Heating in the house

At the first stage, you should decide on the types of radiators and options for their connection, since buildings should be prepared in advance for the selected type of heating. A modern space heating system includes several components.

These include:

Do-it-yourself polypropylene heating wiring without a soldering iron

You can find different versions of them in large quantities in our markets.

General instructions for installing batteries look like this:

- First select a place to place them;

- bring pipes to them;

- connect them together;

- perform a test run, and if everything is in order, turn on the heating at full power.

How to install heating radiators with polypropylene pipes with a jumper for quick shutdown

Classification of fittings and adapters

Assembling pipelines using special nozzles is the most popular method of wiring engineering systems. In order to select the necessary types of fittings for polypropylene pipes, you should familiarize yourself with their detailed classification.

For the manufacture, release and supply of technical polypropylene products, the provisions of state standard No. 52134 of 2003 are used.

Types of fittings for polypropylene pipes Source ecomont.ru

Place of radiators in the heating system

The use of radiators in heating residential premises plays a key role today. Not all residential properties, especially apartments in multi-storey buildings, can be converted to underfloor heating. Therefore, the main work of heating internal living spaces is performed by radiators or the good old batteries that are familiar to us.

Radiators transfer thermal energy from the coolant to the surrounding space. Heat transfer is carried out due to the large heating surface of the heating device. Modern models have a number of technical improvements, thanks to which it has become possible to connect in a variety of options and with any wiring diagram.

in old cast iron and steel batteries there was only one upper and one lower pipe, through which hot water is supplied and the return is released.

In modern models, in addition to the main supply and outlet pipes, there are built-in air vents. This design of batteries radically changed the quality of functionality of the heating system. If there are air pockets in heating devices, it is enough to open the drain valve and bleed the air.

In many ways, thanks to modern models of heating batteries, it has become possible to choose the most convenient connection scheme and install heating devices in those areas of the living room in which they are most effective. The quality of operation of the heating water circuit depends on correctly installed piping. The process is necessary if you are using a pipeline made from polypropylene pipes.

Important! If there are metal risers, the piping is made from other consumables. It can be metal copper pipes or metal-plastic

The use of polypropylene pipes in this case is strictly prohibited.

The reason for the incompatibility of metal pipes with polypropylene products is the presence of a threaded connection. Considering the fact that propylene pipes have a high coefficient of thermal expansion, when hot coolant is supplied, the threaded connection will lose its tightness and stability. Therefore, if you want to connect a heating radiator made of polypropylene pipes, try to use fittings, adapters and couplings made from similar materials.

the difference in diameters of pipes made of different materials should be taken into account

Piping options

The first stage of installing PP pipes for water supply is drawing up a detailed diagram of the distribution, fastening and connection of pipes. Unnecessary details and bends should be avoided.

There are two ways to organize the installation of polypropylene water pipes - open and closed. The second option is more complicated and requires precise calculation and execution. In this case, the number of joints is minimized, and access to the joints is organized.

The advantages of open-type wiring are simplicity of installation, ease of maintenance, and the ability to replace parts of the system if necessary.

The pipeline layout can be serial (tee) or parallel (collector). With sequential wiring, do-it-yourself installation of water supply from polypropylene pipes is carried out from the main line to the places of water consumption. Cold and hot water pipelines depart from the main riser. Tees are used for drainage to water consuming points.

Pipeline routing is impossible without the use of tees

Along with ease of installation and saving on materials, such a system has a drawback - when repairing one device or consumer, it is necessary to disconnect the entire network.

The collector system has one input with several outputs. The consumption points are independent, but this increases labor costs and installation costs.

Choosing pipes

Concerned about the choice of pipes for the heating system in a private home, the vast majority of owners opt for polypropylene products. This can be explained by a solid list of their undeniable advantages over pipelines made of other materials:

- polypropylene is not subject to corrosion, which significantly increases the service life of the heating network;

- installation is easy and simple. It is enough just to master very simple skills in using a special welding machine;

- deposits do not accumulate on the inner surface of the pipeline;

- propylene pipes are durable and at the same time have a sufficient margin of flexibility;

- even if the heating system freezes, polypropylene pipes will not be damaged;

- construction of a heating system based on polypropylene pipes is much cheaper than using other materials.

For hot water supply and heating systems, pipes marked PN 20 and PN 25 are best suited. Such pipelines are designed to work with coolant having a temperature of up to 100 degrees Celsius and a working pressure of 20 and 25 atmospheres, respectively.

Some people mistakenly believe that using larger diameter pipes and valves will improve the efficiency of the heating system. This is by no means true, and such an approach will only make the design of the heating system more cumbersome and expensive.

Positive qualities of PP pipes

Such pipes have the following advantages:

- long service life (minimum 25 years);

- a large selection of connecting fittings and other components;

- absence of condensation and various types of deposits on the surface;

- immunity to aggressive environmental influences;

PP pipes and fittings - low noise level;

- strength;

- light weight;

- corrosion resistance;

- ease of installation work.

Attention! In most cases, the maximum permissible temperature of the working fluid is 90°C (this includes products of the “twentieth” and “twenty-first” brands). When supplying cold water, where the temperature often does not exceed 20ᵒC, pipes from “eleventh” to “sixteenth” grades are used.

Polypropylene pipes

Polypropylene fittings

Stages of connecting heating radiators

Installing batteries in the house and subsequent connection will require additional equipment and components from you. All shut-off valves, as well as main consumables, must also be made of polypropylene. Ball valves today are available in any modification, both straight and angular.

For reference:

You can use brass fittings, but they are more expensive and, most interestingly, the joints between brass fittings and a propylene pipe or coupling will lose their strength over time.

To make the connection correctly, you will need: seals, a set of keys, thread paste, mounting tape, threads for making threads.

Tying is done as follows.

Multiflex is used - equipment into which a coupling equipped with a union nut is inserted. Such a connection can interact with any outputs and inputs.

Polypropylene pipes are laid at a suitable height. The permissible gap between the pipeline and the wall is 20-30 cm. Special brackets are where the pipe is attached to the wall.

If you want to hide pipes in the wall, then the pipe is exposed to the surface only at the points of connection to the radiators.

Batteries are usually attached to the wall using pins. In some cases, corner brackets are used on which the batteries are suspended. For sectional radiators, the number of brackets is determined by the number of sections.

Installation of a tap in a battery. The plastic tap is disassembled. Then the fitting is screwed into the socket and secured with a union nut, after which the nut is tightened tightly. The plastic body of the valve is placed over the fitting.

The supplied pipe, using bends, is brought directly to the tap, after which the soldering iron comes into action. To work with polypropylene pipes, use an 800W heater, which is set to a heating temperature of 270 0 C. Setting the temperature neither more nor less is not recommended. The heated coupling is placed on the outlet of the faucet. The whole process, with appropriate preparation, takes no more than 5-10 minutes. Do not forget to install thermostatic regulators at the connection points.

For reference:

the pipes connected to the radiator must be geometrically correctly positioned, without tension or tilting. Otherwise, the connection point will be under constant voltage, and the created slope of the line will disrupt the normal circulation of water in the system.

To get an idea of how the finishing work is done: connecting the pipes to the radiator, we suggest you watch this video.

Necessary auxiliary elements of the system

When performing installation work, not only polypropylene pipes for water supply are required. You may also need couplings, angles, bends, tees, plugs, crosses, clips and clamps. A pre-created pipeline diagram will help you purchase the required number of elements. When choosing, it is important to consider their sizes, diameters and other characteristics. It is better to select fittings from the same manufacturer, the same as the PP pipe.

Pipes and fittings for them must be of the same diameter

Couplings are used to connect straight sections of pipes or when switching to products of a different diameter. Using the corners, you can avoid obstacles and install the pipeline at the required angle. Crosses are used at cross-connection points of system elements.

Helpful advice! It is recommended to install the turning of the internal corner of the hot water pipeline at a distance of approximately 30-40 mm from the wall.

Reliable fastening of PP pipes to the wall is done with clips, the riser is fixed with metal clamps with rubber gaskets. Their connected ends are reinforced with bolts and nuts to increase rigidity. Clips can be used both on straight sections and in corner joints. If the pipelines are located one above the other, then there are double clips to secure them.

Which pipes to use

During the installation of a heating system from the pipes in question, you may need to connect plastic elements with metal-plastic pipes. When performing such work, make sure that the diameters of both types of pipes match each other.

Connections of polypropylene and metal pipes to each other

Follow the following pattern:

- for connection to metal-plastic products 20x2 mm, use polypropylene pipes measuring 25x4.2 mm;

- to metal-plastic pipes with dimensions of 16x2 mm, you need to connect polypropylene pipes with dimensions of 20x3.4 mm;

- Polypropylene pipes with dimensions 32x5.4 mm are connected to metal pipes with dimensions of 26x3 mm.

If pipes are laid to the batteries in the house from the main pipeline, and the wiring is carried out in accordance with a two-pipe scheme, it is necessary to lay a polypropylene pipe measuring 20x3.4 mm.

The use of pipes with a larger diameter does not make much sense. There is also no point in using radiator valves larger than 1.2 inches. Therefore, the statement that as the diameter of polypropylene pipes and thermostatic valves increases, the rooms become warmer is not true.

To ensure the required performance of the heating system, it is important that the supply pipe between the boiler and the latest battery is no more than 25 m long. In this case, the boiler power should not exceed 12 kW

Thus, in order for, for example, a heating system with pipes measuring 20x3.4 to work as efficiently and correctly as possible, it must include a maximum of 6 batteries of 10 sections each.

If it is necessary to connect more batteries, the length of the pipes for their installation will have to be increased, which will negatively affect the uniform heating of batteries installed at a greater distance from the heating boiler.

Installation of heating from polypropylene pipes and aluminum radiators

However, if you cannot refuse to connect more batteries or increase the length of pipes, equip the heating system using pipes of a larger cross-section. For example, 32x5.4 mm. Connect metal-plastic pipes 26x3 mm to them.

There is also another option for solving this problem - instead of one heating circuit, you can equip two.

Installation equipment

To install a pipeline made of polypropylene pipes, you will need a machine with nozzles for welding plastic pipes, a hammer drill, a grinder, and a device for cutting products and chamfering. Additionally, you may need an adjustable wrench, a level and a square, and the sealing material required for the threaded connection.

Attachments are not always included with the welding machine. They come in different diameters corresponding to pipes and fittings: 1.6; 2.0; 2.5; 3.2 cm, etc.

To install pipes you will need special tools

Cutting polypropylene pipes is done with special scissors, but in case of a small amount of work, you can use a regular wood hacksaw.

Important! Regardless of the tool used, the cut should be most perpendicular to the axis of the pipe.

Permissible deviations from perpendicularity are given in the table.

Table 1

| Pipe diameter, cm | Tolerance, mm |

| 20 | 8 |

| 16 | 7 |

| 12,5 | 6 |

| 11 | 5 |

| 9 | 4 |

| 6,3 | 3 |

| 4 | 2 |

| 3,2 | 2 |

| 2 | 2 |

When installing a water supply system, it is important to comply with safety requirements. Working with an angle grinder or other cutting tools should be carried out wearing safety glasses. When tapping walls or welding, you must wear a respirator.

Reinforced polypropylene pipes

To reinforce (strengthen) polypropylene pipes, fiberglass or aluminum foil is used. The sole purpose of reinforcing polypropylene is to reduce the degree of its “sagging” when heated. To do this, the reinforcing layer can be laid inside the PP layer or located outside the surface of the pipe, which to some extent determines the operational properties of the pipes.

More about this...

PP pipes reinforced with glass fiber

Polypropylene pipes reinforced with glass fiber have three layers: the inner and outer layers consist of ordinary (pure) polypropylene, and the middle layer consists of a mixture of PP and fiberglass.

The elongation of pipes of this type is no more than 1.5 cm per 10 meters of pipe, which is practically not noticeable when using them.

Another advantage of this type of pipe is its simple welding using conventional welding equipment, the same “iron” used for welding ordinary, non-reinforced polypropylene. In this case, the pipes do not require preliminary preparation and removal of the fiberglass layer.

It remains to add that PP pipes with fiberglass can withstand pressures of up to 25 atmospheres, are unpretentious, are not subject to corrosion and, thanks to all these properties, are the most popular among builders and heating engineers.

Aluminum reinforced pipes

When reinforcing, aluminum can be in the center of the polypropylene layer or located almost outside it. The last option, in which a layer of aluminum foil is on the surface of the pipe, is called classic. When using it, minimal thermal expansion of the pipes is observed. However, connecting such pipes requires preliminary removal of the aluminum reinforcing layer (stripping it), which in itself is a complex and time-consuming process.

Pipes with internal aluminum are easier to prepare for welding. To do this, a special stripping tool is used, with which an angular cut of the edge of the pipe is made, protecting the aluminum from subsequent contact with the coolant.

Violation of pipe welding technology and poor cleaning of aluminum can lead to damage to the pipeline and the occurrence of emergency situations.

As you can see, heating can be made of polypropylene, the main thing is to install it correctly!

Installation. Primary requirements

During the installation process, adhere to the following recommendations:

- cutting pipes into separate fragments and pieces is carried out only using special scissors;

- cut strictly at an angle of 900;

- do not make too long continuous sections of the heating circuit, avoid excessive bends in the working line;

- it is necessary to have a sufficient number of holders and fasteners for pipes on hand, thereby ensuring the stability of the entire pipeline, eliminating the effect of sagging;

- before connecting segments and fragments, check the edges and internal diameter for contamination;

- installation is carried out only at positive air temperatures, not lower than 50C.

When laying the heating main with polypropylene pipes, it is important to maintain the integrity of the consumable material. Avoid mechanical damage to pipes, which will later form the basis of the pipeline.

Cleaning of reinforced aluminum pipes is mandatory. Aluminum cannot be soldered, so use a shaver to remove excess aluminum to a depth of 1-2 mm. This guarantees the necessary strength and tightness of the connection during the soldering process.

To create a threaded connection, special fittings are used, products that already have a cut thread.

During the soldering process, the soldering iron heats up to a temperature of 2600C. It is not recommended to heat the soldering iron any more or less. Otherwise, the polypropylene may overheat or, conversely, the required joint strength may not be achieved. No further installation should be carried out immediately after soldering. Within 3-5 minutes, the soldered joint should be in a quiet position.

Important!

Soldering, as well as the installation itself, must be carried out in a ventilated area. If this condition is not met, you can get poisoned by vapors of molten polypropylene.

Once installation is complete. The entire heating system is checked for functionality during a test run. The water temperature is not brought to the optimal temperature immediately, but over several days, thereby increasing the load, operating pressure and coolant supply rate. During the test run, all connections and connections to the radiators are checked.

We connect the heating radiator to polypropylene pipes

In the private sector, in old housing stock and in new buildings, work is currently underway to re-equip heating systems. Old heating equipment, steel and cast iron heating radiators are replaced with new devices. Modern industry produces bimetallic, steel heating devices with improved parameters and characteristics. Accordingly, in parallel, the old steel pipelines through which the coolant circulates are being replaced with new consumables. Today, polypropylene pipes are taking the lead in creating a heating circuit.

Accordingly, in view of such a large-scale modernization of heating systems, reasonable questions arise. How is a polypropylene water circuit installed at home? What does it look like to connect a heating system radiator to polypropylene reinforced pipes. Let's look in detail and consider what it means to connect polypropylene consumables to heating sources in detail.

Features and nuances of the practical use of propylene pipes

Installing heating from propylene pipes is not a complicated process, however, it contains certain subtleties, features and nuances. Every little detail must be taken into account, otherwise your heating will work intermittently, and the hot water pipeline will be a source of additional hassle.

All work begins only after carefully drawing up a heating scheme. Based on the working diagram, the type and quantity of consumables, the presence of fittings, pipe diameter and installation methods are determined.

For reference:

pay attention to the diameter of the pipe. The use of narrow polypropylene channels for heat supply lines will significantly reduce the intensity of heat supply to heating sources.

Another equally important point that determines the functionality of the heating main is the choice of products. For heating equipment, you can only use reinforced polypropylene pipes, which have a low coefficient of thermal expansion. For multi-layer consumables these values are 0.03 mm/m0C, while for conventional, unreinforced, single-layer products the coefficient is 0.15 mm/m0C.

In other words, the following happens. Ordinary propylene begins to change shape over time when exposed to high temperatures. A single-layer pipe becomes plastic, losing its linearity. Thermal linear extension is triggered, as a result of which the pipeline begins to sag over extended sections and takes on an unsightly appearance. No such defects are observed in heating pipes reinforced with aluminum or fiberglass.

Practical details that should be observed during the installation process are as follows:

- It is not recommended to connect polypropylene pipes directly to heating devices;

- monitor the operation of the autonomous boiler, preventing the coolant from boiling.

In order to avoid such situations, when connecting the polypropylene line to the boiler, use metal adapters or other devices and equipment. Equip your heating system with automated heating temperature controllers.

On a note:

When installing polypropylene pipelines, it is not recommended to use threaded connections with metal fragments of the pipeline. Such a connection loses its stability and tightness over time.

Heating system options

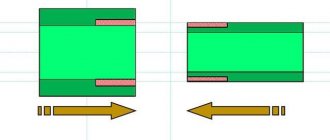

Today, there are two heating systems that can be used to install heating radiators in a house: single-pipe and two-pipe

One pipe heating radiator connection diagram.

A single-pipe system is a heating system in which hot water enters the entire building and flows from top to bottom through pipes and heating devices that are installed in individual apartments. This system is quite common today; it is used for apartment buildings. But this installation method has significant disadvantages:

- there is no way to regulate the temperature of heating equipment (in rare cases there is a chance to install an additional expensive system);

- on the upper floors the temperature is higher than on the lower ones;

- if repair work is necessary, the entire riser is turned off;

- Complete disconnection from the central heating system is quite difficult.

A two-pipe system for connecting heating radiators involves supplying hot water through one pipe, and already cooled water through the other (this is the so-called return). All radiators with such a system are connected only in parallel. A two-pipe heating system is used for private houses and cottages.

It is not only very convenient and effective, but also has such advantages as the ability to adjust the temperature of the radiators, which will be the same for all batteries, regardless of the number of floors.

The heating system itself consists of such elements as:

Two-pipe heating radiator connection diagram.

- heating radiators with a plug at the bottom and a valve at the top;

- radiator cap;

- thermostat and valve (for a two-pipe system);

- stopcock;

- shank;

- bypass (for a two-pipe system);

- couplings and locknuts for fastening heating radiators;

- risers in the form of heating pipes (can be made of polypropylene, polyethylene, metal).

Go shopping

What to look for when choosing pipes?

Operating pressure

Typical pressure in cold water supply lines is 3-5 atmospheres. It can rise higher (up to 8-10 kgf/cm2) only in the presence of pumping stations - pumping stations that lift water to the upper floors of high-rise buildings or to groups of houses built on elevations. Therefore, for cold water supply you can safely use pipes with a nominal pressure of 10 atmospheres (PN10).

It’s interesting: the working pressure of a polymer pipe is inextricably linked with another of its characteristics - SDR (standard dimensional ratio). SDR is the ratio of the pipe diameter to its wall thickness. The lower the SDR, the higher the pressure rating.

The markings indicate the nominal pressure and SDR

The pressure in autonomous hot water supply circuits that take heat from closed heating systems is usually exactly equal to the pressure of cold water. But, as in the famous joke, there is a nuance.

The nominal pressure is the pressure at which the pipe will last at least 50 years at a temperature of +20°C. As the temperature rises, both the service life of the pipeline and the pressure of its destruction rapidly drop. Let's say, at +90 degrees, a PN20 pipe lasts no more than ten years and can withstand only 8-9 kgf/cm2.

The relationship between temperature, pressure and service life of a polypropylene pipeline

That is why PN 20 is a reasonable minimum operating pressure for any DHW system.

Reinforcement

First, a few facts:

- PN20 and PN25 pipes are produced with reinforcement;

- Aluminum foil and fiber (chopped mineral fiber) are used as reinforcing materials. The foil is half a millimeter thick and is glued between the inner and outer polypropylene shells.

- The fiber is inserted into the middle layer of polypropylene; all layers of the pipe are formed on one extruder and reliably welded to each other due to molecular diffusion, simply due to the production technology;

Pipes with mineral fiber reinforcement

- Fiber reinforcement reduces the elongation of a linear meter of pipeline when heated by 50 degrees from 6.5 to 3.1 mm, and foil reinforcement to 1.5 mm.

And now - practical conclusions.

If you buy a pipe from a well-known manufacturer (TEBO, Valtec, etc.), it is better to prefer aluminum reinforcement. The name of the manufacturer in this case serves as a guarantee of compliance with production technology and high quality gluing of pipe layers.

Valtec reinforced pipes: the name guarantees quality

If you have chosen products from a little-known brand, then your choice is fiber reinforcement. Simply because minor violations of technology will not lead to stratification of your water supply.

Diameter

If you are replacing a steel pipe with a polypropylene one, then follow a simple rule - the internal diameters of the pipes must match. Remember that a steel pipe is marked with a nominal diameter (it is approximately equal to the internal diameter), and a plastic pipe is marked with an external diameter. Let's say, to replace a steel riser with a size of DN20, you will need a polypropylene pipeline with a size of DN25.

A steel pipe is marked with a nominal bore, a plastic pipe with an outer diameter

If you are installing water supply pipes in an apartment from scratch, polypropylene is selected according to diameter as follows:

| Image | Section of the water supply system and outer diameter of the pipeline |

| The line from the riser to the plumbing fixtures is 20 mm. |

| The water supply riser is 25 mm for a house height of up to 9 floors and 32 mm for higher floors. |

| The riser of heated towel rails without water points connected to it is 25 mm. |

Tying polypropylene pipes instructions

Radiator piping can be done using a variety of pipes, but experts recommend using polypropylene pipes. Ball valves for piping are also purchased in polypropylene; they can be straight or angular; this option is the simplest and most inexpensive. Brass fittings are more expensive, and their installation is more difficult.

Polypropylene strapping is done as follows:

- the coupling with a union nut is inserted into the multiflex, which easily connects to any outlet;

- The pipes themselves are attached to the walls at a convenient height; they should not fit tightly to the surface; it is better to leave a gap of 2-3 cm. The pipes are secured using special brackets, which are fixed to the wall with nails or self-tapping screws.

Polypropylene piping to radiators can also be carried out when laying pipes in the wall, in which case they come to the surface only at the connection points.

Radiator piping can be done using a variety of pipes, but experts recommend using polypropylene pipes.

Battery fasteners can be very different, most often it is a pin connection that is fixed to the wall surface. Corner brackets can also be used, which also allow radiators to be suspended at the required height. For panel batteries, fasteners are supplied included; for sectional batteries, they must be purchased separately. Typically, two brackets or pins are sufficient for one section.

The taps are connected as follows:

- the tap is disassembled, the fitting and union nut are screwed into the radiator;

- Use a special wrench to tighten the nut tightly.

As you can see, this process is extremely simple. To perform such work, you only need to purchase a special plumbing wrench for American women, without which it is unlikely that you will be able to simply install a faucet.

To install batteries and tie them, the following materials and tools are required:

- a set of special keys;

- seals for threaded connections;

- tow and thread paste;

- threads for carving.

Features of connecting radiators

Heating installation has some features:

- It is necessary to maintain a distance of 100 mm from the radiator to the window sill. If the gap between the batteries and the bottom of the window sill is different, then the heat flow is disrupted and the effect of the heating system will be low.

- The distance from the floor surface to the battery should be 120-150 mm, otherwise a sharp temperature change will occur.

- In order for the heat transfer of the equipment to be correct, the distance from the wall must be at least 20 mm.

At the same time, we take into account that the installation and efficiency of heating radiators is greatly influenced by the installation method: under an open window sill the efficiency of the heating system is maximum - 96-97%, in an open niche - up to 93%, in a partially closed form - 88-93 %, completely closed - 75-80%.

The heating radiator can be installed using a variety of methods; its piping is done with metal, polyethylene, polypropylene pipes

During installation, it is important to correctly position not only the pipes, but also the batteries themselves, and make the connection in accordance with all recommendations and standards. In this case, the heating system will work very efficiently and will not require repair work.

Share a useful article:

Stages of installation of a water supply system

Before installing new pipes, the water supply is shut off and the old system is dismantled. The premises are cleared of equipment and materials that are not useful during work.

If there is a need for additional sealing of the connection of parts, you can use FUM tape

The pipes are cut into pieces of the required size, and the upper part of their ends is chamfered. According to German DVS standards, its angle should be 15 degrees and the recess should be up to 3 mm. The state standard regulates a depth equal to 1/3 of the pipe thickness and a slope of 45 degrees.

Note! When installing a water pipeline, individual branches are first assembled. They are subsequently combined into a single system.

Next, the ends of the pipe are cleaned of dirt and degreased. Using welding equipment for polypropylene pipes, it is connected to the fitting. In this process, it is important not to overheat the parts, since their melting and deformation will not allow further connection.

The pipes are attached to the walls using clips. On level areas, the distance between adjacent parts should not exceed 1 m. Elements of equipment and fittings are fixed rigidly using clamps. The connections are sealed with fum tape.

Types of radiators for piping

To install a heating system, you must select the type of radiator. Different types of heating equipment differ in mounting to the wall, materials of manufacture, and pipe connections. Today manufacturers offer the following options:

Construction of sectional radiators.

- Panel steel batteries made in the form of relatively thin solid panels. The connection of such radiators can be side or bottom.

- Sectional lightweight, made of aluminum. Bimetallic ones are also often used. Such batteries can be connected in one or several sections, the connection to the general system is lateral, polypropylene pipes are ideal.

For apartments with central heating, bimetallic radiators are used (cast iron ones are used less and less, this is explained by their large weight, bulkiness, and fragility). This is due to the fact that the water supplied to the heating system often contains alkali and sand, which can damage other types of radiators.

For a private home, aluminum and steel panel radiators are excellent, but all connection conditions must be met (for a copper pipeline, steel and aluminum radiators are used, for a regular one, only aluminum ones are possible).

Accessories for connecting radiators

Heating is a rather complex system, the connection of which requires the participation of a specialist. In addition to radiators and pipes, it is also necessary to prepare components, without which the connection will simply be impossible.

The connection kit consists of:

Accessories for connecting radiators.

- a set that includes a plug, adapters, a manual air vent, a key for releasing air from the batteries, plus pipes;

- fittings, or adapters, which have right and left threads;

- special tools for screwing on adapters.

Shut-off valves for batteries are also required, and do not forget about pipes. This also includes ball valves, valves for stopping the supply of the working flow or regulating it.

Mechanical joining method without soldering: connection options

Soldering as a method of joining pipeline sections is more often used during installation supervision in production. In everyday life, the most popular technologies are express installation without welding.

The time-tested practice of joining without the use of special tools ensures high quality joints of plastic pipes without soldering using couplings.

The widely known method is based on the use of shaped parts. With their help, you can not only ensure the continuation of the water supply circuit, but also change its direction, distribute the working medium or block the flow.

Advantages of installation technology without heating:

- Finished polypropylene products are cheaper to connect using this method than metal ones due to the low cost of fittings.

Connections of plastic pipes without soldering using couplings Source stroy-podskazka.ru

- The design of the fittings makes it possible to manually assemble a complete engineering system of drainage, water supply, and sewerage.

The size and technical capabilities of parts are determined by their configuration (shape, wall thickness, combination).

Connection using compression fittings

When choosing how to connect plastic pipes for water supply without soldering, many people often use the compression fitting method. With this connection method, the process of heating adjacent parts is eliminated. A special coupling, under mechanical action (crimping), reliably fixes the two ends of the tubes equipped with o-rings inside. After installing the adapter, the joints are lubricated with silicone sealant.

Switching from metal-plastic to polypropylene using fittings is an indispensable way to join pipes made of different materials.

The advantages of this method:

- a minimum set of tools is used for installation;

- Even a beginner can trust the pipeline connection;

An example of lubricant used when installing polypropylene pipes Source construct.smazka.ru

- a reliable connection is created at the installation site of the compression fitting;

This method, first of all, is good because it can be used when updating cast-iron water pipes with polypropylene analogues. This method is also in demand when assembling heating systems, including the installation of radiators.

Connection using adhesives

Among the docking options that make it possible to do without special equipment is the use of assembly adhesives.

The base composition of the adhesive is polyvinyl chloride mixed with a solvent. Manufacturers also add various additives and plasticizers to it to improve adhesion at joints.

Advantages of the method:

- joining products using an adhesive provides the assembled structure with the necessary characteristics of strength and tightness;

- upon completion of work, a reliable connection is formed at the installation site, invisible during visual inspection;

- No special skills are required for docking.

Important ! During work, safety precautions should be observed, do not work near open sources of fire and avoid contact of the composition with the skin.

Fitting polypropylene pipes before gluing Source www.asvshop.com

See also: Catalog of companies that specialize in engineering communications.

How to install with glue

Before connecting polypropylene pipes, you need to prepare the necessary parts, tools and provide conditions for installation work.

The surfaces on which the adhesive composition will be applied should be treated with a degreaser. To apply the composition, a brush with bristles made from natural materials is suitable. It is also recommended to ensure the room temperature ranges from 5 to 35 degrees.

Considering that the pipeline parts will be joined with a minimum gap, a thin layer of glue will be sufficient. Holding the pipes until they set usually does not exceed 20-30 seconds. Upon completion of work, it is recommended to ventilate the room well, while drafts should be avoided.

What kind of piping can be made from polypropylene pipes

The piping for a home heating system can be very different. The thing is that the consumer is always trying to reduce the amount of consumables, while simultaneously trying to install radiators in all heated rooms.

It should be said right away that these are relics of the past. Unlike expensive metal pipes, polypropylene consumables are much cheaper and easier to install. therefore, it is not worth saving on the length of the pipeline. Choose the type of harness that will bring maximum benefit in your case. The only reasons that may influence the choice of type of harness are the following factors:

- what heating circuit is used (one-pipe system or two-pipe);

- what type of radiator connection you have chosen (diagonal, side or bottom).

As a rule, when using any heating scheme: single-pipe or two-pipe, you can use any type of heating radiator connection.

According to experts, pipeline laying must minimize the number of bends. A smooth highway remains resistant to hydrodynamic loads. The number of zones in which air can accumulate will be reduced in the pipeline.

There are specific features for piping a single-circuit and double-circuit heating system using polypropylene pipes.

- Typically, such a system uses a series connection of radiators;

- A bypass is always installed in front of the battery, connecting the supply pipe and return pipe. During normal operation of the heating system, the bypass is not activated. When carrying out maintenance work or in the event of an emergency, the water supply to the radiator is stopped. The coolant circulates freely through the bypass.

- Both parallel and serial connections of batteries are used;

- Both radiator hoses are connected to different pipes. The upper one is connected to the supply pipe, the lower pipe is connected to the return pipe. Typically, radiators are connected in parallel in two pipe systems, so installing bypasses is not required.

Tying polypropylene pipes with radiators is done in two ways: soldering and using fittings. Radiators are installed and connected using a soldering iron and American-style plumbing wrenches.

What is special about propylene pipes used in heating systems?

Since the appearance of propylene on the heating equipment market, the process of organizing intra-house communications has become much simpler and cheaper. Unlike metal pipes, a pipeline made of polypropylene consumables is 3-5 times cheaper. Moreover, due to the affordable cost of products, you no longer have to save on the length of communication lines. Previously, it was the factor of the high cost of consumables that was the main reason why heating in the house was done to a minimum, with significant technological and design restrictions.

Laying heating circuit pipes using propylene products allows you to equip full-fledged home heating, which can heat all living spaces. The low cost of propylene consumables is the result of the low cost of the production process. However, this is not all the advantages that polymer consumables have. Let's look at some other important aspects. For example, polypropylene pipes are:

- resistance to high temperatures;

- good resistance to mechanical loads;

- resistance to corrosion processes;

- high performance characteristics;

- long service life;

- environmental Safety.

Of all the above, it is especially worth highlighting the heat resistance of polypropylene. The material begins to change its structure and shape only at very high temperatures. When reaching 1400C, the plasticity of the material increases. Polypropylene easily changes shape. At around 1750C, polypropylene begins to melt. This feature of the substance is key for its industrial use. In heating systems, the temperature of the coolant can reach a maximum of 950C, which is quite consistent with the technological parameters of polypropylene products.

On a note:

Even for heating equipment that produces a coolant temperature of 1050C, it is possible to use propylene pipes. Additionally, in such communications, means are used to cool the coolant, preventing the boiling process.

The addition of certain stabilizers to the polymer composition makes propylene pipes resistant to corrosion, aggressive environments, and dynamic loads. Due to these components, the service life of propylene pipelines is significantly increased.

Polypropylene is highly water resistant, which makes it possible to use pipes made from this material when laying liquid communications, including water supply and heating circuits.

Eg:

Over the course of six months of operation, polypropylene absorbs only 0.5% moisture upon contact with cold water. For heating systems, this figure is only 2%.

Despite a lot of positive properties and characteristics, polypropylene pipes have one drawback, which, if the installation technology is not followed, can negatively affect the condition of the pipeline. We are talking about a high coefficient of thermal expansion. This aspect must be taken into account when choosing consumables for the heating circuit.

Thanks to these qualities and properties of polymers, polypropylene pipes have become an excellent alternative to the use of metal consumables and metal-plastic products. The only condition that will allow you to make the most of all the positive qualities of polypropylene pipes is the correct installation of heating.

Methods for installing radiators and piping

The heating radiators are connected after the windows and doors are installed and the floors and walls are prepared for final finishing. Connection options and types of radiators and pipes are selected in advance so that the room is already ready for their installation.

A modern heating system consists of a number of components. Among them are the heating boiler itself, the pipeline and heating devices - radiators, which are presented in a wide range.

The process of installing the battery is quite simple: you need to mark the installation location, connect the pipes, install the radiator itself and make the connection. Let's look at the process of installing radiators using polypropylene heating pipes in more detail. Let's find out what types of systems and connections can be used for this, what is necessary for connecting the heating system itself.

How metal-plastic and polypropylene pipes are joined

There is only one way to install pipes made of different materials. This is a threaded installation, since soldering and gluing products cannot be used here.

This is explained by the fact that the joint must not only be hermetically sealed, but also be able to experience high dynamic loads (maximum pressure difference).

Quick installation of pipes from various materials Source glawtruba.ru

Before connecting a metal-plastic pipe with a polypropylene pipe, you need to select the necessary parts:

- Metal-plastic products are equipped with special tips.

- Polypropylene sections, in turn, are equipped with a coupling on which a thread is applied.

Thermal expansion of polypropylene

Polypropylene, just like any other plastics, has a thermal expansion that averages 15 cm per 10 linear meters of pipe when it is heated by 40 degrees or more. This means that polypropylene can be used without fear for cold water supply, but for heating and hot water supply, pipes made from simple PP are not suitable: they will sag, creating zones of coolant stagnation and contributing to a local increase in pressure in the pipeline, which in turn can lead to to an emergency.

It is unlikely that there will be users who agree with such risks of using polypropylene pipes. It is for this reason that reinforced rather than simple polypropylene is used for the installation of heating systems.

Installation of serial wiring

The principle of the sequence of inserting the outlets on the incoming pipe is carried out using tees. They are installed sequentially on the supply pipe, each opposite its supply object.

In this way you can connect 2-3 objects. It is more profitable to dilute a larger quantity in parallel.

Installation of parallel wiring

To install parallel wiring, you need a special part - a collector. Polypropylene manifolds are produced for installation of cold and hot water supply with 3 or more outlets.

The manifold is a unit with several outlets that is installed on the incoming pipe. As a rule, each outlet is equipped with a separate valve, which allows you to isolate the water supply to each branch.

We recommend that you read: What is the maximum pressure that a polypropylene pipe can withstand?

Often the wiring is combined. For example, cold water supply in a private house is installed in parallel through a 5-outlet manifold. Outputs go to the sink, toilet, washing machine, shower and boiler.

The hot water supply from the boiler only needs to be supplied to the sink and shower. A tee is installed here. One inlet is the supply from the boiler, two outlets distribute the supply to both objects.

Note! In the example given, the hot water supply (and therefore the water temperature) of the shower stall will drop as soon as the water in the sink is turned on, and vice versa.

Types and types of connection fittings

The English word "fit" means to gather. It is thanks to him that the fitting got its name. With the help of such connecting elements, pipes are joined in the same and different planes.

They allow you to create branched systems and avoid obstacles. When using fittings, pipes of the same or different diameters are joined.

Manufacturers produce threaded and soldered connecting elements. The first type allows you to connect polypropylene communications with steel pipes and fittings in the form of taps and valves.

The second type is intended for connecting polymer elements to each other by soldering. First of all, when using special welding equipment. It heats the parts, so their structure softens. Only after this the fitting can be put on the pipe.

Couplings and adapters

The simplest fitting for polypropylene pipes is a coupling. It is made in the form of a barrel, the internal diameter of which corresponds to the cross-sectional size of the pipe along the outer edge.

PP coupling

The couplings have thicker walls. They are used to connect pipes of the same diameter, inserted into the so-called barrel on both sides if it is made entirely of polypropylene. When the coupling is threaded, soldering is performed on one edge only.

Combined coupling PP

An adapter is an element that allows you to connect pipes of different diameters. Used in branched systems with several consumers.

Adapter PP

Using adapters, it is possible to narrow the diameter of the communication and create excess pressure in the circuit.

Angle, tee and cross

In most cases, utility lines have a branched structure. Angles are used to rotate the system 90° and 45°. They form a system of the required configuration. After all, polypropylene is a hard and elastic material that bends only after heating.

However, this method is not used when laying communications. As a result, when bending, the cross-sectional size and wall thickness of the pipes change. This reduces the strength characteristics of the system. Consequently, it often leads to the appearance of a leak when the pressure and temperature of the moving medium increases.

Corner pp

Angles are also available with a 3/4 female thread on one end. They are used during installation of mixers.

Tee pp

Tees and crosses are used to branch utility lines. They allow you to connect two or three taps together. The sizes of fittings for polyethylene pipes are selected depending on the design.

Crosspiece pp

Tees and crosses allow you to create bends at right or acute angles. This type of fitting is also available with threads on one end. In this case, they are used when installing shut-off valves.

Bypass and compensators

Bypasses are used to bypass obstacles on the way of laying systems. With their help, a more round bend is created than when using corners. Contours allow you to smoothly change the direction of pipelines. Therefore, it is possible to lay communications that have a more attractive and neat appearance.

PP bypass

Compensators are parts of engineering systems that can “absorb” pressure and temperature changes in hot water supply and heating pipelines. They increase reliability and maintain the integrity of networks. Several ready-made solutions are available. Polypropylene expansion joints are made in the form of a loop.

American fitting

The installation process of PP systems is made easier by the American. This is an element made of metal and plastic with a rubber insert. The parts are used for detachable sealed connections.

American pp

Such fittings with internal or external threads on one side are used when installing shut-off valves, hydraulic accumulators, circulation pumps, heating radiators, and so on.

Taps, valves and plugs

During the operation of utilities, it is often necessary to shut off the water. This is achieved by installing taps and valves. They can be made of polypropylene or brass.

In the first case, parts are soldered into systems. In the second, adapters are additionally used. Consequently, they allow threaded connections of network parts made of different materials.

Crane pp

Plugs are used in places where polypropylene pipelines end.

Plug PP

Such parts can be soldered to permanently block the outlet or temporarily installed using a threaded connection.

Common questions and answers about soldering polypropylene

Is it possible to solder pipes from one manufacturer and fittings from another?

Of course it is possible, but I would like to warn you that both couplings and pipes should be used of proper quality. You should not use parts from unnamed manufacturers. In unprofessional stores they often sell pipes from different companies, but the fittings are the same, from an unnamed manufacturer. I don't recommend using this combination. In general, nothing prevents you from soldering pipes and fittings from different manufacturers, with or without different reinforcement on different sides of the coupling.

Is it possible to bend polypropylene pipes?

They cannot be bent, either during installation or after. If there is a need to bend the pipe during installation, then you should use contours or combinations of corners. To be fair, it is worth noting that the weak point of the bending pipeline is the junction of the pipe and the fitting. This mating point breaks off at some breaking force. To make sure of this, just solder a test structure from a corner and two 50 cm pipe sections, and try to break this “poker” with your hands.

Sometimes there is a need to solder a node with a non-standard angle. Let me remind you that PP corners come in only two types: 90 and 45 degrees, at least I haven’t come across any others. What to do if you need to turn the pipe to a different degree? There are two methods known to me:

Using two 45° corners, you can make any angle by changing the angle of rotation of the corners relative to each other. The disadvantage of this method is that due to the non-standard rotation, the connection will not be in the same plane.

The second way is to disrupt the alignment of the pipe and fitting at several connections. Do not forget that the straightness at the junction of the pipe and fitting should not deviate by more than 5°.

How to solder pipes if the faucet does not hold it?

It is strictly forbidden to weld if there is water in the area to be soldered. If for some reason it is not possible to completely shut off the water, you need to stop it while welding. On the Internet they advise plugging the pipe with bread crumbs, but the problem is that the crumb is immediately squeezed out by the newly created pressure in the pipe. Therefore, the method will only work when it is possible to open the area up to the soldering point for air to escape. And when the pipes are soldered, the crumb easily pops out when pressure is applied.

Advice: if during welding you could hear the hissing of water on the nozzle, it is better to cut out the assembly and redo it! It’s better to spend extra time during installation than to fix and eliminate leaks in the future, with a bunch of problems that pop up!

In this photo you can see that the plug on the filter is unscrewed and excess water flows down the cloth from there. And in the place of soldering the bread crumb is plugged. Thanks to the open filter, we had a little over a minute to do the soldering before the water squeezed out the crumb.

Actually, this is where I propose to end the presentation of information. Over time, I plan to expand the list of common questions about soldering polypropylene pipes.

Rate this publication:

- Currently 3.95

Rating: 3.9 (19 votes)