Nowadays, electric arc welding, carried out in the environment of special protective gases, has found widespread use in industry and everyday life. It is not surprising that quite a lot of developments have been made in this area: manufacturers of welding equipment offer a wide variety of devices and devices that make it possible to achieve very high quality welded joints. Each new development increases the speed of welding, helps reduce costs and improve working conditions.

Let's take a closer look at the most effective and interesting equipment for gas shielded welding , introduced and widely used in production .

Which company's semi-automatic welding machine is better to choose?

Due to the wide variety of brands of such complex technical equipment, the buyer's choice can be difficult. Experts recommend taking into account the reputation, experience of manufacturers, and what advantages they have that set them apart from their competitors. In the domestic market, the greatest demand is observed among the following companies:

- Wester is a trademark that belongs to the group. The main production is located in China. Under this name, auto tools, welding machines, pneumatics, household and semi-professional equipment for construction and repair work are presented on the Russian market. Demand is observed not only in Russia, but also in many European countries.

- Aurora is a Russian company that represents high quality equipment with a minimum warranty period of 2 years or more. Welding equipment is assembled in China. In addition, the range is constantly updated with new models of compressors, generators, mini-washers, and pumps.

- Resanta is a young Latvian company that produces high-quality electrical equipment at low prices. On the Russian market you can see a wide range, among which MAG/MIG semi-automatic welding machines will be presented in dozens of varieties in terms of power and other parameters.

- Elitech is a Russian company that entered the market in 2008. Despite the short production period, it has already mastered the production of a wide range of high-quality equipment with affordable price tags. The main factories are located in China, where the products are also in demand.

- Fubag is a German company operating since 2007. Most of the products are welding equipment and related products with good technical characteristics and average prices. Today Fubag has become a partner for most professionals.

- FoxWeld is a large-scale manufacturing and trading company that sells electric and gas welding equipment assembled from consumables of Asian and European origin. Being a Russian company, cooperation is carried out only with branded suppliers of parts, components, and raw materials.

- BlueWeld is an Italian manufacturer offering various welding machines, components, accessories, and branded accessories for them. The company has been operating since 1963, since then the company has achieved a high rate of sales growth on the Russian market, and it has been able to improve the quality and characteristics of its products thanks to its own scientific laboratory.

- Svarog is a Russian manufacturer that introduced equipment for repairs and construction work to the market. All products were released subsequently in cooperation with the Chinese company Shenzhen Jasic Technology.

- Brima is one of the oldest German companies presenting welding equipment on the Russian market. Work experience has exceeded 50 years. You can work with such devices even if you have no experience, since each unit is reliable and multifunctional.

- Forsazh is a trademark owned by the Russian company. Over 20 years of fruitful work, the company has established customer service and introduced advanced functions, which made it possible to create professional-level tools. Inverter welding machines are in greatest demand.

Rating of semi-automatic welding machines

Buying a reliable semi-automatic welding machine for your home, cottage, car, construction or repair work is not so easy. Even having decided on the manufacturer, the search circle will narrow down to several dozen models. Therefore, you can rely on the criteria by which experts, welders, and other specialists chose the leaders of 2021. In total, over a hundred nominees were considered, after which the top ten were determined based on several indicators:

- Power and voltage range during operation;

- Reproducible technologies, e.g. MIG/MAG, TIG, MMA;

- Current range, constant switching factor;

- Purpose of the equipment;

- Intensity of work cycles;

- Ease of control;

- Dimensions, weight, mobility;

- Endurance of difficult working conditions;

- Complete set, cord length.

An indicator of reliability can be considered a warranty from the manufacturer; the higher it is, the longer the expected service life. During the analysis of each nominee, experts took into account reviews from craftsmen, buyers, and real experience in using such tools. It was possible to discard unsuitable models thanks to statistics on repairs and complaints about breakdowns.

The best electric chain saws

Types of semi-automatic welding machines

Household

These are simple models with low power, which are affordable and convenient for doing work in the country or in the garage.

With their help, you can weld a water tank or fuel container, put a patch on a car body, or make your own gate. Usually every reputable owner in a village or small town has such a device.

Advantages:

- easy to maintain and repair yourself;

- simple device;

- Suitable for a variety of yard work;

- suitable for beginners;

- a light weight;

- compact dimensions;

- Efficiency 30-50%.

Flaws:

- low power;

- low indicators of maximum current strength;

- short cable channel.

Semi-professional

This type of device has increased power, a larger range of settings and expanded capabilities for creating metal structures. They are used for private workshops or service stations, where semi-automatic machines work for 4-6 hours every day.

Advantages:

- high build quality;

- varying degrees of protection;

- power from 5 to 7 kW;

- various input voltage options;

- high maximum current strength;

- Efficiency 60-70%;

- cable length 2-3 m.

Flaws:

- more expensive spare parts;

- heavy weight;

- It is not always possible to lower the current to 10-20 A.

Professional

Such devices are characterized by voluminous bodies and large mass. Their wire feed mechanism and cable channel are designed to accommodate different diameters, which allows welding both thin metals of car bodies and containers, and thick steel of flanges and channels. They are used in industries from mechanical engineering to the creation of water treatment systems.

Advantages:

- high power;

- different cable lengths;

- maximum ampere setting up to 500 A;

- good degree of protection;

- there are models with trolleys;

- Efficiency 80-100%;

- idle speed 50-80 V.

Flaws:

- large mass;

- often powered only from 380 V.

Advantages

It is not for nothing that this technology has become widespread in industry, as it has a number of advantages:

- High productivity of the welding process when it comes to mass production;

- Everything is done the same according to the given settings, so there is no negative human factor;

- The seams are of high quality, as gas provides excellent protection;

- You can join difficult-to-weld and even dissimilar metals;

- A large number of people are not required to operate the machine.

Solaris MULTIMIG-225

The first semi-automatic machine in our rating is the MULTIMIG-225 model from the Solaris brand. The device is not cheap, but it boasts excellent technical characteristics. The semi-automatic machine produces an honest 220 Amps when welding in MIG mode and 200 Amps when welding in MMA mode. This is enough to perform most welding work in a country house or small workshop.

MULTIMIG-225 works perfectly even with unstable or low voltage, which is very important when welding in the country. The heart of the device is modern IGBT transistors, thanks to which the semi-automatic machine can boast of great functionality. For example, the machine is capable of not only MMA and MIG welding, but also spot welding under certain settings. In short, a universal assistant in everyday life and during repairs.

The device comes with a burner with a Euro connector. The body has a convenient metal carrying handle. The body itself is also made of metal and is resistant to corrosion.

Below is one of the real reviews from a welder:

I spent a long time choosing a welding machine and noticed that my neighbor had this exact model. I used it a couple of times and was pleased with the results. I bought myself exactly the same Solaris. I am 100% confident in him! The seams turn out neat, just as needed. The metal does not spatter, the arc burns well. I use it and enjoy the work.

Spark PowerARC 230

The review of inverter-type semi-automatic welding machines is supplemented by a popular model from the Spark brand, namely PowerARC 230. This semi-automatic machine copes well with welding in a shielding gas environment and with welding without gas using flux-cored wire. The device operates with small voltage drops and produces up to 230 Amperes. For welding, you can use wire with a diameter of up to 1 mm.

Gas equipment used in gas-shielded welding machines

Gas equipment used in shielded gas welding includes cylinders, gas reducers, gas heaters and dryers, flow meters, gas mixers, electromagnetic gas valves and gas-electric burners.

Cylinders (Fig. 5) are designed for storing and transporting protective gas under high pressure. The most commonly used are cylinders with a capacity of 40 dm3, the dimensions and weight of which are given below (the weight is indicated without valves, caps, rings and shoes).

All gases, except carbon dioxide, are in the cylinders in a compressed state, and carbon dioxide is in a liquid state.

The reducer (Fig. 89) is designed to reduce the gas pressure entering it from a cylinder or distribution pipeline and automatically maintain a constant set operating pressure.

The gas pressure in the cylinder is shown by the high pressure gauge 2. The protective gas from the cylinder enters the high pressure chamber 1, passes through the valve 11, slightly opened by the spring 8, and enters the low pressure chamber 10. When passing through the valve, the gas overcomes significant resistance, resulting in pressure behind the valve , i.e. in the low pressure chamber, decreases. This pressure is indicated by low pressure gauge 3. From the low pressure chamber, protective gas passes through

valve 6 is directed to the welding head (holder). Automatic maintenance of the operating pressure in the reducer constant occurs as follows. With a decrease in gas flow, its pressure in the low-pressure chamber will increase, and it will press with greater force on the membrane 7, which will move down and compress the spring 8. In this case, the spring 4 will close the valve 11 and will keep it in this position until until the pressure in chamber 10 (low operating pressure) becomes equal to the original again. On the contrary, with an increase in gas flow, its pressure in the low-pressure chamber decreases, the membrane, under the action of spring 8, moves upward and opens the valve.

.

In this way, the supply of protective gas from the high to low pressure chamber is automatically regulated and thus the operating pressure is maintained constant. If the pressure accidentally increases above the permissible value in the low pressure chamber, safety valve 5 will open and the compressed gas will be released into the atmosphere.

The operating pressure of the shielding gas is adjusted as follows. When adjusting screw 9 is screwed in, springs 8 and 4 are compressed, valve 11 opens and the pressure in the low-pressure chamber increases. The more the valve is open, the more gas will flow through it and the higher the operating gas pressure will be. When screw 9 is unscrewed, on the contrary, valve 11 closes and the gas pressure in chamber 10 decreases.

When welding in an argon environment, AR-10, AR-40 or AR-150 gearboxes are used. When welding in carbon dioxide or its mixtures, reverse-action gearboxes are used, which are also flow meters (Fig. 90), U-30 and DZD-1-59M. It is also possible to use conventional oxygen reducers, for example RK-53, RKD-8-61, etc.

The heater (Fig. is designed to heat the carbon dioxide coming from the cylinder into the reducer in order to prevent the reducer from freezing. With a large flow of carbon dioxide (due to the absorption of heat during the evaporation of liquid carbon dioxide), the temperature of the gas decreases, which can lead to freezing of the moisture present in it and blockage of gearbox channels.

is designed to heat the carbon dioxide coming from the cylinder into the reducer in order to prevent the reducer from freezing. With a large flow of carbon dioxide (due to the absorption of heat during the evaporation of liquid carbon dioxide), the temperature of the gas decreases, which can lead to freezing of the moisture present in it and blockage of gearbox channels.

The heater is used when welding in carbon dioxide. It consists of a body 1, a coil tube 3 through which carbon dioxide passes, a casing 2, thermal insulation 4 and a heating element 5 made of chromium-nickel wire located inside the coil. The heater is attached to the cylinder with a union nut 6. It is powered by direct current of 20 V or alternating current of 36 V. Wires from the control cabinet are connected to terminals 7.

The desiccant, used by using wet carbon dioxide to absorb moisture from it, can be of high or low pressure.

High pressure dryer

installed before the reduction gear, is small in size and requires frequent replacement of the desiccant, which is inconvenient to operate.

The pre-reducer gas dryer (Fig. 9) is used to absorb moisture contained in the gas and is installed after the gas preheater. It consists of a housing 7, into which mesh washers 4 are inserted at the top and bottom. On the inside of the housing in front of the washers, filters 5 made of glass wool are installed. The inside of the housing is filled with desiccant. Dehydrated copper sulfate CuSO4 · 5НдО or silica gel brand ShSM is used as a moisture absorber. Before filling the desiccant, vitriol or silica gel must be calcined for 2 hours at a temperature of 200 ° C. Using nut 2, sleeve 1 compresses the mass of the desiccant through spring 3 until it is completely compacted.

The dehumidifier is designed to dry 30-35 m3 (i.e. 4-6 cylinders) of carbon dioxide with one charge.

Low pressure dryer

(Fig. 10), which has significant dimensions, is installed after the reduction gearbox; it does not require frequent replacement of the desiccant. It is advisable to use low-pressure dryers mainly for centralized gas distribution.

Silica gel or aluminum glycol is used as an absorbent, less often copper sulfate and calcium chloride. Silica gel and copper sulfate, saturated with moisture, can be restored by calcination at 250-300 ° C.

Flow meters are designed to measure the flow of shielding gas. They can be float and throttle types. Float type flow meter—

rotameter (Fig. 11, a) - consists of a glass tube1 with a conical hole. The tube is positioned vertically, with the wide end of the hole facing up. Inside the tube there is a light float 2, which can move freely in it. When passing from bottom to top, the gas will lift the float until the gap between it and the wall of the tube reaches a value at which the pressure of the gas stream balances the mass of the float. The greater the gas flow rate and its density, the higher the float rises. The rotameter is equipped with a scale 5 calibrated for air flow. To convert to the consumption of protective gases, use graphs. The general view of the RS-3 rotameter is shown in Fig. 11, b.

Throttle type flow meter

(Fig. 11, b) is built on the principle of measuring the pressure drop in areas before and after the throttling diaphragm 3 (P1 and P2

),

which depends on the gas flow and is measured by pressure gauges 4. The approximate flow rate of the shielding gas can also be judged by the reading of the low pressure pressure gauge gas reducer. To do this, a throttle washer (nozzle) with a small calibrated hole is installed at the output of the gearbox. The rate of gas flow through its hole, and, consequently, the gas flow rate will be proportional to the gas pressure in the working chamber. This principle is used in the U-30 gearbox, where pressure gauge 8 (see Fig. 7) directly shows gas flow, and not the pressure in the working chamber. For this purpose, the gearbox is equipped with two nozzles 9 and 13 with calibrated holes of different diameters. By turning the valve body 11 of the limit pressure against the corresponding nozzle, channel 10 is installed, each position of which corresponds to a scale division on the pressure gauge 8.

Mixers are designed to produce mixtures of CO2+O2 and CO2+Ar+ O2 gases. The UKP-1-71 station mixer for producing a mixture of CO2+ O2 gases taken from cylinders and automatically maintaining a constant specified composition and flow rate of the gas mixture consists of a pressure regulator with a DKP-1-65 reducer and a gas mixing unit. Change the composition of the mixture by replacing the nozzles. The UKR-1-72 ramp mixer allows you to obtain a CO2+ O2 mixture by selecting oxygen from the cylinder ramp, and carbon dioxide from an isothermal container intended for liquefied supercooled carbon dioxide. The mixer provides gas supply to 10-50 welding stations.

The gas valve used to save shielding gas should be installed as close as possible to the welding torch; sometimes it is built into her handle. The most widespread are electromagnetic gas valves. The gas valve should be turned on so that a preliminary (before the arc is ignited) supply of protective gas is ensured, and turned off after the arc breaks and the weld crater has completely hardened.

The bypass ramp is used to supply shielding gas to the welding shop at significant consumption. It consists of two groups of alternately connected cylinders, a manifold with gas equipment and a pipeline through which shielding gas is supplied to the welding stations. Pipelines for supplying carbon dioxide and its mixtures are painted black.

ELAND MIG-130

The rating of semi-automatic welding machines will be incomplete if we do not add an ultra-budget model for those who are on a budget. ELAND MIG-130 is a standard budget Chinese semi-automatic, of which you can find plenty in any specialized store. However, this model is quite reliable and gets the job done.

The device requires 220V for power supply, so it is not suitable for welding in low voltage conditions. According to the manufacturer, the maximum current is 130 Amperes, which seems to be true. You can cook for no longer than 5 minutes without a break. The device weighs a little less than 20 kg, so be prepared for that. Overall, the ELAND MIG-130 is a good option for the price. It does not have any special characteristics, but it works stably and is inexpensive. What else does a beginner or summer resident need?

Feedback from a welder:

I spent a long time choosing among different welding machines. In the end I bought this one. It was necessary to digest the arches of the car. I read in reviews that the metal spatters a lot when welding, but everything was fine for me. I think it depends on the quality of the wire and the correct settings of the device. Cook stainless steel without any questions at all. For the money, this is a decent option for the home and small jobs.

Advantages and disadvantages of semi-automatic welding

The advantages of welding in semi-automatic mode include the following.

- Possibility of joining thin sheet materials. By selecting the operating mode of the device and the diameter of the wire, we achieve minimal thermal loads and reduce the warping effect.

- The quality of the seam does not depend on its length. If necessary, parts can be joined by spot welding.

- Variety of materials. The semi-automatic machine is capable of working with both structural carbon steels and many high-alloy tool steels. By changing the type of current and polarity, you can set the modes for welding non-ferrous metals, including those with high chemical activity.

- Ease of setup. The operator can quickly set the required mode, which is very convenient when performing small jobs.

Such devices also have a number of disadvantages that limit their use.

- Inability to work with large diameter wire due to its high rigidity.

- Difficulties in carrying out welding activities outdoors. To prevent the wind from blowing away the protective atmosphere, it is necessary to increase the consumption of inert gas.

- Intensive metal spattering at currents above 500 A.

- High intensity of radiation from the arc.

- The need to refill cylinders.

DGM DUOMIG-250E

DGM DUOMIG-250E is an inverter-type semi-automatic welding machine designed for MMA and MIG welding. It cooks without problems both with a covered electrode and in a protective gas environment. Suitable for working with different types of steel and for body work. The device has a convenient digital display on which everything is clearly visible. The semi-automatic machine produces up to 230 Amperes and copes with welding thick metals.

Feedback from a welder:

Great device! 8 out of 10. I bought this semi-automatic 5 years ago, I cooked a lot and often, I didn’t regret it. We had to do everything. And he cooked the gates, and he cooked the bodies. Everything is working as it should. At the same time, sometimes I did not have the wire of the required diameter, and I used a thin one, plus I reinforced the structure with a channel. In the end, everything is fine, no complaints. I am very pleased with the device; in all the years of use there have been no problems. The only negative: sometimes the button on the sleeve gets stuck, but this is not critical after five years of use.

Kinds

When considering what gas shielded arc welding is, it is worth paying attention to its types. Each of them has some distinctive features that can affect the quality and appearance of the resulting weld.

The following types of welding carried out in shielding gases are distinguished: MMA, MIG, MAG, TIG. To understand what these technologies are, it is worth considering their main features:

- MMA . This is manual arc welding, which has the abbreviation RDS. The elements are connected using an electrode and a metal rod, which is coated with coating. It contains components that support the arc, protect the welding zone, and contribute to the correct formation of the welded joint;

- Types of MAG/MIG welding . These welding technologies are similar to each other, but many often have the question - what is mig/mag welding? These designations refer to the type of shielding gas used - it can be inert or active. It is the gas that protects the hot metal zone from oxidation as a result of contact with oxygen;

- TIG . It is worth paying attention to the fact that TIG and MIG welding have similar properties; both technologies are produced in an environment of inert gases. But during this process, non-consumable electrodes are used - thin sharpened tungsten rods. They are resistant to high temperatures.

Interesting! In addition to MMA, MIG, MAG, TIG welding, there is another type - flux. This process is carried out under a layer of flux. Allows you to obtain an even and durable seam, promotes the formation of a monolithic crust after cooling. But this method has a high cost.

AuroraPRO Overman 200

Another popular welding machine from the Aurora brand in our rating. The Overman 200 is designed for MIG and MAG gas shielded welding. There is also a “NO GAS” mode, you can weld with cored wire. The welder can regulate the welding current, voltage, adjust the inductance, penetration depth and monitor the shape of the bead.

Also, this model works perfectly at reduced voltage from 140V and above. Consumes about 6 kW. If you want to connect this device to a generator, then choose a generator with a power of 8 kVA or more. The Overman 200 produces an honest 200 Amps. The device is very compact and relatively lightweight, weighing no more than 15 kg.

Feedback from a welder:

The device is very good. Suitable for both home and work. All stated characteristics are completely true. The efficiency is high, the device does not overheat, you can cook for a long time. If you are fully equipped, you can cook aluminum with high quality. You can adjust the inductance and heat the carbon dioxide. The build quality is excellent.

Features of welding in carbon dioxide and nitrogen

Shielded gas arc welding with a consumable electrode is carried out using carbon dioxide. This is the cheapest method, which is in great demand today. Under the influence of strong heating in the melting zone, CO₂ turns into CO and O. To protect the surface from an oxidative reaction, silicon and manganese are present in the wire.

This also leads to some inconvenience. Silicon and manganese react with each other, forming slag. It appears on the surface of the seam, requiring elimination. This is not difficult to do. This circumstance has no effect on the quality of the weld.

Before starting work, remove water from the cylinder by turning it over. This needs to be done at certain intervals. If this manipulation is not performed, the seam will become porous. Its strength qualities will be low.

Gas shielded arc welding can be performed using nitrogen. This technology is used for soldering copper workpieces or stainless steel parts. Nitrogen does not react chemically with these alloys. During welding, graphite or carbon electrodes are used. If tungsten contacts are used for these purposes, this causes their overuse.

It is important to configure the equipment correctly. It depends on the complexity of the weld, the type of material and other conditions. Most often, equipment with a voltage of 150-500 A is used. It creates an arc of 22-30 V, and the gas consumption is 10 l/min.

WATT CombiMIG 250

Another semi-automatic welding machine on our list is the budget WATT MMA 200. Unfortunately, it is not easy to find on sale now. But it is still available in some online stores.

The device is designed for welding in MIG/MAG mode, and does the job well. There is also the possibility of conventional MMA welding with a coated electrode. The power supply requires a voltage of 220V, but as practice shows, it works great even with small drawdowns. It produces up to 230 Amps, which is not enough for a practicing welder, but just right for a beginner.

This welding machine is very compact, weighs little, and has a convenient handle for carrying. The body of the device is quite strong and durable, but we still recommend treating it with some attention. The arc ignites easily and burns stably. The efficiency is high, you can cook for a long time.

Reviews from welders:

The device cooks excellently, despite its modest price. Any type of steel can be welded. During the entire period of use, the semiautomatic device never overheated, which surprised me. The kit includes cables and a holder for electrodes. They are of good quality and suitable for a beginner. For 2 years of work, no complaints.

A very good device for the money. I have been using it for 5 years, the flight is normal. Never let me down. Cooks even at low voltage.

MIKKELI MIG/MMA-200E

An inexpensive inverter semi-automatic device that is rarely talked about. But in vain. This welder can be found on sale without any problems. For some craftsmen, this is the best semi-automatic welding machine in its class.

The device is designed for manual arc welding, as well as for welding in MIG/MAG modes. It operates from a regular power supply and does not require special conditions to power it. Produces from 40 to 200 Amps of welding current, this is enough for most household tasks. Works without interruption for 60% of the entire welding cycle. It's not much, but it's enough for a summer house or home.

Welding with electrodes with a diameter from 1.6 mm to 4 mm is possible. For welding wire, use material with a diameter of 0.6 to 1 mm. The wire feed speed can be adjusted from 21 to 13 meters per minute.

The weight of the device does not exceed 16 kg. The dimensions are compact and can be transported without problems.

When welding at low current, the arc is stable and continuous; you can work with thin sheets of low-carbon, stainless and alloy steel. At the same time, the quality of the seams will remain excellent for this class of devices. The device does not spark, the arc does not “walk”, the weld pool is homogeneous. Overall, this model is great for home work or a small workshop.

Design

Mobile welding machines consist of the following main elements:

- welding head;

- control system;

- trolley (with or without drive);

- equipment cabinet and other electrical equipment.

In mobile welding machines, the trolley is the basic structural element on which the control panel, wire cassettes, containers for flux or gas, and other equipment are installed. There are two main classes of trolley design:

- Tractor type - movement occurs with the help of runner wheels. The movement of welding tractors is ensured by an electric motor with a gearbox.

- Carriage type - the mechanism moves exclusively along guides.

Fixed machines do not have a mechanism for moving along the seam - a trolley - and are also optimized for use as part of other mechanisms (installations). This determines not only their execution, but also the way the equipment is controlled.

The welding head (as part of a mobile machine or suspended), in turn, has the following main functional design elements:

- Electrode wire feeding mechanism, consisting of an electric drive and a gearbox. If an AC electric motor is used to operate the head, then adjustable gearboxes are required. For the correct operation of DC electric motors, an unregulated gearbox will be sufficient.

- Rollers for stable wire feeding without delays or slippage. As a rule, two pairs of drive rollers are used for this purpose. In some cases, to prevent slipping, a notch is applied to their surface, but sometimes this solution is unacceptable due to the risk of crushing the electrode wire.

- The mouthpiece is a means of ensuring contact of the arc with the welding zone. The main task of this unit is to rigidly fix the wire in relation to the weld pool. To combat wire bending, a correct mechanism is sometimes mounted in front of the mouthpiece, which reduces wandering of the electrode end. Another important task of the mouthpiece is to ensure stable electrical contact with the wire for high-quality, uninterrupted welding. Depending on the diameter of the electrodes used, the industry uses either roller sliding contact devices (for 3-5 mm wire) or tubular nozzles (for 0.8-2.5 mm wire).

- Means for adjusting the position of the head - in a vertical position (to adjust the optimal wire extension and/or angle of inclination of the electrode relative to the seam) and a transverse position (to direct the welding head in the center of the welded joint and adjust it during operation).

SVAROG REAL MIG 200

Russian semi-automatic welding machines are also worthy of the attention of welders. In this rating, we decided to talk about one excellent model from Svarog - REAL MIG 200. This is a well-known and popular device that has long established itself as a good option for a summer house and workshop.

With this machine you can easily weld aluminum and stainless steel, carry out MMA and MIG/MAG welding. The built-in wire feeder is reliable and easy to use. It can be used to run wire. The arc burns stably even with significant voltage drops.

MMA and MIG/MAG modes work at 5 plus. To cook using the MMA method, you need to connect an electrode holder to the device. The maximum current is 160 Amperes. This is not enough for serious work, but it is enough for a home craftsman. For welding, you can use electrodes with a diameter of up to 4 mm, so you can weld even thick metal.

But this device is at its best in MIG/MAG mode. You can weld all types of metals: ferrous, non-ferrous, various types of steel. You can set the welding current up to 200 Amps, which is enough even for a small workshop. The penetrations are deep, there are no defects. The device operates very stably and is not afraid of voltage surges.

Regulator (reducer)

Designed to reduce the gas pressure coming from the cylinder and automatically maintain a constant operating flow rate (pressure).

Attaches to the cylinder valve using a union nut.

Gas pressure and flow are controlled by rotating the handwheel. Gas is withdrawn through a nipple to which a hose is attached.

The U-30P-2 carbon dioxide flow regulator is equipped with an electric heater, which is installed on the housing shank (supply voltage 36 V, power consumption 200 W)

TOP 5 best semi-automatic welding machines by price/quality for 2021

Semi-automatic welding machines are often chosen for domestic use, as they not only have the necessary technical characteristics, but also an acceptable cost.

SPECIAL MAG-170 INVERTOR

This model of welding inverter is designed for semi-automatic welding at home.

The device is single-phase, so it can be connected to a household power supply without fear of voltage drop. The output current is constant, and the open circuit voltage of 56 V allows you to work with metals of different types and thicknesses.

The device is considered universal, as it allows you to weld metals with both coated electrodes and wire with a diameter of 0.60 to 0.80 mm.

The device is easy to use and easy to start, as it has a hot start function.

Thanks to this, even beginners will be able to carry out welding work, especially since all the nuances of the work are described in detail in the user manual.

Specifications:

- weight 9.8 kg;

- dimensions (W/H/D) 285x290x395 mm;

- power 6.40 kW.

pros

- light weight makes transportation easier;

- convenient storage due to compact dimensions;

- affordable cost;

- suitable for electrode and wire welding;

- allows for high-quality welding of metals of different thicknesses.

Minuses

- mask from the kit is of low quality;

- poor quality ground cable.

Wester MIG 140i

An inexpensive but quite functional semi-automatic welding machine is specially designed for domestic use, but with its help you can perform other work in a small auto repair shop.

The device is universal, as it allows you to obtain a high-quality weld using both manual arc and semi-automatic methods using electrode wire.

Constant output current and open circuit voltage of 55 V allows you to work with different types of steel, aluminum of different thicknesses and other metals and alloys.

You can start working immediately after purchasing the device, since everything you need is provided with the device itself: a torch, a cable with an electrode holder, a brush-hammer, a welding shield, steel welding wire and a contact tip.

Even beginners will be able to work with a semi-automatic welding machine, because all the working nuances are described in detail in the instructions.

Specifications:

- weight 9 kg;

- electrode diameter 1.60 mm;

- power 4.70 kW.

pros

- optimal price/quality ratio;

- ideal for use at home, in the garage or small car service;

- suitable for different types of welding;

- extended equipment;

- allows you to get an even and high-quality seam.

Minuses

- poor quality mask included;

- short cable.

Svarog REAL MIG 200 (N24002N) BLACK

Some users may find the price of this welding machine too high, but it is fully compensated by its functionality and well-thought-out technical characteristics..

Metalworking and carbon dioxide

We will not be able to talk in detail about all the points that exist in semi-automatic welding in the field of nitrogen shielding gas. We'll talk about working in carbon dioxide.

This method has become popular and effective over the past 15 years. It is worth taking this information into account.

Selecting wire for welding

This point is very important when metalworking in a carbon dioxide environment. If you take a part that contains a small amount of carbon, it runs the risk of oxidizing. To prevent this from happening, it is necessary to use wires containing manganese and silicon.

Don't forget this if you want to get a good job! If there is a need to weld an alloyed alloy, use special wire. Next we will talk about well-known brands of wires for welding these types of metal.

Preparing metal for processing

You want the seam to be smooth and beautiful, right? To do this, it is worthwhile to prepare metal structures. First, clean the parts from corrosion, as well as from paint and dirt.

If there are any oil traces left, they must also be removed. In the case where the parts are slightly dirty, you can use a rag. If lengthy cleaning cannot be avoided, use a special metal brush.

Be sure to remove grease from the entire surface of the structure. This can be done using special cleaning products.

Select operating mode

If you have chosen the correct welding mode, then you have already done 50% of the work towards obtaining a welded joint. This point needs to be thought through carefully so that you don’t have to start all over again later.

The metalworking mode is a combination of some settings that are installed on the machine. They completely depend on what type of work you need to do.

Speaking about welding using a unit with carbon dioxide, the settings will look like this:

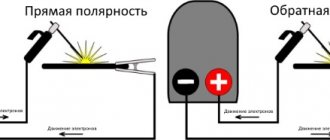

- Type and polarity of current. As a rule, a static current of reverse polarity operates. In the case of straight polarity, you may get an unstable arc. Do you want to use alternating electricity instead of constant electricity? Place an oscillator in the circuit, which will help the mechanism work correctly.

- Diameter of wires. The readings directly depend on the thickness of the metal that will have to be processed. For a thin structure, thin wires are suitable, and vice versa. The strength of electricity is selected depending on the diameter of the wire. The principle is this: the strength of electricity during welding is directly proportional to the depth of penetration. The speed of work will correspond to the same formula.

- Arch tension. It depends on the length of this arch. The current strength will determine the set voltage. Setting up this indicator is quite simple. As the voltage increases, the penetration depth increases. The width of the connections also becomes larger. If you know these indicators, you will be able to determine the required arch tension.

- Wire insertion speed. This indicator can only be determined through experience. Remember that the arch should burn steadily, and the wire should burn slowly. A novice master usually uses units that automatically regulate the speed of wire feeding.

- Wire coming out. This point is also determined by frequent work. The overhang should not be either large or small. In the first case, the arc burns out unstable. The seams are uneven and crooked. In the second case, you will lose the ability to control the welding process, because it will take place quite quickly.

The best professional semi-automatic welding machines

This section presents the TOP professional semi-automatic welding machines, which are adapted for long-term uninterrupted performance of work operations. Equipment in this category has the following parameters:

- stabilized current up to 220 A or more;

- duty cycle – from 50%;

- power more than 6 kW;

- built-in wheels for moving equipment;

- long cables;

- extended range of settings.

Which semi-automatic welding machine to choose is determined after clarifying personal requirements. In this case, special attention should be paid to reliability. A certain increase in investment is justified by the high quality of welded joints and long service life.

Fubag INMIG 200 SYN LCD (TIG, MIG/MAG, MMA)

This is the best semi-automatic machine in combination of price and quality. The equipment is equipped with automated functions and modes that greatly simplify the creation of high-quality welded joints. Synergic control technology optimizes settings without user intervention, taking into account the characteristics of the technological process. Digital display simplifies control operations. The universal semi-automatic model is suitable for working with thin and thick workpieces.

Pros:

- the best professional semi-automatic;

- gas hose length – 3 m;

- copper connecting wires;

- efficient cooling system;

- long service life.

Minuses:

- To use wire with a diameter of 6 mm, you need to purchase a special roller.

Aurora SPEEDWAY 200 (MIG/MAG, MMA)

The professional semi-automatic welding machine is created using reliable components and components. Combined with responsible assembly, this approach ensures long-term preservation of good operating parameters over a long period of time under intensive use. The electronic control unit maintains the current with high precision. Smooth wire feed with adjustable speed performs its functions without failure. When performing work operations, one should not forget about the duration of breaks, which should be at least 40% of the total cycle duration.

Pros:

- one of the best semi-automatic welding machines in terms of reliability;

- good energy efficiency indicators;

- ease of setup;

- flawless functionality of the wire feed system;

- convenient indication of modes;

- easy setup.

Minuses:

- The minimum welding current of 40 A causes difficulties when welding thin sheets.

Cedar MIG-250GW (MIG/MAG, MMA)

Such equipment is purchased for organizing professional activities. The semi-automatic device is connected to a three-phase 380 V network and consumes up to 9.5 kW of power. The external reel is designed to install European standard D300 reels. With this equipment, long work operations can be completed without unnecessary delays. Two digital displays simplify setup and operational control.

Pros:

- welding current – up to 250 A;

- ability to work with thick wire (1.2 mm);

- outer large bobbin;

- protection of corner structural elements with special overlays.

Minuses:

- weight – 23kg.

Svarog PRO MIG 200 (N229) (TIG, MIG/MAG, MMA)

This universal technique is suitable for high-quality reproduction of manual and semi-automatic welding modes. The extended current range allows you to correctly create connections between thin and thick workpieces. Anti-stick, arc force and other useful functions make it easier to create high-quality seams.

Pros:

- current range starts from 10 A;

- small dimensions and weight;

- ease of transportation;

- excellent set of welding modes;

- professional level of equipment with automation equipment;

- Convenient body design with a large handle and protective pads.

Minuses:

- with significant power consumption, it is necessary to take into account the restrictions on the permissible load of the wiring of a single-phase 220V network.

The best inexpensive semi-automatic welding machines

Budget equipment is quite reliable, functional and at the same time has an affordable price. Cost savings are achieved through a reduced set of options. If you need a simple unit, we present to your attention 3 inexpensive semi-automatic welding machines.

RESANTA SAIPA-135 (MIG/MAG, MMA)

9.4 Rating Based on customer reviews

Durability8.5Quality10Price10Reliability9.5Reviews9 class=”wpsm-divider dotted_divider” style=”margin-top: 1px;margin-bottom: 5px;”>

The semi-automatic welding machine from the RESANTA company is well suited for welding using wire in a gas environment and working with piece electrode elements. When processing non-ferrous metals, inert gases are used - helium, argon. If you plan to work with alloy and low-alloy steels, pay attention to the active gas.

The welding device allows you to regulate the current automatically and change the wire feed speed. The optimal diameter of the working part is 0.6-0.8 mm; the pulling mechanism is suitable for placing a reel within 5 kg.

To switch the semi-automatic welding machine to the MMA welding mode, turn on the switch on the panel, then connect the cable with the electric holder (it is included in the kit). The presence of reliable protection guarantees the absence of sheer drops of rain and large particles from falling on the body. Overheating is excluded.

class=”wpsm-divider dotted_divider” style=”margin-top: 5px;margin-bottom: 1px;”>

PROS:

- unpretentiousness in maintenance;

- stable power parameters;

- possibility of using MMA welding;

- polarity settings;

- compactness;

- place for installing the coil;

- low price.

MINUSES:

- modest functionality.

Wester MIG 140i (MIG/MAG, MMA)

9.2 Rating Based on customer reviews

Durability9Quality9.5Price9.5Reliability9Reviews9 class=”wpsm-divider dotted_divider” style=”margin-top: 1px;margin-bottom: 5px;”>

Semi-automatic welding machine of inverter type for welding and depositing metal using electrode consumable wire. Shielding gases or flux-cored wire are used as the working medium. The semi-automatic machine allows for electric arc welding.

The adjustments are smooth and the settings are flexible, which makes operating the device as comfortable as possible. This will allow you to solve problems of any complexity. The current at maximum voltage reaches 60%, this is enough to solve professional problems and quietly implement complex projects. The dimensions are compact, the weight is small, the efficiency is high - due to the use of IGBT inverter technology. Built-in thermal protection will keep the inverter operational in case the maximum permissible temperature values are exceeded. There are convenient light indicators, and there are covers on the case to protect against external factors. Transportation is simple, largely due to the comfortable handle.

class=”wpsm-divider dotted_divider” style=”margin-top: 5px;margin-bottom: 1px;”>

PROS:

- optimal configuration;

- reliable protection;

- presence of light indicators;

- carrying handle;

- Possibility of professional use.

MINUSES:

- No.

Wert MIG 160 (MIG/MAG, MMA)

8.7 Rating Based on customer reviews

Durability8.5Quality9Price8Reliability9Reviews9 class=”wpsm-divider dotted_divider” style=”margin-top: 1px;margin-bottom: 5px;”>

The semi-automatic welding machine from the Wert company is well suited for novice craftsmen and simple tasks. A good choice for servicing your car yourself. One of the most affordable solutions in its category. It is possible to install coils up to 5 kg, which is generally the norm for the group under consideration.

The quality of the manufacturer's equipment is high, the price is reasonable. The wire feed is regulated with current. Jamming is minimal and usually starts when the hose is bent. Overall, the installation is trouble-free. Soft self-defense is suitable for welding. There are no restrictions on the size of parts. If there is a poor power supply or dead wiring, arc ignition may be weak - it is better to use wire. A worthy solution for your money.

class=”wpsm-divider dotted_divider” style=”margin-top: 5px;margin-bottom: 1px;”>

PROS:

- good functionality;

- good reliability;

- availability;

- 5 kg spools.

MINUSES:

- there is no adjustment of wire feed separately from current.