Material strength

Steel has one important property - strength. Tests are carried out to determine the strength of the material. A steel rod of the selected grade is stretched, and then it is checked how the sample has changed after the applied forces. Based on the test results, a graph is drawn up, which indicates the applied force (stress) and the level of deformation.

Metal has such an important parameter as its yield strength. The yield strength of a sample can be determined by testing. If minor loads were applied to the workpiece, its shape will be restored. When the stress applied to the workpiece goes beyond the yield point, the sample will undergo irreversible changes.

The purpose of the test is to determine the maximum stress that the specimen can withstand. Therefore, the tests continue until the sample ruptures. In this case, testers will learn what the tensile strength of the steel is.

Strength of steels

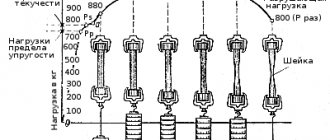

The mechanical properties of steels, like other metallic materials, are most often determined using a tensile test. A tensile test involves applying a tensile force to a sample - most often in the form of a rod - and measuring the change in length of the sample as the applied force increases (Figure 1). The sample is cut from the material or product of interest. The test result is a tensile diagram - a graph on which stress is plotted vertically (force per unit area of the sample), and deformation (relative change in the length of the sample) is plotted horizontally.

Figure 1 – Stress-strain diagram when testing a tensile specimen

At small deformations, the rod behaves elastically—it “springs back” back to its original length if the applied stresses are removed. When the stress is above a value called the yield strength, the rod begins to deform plastically. This means that after the applied stress is removed, the rod no longer returns to its original length, but receives an irreversible elongation. By stretching the rod until failure, find the maximum stress on the stress-strain diagram. This maximum stress is called the tensile strength or tensile strength of the material from which the specimen was made.

Product hardness

Steel has hardness, which is measured using an indenter. An indenter is a material that is driven into steel until an imprint is left. Of course, it must be stronger and harder than steel. The best material for such a tool is diamond. Hardness is measured using the Rockwell scale, and the hardness of the workpiece can also be determined using the Brinnell and Vickers scale. By measuring Rockwell hardness, the depth of the indenter mark on the workpiece is determined. There is a relationship between hardness and strength in hardened steels when properly tempered.

Plasticity of metal

Steel is characterized by ductility; this property cannot be underestimated. Thanks to its ductility, steel can be used to create any workpieces and products. Not all steels are ductile. If a material is not ductile, then it is brittle, and those that are brittle have become vulnerable. Products made from such materials may collapse as a result of mechanical stress. If ductile steel bends under mechanical stress, then brittle steel breaks.

You can check ductility (or brittleness) using the tensile test already described above. After reaching the yield point, the plastic workpiece will begin to stretch well. A fragile sample will simply break. In a similar way, you can test the material for contraction by applying force in the opposite direction.

Plasticity of steels

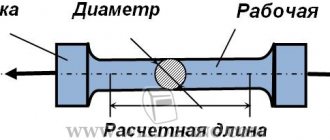

If, in a simple bending test, the metal fails only after a large plastic deflection, then it is considered ductile. If there is no such deflection at all or it is insignificant, the material is called brittle. Good ductility of the metal is manifested during tensile testing by a high elongation of the sample and/or its narrowing. Elongation expresses the percentage increase in the length of a specimen after failure to its original length (see Figure 1). Similarly, contraction expresses the percentage reduction in the area of the sample compared to its original area (Figure 2).

Figure 2 – Tensile diagram for brittle and ductile metals

Most often, the mechanical properties of steels as a whole are assessed by three indicators: tensile strength, yield strength and elongation. The strength and ductility limits are usually expressed in megapascals (MPa), elongation - in percent (%). Almost always, as the strength of a metal or alloy increases, its ductility decreases.

Metal fatigue

Metal fatigue is a property that describes the destruction of steels under the influence of cyclic loads. Fatigue failure occurs as follows. For example, we can take a part that is subjected to tensile loads in one part and compressive loads in the other. Cyclic stress occurs, but it is below the yield stress. The part will work for a long time until a point of stress concentration appears on its surface. It could be a minor scratch or nick.

After scoring occurs, the stress at the point of concentration will exceed the yield strength. This will lead to cracks and more serious defects. As a result, the part will collapse. Shafts, springs, and wheel axles experience similar loads. They are subject to cyclic loads.

Metal fatigue is also characteristic of those parts that constantly experience vibrating loads. For example, this happens with parts on airplane wings. It is almost impossible to prevent destruction; the only way is regular inspection and prevention. If a part is damaged, it is safer to replace it. Steel valves in automobile engines are susceptible to fatigue. At the slightest damage, components are replaced.

December 05, 2017

Share with friends:

Appendix 2. Mechanical characteristics of steels

Home / Services / GOSTs and SNiPs / GOST 14249-89 Vessels and apparatus. Norms and methods of strength calculations /print version

Mechanical characteristics: for carbon and low-alloy steels - table. 1 and 2, for heat-resistant chromium steels - table. 3 and 4, for heat-resistant, heat-resistant and corrosion-resistant steels of the austenitic and austenitic-ferritic class - table. 5 and 6

Table 9

| 210(2100) | 300(3000) | 280(2800) | 220(2200) | 195(1950) | 270(2700) | 280(2800) | |||

| 100 | 230(2300) | 201(2010) | 265,5(2655) | 240(2400) | 213(2130) | 188(1880) | 240(2400) | 240(2400) | |

| 150 | 224(2240) | 197(1970) | 256,5(2565) | 231(2310) | 209(2090) | 183(1830) | 231(2310) | 231(2310) | |

| 200 | 223(2230) | 189(1890) | 247,5(2475) | 222(2220) | 204(2040) | 177(1770) | 222(2220) | 222(2220) | |

| 250 | 197(1970) | 180(1800) | 243(2430) | 218(2180) | 198(1980) | 168(1680) | 218(2180) | 218(2180) | |

| 300 | 173(1730) | 162(1620) | 226,5(2265) | 201(2010) | 179(1790) | 150(1500) | 201(2010) | 201(2010) | |

| 350 | 167(1670) | 147(1470) | 210(2100) | 185(1850) | 159(1590) | 132(1320) | 185(1850) | 185(1850) | |

| 375 | 164(1640) | 140(1400) | 199,5(1995) | 174(1740) | 147(1470) | 123(1230) | 162(1620) | 174(1740) | |

| 400 | — | — | 183(1830) | 158(1580) | — | — | — | 158(1580) | |

| 410 | — | — | — | 156(1560) | — | — | — | 156(1560) | |

| 420 | — | — | — | 138(1380) | — | — | — | 138(1380) | |

Table 10

| Design temperature of the vessel or apparatus wall, °C | Calculated value of tensile strength Rt, MPa (kgf/cm2), for steel grades | |||||||

| VSt3 | 09G2S, 16GS | 20 and 20K | 10 | 10G2, 09G2, 17GS, 17G1S, 10G2S1 | ||||

| thickness, mm | ||||||||

| up to 20 | over 20 | up to 32 | over 32 | up to 160 | ||||

| 20 | 460(4600) | 380(3800) | 470(4700) | 440(4400) | 410(4100) | 340(3400) | 440(4400) | |

| 100 | 435(4350) | 360(3600) | 425(4250) | 385(3850) | 380(3800) | 310(3100) | 385(3850) | |

| 150 | 460(4600) | 390(3900) | 430(4300) | 430(4300) | 425(4250) | 340(3400) | 430(4300) | |

| 200 | 505(5050) | 420(4200) | 439(4390) | 439(4390) | 460(4600) | 382(3820) | 439(4390) | |

| 250 | 510(5100) | 435(4350) | 444(4440) | 444(4440) | 460(4600) | 400(4000) | 444(4440) | |

| 300 | 520(5200) | 440(4400) | 445(4450) | 445(4450) | 460(4600) | 374(3740) | 445(4450) | |

| 350 | 480(4800) | 420(4200) | 441(4410) | 441(4410) | 430(4300) | 360(3600) | 441(4410) | |

| 375 | 450(4500) | 402(4020) | 425(4250) | 425(4250) | 410(4100) | 330(3300) | 425(4250) | |

Table 11

| Design temperature of the vessel or apparatus wall, °C | Calculated value of the yield strength Rp0.2, MPa (kgf/cm2), for steel grades | ||||

| 12MH | 12ХМ | 15ХМ | 15Х5М | 15Х5М-У | |

| 20 | 220(2200) | 220(2200) | 233(2330) | 220(2200) | 400(4000) |

| 100 | 219(2190) | 219(2190) | 230(2300) | 210(2100) | 352,5(3525) |

| 150 | 218(2180) | 218(2180) | 229(2290) | 207(2070) | 345(3450) |

| 200 | 217,5(2175) | 217,5(2175) | 228(2280) | 201(2010) | 337,5(3375) |

| 250 | 217,5(2175) | 217,5(2175) | 228(2280) | 190(1900) | 330(3300) |

| 300 | 212(2120) | 212(2120) | 220(2200) | 180(1800) | 315(3150) |

| 350 | 206(2060) | 206(2060) | 213(2130) | 171(1710) | 300(3000) |

| 375 | 202(2020) | 202(2020) | 210(2100) | 164(1640) | 270(2700) |

| 400 | 198(1980) | 198(1980) | 205(2050) | 158(1580) | 255(2550) |

| 410 | 195(1950) | 195(1950) | 204(2040) | 155(1550) | 240(2400) |

| 420 | 194(1940) | 194(1940) | 202(2020) | 152(1520) | 225(2250) |

Table 12

| Design temperature of the vessel or apparatus wall, °C | Calculated value of tensile strength Rt, MPa (kgf/cm2), for steel grades | ||||

| 12MH | 12ХМ | 15ХМ | 15Х5М | 15Х5М-У | |

| 20 | 450(4500) | 450(4500) | 450(4500) | 400(4000) | 600(6000) |

| 100 | 440(4400) | 440(4400) | 440(4400) | 380(3800) | 572(5720) |

| 150 | 434(4340) | 434(4340) | 434(4340) | 355(3550) | 555(5550) |

| 200 | 430(4300) | 430(4300) | 430(4300) | 330(3300) | 535(5350) |

| 250 | 440(4400) | 437(4370) | 437(4370) | 320(3200) | 520(5200) |

| 300 | 454(4540) | 445(4450) | 445(4450) | 318(3180) | 503(5030) |

| 350 | 437(4370) | 442(4420) | 442(4420) | 314(3140) | 492(4920) |

| 375 | 427(4270) | 436(4360) | 436(4360) | 312(3120) | 484(4840) |

| 400 | 415(4150) | 426(4260) | 426(4260) | 310(3100) | 472(4720) |

| 410 | 413(4130) | 424(4240) | 424(4240) | 306(3060) | 468(4680) |

| 420 | 410(4100) | 421(4210) | 421(4210) | 300(3000) | 462(4620) |

Table 13

| Design temperature of the vessel or apparatus wall, °C | Calculated value of the yield strength Rp0.2, MPa (kgf/cm2), for steel grades | |||||

| 08Х18Г8Н2Т (KO-3) | 07X13AG20 (ChS-46) | 02Х8Н22С6 (EP-794) | 15Х18Н12С4ТУ (EI-654) | 08Х22Н6Т, 08Х21Н6М2Т | 06ХН28МДТ, 03ХН28мдт | |

| 20 | 350(3500) | 350(3500) | 200(2000) | 350(3500) | 350(3500) | 220(2200) |

| 100 | 328(3280) | 260(2600) | 160(1600) | 330(3300) | 300(3000) | 207(2070) |

| 150 | 314(3140) | 230(2300) | 150(1500) | 310(3100) | 280(2900) | 195(1950) |

| 200 | 300(3000) | 200(2000) | 135(1350) | 300(3000) | 283(2830) | 186(1860) |

| 250 | 287(2870) | 190(1900) | 125(1250) | 280(2800) | 250(2500) | 175(1750) |

| 300 | 274(2740) | 180(1800) | 115(1150) | 270(2700) | 240(2400) | 165(1650) |

| 350 | — | 170(1700) | — | — | — | 160(1600) |

| 375 | — | 165(1650) | — | — | — | 157,5(1575) |

| 400 | — | 160(1600) | — | — | — | 155(1550) |

Table 14

| Design temperature of the wall of the vessel or apparatus, °C | Calculated value of tensile strength Rt, MPa (kgf/cm2), for steel grades | ||||

| 08Х18Г8Н2Т (KO-3) | 07X13AG20 (ChS-46) | 02Х8Н22С6 (EP-794) | 15Х18Н12С4ТУ (EI-654) | 06ХН28МДТ, 03ХН28мдт | |

| 20 | 600(6000) | 670(6700) | 550(5500) | 700(7000) | 550(5500) |

| 100 | 535(5350) | 550(5500) | 500(5000) | 640(6400) | 527,5(5275) |

| 150 | 495(4950) | 520(5200) | 480(4800) | 610(6100) | 512,5(5125) |

| 200 | 455(4550) | 490(4900) | 468(4680) | 580(5800) | 500(5000) |

| 250 | 415(4150) | 485(4850) | 450(4500) | 570(5700) | 490(4900) |

| 300 | 375(3750) | 480(4800) | 440(4400) | 570(5700) | 482,5(4825) |

| 350 | — | 465(4650) | — | — | 478(4780) |

| 375 | — | 458(4580) | — | — | 474(4740) |

| 400 | — | 450(4500) | — | — | 470(4700) |

Table 15

| Design temperature of the vessel or apparatus wall, °C | Calculated value of the yield strength Rp1.0, MPa (kgf/cm2), for steel grades | ||||

| 12Х18Н10Т, 12Х18Н12Т, 10Х17Н13М2Т, 10Х17Н13М3Т | 08Х18Н10Т, 08Х18Н12Т, 08Х17Н13М2Т, 08Х17Н15М3Т | 03Х21Н21М4ГБ | 03Х18Н11 | 03Х17Н14М3 | |

| 20 | 276(2760) | 252(2520) | 270(2700) | 240(2400) | 230(2300) |

| 100 | 261(2610) | 234(2340) | 260(2600) | 200(2000) | 210(2100) |

| 150 | 252(2520) | 222(2220) | 257(2570) | 187,5(1875) | 195(1950) |

| 200 | 240(2400) | 210(2100) | 257(2570) | 180(1800) | 180(1800) |

| 250 | 231(2310) | 198(1980) | 250(2500) | 173(1730) | 170(1700) |

| 300 | 222(2220) | 184,5(1845) | 223(2230) | 168(1680) | 155(1550) |

| 350 | 216(2160) | 169,5(1695) | 215(2150) | 162(1620) | 152(1520) |

| 375 | 210(2100) | 162(1620) | 212(2120) | 160(1600) | 135(1350) |

| 400 | 205,5(2055) | 154,5(1545) | 210(2100) | 160(1600) | 130(1300) |

| 410 | 204(2040) | 153(1530) | — | 160(1600) | 125(1250) |

| 420 | 202,5(2025) | 151,5(1515) | — | 160(1600) | 123(1230) |

| 430 | 201(2010) | 150,75(1508) | — | 160(1600) | 122(1220) |

| 440 | 199,5(1995) | 150(1500) | — | 160(1600) | 121(1210) |

| 450 | 198(1980) | 148,5(1485) | — | 160(1600) | 120(1200) |

| 460 | 196,5(1965) | 147(1470) | — | — | — |

| 470 | 195(1950) | 146(1460) | — | — | — |

| 480 | 93,5(1935) | 145,5(1455) | — | — | — |

| 490 | 192(1920) | 144(1440) | — | — | — |

| 500 | 190,5(1905) | 142,5(1425) | — | — | — |

| 510 | 189(1890) | 141(1410) | — | — | — |

| 520 | 187,5(1875) | 139,5(1395) | — | — | — |

| 530 | 186(1860) | 138(1380) | — | — | — |

Note. The yield strength for forgings, long products and pipes at 20 °C should be taken as follows:

- for forgings made of steel grades 12Х18Н10Т, 10Х17Н13М2Т, 10Х17Н13М3Т - ;

- for forgings and long products made of steel grade 08Х18Н10Т - ;

— for long rolled steel grades 12Х18Н10Т, 10Х17Н13М2Т, 10Х17Н13М3Т -;

- for forgings made of steel grades 03Х17Н14М3, 03Х18Н11 - ;

- for long products made of steel grade 03Х18Н11 - ;

- for pipes made of steel grade 03Х21Н21М4ГБ (ZI-35) - ;

- for forgings made of steel grade 03Х21Н21М4ГБ (ZI-35) - (forgings)

where the yield strength of the forging material is determined according to GOST 25054 (by agreement).

Table 16

| Design temperature of the vessel or apparatus wall, °C | Calculated value of the yield strength Rp0.2 MPa (kgf/cm2), for steel grades | ||||

| 12Х18Н10Т, 12Х18Н12Т, 10Х17Н13М2Т, 10Х17Н13М3Т | 08Х18Н10Т, 08X18H12T, 08Х17Н13М2Т, 08X17H13M3T | 03Х21Н21М4ГБ | 03Х18Н11 | 03X17H14M3 | |

| 20 | 240(2400) | 210*(2100) | 250(2500) | 200(2000) | 200(2000) |

| 100 | 228(2280) | 195(1950) | 240(2400) | 160(1600) | 180(1800) |

| 150 | 219(2190) | 180(1800) | 235(2350) | 150(1500) | 165(1650) |

| 200 | 210(2100) | 173(1730) | 235(2350) | 140(1400) | 150(1500) |

| 250 | 204(2040) | 165(1650) | 232(2320) | 135(1350) | 140(1400) |

| 300 | 195(1950) | 150(1500) | 205(2050) | 130(1300) | 126(1260) |

| 350 | 190(1900) | 137(1370) | 199(1990) | 127(1270) | 115(1150) |

| 375 | 186(1860) | 133(1330) | 195(1950) | 125(1250) | 108(1080) |

| 400 | 181(1810) | 129(1290) | 191(1910) | 122,5(1225) | 100(1000) |

| 410 | 180(1800) | 128(1280) | — | 121,5(1215) | 98(980) |

| 420 | 180(1800) | 128(1280) | — | 121(1210) | 97,5(975) |

| 430 | 179(1790) | 127(1270) | — | 120,5(1205) | 97(970) |

| 440 | 177(1770) | 126(1260) | — | 120(1200) | 96(960) |

| 450 | 176(1760) | 125(1250) | — | 120(1200) | 95(950) |

| 460 | 174(1740) | 125(1250) | — | — | — |

| 470 | 173(1730) | 124(1240) | — | — | — |

| 480 | 173(1730) | 123(1230) | — | — | — |

| 490 | 171(1710) | 122(1220) | — | — | — |

| 500 | 170(1700) | 122(1220) | — | — | — |

| 510 | 168(1680) | 120(1200) | — | — | — |

| 520 | 168(1680) | 119(1190) | — | — | — |

| 530 | 167(1670) | 119(1190) | — | — | — |

* For steels 08Х17Н13М2Т, 08Х17Н15М3Т the yield strength at 20 °С is 200 (2000) MPa (kg/cm2).

Notes:

1. For forgings made of steel grades 12Х18Н10Т, 10Х17Н13М2Т, 10Х17Н13М3Т, the yield limits are given in table. 16, multiplied by 0.83.

2. For long rolled steel grades 12Х18Н10Т, 10Х17Н13М2Т, 10Х17Н13М3Т, the yield limits are given in table. 16, multiplied by

where R*p0.2 is the yield strength of the rolled section material, determined according to GOST 5949.

3. For forgings and long products made of steel grade 08Х18Н10Т, the yield limits given in table. 16, multiplied by 0.95.

4. For forgings made of steel grade 03Х17Н14М3 the yield limits given in table. 16, multiplied by 0.9.

5. For forgings made of steel grade 03Х18Н11, the yield limits given in table. 16, multiplied by 0.9; for long rolled steel grade 03Х18Н11, the yield limits are multiplied by 0.8.

6. For pipes made of steel grade 03Х21Н21М4ГБ (ZI-35), the yield limits given in table. 16, multiplied by 0.88.

7. For forgings made of steel grade 03Х21Н21М4ГБ (ZI-35), the yield limits given in table. 16, multiplied by the ratio

where R*p0.2 is the yield strength of the forging material, determined according to GOST 25054 (by agreement).

Table 17

| Design temperature of the vessel or apparatus wall, °C | Calculated value of tensile strength Rt, MPa (kgf/cm2), for steel grades | |||||

| 03Х21Н21М4ГБ | 08Х22Н6Т, 08Х21Н6М2Т | 03Х17Н14М3 | 03Х18Н11 | 08Х18Н10Т, 08Х18Н12Т, 08Х17Н13М2Т, 08Х17Н15М3Т | 12Х18Н10Т, 12Х18Н12Т, 10Х17Н13М2Т, 10Х17Н13М3Т | |

| 20 | 550(5500) | 600(6000) | 500(5000) | 520(5200) | 520(5200) | 540(5400) |

| 100 | 540(5400) | 583(5830) | 474(4740) | 450(4500) | 480(4800) | 500(5000) |

| 150 | 535(5350) | 550(5500) | 453(4530) | 433(4330) | 455(4550) | 475(4750) |

| 200 | 535(5350) | 515(5150) | 432(4320) | 415(4150) | 430(4300) | 450(4500) |

| 250 | 534(5340) | 503(5030) | 412(4120) | 405(4050) | 424(4240) | 443(4430) |

| 300 | 520(5200) | 500(5000) | 392(3920) | 397(3970) | 417(4170) | 440(4400) |

| 350 | 518(5180) | — | 376(3760) | 394(3940) | 408(4080) | 438(4380) |

| 375 | 517(5170) | — | 368(3680) | 392(3920) | 405(4050) | 437(4370) |

| 400 | 516(5160) | — | 360(3600) | 390(3900) | 402(4020) | 436(4360) |

| 410 | — | — | 358(3580) | 388(3880) | 400(4000) | 434(4340) |

| 420 | — | — | 356(3560) | 386(3860) | 398(3980) | 432(4320) |

| 430 | — | — | 354(3540) | 384(3840) | 396(3960) | 431(4310) |

| 440 | — | — | 352(3520) | 382(3820) | 394(3940) | 430(4300) |

| 450 | — | — | 350(3500) | 380(3800) | 392(3920) | 428(4280) |

| 460 | — | — | — | — | 390(3900) | 426(4260) |

| 470 | — | — | — | — | 388(3880) | 424(4240) |

| 480 | — | — | — | — | 386(3860) | 422(4220) |

| 490 | — | — | — | — | 385(3850) | 421(4210) |

| 500 | — | — | — | — | 383(3830) | 420(4200) |

| 510 | — | — | — | — | 381(3810) | 418(4180) |

| 520 | — | — | — | — | 380(3800) | 416(4160) |

| 530 | — | — | — | — | 374*(3740) | 412*(4120) |

* For a design wall temperature of 550 °C.

<< back / top / forward >>

April 19, 2012