Types of steel bends

A steel bend is a piece of pipe bent at the required angle. Steel bends are divided into types depending on the material, diameter, bend angle, and production method.

Various types of steel can serve as material for bends:

- carbon;

- stainless (alloyed);

According to the manufacturing method, bends are divided into the following types:

- steeply curved seamless;

- stamp-welded;

- welded sector;

- bent.

Bends can be cold-formed or hot-formed.

Steel pipe bends

Classification of bends

Bends differ primarily in the materials from which they are made. In addition, they can have different diameters and bending angles. Each tap corresponds to a brand defined by GOST, by which you can find out all the necessary information about the product.

1 - steel pipe; 2 — thermal insulation made of polyurethane foam; 3 - galvanized shell; 4 - UEC system cable

Kinds

BENDED BRANDS

There are three types of steel bends, differing in the type of steel from which they are made. They can be made of stainless, alloy or carbon steel. Different types of bends are used for different purposes. The material from which it is made depends on the environmental conditions in which it will be used.

Size

If the diameter of the pipes used in the pipeline is less than 50 mm, steel bends are used for their branches. Such products can be welded or seamless. It depends on how the product is made. Seamless fittings are of higher quality and more expensive.

Production

Production of steeply curved bends from steel and stainless steel pipes

It also depends on the production method whether the bends will be stamped, cold-formed, or something else.

We recommend: Types and advantages of ball valve

Elbow material

To correctly select the material from which the outlet will be made, it is necessary to take into account the conditions of its operation, the necessary reliability of this element, as well as the aggressiveness of the working environment in which it operates.

For example, in general purpose pipelines, bends made of carbon steel are used.

In the presence of an aggressive environment that can cause corrosion of the material, alloy and stainless steel are used. Bends made from such steels are used in pipelines for the oil and gas, chemical, food or pharmaceutical industries.

For example, bends made of stainless steel grade 12Х18Н10Т can be used in pipelines transporting steam, hot water, alkaline, acidic and other working environments prone to causing metal corrosion. Bends made of 3HFA alloy steel can operate at ambient temperatures from -60 ºС to + 40 ºС, working medium temperatures up to +40 ºС and pressures up to 7.4 MPa. Such bends have increased resistance to corrosion in the cold and are used in oil and gas systems in the North.

According to SmartInox specialists, in order to correctly select the material from which the outlet will be made, it is necessary to take into account its operating conditions, the necessary reliability of this element, as well as the aggressiveness of the working environment in which it operates.

Bends of the second version

Semi-finished products for the manufacture of fittings are grades that meet technological conditions and state standards. Among them are steel 20, 10G2, 2YuCh, 15GS, and other carbon and alloy steels specified in GOST 17380.

- Bending angle for 1-1.5 DN – 45°, 60°, 90°, 180°.

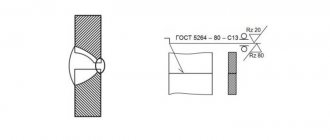

- Acceptable edge options are specified in GOST 16037.

The main differences between version 1 and version 2

The main differences between different types of reinforcement are the composition of the steel.

- Semi-finished products for the first use are brands accepted by international documents.

- For the second - brands that meet domestic standards and conditions.

Therefore, when choosing a bend material, they are guided by the area of application. Pay attention to the parameters of working environments, climatic conditions, possible temperature changes, pressure.

Other differences between the fittings are the markings. The second version requires the indication of the batch number, the symbol “P” for products controlled by regulatory authorities. The sign can be branded, etched, engraved. Unlike execution 1, the GOST indication is marked without a dash and year.

Design features

Steeply curved bends

The main characteristics of steeply curved bends are given in GOST 17235-2001, GOST 17235-83 and other documents, including various departmental specifications.

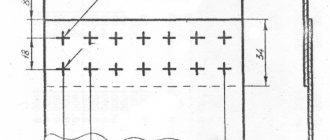

Steeply curved seamless bends are made by pulling a section of pipe through a special mold. This method allows you to obtain a high quality outlet. Bends of this type are made from both carbon (type steel 20) and stainless steel (type 10Х18Н10Т). In this case, the bends can have a bending radius from one DN to one and a half DN (DN is the nominal diameter of the pipe), with angles of 30º, 45º, 60º and 90º. The diameter of such an outlet can be from 18 to 426 mm and it must withstand pressure up to 16 MPa.

Steeply curved bends

Stamp-welded bends

Stamp-welded bends are made from stamped steel sheets by welding. This method allows you to create a bend with a thick wall and a diameter of up to 1420 mm. These bends are used in main pipelines of the oil and gas industry. The material for such bends is structural, stainless or alloy steel . The regulatory document in this case is departmental specifications (for example, specifications 102-988-95).

Stamp-welded bends

Sectional bends

Welded sectional bends consist of separate sectors of pipes that are welded together. This design is cheaper, but it is less reliable. Typically, bends of this type are used in pipelines operating at low (up to 2.5 MPa) pressure and temperature not exceeding +425 degrees. The permissible diameter ranges from 108 to 1620 mm. Bends of this type are made of carbon or low-alloy steel and are used in thermal power plants.

Sectional bends

Bent bends

Bent bends are usually used when it is impossible to use steeply curved bends. The difference between the former and the latter is that the latter have a much larger bending radius and a straight section. Bent bends can have a bending radius from 2 to 20 DN, and a bending angle of 2º - 90º. Such bends are made in accordance with GOST 24950-81 and TU and can be used in pipelines with pressures up to 100 MPa and temperatures from -50 to +510 ºС.

Bent elbows can be bent cold or hot on special pipe bending machines. The presence of a straight section in such bends increases their weight, which is a disadvantage.

Bent bends

Steeply curved bends 2D and 3D

Steeply curved bends

used for pipelines with a diameter of up to 820 mm, when operating under loads of up to 16 MPa and temperatures from -70 to +450 ° C.

They are produced in three ways:

1) Hot drawing, for bends DN 50-800 mm;

2) Stamping and welding, for bends with a diameter of over 800 mm;

3) Welding sectors, mainly for diameters over 500.

The most common bends in our field are steeply curved ones, made by hot drawing.

Controversial situations arise when working with bends starting with a diameter of 530 mm; here there are a couple of points that you need to know.

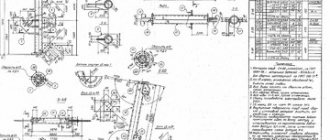

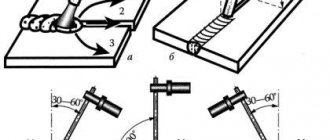

Welding of bends

Welding bends with pipes is a rather responsible operation. It must be performed by highly qualified welders.

In this case, various types of welding can be used - gas welding, manual arc welding (MAW), automatic submerged arc welding, gas-shielded welding and the like.

When welding pipes and bends, a number of requirements must be met, which are set out in the relevant instructions, for example VSN-006-89.

Before welding, it is necessary to check the welded surfaces of the elbow and pipe. All detected external and internal defects must be eliminated.

It is necessary to control the displacement of the inner edges. For example, when connecting elements with equal diameters, such a displacement should not be more than 2 mm.

Centering of the welded products is carried out using centralizers or rotators .

With RDS, welding of the first root weld is carried out with direct current. In this case, in the event of a welding interruption, it is necessary to maintain the preheating temperature in this place.

After welding and grinding the root of the seam, a second pass is made, which should be made along the uncooled root seam. The time between these two processes should not exceed 5 minutes.

Next, fill seams and facing seams are performed. In this case, it is necessary to ensure the seam temperature is not lower than +5 ºС. The facing seam should overlap the main layer of the pipe by 2.5-5 mm and have a height of 1-3 mm greater than the level of the pipe wall or outlet.

To weld bends in production conditions, various devices and entire complexes are used.

The most common are pipe rotators. The principle of operation of such a rotator is that the pipeline elements are clamped in special clamps and rotate around their axis. This makes manual welding easier and better quality, or automatic welding is carried out.

A feature of welding a pipe with a branch is that the system must work taking into account the uneven distribution of masses. To solve this problem, the rotator uses servos and special support stands with rollers.

The advantages of using such a rotator are as follows:

- working with large diameter pipes;

- thanks to the autonomous drive, the ability to change the speed of rotation of the pipe;

- precise alignment of welded parts. In this case, the clamping rollers themselves act as a centralizer;

- ability to work with both straight pipes and complex pipe parts (bends, tees, flanges).

Welding of steel bends

What is a steep bend

A sharply curved bend is a curved section of pipe with a bend radius of 1 – 1.5DN. DN is a conditional diameter or nominal size, in Russia it is also designated as DN. This knee is made:

- stamping method;

- by pulling the workpiece through a horn-shaped core.

Both production methods produce seamless parts without welds, which are characterized by increased strength. The production of seamless welded steeply curved elbows is regulated by the following standards:

- GOST 17375-2001;

- GOST 30753-2001;

- OST 34.10.699-97;

- series of standard documentation 5.903-13 (TS-582).

The documentation determines the scope of application, diameter, wall thickness, bending radius (2D - 1DN, 3D - 1.5DN), weight of pipe parts, maximum operating pressure in the system - 16 MPa (160 kgf/cm2).

Elbows made using welding can also be steeply curved.

Characteristics of bent bends

The bending radius of the fitting is from 1.5 to 2 DN. A steeply curved pipe piece is a straight pipe with a bent end. The straight area makes the bend bulky and makes it heavier. The production of bent reinforcement requires more raw materials, and its fixation is labor-intensive. Allowable bending angles are any, starting from 1º.

The blanks for the fitting are seamless or electric welded pipes. In some cases, the thickness of their walls is increased. There are two production methods, and with any of them, only the middle part of the workpiece is exposed.

- Cold bending (CB). Deformation of the pipe without exposure to high temperatures gives a large bending radius (from 15 m). The bending angle of the products does not exceed 27º, DN is 219-1420 mm. The regulatory standard is GOST 24950-81.

- Hot bending (HO). Heating is carried out by high-frequency current. Bending radius is 1.5-6Du, outer diameter of pipelines is 57-1420 mm. With all the advantages, the products weigh more than all other types of bends. Production is regulated by TU 102-488-95, 1469-014-01395041-03 and other Technical Conditions.

Unlike steeply curved reinforcement, bent reinforcement smoothly bends around obstacles, creates minimal resistance to the movement of working media, and is less susceptible to hydraulic shocks.

What is the difference

Thus, manufacturing methods and knee angles influence their application.

- Steeply curved reinforcement is easier to manufacture. Small bending radius simplifies connection to pipes. Hot-formed products are distinguished by their low weight and dimensions. Possible angles: 30, 45, 60, 90, 180°.

- Bent parts are characterized by labor-intensive production. At the same time, the elbows are able to withstand greater pressure, are resistant to aggressive media, and are compatible with thick-walled pipelines. The rotation angle can be any.