Why contact us

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

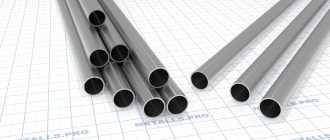

Installation of stainless pipelines

Stainless steel pipes are widely used in the food industry, due to the strength and resistance of the material used to corrosion, even in aggressive environments. Installation of stainless pipelines is in demand on the market. Such pipes are used for the production of any food products, since the steel meets all sanitary and hygienic requirements

And it doesn’t matter how long ago the pipeline was installed, because the stainless steel will not interact with the product, and any penetration of substances from the pipeline system into the raw materials is excluded. Such products meet all toxicological requirements, do not require painting or other additional processing and retain a neat appearance.

The manufacturing enterprise Region LLC carries out a complex technological complex of works on the installation of stainless steel pipelines

Our company’s specialists pay special attention to the correct connection of individual pipes into a common system

Thanks to this approach, we can guarantee stability and reliability of operation and, importantly, process control over the quality of the resulting product. This level can only be achieved by professional workers who use suitable tools and comply with the rules and regulations for such work.

This level can only be achieved by professional workers who use suitable tools and comply with the rules and regulations for such work.

Stainless steel pipes are perfectly formed and easily welded, which allows you to assemble non-standard pipelines according to your ideas.

carries out installation work of any complexity:

— high-quality installation of stainless pipelines;

— installation of platforms and overpasses for further installation of dairy equipment and laying of pipelines;

— installation of stainless steel containers;

— manufacturing of equipment according to drawings;

— all types of insulation work necessary when laying a pipeline;

— preparation of commissioning works of installed dairy equipment.

Additionally we offer:

— Departure of a team of installers to any region of the country.

— Installation of technological equipment for the dairy industry requires special responsibility and high professionalism from the workers carrying out this process. Therefore, our installation specialists regularly improve their skills and have all the necessary certificates allowing such work to be carried out.

Installation of dairy equipment by Region LLC specialists includes:

— Guarantee for work performance;

— Full compliance of installation work with approved standards of the Russian Federation;

— Ensuring proper setup and subsequent maintenance of equipment, as well as training of personnel to work on it;

— Certification of installation specialists for work in food production;

— Guaranteed delivery of the facility to Rostechnadzor authorities.

If you have purchased expensive technological equipment for dairy production, then do not skimp on installation. Hire specialists who can perform the installation professionally and guarantee subsequent long-term operation of the equipment.

Installation features

*

When installing a stainless steel pipeline, you must adhere to certain nuances. For example, corrugated products are famous for the fact that they bend well, but there is no need to abuse this: with repeated bending in the same place, there is a possibility that a crack will appear and, as a result, a leak. The norm also applies to flexibility, therefore, having given the product the required shape, it is no longer recommended to change its configuration.

Installation of corrugated products is similar to how systems are connected using compression fittings. The only thing is that the connecting elements for the corrugation do not provide a fitting. The crimping process is carried out thanks to the internal gasket of the fitting. Corrugated pipes are flexible and therefore require less time to install.

Important! When choosing fittings for connection, follow the recommended list offered by the manufacturer. You should not skimp on connecting elements, which may cause an emergency.

Sequence of work:

- We separate a piece of pipe of the required size, for which we use a pipe cutter or other cutting tool. Before starting this operation, it is recommended to first measure the distance of the pipeline, taking into account kinks.

- The union nut on the fitting is loosened. To do this you will need a spanner wrench. A piece of tube is inserted into the fastening element until it stops.

- Using the same wrench, the union nut is tightened until the product is completely secured in the fitting.

- At this stage, you can bend the corrugation to achieve the desired configuration. Next, it is attached to the wall.

- The final stage is checking the tightness. That is, the water turns on and, if no leaks are detected, the installation is successful.

Installation of corrugated stainless steel pipes is a simple procedure that anyone can handle.

Do not over tighten the union nut

*

Location rules

Location on the roof

When designing the installation of such combustion product removal systems, take into account the standards provided for by technical standards:

- The roof duct outlet, located on a flat roof or 1.5 m from the ridge, must have a height of at least 0.5 m.

- The chimney, located at a distance of 1.5–3 m from the ridge, reaches its level.

- The edge of the pipe, located at a distance of more than 3 m from the ridge, is flush with a line 10° from the horizon of the ridge line.

- The minimum height of the chimney is 5 m, the maximum length of the horizontal section is 1 m.

- The thickness of the channel walls for solid fuel boilers is 1 mm, devices on

- liquid fuel - 0.8 mm, for gas appliances 0.5–0.6 mm is sufficient.

- The joints of the structure do not fall on the floor.

- The passage through the roof of the sandwich pipe has a gap of 13 cm, through the ceiling - 20 cm.

- The permissible number of turns of smoke exhaust channels is 3. The diameter of the pipe is not less than that of the outlet pipe.

Installation methods

When laying water supply or communications for other purposes using stainless steel pipes, several types of connections are possible, namely:

- welded;

- use of flange type connecting elements;

- crimping.

To connect using water supply and heating networks, you will need not only special equipment, but also a qualified specialist. Such a process is usually carried out, and the welding itself is performed in an inert gas environment. The most modern method that allows high-quality joining of stainless pipes is plasma welding, which also requires the use of special and expensive equipment.

Press fittings provide high-quality connections and quick installation, but are expensive and require special tools

In domestic conditions, it is not always possible to use welding, since for this you need not only to have special equipment at your disposal, but also to attract a qualified specialist to operate it. In this regard, in such cases, threadless flange or threaded fitting connections are used.

Flanges are essentially two ring-shaped elements connected to each other using studs or bolts. To achieve tightness when using flanges, use a special sealing element made of rubber or other soft polymer material. Parts such as flanges, which are quite large in size, are used mainly when pipeline elements need to be periodically dismantled and maintained, spending a minimum of time. The disadvantages of connections of this type are that they react rather poorly to temperature changes and pressure surges in the pipeline.

The service life of fittings for corrugated pipes is practically unlimited; you only need to change the seals, which can last up to 30 years

A more reliable option are fittings, the design of which includes a silicone gasket that ensures tightness. You can dismantle such connections several times without worrying about their reliability.

Advantages of stainless steel pipelines

Any product has both strengths and weaknesses. In the case of pipes made of stainless steel, they have more advantages than disadvantages.

Advantages:

- Withstands high temperatures and pressure. The normal pressure level is 15 atm, where the limit should not rise above 50 atm. Operation of the products is allowed at operating temperatures from -50 to +110 degrees Celsius. Let’s make a reservation here: the maximum temperature is a conditional value. If it rises higher, the sealing gaskets and couplings will deteriorate, and the stainless steel itself begins to deteriorate only at +800 degrees.

- Areas of application. Using stainless products, radiator and water heating systems are installed, “warm floors” are installed, gas and water pipelines, fire extinguishing systems, air conditioning systems, and so on are installed.

- No susceptibility to corrosion.

- Stainless steel is chemically inert to other metals. This means that if the installed pipes in the next room are made of copper or aluminum, nothing bad will happen.

- High level of strength. This means that they successfully withstand high mechanical loads.

- Easy installation. All work is done, if desired, with your own hands. Of course, you will need skill to quickly assemble the connections, as well as a couple of tools for installation: a hacksaw and an adjustable wrench.

- Flexibility. The minimum permissible bending radius is equal to the cross-section of the pipes, which makes installation even easier.

- Life time. The operating time is not affected by the temperature of the circulating coolant.

They have enough advantages. But, ideal products do not yet exist, so even stainless steel types have disadvantages.

Minuses:

- High price. For example, it is cheaper to install a system from black rolled steel.

- Oxidizes upon contact with chlorine. If the water circulating through the pipeline contains a lot of chlorine, then over time, rust spots will begin to appear on the inner surface of the pipes. As a precaution, it is recommended to flush the system with plain water from time to time.

At the moment, such a variety of stainless products as corrugated pipes is produced, which has become an excellent analogue in comparison with rigid products. Their free-flexing shape makes them even easier to install, especially in confined spaces. They are not afraid of sub-zero temperatures and water hammer.

Flexibility is a significant advantage

Installation of a stainless steel chimney

Actually, if the chimney layout is carefully thought out, approval has been obtained from regulatory authorities (this is a mandatory condition), and all the necessary parts for the future system have been purchased, then installation is not particularly difficult. All elements are equipped with adapted mating areas, and connecting them one to another is a simple and intuitive task.

It is advisable to further strengthen pipe joints, especially inside living spaces, with a special sealant that can withstand temperatures up to 1000-1500º - it is easy to find in specialized stores that sell components for chimneys. This will ensure that combustion products hazardous to health are avoided from entering the premises and reducing draft in the system.

Sealant for chimney systems

When mounting the chimney on an external wall with brackets, the distance between them should be no more than 2 m. A bracket (support) is required where the pipe passes through the wall and where the condensate collector (inspection compartment) is attached.

If installation is carried out indoors, then the main attention is paid to the places of passage through the ceilings. Some manufacturers of chimney systems include special elements for these purposes in their range.

But, if there are none, it’s easy to make them yourself.

Self-made box for passage through the ceiling

Essentially, this is a box with a central hole for the passage of a pipe of the appropriate diameter, and a length of walls that provides the required distance of the chimney from the floor material. Very often it is also made from stainless steel.

It's installed in the right place

It is mounted in the thickness of the ceiling, the free space in it is filled with non-combustible material (basalt wool or expanded clay). It can be covered with a decorative plate at the top and bottom.

Top and bottom can be covered with a plate

On the roof there is a slightly different approach.

Firstly, if it has a certain angle with the horizon, the hole for the pipe will not have a round shape, but an elliptical or rectangular elongated shape.

Cutout in the roof for the chimney pipe

Secondly, you should immediately take into account the location of the ceiling beams and rafters - it is necessary that the chimney runs approximately in the center of the distance between them.

Installation of a passage through the roof

- Thirdly, in addition to thermal insulation, it is necessary to provide waterproofing on top - so that precipitation or condensed moisture does not penetrate into the attic. Today it is easy to purchase special flexible elements that will fit any roof profile.

- It would be useful to put a “skirt” on the chimney pipe, which will protect the joint with the roof from direct rain.

“Skirt” to protect the passage through the roof from direct rain jets

The pipe is topped with a head - an umbrella. In a number of cases, which have already been mentioned, the installation of a special element - a spark arrester - will be required.

Services offered

Key areas of our activity:

- installation of stainless steel pipelines and technological equipment;

- installation and piping of capacitive equipment;

- electric installation work;

- thermal insulation of pipelines;

- engineering and integrated solutions;

- supply of components and pipelines made of stainless steel.

What is a stainless steel chimney?

First of all, a few words about what a set of parts for assembling a stainless steel chimney is.

There are three options:

Components made of single-layer material, thickness from 0.6 to 2 mm, so-called mono-systems. They are certainly cheaper, but their scope of application is significantly limited. They are used only inside an insulated room, since a large temperature difference between the outside and inside the pipe will lead to an absolutely unnecessary waste of energy, to the abundant formation of condensate in the cavity, and will affect the overall performance and durability of the entire heating system. Their only advantage is that indoors they are often used as secondary heat sources - for example, tanks for heating water or external liquid or air heat exchangers can be mounted to them.

Single-layer and sandwich pipes

- Corrugated stainless steel parts - they are used to create curved transitions, for example, from the heating device itself to the rigid section of the chimney. However, they do not always have the required strength and heat resistance, and often inspectors of regulatory authorities simply refuse to approve projects using corrugation.

- The most universal are components from the category of sandwich pipes, in which a layer of fireproof material with high thermal insulation is laid between the inner and outer stainless coating - as a rule, this is basalt mineral wool. Such elements can be safely used for both internal and external installation of the chimney.

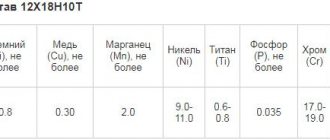

The next question is the grade of stainless steel. The metallic sheen of all parts is almost the same, but the performance characteristics can vary significantly

Therefore, when choosing, you should definitely pay attention to the product labeling:

- Steel grade 430 is used for parts that are least susceptible to aggressive influences. As a rule, external casings are made from it - the surrounding humid atmosphere is not dangerous for it.

- 409 steel – optimally suited for appliances running on solid fuel (fireplaces, stoves).

- Steel 316 – enriched with inclusions of nickel and molybdenum. This increases its heat resistance and resistance to chemical (acid) attack. If you need a chimney for a gas boiler, then this will be the right choice.

- Steel grade 304 is largely the same as 316, but the content of alloying additives is lower. In principle, it can be a replacement for an analogue, with the advantage of a lower price.

- The 316i and 321 brands are the most versatile. The temperature limit of their operation is about 850ºC, and this is combined with high acid resistance and excellent ductility.

- Stainless steel 310S is the most “elite” material, which, along with all other positive qualities, is distinguished by its resistance to temperatures up to 1000ºC.

The range of manufactured stainless steel chimney parts is very diverse and can satisfy the needs of almost any designed system.

The range of components is very wide

- Straight sections with a length from 330 to 1000 mm. All of them have a special socket connection that does not require any additional elements.

- Elbow (bend) 45º, used when it is necessary to change the direction of the chimney on vertical or inclined sections.

- 90º bends - as a rule, are used to transition from a short horizontal section at the heating device to the main part of the chimney pipe.

- Tees at an angle of 45 or 87º - are installed at the installation site of the condensate collector or, in the case of installing two devices, when they are connected to a single chimney system (separate approval from regulatory authorities is required).

- Chimney inspection elements - designed for regular monitoring and cleaning of the system.

- Condensate collector - installed in the lower part of the main vertical section and serves to regularly clear the chimney of accumulated moisture.

- Elements of the upper part of the chimney - spark arrester, cap, waterproofing skirt.

- You can also purchase special elements for passing through a wall, interfloor ceiling or roof. If such parts are not provided by the supplier, you will need to make them yourself.

Types of products

Stainless steel products are used in many industries, so when choosing them you should take into account many parameters. For example, with the help of anti-corrosion types, internal and external pipelines are laid, monumental and lightweight structures are erected, and they are also used for design projects. When choosing a suitable material, you need to know what loads it will be subjected to during operation.

Pipes differ in cross-sectional shape. For example, water pipelines through which liquid is transported are assembled from products with the usual round cross-section. It is recommended to install the load-bearing elements of the frame using products of square or rectangular cross-section.

Stainless metal also differs in surface, which depends on the characteristics of the finishing treatment with abrasives or on the electrochemical reaction. As a result, the manufactured pipeline products have a smooth or rough, matte or glossy surface.

There are 2 ways to produce stainless pipes:

- Hot rolled. This method comes down to two main operations: first, the round billet is heated until it becomes plastic, then it is processed on a piercing mill. The resulting hollow sleeve is crimped, stretched and rolled. Next, the finished product is cut into pieces in accordance with GOST 9940 81.

- Cold and warm rolled products. The technology is similar, but immediately after finishing the firmware, the product is cooled with water. The minimum length parameter is 300 mm, the maximum is 12.5 m.

Installation of a stainless steel chimney

Modular chimneys are now a favorite, since with their help you can easily come up with and install a system of any configuration, without worrying about damage to the operation of heating equipment or draft.

The preparatory stage includes calculations of the chimney, drawing up a sketch and marking out the walls for fastenings. The last operation makes it possible to determine as accurately as possible the total length of the structure, the required number and type of parts for connecting the sections.

Assembling the internal chimney

Installation of a stainless steel chimney begins with a heat generator.

- An adapter is put on it, the connection is coated with sealant, then fixed with a clamp. Then single-wall pipes are inserted and interspersed with components. The modules are installed to a depth equal to half their outer diameter.

- After the channel for access to the roof has been formed, a ceiling-passage assembly is formed - homemade or (better) factory-made. A sandwich pipe is brought out through the roof, a corner passage, a cone, a skirt and a cap-head are put on it.

- After final adjustment of the elements, the internal seams of the chimney are treated with sealant. If they prefer to leave the structure collapsible, then use heat-resistant polyurethane foam only at the joints of the modules.

Single-layer pipes are insulated, all joints are waterproofed using seals and sealant.

Installation of external structure

In this case, the first stage is no different:

- First, in the same way, put an adapter on the heating device pipe, ensure its tightness, then attach the clamp. Then a horizontal section is installed, which is led out onto the street through a passage unit.

- Below the exit of the horizontal section of the chimney structure, a bracket having a plate for installing an inspection and a condensate drain is fixed on the wall, then these elements are installed.

- A vertical channel is assembled, which is secured with brackets to the wall every 1500-2000 mm. If the chimney is heavy, then additional fastenings are made at the joints of bends and tees.

A cone and a cap-head are installed at the top.

Homemade pass-through unit

Internal installation of a stainless steel chimney is more demanding for the master: the main difficulty lies in one device - the ceiling-passage assembly, which guarantees the necessary clearance, as well as high-quality waterproofing. You can make a similar detail yourself. This is a box that has a hole in the center for a pipe. The height of its walls is equal to the thickness of the ceiling (wall, roof).

- First, the necessary hole is made in the structure, then the edges are further strengthened. Two blank plates are cut out of a metal sheet (usually from the same stainless steel), the sides of which are 50 mm longer than those of the prepared hole, the height is equal to its height.

- These “extra” 500 mm are bent at a right angle. The elements are secured on both sides of the hole made with self-tapping screws. Another pair is made in the same way; they are placed overlapping with the first. Then they make a bottom in which a hole is cut for the chimney. It is laid on plates.

- The free space is filled with basalt wool or expanded clay. The box is covered from below and above with decorative plates.

Chimney design

The design of a system for the removal of combustion products begins with the selection of a modular system and preparation of the project. Since the requirements for chimneys for gas boilers are increased, their design must be submitted to technical supervision services and permission for installation work must be obtained.

- The minimum permissible total height of the chimney is 5 meters, otherwise the draft will be insufficient.

- The maximum length of the horizontal section of the channel is 1 meter;

- Outside the building and in unheated rooms, the chimney must be thermally insulated, unless it is a sandwich system.

- The height of the chimney pipe above the roof:

- at least 50 cm if the roof is flat or the distance from the ridge of the pitched roof to the pipe is less than 150 cm;

- flush with the ridge or higher, if the distance from the pipe to the ridge is from 150 to 300 cm;

- below a line with a slope of 10° from the horizon of the ridge, if the distance between the ridge and the pipe is more than 300 cm;

- above the level of buildings attached to the building.

- If the roofing material is not resistant to fire, regulations require the installation of a spark arrestor.

- The minimum distance between a single-wall stainless steel pipe and the floor and roof structures is 1 meter; (for a sandwich - 20 cm), the pipe must be insulated with non-flammable material (basalt wool).

- A gap of 13 cm is required between the pipe and the roof (including those made of non-combustible materials).

- Pipe connection points should not be located inside structures (ceilings, walls). The minimum distance from the joint to the structure is 70 cm.

- Horizontal and inclined sections of the chimney duct must be assembled “according to the smoke” - the next element is put on the previous one so that combustion products are removed as efficiently as possible. The vertical channel is mounted “along the condensate” - so that the moisture flows freely, the subsequent element is inserted into the one located below.

- Throughout the entire length of the chimney duct, its internal diameter must be no less than the diameter of the outlet pipe of the heating unit.

- No more than three turns are allowed along the entire length of the chimney.

Chimney installation diagram

There are various installation schemes for stainless steel chimneys. In the case of using a sandwich system, it is easier to bring the pipe outside so as not to punch holes in the ceilings and roof. The pipe is secured to the external wall using special brackets. The external chimney can also be mounted inside a metal profile frame to prevent accidental mechanical damage, especially in the case of high wind loads.

Features of stainless steel connecting fittings

Steel fittings are structurally little different from analogues made from other materials. Conventionally, we can distinguish within any shaped element a body corresponding to the function it performs, and pipes with fasteners.

The popularity of stainless steel connecting fittings is due to a set of positive qualities characteristic of steel, as well as a large selection of connecting parts.

Advantages and disadvantages

Stainless steel reinforcement has many advantages over analogues made from other metal alloys and polymers:

- high mechanical strength,

- resistance to high temperatures,

- environmental friendliness,

- almost zero chemical activity,

- corrosion resistance,

- compatibility with most materials,

- non-flammability,

- variability in the design of the body and fasteners,

- ease of use.

Note! Stainless steel fittings, unlike their black steel counterparts, can even be used to connect copper pipes.

The service life of stainless steel products deserves special attention - 20-30 years, and some manufacturers provide a guarantee of even 40. When compared with analogues made of black steel, which last only 10 years, this is an undoubted advantage. But in comparison with plastic and cast iron counterparts, which have a service life of half a century, stainless steel definitely loses.

There are few disadvantages to shaped stainless steel elements:

- inability to form a tight connection without additional sealing agents;

- possible loosening or, conversely, sticking of dismountable joints, which is why the units require regular maintenance;

- large, especially compared to plastic analogues, weight;

- high price.

We recommend that you read:

Types of fittings

Stainless steel shaped elements are very diverse in terms of body type and tasks performed, fitting manufacturing method, and fastening options.

Note! The shape of the body and the functions of the connecting fittings are interrelated, that is, fittings designed to perform different tasks have different structures.

According to these characteristics, they are divided into the following types:

- Straight ones, called couplings and bends. They are used to connect identical pipes located on the same line. The coupling has a short body sufficient to connect elements of the pipe network, the pipes of which are located nearby. A bend - an elongated coupling or a section of pipe with fasteners at the ends - is needed to compensate for the distance between the connected elements.

- Transitional, these include gearboxes and fittings. The purpose of these fittings is to connect two pipes whose characteristics differ. The reducer allows you to organize a transition between pipes with different sections or different fasteners; accordingly, the pipes of such an adapter differ either in diameter or in the method of fixation. A fitting is an additional part that is used to form an assembly of pipes made of different materials. One of the fitting pipes is elongated and can be smooth, ribbed or notched - it is inserted into a polymer or metal-plastic pipe. The second pipe allows you to connect the resulting structure to another pipe, usually metal, using a coupling.

- Angular, called bends or corners. The body of such a fitting is curved, the bending angle varies from 90 to 165 degrees, and the radius of rotation depends on the diameter of the pipes.

- Branching - tees and crosses. The tee body is a coupling with a side branch, which can be located at an angle from 15 to 90 degrees to the axis. The crosspiece differs from the tee in the large number of additional pipes and in the fact that they are always located only at right angles to the main axis. Branch fitting pipes can be the same or different sizes. Such shaped elements are used to connect or cut the flow of the working medium in the pipeline.

- Sealing, called plugs. Plugs are necessary to shut off pipeline pipes that are temporarily not in use.

Classification by manufacturing method and fixation method

Fitting bodies can be one piece with mounting pipes; such products are considered the most reliable due to the simplicity of the design and the absence of additional connections.

There are also dismountable shaped fittings, in which not only the fastening elements, but also parts of the body can be detached.

Note! Collapsible fittings are much more expensive than solid fittings, but they are easier to install and are indispensable when carrying out work in hard-to-reach places.

According to the method of manufacturing the body, stainless steel fittings are also divided into:

- seamless - cast entirely, due to which it has no weak points, but also costs more;

- welded - individual parts of the body are cast, which are then connected by welding; the strength and durability of such a fitting depends on the quality of the seam, since it is this that experiences the greatest loads during operation of the unit.

We recommend that you read: Design and scope of flanged ball valves

According to the fixation method, they are distinguished:

- Threaded. The cheapest and simplest connecting fittings have external or internal threads on the pipes. To connect a pipe and a fitting, it is enough to twist them together using an adjustable wrench, having previously wound tow or FUM tape onto the external thread of one of the connected elements. The result is a dismountable unit that is easy to dismantle, and the fitting can be reused.

- Flanged. The connecting pipes of the fittings are equipped with flanges - transverse platforms with holes. To connect pipeline parts, their flanges are combined, having previously laid a sealing ring gasket between the platforms, and then tightened with bolts. A collapsible unit is formed, which, due to its massiveness and large size, is usually used on large domestic and industrial pipelines.

- Crimping. The connecting pipes of such fittings are threaded and a crimp nut is included. The nut is put on the pipe, then the threaded part of the fitting is inserted into the end of the pipe, after which the compression nut is tightened, rotating it along the resulting structure towards the body. The resulting connection is conditionally permanent, although the fitting can be reused after dismantling.

- Press fittings. The design of such shaped fittings is similar to crimp fittings, but instead of threaded pipes, the fitting body is equipped with smooth or ribbed fittings, and the fixing element is a press ring. The mechanism for making the assembly is also similar to crimping, but crimping the ring requires special press pliers. After fixing, a reliable one-piece unit is obtained.

- Welded. A distinctive feature of welded fittings is the absence of a fastening element on the body. The fitting and pipe are paired using welding equipment - the ends of the products are heated and fused together. The resulting assembly is reliable and sealed, but it can only be completed by connecting identical materials, so welded fittings are only suitable for stainless steel pipes.

- Combined. Such fittings are reducers - adapters between pipes that differ in the method of fastening. Most often, combined couplings are those that have different fasteners on different pipes.

Threaded and flanged fittings also differ in flow capacity. Threaded fittings are produced with a diameter of up to 16.3 cm, since with a larger cross-section, vibration of the working medium gradually unwinds the thread, making the assembly leaky.

Flange fittings are produced with a diameter of 5 cm, since small flanges are difficult to install.

Crimp and press fittings are suitable for connection only with elastic pipes, which, after deformation, tend to restore their original shape and fill the gaps between the fitting parts, making the assembly airtight. On rigid pipes, when using crimp or crimp fittings, cracks and chips form.

We recommend that you read: How does a heating air valve work and how to choose it?

Step-by-step assembly of a chimney in a house

The correct operation of the boiler largely depends on the quality installation of the chimney.

Assembly algorithm:

- A tee with a condensate collector and an inspection is connected to the nozzle of the heating unit.

- Holes are cut: round or square in the attic floor, oval or rectangular in the roof.

- The pipe is increased to the required height. At the ceiling level, a ceiling-passage device is put on it, which is fixed in the ceiling and filled with thermal insulation. In an opening cut into the roof, the chimney must also be insulated.

- After passing the hole in the roof, a special “skirt” is put on the pipe, which is needed to protect it from leakage. The base of the “skirt” is fixed to the roof. The top of the pipe is equipped with a deflector to protect it from rain, wind and clogging. If the roof is made of flammable materials, an additional spark arrestor is installed.

- The joints are tightened with clamps and treated with sealant; if necessary, the structure is strengthened by securing it with brackets inside the attic.

Outdoor installation

- Mark the location of the chimney in the wall and cut a hole taking into account the thermal insulation.

- Connect the passage pipe to the pipe of the heating device and lead the chimney to the street. Isolate the passage of the wall.

- Attach a tee with a dropper and an inspection to the removed pipe.

- Raise the chimney up to the required height; if necessary, fix the structure with a bracket every two meters. The joints are tightened with clamps and covered with sealant. A conical nozzle - a deflector - is attached to the top of the pipe.

- Cover the chimney with a protective compound to prevent rust from forming.

- If the structure is made of single-layer pipes, insulate along the entire length.

Expert advice

The service life and quality of the installed water supply depends on many things, so you need to carefully select the appropriate products.

What to consider:

- inspect the purchased product: it should not have cracks, kinks or other visual damage;

- the product should bend easily, while maintaining its strength - this allows installation in cramped conditions;

- You shouldn’t save money and buy cheap products - it’s better to choose a reputable manufacturer; a high-quality stainless pipe can have a price from 1 to 3 thousand rubles, which depends on the type of product and type of steel;

- During installation, follow the instructions;

- Having installed the system, be sure to check its integrity, for which you will need to set the maximum permissible pressure level;

- make sure that the fittings are complete;

- if you need to combine corrugated stainless steel with a pipe made of another material, use fittings made of brass;

- if you want the system to last longer, do not install cheap, low-quality fittings;

- when tightening plastic elements, you do not need to overdo it, otherwise they will simply burst;

- Prepare the necessary tools in advance: open-end wrenches, metal scissors, fittings.

Corrugated pipes are durable and reliable products, the demand for which is gradually growing. They are popular in the fields of construction and repair: they are used to assemble gas and water pipes, lay heating systems and even chimney structures. In addition, they are quite easy to install. The only condition for the long service life of the assembled system is that the materials must be of high quality, so approach your purchase wisely.