specific value of the minimum production program depends on the utilization rate of the metal, its cost and the size of the product. It is advisable to transfer expensive materials to the cross-wedge rolling method for production programs of more than 500 pieces. With production programs on average 1000–10000 pcs. It is advisable to use stamping for products.

Technological schemes of rolling production at a metallurgical plant

Depending on the source material, metallurgical plants use two schemes for the production of rolled products (Fig. 2). When using ingots 1 as the starting material, the technological scheme provides for a section of heating wells and a crimping mill - blooming or slab 2, 3.

Rice. 2. Scheme of rolled products production

When using blooms or slabs as the starting material, the technological process begins with billet mills - a continuous billet mill 4 for section rolling or a wide-band hot rolling mill 5 for sheet rolling.

Subsequent technological operations for obtaining rolled products are the same for both schemes. In the production of long products, the billet is supplied to large-section and medium-section 9 mills, small-section, wire 6 and strip 7 mills. Directly from the blooms, rolling is carried out on rail-beam and large-section mills 8. In sheet production, the billet is supplied to single- and multi-stand cold rolling mills 10. In plate mills, ingots and slabs are used as the starting material.

Transverse knurling of gears

Hot rolling of teeth is carried out in two ways: with axial feed of workpieces and with radial feed of gear rolls (Fig. 4).

Gears with a modulus of less than 4 mm are rolled during axial feeding of the workpiece 1 by two rolls 2, which have a conical intake and a cylindrical calibrating part (Fig. 4 a). The toothed rollers are set at a certain center-to-center distance, and the workpieces, strung on a rod in the form of a stack and clamped by a hydraulic device, are placed exactly in the middle between the rollers. Before rolling, the workpieces are heated in a ring inductor 3. The speed of the axial feed of the workpieces (2–10 mm/sec) is chosen so that during its passage through the inductor the workpiece is heated to the rolling temperature (1200 °C).

This technological process ensures the production of ring gears with straight and oblique teeth with an accuracy of up to 10 degrees. It is used in cases where rolled gears operate at relatively low speeds.

Figure 4 - Schemes for rolling gear teeth: a - with axial feed of workpieces, b - with radial feed of gear rolls; 1 – workpiece; 2 – gear rollers; 3 – inductor; 4 – support rings

Wheels with a module of 5 mm and higher are rolled with radial feed of two rolls (Fig. 4 b). The heated workpiece is clamped between a pair of support rings 4. The teeth are rolled with a machining allowance of 0.5–1.5 mm per side. During the rolling process, process lubricant is supplied to the rolls. The roll flanges prevent the metal from being squeezed out into the ends of the workpiece during rolling.

Process control

In the process of metallurgical production, melting control, control of production processes, as well as finished products are carried out. Melting control establishes the compliance of the ingots of a given melt with the technical conditions: the quality of the steel is determined, the conformity of the quality of the steel for the rolling of certain products. Based on the results of melt control, a technology for rolling ingots of a given melt is assigned.

Control of production processes is carried out in the following areas:

- Storage of ingots, billets;

- Heating before rolling;

- Rolling of ingots into blanks and blanks into finished products;

- Cutting, straightening of blanks and finished products;

- Cooling after hot rolling and heat treatment;

- Finishing, marking and delivery of finished products.

Control of production processes is carried out on the basis of technological instructions for each site.

Control of finished products establishes compliance of finished rolled products with GOST requirements or technical specifications: for physical and mechanical properties, for internal and surface defects, for dimensions and straightness (flatness) of rolled products, etc.

Multi-Roll Rolling Processes

Plates, sheets, strips, tapes, and foil based on refractory metals are widely used in many modern industries. Alloys of molybdenum, tungsten, niobium, tantalum, and chromium are used as structural materials in aviation, space, and chemical engineering.

The quality of manufactured semi-finished products is regulated by standards and special technical conditions that determine maximum deviations for nominal dimensions, shape deviations, and mechanical characteristics.

Cracks, holes, delamination, dents, marks from rollers, scratches, etc. are not allowed on the surface of the sheets.

For cold rolling of sheets, strips, strips and thin foil from refractory metals, multi-roll mills are used (Fig. 5 a) providing high precision of flat rolled products, high quality of surface finishing of sheets and strips, the ability to regulate the profile of the rolled strip, reduce the number of intermediate anneals, and the absence of warping and cracking of the side edges of strips and tapes.

Twenty-roll mills are widely used for rolling thin strips and especially thin foil. On mills with work rolls with a diameter of 20 mm, strip with a minimum thickness of 0.02 mm is rolled. Mills with work rolls with a diameter of 10 mm are often used, on which strips with a thickness of 0.003–0.007–0.01 mm are rolled. On mills with a roll diameter of 6 mm, the strip is rolled to a thickness of 0.0018–0.0025 mm.

Multi-roll mills have high stand rigidity. They are equipped with automatic control systems for adjusting strip thickness and tension, pre-setting thickness, tension and rolling speed, temperature control and other means of automating the rolling process.

This ensures that strict requirements for the thickness of rolled products are met. Thus, for a rolled product thickness of 0.0025–0.0032, 0.1 mm, the thickness tolerances are ±0.000127, +0.00055 mm, respectively.

For hot rolling of sheets, semi-planetary mills are used (Fig. 5 b). They are designed for rolling slabs measuring 25x400x11000 mm. The thickness of the finished strip is 1.6-6 mm.

The mills include a back-up roll with a diameter of 400 mm, which is surrounded by 22 work rolls with a diameter of 70 mm. The diameter of the upper regular roll is 600 mm. The work rolls perform planetary motion along the surface of the support roll and rest on the surface of the shoe. This design ensures the rigidity of the planetary set, and in combination with the upper roll of the entire mill as a whole.

Planetary mills (Fig. 5c, d) provide high quality and good flatness of sheets as a result of favorable operating conditions for the tool (each roll is in contact with the heated metal no more than 6% of the time) and greater rigidity of the roller system.

Planetary mills are used for hot rolling of sheet blanks, as well as plates, rods and wires made of heat-resistant alloys (Fig. 5 c, d). Planetary mills have 20 pairs of work rolls located in cages around the support rolls. In one pass, a slab 45 mm thick is rolled into a strip 2.5 mm thick and 2800 mm wide; the slab feed speed into the rolls is 0.05 m/sec, the exit speed is 9 m/sec.

A high degree of deformation leads to significant changes in the structure and mechanical properties of the metal. In the process of planetary rolling with large reductions, strong crushing of grains occurs and the formation of a directional oriented structure.

Figure 5 – Design diagrams of rolling mills: a – multi-roll; b – semi-planetary; c, d – planetary; 1 – support shoe; 2 – support roller; 3, 4 – guide and feed rollers, respectively; 5, 6 – working rollers; 7 – separator

During hot rolling in air, intense gas saturation with oxygen occurs. The surface layer contains 10–20 times more oxygen than the original material. The presence of an increased oxygen content significantly reduces the plasticity of the material, and oxidative processes also occur intensively.

Creation of non-oxidizing processing conditions makes it possible to eliminate or minimize irreversible losses due to oxidation; practically eliminate gas saturation of the metal during processing; use elevated plastic deformation temperatures, which increases ductility and reduces deformation force, and generally improves the quality of the product.

The implementation of non-oxidizing processing processes is carried out on rolling mills in a vacuum or gas environment with a controlled composition (Fig. 6)

Figure 6 – Two-roll vacuum longitudinal rolling mill 600: 1 – receiving table; 2 – vacuum valves; 3 – loading chamber; 4 – heating furnace; 5 – working cage; 6 – working chamber; 7 – unloading chamber; 8 – unloading table

The efficiency of rolling in a vacuum or gas environment with a controlled composition is determined by the following factors: the production of semi-finished products or high-quality products with increased or new physical, chemical and mechanical properties; increasing the yield of suitable material; eliminating a number of technological process operations to remove oxidized and gas-saturated layers and increasing productivity.

Roll calibration

Calibration solves the following problems:

- Establishing the number of passes;

- Establishing the shape and dimensions of the cross-section of the strip after each pass;

- Sequence of alternating stripe shapes.

Rolling produces simple (circle, square, strip, etc.) and complex (rails, beams, angles, etc.) types of rolled products.

Rolling of section and sheet steel is carried out with a greater or lesser number of passes through the rolls.

With each pass through the rolls, the cross-sectional area of the strips is reduced and, if necessary, a rough shape is given to the final product.

Rolling of sheets and broadband steel is carried out on a smooth roll barrel. The profile of the forming barrel is determined by calibrating the sheet rolls.

During hot rolling, the roll barrel is made concave, and during cold rolling, it is convex. Concavity compensates for the thermal expansion of the roll barrel, convexity compensates for the deflection of the roll due to the rolling force.

To obtain the required shape of rolled products, ring grooves of various shapes are cut on the barrel of rolls of section rolling mills on roll lathes.

A circular groove on one roll is called a groove. The streams of two rolls form a caliber.

The shape of the gauges used to produce rolled products of simple shape - square, circle, is shown in Fig. 1 (c, f, g).

Oval gauges are used in combination with square and round gauges (Fig. 1, 6, c, etc.), rhombic gauges - in combination with square gauges (Fig. 1, e).

Rectangular (box) gauges (I, II) are used for drawing metal on blooming mills, continuous billet mills and roughing stands of section mills.

Rice. 1. Scheme of calibration of rolls of small-section mill 250

Depending on the purpose, there are four groups of calibers:

- Exhaust, used to reduce the cross-sectional area;

- Preparatory, they further reduce the cross-sectional area and give the strip the rough shape of the finished product;

- Pre-finishing, they further reduce the cross-sectional area and prepare to obtain the final shape of the rolled product;

- Finishing, gives the strip its final shape.

Rolling of sections and sheet steel is carried out in several passes through rolls. The distribution of reductions among passes is made taking into account the force on the rolls, the power of the main electric motor, the strength of the working stand parts, the conditions for gripping the metal by the rolls, and the plasticity of the metal.

When rolling cast metal, the reduction in the first passes is assumed to be small, since the ductility of the metal is low due to its coarse-grained structure. Taking into account the above factors, the minimum possible number of passes is achieved. In Fig. 1 schematically shows the calibration of the rolls of the small-section mill 250.

Depending on the cross-sectional area of the finished rolled product, a square billet receives compression in all 12 stands (Fig. 1, b, f), or only in eight stands when rolling a billet with a diameter of 18–19 mm (X, c). Box gauges are cut on the rolls of the first two stands. On the rolls of working stands III, IV, V, VI, grooves of gauges of the oval-square system are cut.

On the rollers of the pre-finishing and finishing working stands, strands of calibers are cut, intended for the preparation and production of round, square and angular profiles.

Production of blanks

Billet mills are designed for rolling blooms into billets for section, wire and pipe rolling mills. Depending on the specialization, billet mills roll from blooms with a cross-section of ZOOx300-370×370 mm: large billets with a square cross-section from 125×125 to 140×140 mm and blooms with a cross-section of 200×200 mm; high-quality square billets with a cross-section from 80×80 to 120×120 mm; round billets with a diameter of 75–300 mm for pipe rolling mills.

In Fig. Figure 5 shows a diagram of the arrangement of equipment for a continuous billet mill (NCM) 900/700/500. Blooms without heating are supplied to the NZS via roller conveyor 1. The NZS consists of three groups of working stands.

Rice. 5. Layout of equipment NZS 900/700/500

The nominal diameter of the rolls for groups of working stands is: I - 900 mm, II - 700 mm and III - 500 mm. Rotators 2 and 6 are installed in front of groups II and III of working stands. In the line of outgoing roller table 3, shears with a force of 8 MN are installed for cutting workpieces with a cross-section of 120×120 mm. After the third group of working stands, workpieces with a cross-section of 60×60–80×80 mm are supplied to refrigerator 5. As follows from the considered technological process diagram for rolling a workpiece at NZS 900/700/500, in each group of working stands, rolling is carried out according to the principle of a continuous process, and Therefore, it is necessary to achieve constant second volumes of metal in groups of stands.

When calibrating NZS rolls, the calibration constant is determined: C=FDpn(1+Sh), where F is the cross-sectional area of the rolled strip; Dp is the working diameter of the rolls; n is the number of roll rotations; Sh is advance of the metal rolls.

Rolling in continuous groups of working stands without support or high tension is possible only if the constant calibration of all stands in each group of NZS is equal. The distance between groups of working stands is assumed to be slightly greater than the length of the roll coming out of the last stand of the previous group of NZS, and it is not necessary to achieve constancy between groups of stands.

Constant calibration is regulated by changing the number of rotations of the rolls. Flexible adjustment of the roll rotation speed is ensured by an individual drive for each working stand. Behind the last stand of the NZS, flying shears 4 are installed, with which the workpieces are cut into measured lengths of 8–12 m.

The exit speed of workpieces from the third group of NZS is 5–7 m/s. The cut workpieces are collected into bundles on a baling roller table and transferred to the mill's refrigerators.

After cooling, the workpieces are inspected and surface defects are removed.

The annual productivity of the NZS 900/700/500 is ~ 5 million tons.

Long steel production

On section rolling mills, profiles with a round section with a diameter of up to 220 mm, a square section with a square side from 8 to 220 mm, a rectangular section with a height of 4 to 60 mm and a width of 12 to 350 mm, equal and unequal angles with a flange width from 16 to 350 mm are produced. 250 mm, beams and channels up to 300 mm high, wire rod with a diameter of 5–9 mm. Channels and beams with a height of up to 600 mm are rolled on rail-beam mills and on special beam rolling mills with a height of up to 1000 mm and a flange width of up to 420 mm.

Any questions? Contact us by phone from the page - Contacts

Bloom production

A bloom is a square blank with rounded corners with a cross-section of up to 400×400 mm.

Depending on the range of blooms and the required productivity, single-stand, two-roll reversible and multi-stand blooming machines are used.

Rice. 3. Layout of blooming equipment 1300

Single-cage blooming plants are most widespread.

A modern crimping machine is a powerful automated single-stand blooming machine with roll diameters of 1300–1500 mm. In Fig. Figure 3 shows a diagram of the arrangement of blooming equipment 1300. Ingots from the steelmaking shop are fed into the span of heating wells 1 on platforms along railway tracks. Ingots weighing 10–15 tons, heated to rolling temperature, are removed from the heating wells by an overhead crane with a tong gripper and transferred to the platform of the ingot carrier 2. Four ingot carriers, continuously moving along a circular path, alternately approach the receiving roller conveyor 3 of the blooming. The next ingot carrier automatically stops parallel to the receiving roller table, and the ingot is loaded onto the roller table rollers using a stationary rack-type pusher. Feeding and rolling roller conveyors 4 transport the ingot to the blooming working stand. A rotary table is installed in the line of the supply roller table - a scale, with which the ingot is automatically weighed and, if necessary, rotated in a horizontal plane by 180°. The rollers of the working roller conveyor bring the ingot to the rolls of the working stand 5.

Rice. 4. Calibration of blooming rollers

The working cage of the Blooming 1300 consists of two massive steel frames weighing 105 tons each. Rolls with a diameter of 1300 mm and a barrel length of 2800 mm, made by forging from chromium-nickel steel, are mounted in the frame assembly on textolite bearings. Setting the gap between the rolls is ensured by a screw pressure mechanism with an electromechanical drive; balancing of the upper roll with the cushions is carried out by a lever-load mechanism. Each roller is driven by a DC electric motor MP-110-65 with a power of 6800 kW, 0-60-90 rpm through universal spindles with sliding liners.

In Fig. Figure 4 shows the calibration of blooming rollers. The ingot is rolled in the first wide caliber. As the cross-section decreases, the roll is transferred to box gauges II, III, IV (see Fig. 4). If a small number of slabs are rolled on a blooming machine, then the first gauge is made in the middle of the roll to evenly distribute the rolling force on the left and right bearings. The specified width (up to 1000 mm) is ensured by passing the slab onto the edge through box gauges. In 9–13 passes through the rolls, the ingots are rolled into blooms with a cross-section of 300×300–370×370 mm.

The turning of the rolls in front of the odd gaps and their installation along the length of the roll barrel against the required caliber is ensured by a hook tilter built into the manipulator ruler and by manipulators installed on both sides of the working stand. The scale formed on the surface of the ingot during the heating process is destroyed during the first passes through the rolls with slight compression and is washed off with water. Under the working cage there is a channel through which scale is transported by a stream of water into settling pit 6 (see Fig. 3). The rolled blooms arrive at the fire stripping machine 7, installed after the working stand, and are transferred to the shearing section 8 by a transport roller conveyor.

Using scissors, the front and rear ends of the bloom are trimmed to remove shrinkage cavities and defective end sections, as well as the bloom is cut into measured lengths. The trim when rolling carbon boiling steel is 3–5%, when rolling calm steel - up to 17.5% of the ingot weight. The cut parts of the blooms end up on a conveyor, which is used to load railway platforms.

To avoid misgrading, blooms and trimmings are branded. The cleaned and trimmed blooms are supplied along roller conveyor 9 for further rolling to a continuous billet mill. On the 1300 blooming machine it is possible to roll slabs with a thickness of 100–200 mm and a width of up to 1000 mm. The annual productivity of the automated blooming 1300 is 5.5–6 million tons of ingots. In specialized sheet production, a slab with a roll diameter of 1150–1250 mm is installed as a crimping mill. The slab working stand has vertical rollers that provide width compression. At the slab mill, ingots weighing up to 30 tons are rolled into slabs with a thickness of 150–300 mm and a width of 1000–1550 mm. The slab production capacity is 6.5 million tons of ingots per year.