Home / Welding technique

Back

Reading time: 4 min

0

1883

The most common type of resistance welding is spot welding (SW).

With its help, sheet metal of small thicknesses is quickly and efficiently joined.

In this article we will describe what TS is, the methods and shortcomings of such work if performed incorrectly.

- Introduction

- Advantages and disadvantages

- TC process Preparatory stage

- Welding units

Description of spot welding technology

The technique for joining parts varies depending on the type of metal and the thickness of the workpieces, but the general procedure for performing the work is the same.

Main stages of the welding process:

- Preparatory activities. The surfaces of the connected structural elements are cleaned of paint and varnish coatings that do not allow current to pass through.

- Compressing parts. The surfaces of the workpieces to be connected are taken with pliers to form areas for current conduction directly between the contacts.

- Warming up of workpieces with an electrical impulse (constant or variable). Thicker elements take longer to heat up.

- Relieving pressure on the parts to be joined (for automatic welding units). This procedure prevents the molten material from being squeezed out.

- Switching off the current when the material reddens in the area where the electrodes are placed.

- The final stage is forging (pressing) the parts during the cooling period of the material. This procedure is performed to create a strong seam.

Equipment settings are carried out depending on the type of metal. The quality of the connection of parts depends on the welding technology used, the impulse and compression modes of the structural elements.

Technological features

The technology is quite simple to understand. When welding, it is necessary to connect parts that will later be welded using reliable mechanisms that are resistant to electric current. Proper fastening is very important so that the elements do not move out.

Next, current is supplied to the workpiece from both sides using electrodes. In places where contact occurs, a high temperature is formed at which the metal melts. With good spot welding, a core is formed, which can be from a few millimeters to a couple of centimeters, depending on the thickness of the material itself.

Low quality metal can be joined without forming a weld core, but such a weld is considered poor quality and may subsequently come apart. Low-quality steel, which is used for welding work, allows the novice master to get a good hand. After literally a couple of dozen seams, the master can get a good grip and perform further high-precision welding work.

Designations according to GOST on the drawings

The procedure for performing work is established by technical documentation. Contact spot welding in the drawings has its own symbols with a letter code. On the front side, the contours of the soldering area are drawn, crosses indicate the points to which arrows are drawn with a description, for example GOST 15878-79-Kt-5. In cross-section, connections look like shaded planes.

Designation of contact seams according to GOST on the drawings.

Process phases

To understand how spot welding works, it is worth considering the main phases of the process, and there are three in total. Each has characteristic features that influence the final results. In the first phase, the metal components are compressed. This causes the appearance of plastic deformation in the contact area. For these purposes, the welding equipment is supplemented with special pliers.

During the second phase, current is supplied to the contact zone. This causes the metal to melt at the welding point and form a molten core. While the current is passing, expansion of the core to maximum values is observed. Compression of the welded components causes the formation of a belt with a dense structure around the liquid core, which prevents the molten metal from leaving the welding zone.

During the third phase, the welding current is turned off, and the metal cools and crystallizes at this time. During cooling, the pressing state of the elements is maintained for a certain period, this relieves stress.

It is worth noting! All important requirements and rules for carrying out work are specified in GOSTs and documentation. A detailed spot welding diagram with indicators will help you understand how the welding process should be carried out correctly.

Scope of application and how it works

The main differences of resistance spot welding:

- short-term impact on the elements being connected;

- small area of material melting;

- voltage – 1-3 V;

- current – from 2000 A;

- force at the connection point is 10-100 kg.

Due to these features, this type of welding is used for soldering metal products whose thickness does not exceed 3 cm.

Application area:

- production of radio-electronic equipment;

- production of automobiles and aircraft;

- construction industry, etc.

Spot welding has become widespread in industry.

Transformers for spot welding are used in auto repair shops (removing dents). This technology is also used for soldering lithium laptop batteries.

Buy or make it yourself

Homemade spot welding for welding cars and other products can significantly save money on the purchase of equipment. Professional devices are quite expensive, for this reason they are mainly used in industries where the amount of work more than covers the cost of purchasing welding equipment.

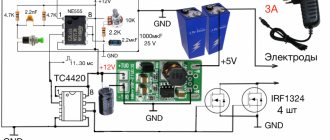

But how can you make spot welding yourself? Of course, this may require certain knowledge and experience. Additionally, you can study special literature and instructions on the process of constructing a home welding machine. To facilitate the process, a special do-it-yourself spot welding scheme can be used.

Homemade spot welding can be used for body work, for jewelry making, for the manufacture and repair of various radio devices. The equipment is always useful for work in the garage. There will be no particular difficulties when working with it, and if you follow all the rules of the technology, you will be able to obtain strong and high-quality welds.

Spot welding technology is a universal method of joining metal structures that can be used in production and at home. But still, in order to get a durable and high-quality seam, you need to know the important nuances, rules and principles of work. Do not forget about possible defects that can negatively affect the structure of the connection of products.

Types of contact welding in general

Contact connections are divided into 4 groups:

- point;

- butt;

- suture;

- embossed.

Each type of welding has its own characteristics and scope.

Point method

The parts are connected by points in one or more places. Under the influence of pulsed current and pressure from the electrodes, the surfaces of materials are heated, melting and joining the metal.

We recommend reading Homemade spot welding machine

Spot welding is the most common type of resistance welding.

Relief welding

This soldering option is similar to the previous one. In this case, convex places for connection are pre-prepared. And the shape of the point depends not on the electrode, but on the convexity itself.

Relief welding is used in the production of electrical equipment and automotive equipment.

Creating a seam

Seam joints are obtained by applying two or more points simultaneously in a row. If they are applied overlapping, sealed seams are obtained. Welding is performed using one or more machines.

Seam joints are created by applying a series of points.

This soldering technique allows you to obtain high-quality seams when connecting products up to 3 mm thick. It is used for the production of steel and aluminum containers (canisters, barrels, etc.).

Butt joint

Contact butt welding is carried out over the entire area of the components being connected.

Work is performed in one of 3 ways:

- resistance;

- continuous melting of the soldering area;

- reflow with parallel heating of the connection area.

The first method is used for welding elements of small cross-section - up to 2 cm², pipes made of metals with a low percentage of carbon content.

The reflow technique is used for parts with a cross-sectional area of up to 10 thousand cm².

Content

- Definitions and diagrams of spot and seam welding

- Spot resistance welding

- Seam (roller) resistance welding

- Plastic deformation in the welding zone

- Technological capabilities of spot and seam welding

- Spot and seam resistance welding technology

- Requirements for welded structures

- Preparation for welding

- Preparing the surfaces of parts

- Assembling parts for welding

- Tack parts

- Classification of welding machines

- Electrodes of welding machines

- Mechanization and automation of seam and spot welding

Spot and seam (roller) resistance welding are the most popular and common methods of resistance welding. Approximately 90% of all welded joints created using resistance welding are spot and seam (roller) welding, because in these methods of joining parts, the advantages of resistance welding given on this page are most fully manifested. Next, we will consider the essence, technology of each of these types of welding and the equipment necessary for this.

What are the pros and cons of

Due to the high productivity and ease of operation of the equipment, spot welding technology has become widely used.

Spot welding allows you to quickly and efficiently join thin metals.

Advantages:

- with low electrical energy consumption, the unit provides more than 100 solderings per minute;

- automation of the work process is possible;

- there is no need to use fluxes, additives and wire;

- strong connections are obtained without residual deformations.

Disadvantage: leaky seams. The unit operates intermittently, materials are welded at several separate points.

Tips and tricks

The transformer for this type of welding has some differences from the others. In this case, spot heating of the metal surface is carried out, which is provided by special pliers in which electrodes are installed.

When making this type of connection, the dimensions of the metal sheets do not play a role; in addition, work can be carried out, including with stainless steel. When choosing a device for home use, the main factor should not be its price.

It is recommended, first of all, to pay attention to the functionality of the device, as well as the strength characteristics of the connection.

The productivity of the unit and the presence of automation of the process itself also matter.

All devices of this type are distinguished by the availability of the necessary work, even in the absence of appropriate qualifications, which makes them affordable and popular among home craftsmen.

You can assemble such a device yourself.

In this case, you will need an appropriate transformer that can provide the necessary electrical impulse, as well as the material from which the pliers are made.

All the necessary elements should be assembled according to a certain principle and scheme, and if all the work is done not only correctly, but also in accordance with the technology, then it will be possible to obtain a device that will provide a strong connection between a variety of metals.

How to independently assemble a spot welding machine at home is described in detail in the video below.

Video:

Required equipment and electrodes

Spot welding units are divided into 2 groups:

- stationary;

- portable.

Portable units are small in size and light in weight. They are more often used for the construction of large-sized metal structures and body repairs. Using this welding, parts up to 5 mm thick can be joined.

Stationary equipment is used in manufacturing plants to produce metal products that a craftsman can hold in his hands. During mass production, they quickly create similar connections. Such installations are quite heavy and take up a lot of space, but the presence of a powerful power source allows you to solder workpieces up to 8 mm thick.

Welding work always begins with preparing the equipment.

Characteristics of the electrodes used for spot welded joints:

- increased temperature resistance – more than 600º;

- high density of the material, allowing it to retain its shape under compressions of up to 6 kg/mm²;

- increased electrical and thermal conductivity without loss of pulse current.

Flat electrodes are used for one- and two-sided welding. In other cases, barrel-shaped elements are used.

Equipment for spot and seam contact welding

Modern equipment for spot and seam resistance welding is a set of elements for solving technological problems. The equipment includes the welding machine itself, means of mechanization and automation of welding processes and a control system for all these devices.

The diagram of the spot welding machine is shown in the figure above. The machine consists of two main parts. The first is mechanical with structural elements that provide rigidity and strength of the machine (body, bracket, etc.) and drives for transmitting force and moving parts. The second part is electrical, which includes a welding current source (welding transformer, rectifier, accumulators - capacitor banks, inverters - frequency converters, etc.) and a secondary circuit with current leads - consoles, electrical holders and electrodes.

Means of mechanization and automation are adaptations to universal machines or devices that ensure the preparation of a product for welding, assembly, tacking, installation, movement and removal of the unit.

A control system is necessary to set the work program (welding modes, sequence of operations, control and automatic adjustment of technological cycle parameters, collection and processing of information about the condition of equipment and product quality).

Classification of welding machines

Welding machines for resistance roller and seam welding are produced in different countries, but they can all be classified according to various criteria:

1. According to the welding method. There are machines for spot, relief and seam welding.

2. As intended. There are universal machines (general purpose) and specialized ones (usually by type of unit or assortment).

3. According to the installation method. There are stationary and mobile machines.

4. By type of food. There are AC machines, low-frequency and DC machines, and capacitor machines.

5. By type of force drive. Machines can be lever, spring, pneumatic, hydraulic, electromechanical, etc.

6. According to the degree of automation. The machines are non-automatic, semi-automatic and automatic.

Electrodes of welding machines

Electrodes of welding machines are a very important element, because the performance of turned and, especially, resistance seam welding depends on their durability. The basic requirements for electrode materials are set out in GOST 14111. For welding aluminum alloys and similar materials, these are, first of all, thermal and electrical conductivity. The requirements also include resistance to plastic deformation at temperatures of 300-500°C (for welding heat-resistant steels).

For the manufacture of electrodes, materials such as copper alloys are used. Pure refractory metals - molybdenum and tungsten - are used as electrode inserts. A separate group is represented by materials strengthened by particles of oxides (Al2O3, CrO3), carbides and nitrides, which have high heat resistance and electrical conductivity.

For welding copper alloys and aluminum alloys, electrode materials with high electrical conductivity are used, and for welding heat-resistant alloys - with high hardness at high temperatures (about 500°C).

Mechanization and automation of seam and spot contact welding

Welding machines for spot and seam contact welding provide almost complete automation of the process. To reduce the duration of auxiliary operations and increase the productivity of the entire process, various mechanized devices, automatic machines, automatic lines and industrial robots are used.

Assembly and welding devices include jigs, stocks, assembly stands, on which the assembly, tacking and welding of products is carried out. In practice, supporting (leveling) devices are also widely used, with the help of which you can orient the welded unit relative to the electrodes or rollers of the welding machine. An approximate diagram of such a device is shown in the figure.

Automatic lines are in demand in the automotive industry, in the production of agricultural machinery, in carriage building, in electronics, in the production of pipe blanks and in other areas of mass production.

Safety precautions during work

When operating point-type units, you must follow the safety rules:

- there should be no damage to the insulation of electrical cables or exposed contacts;

- the unit must be grounded;

- when connecting equipment to the electrical network, the contacts must correspond to the nominal values;

- it is necessary to use automatic machines;

- setup and maintenance of the device during operation is carried out only after disconnecting from the power supply.

We recommend reading: How to make a welding machine from a microwave

Carrying out welding work is associated with increased danger for the welder.

The welder must wear thick overalls, a special mask or goggles, and dielectric gloves. At the same time, the handle of the pliers is reliably isolated. When working indoors, you need to wear a respirator and an exhaust hood.

Types of devices used

When resistance spot welding, the unit is capable of delivering different currents.

Based on these characteristics, equipment is divided into categories:

- with direct and alternating current;

- low frequency;

- capacitor.

To weld steel mesh, enterprises use multi-point units, which allow connections to be made simultaneously in several places.

But the most popular are single-point models that use alternating current.

Types and types of devices

There are several methods by which this type of welded joint can be made, namely soft and hard. Based on this, devices that comply with GOST are selected.

Currently, specialized stores offer a large selection of appropriate devices for this type of welding, each of which has its own price.

The price of a welding machine depends, among other things, on what kind of transformer is installed. In most cases, enterprises have a machine for this type of welding, the price of which is quite high.

This machine allows you to perform a large volume of work with a wide variety of metals. Also, the machine for this type of welding has great functionality and high work potential.

IMPORTANT TO KNOW: All about resistance welding - technology and devices

In addition, large enterprises use laser welding, the price of which is also at a high level.

For domestic purposes, more compact devices are used, which include a transformer of a certain power and, accordingly, pliers.

The price of such mini devices is determined based on its functionality and manufacturer's brand. Both the machine and the compact welding machine provide spot connections of copper, steel, stainless steel, and many other metals.

The most popular car is a spotter, the price of which is quite affordable. In such units there are no special pliers, and the current is transmitted through a terminal connected directly to the part and the electrode.

Video:

The spotter has compact dimensions, despite the fact that the clamping force is transferred to the workpieces manually. Its main advantage is its low price with the ability to connect steel, copper, and stainless steel.

The spotter's operation scheme is quite primitive, while the quality of work fully complies with GOST. This device has a fairly powerful transformer installed, which provides the necessary voltage.

The video posted above shows a diagram of how a hand-held spotter works. When purchasing a hand-held device, you should keep in mind that the price is determined based on several conditions, including what kind of transformer is installed.

More professional equipment, such as laser welding or a special machine, is usually not used at home, since its price is quite high.

What characteristics should you use to choose a device?

When choosing equipment, you need to take into account the following parameters: operating modes of the device, power, material thickness, electricity consumption.

Operating modes of the device

Depending on the properties of the current, the operating mode of the unit can be hard or soft.

In the first case, high-density current is used, the welding cycle is less than 1.5 s. In this mode, productivity increases, but the parts to be joined must be strongly compressed. For work, electrodes are used whose diameter exceeds the total cross-section of the elements being soldered several times.

Welding can be performed in hard or soft mode.

In the second case, a current of lower density is used, the welding cycle is increased to 5 s. This allows you to reduce the pressure of the pliers on the workpieces and work with electrodes whose diameter is equal to the thickness of the parts.

Voltage power

The welding machine can be connected to a single-phase line of 220 V and a three-phase line of 380 V. Power consumption, depending on the model, can range from 3 to 12 kW. It is not recommended to connect equipment operating with a power higher than 5 kW to a standard electrical network, because The wiring may melt.

Thickness of welded sheets

This parameter determines the maximum cross-section of parts that can be welded by the unit. When soldering thicker workpieces, poor-quality seams are obtained.

The parameter designation can be common or separate. For example, in the first case – “5 mm”, in the second – “2.5+2.5 mm”, but the meaning of these parameters is the same.

Industrial models capable of welding 3 steel sheets simultaneously are designated “3+3+3 mm”.

Economical consumption

Cheap units are designed for manual control. Some models only work at maximum current, because... its adjustment is not provided. The welder independently squeezes the pliers and monitors the period of contact of the electrodes until the desired penetration is achieved.

The power of the welding machine is one of the main characteristics.

To ensure a high-quality seam, the transformer is first tested on rough blanks of the same cross-section as the main elements. This is done to determine the pressing time. After this, you can proceed to finishing work.

Models are available in which the current strength is regulated - synergetic (microprocessor) control. This greatly simplifies welding work. The operator indicates on the instrument panel the type of connection and the thickness of the workpieces. The control mechanism independently selects the optimal parameters for operation and turns on/off the current supply. The master’s task is only to bring the electrodes to the junction of the parts. But this is expensive equipment.

We recommend reading: How to make spot welding for a 18650 battery

What defects are possible during spot welding?

In production and domestic conditions, multi-point technology for welding steel products is in demand. It is used to connect thin parts. The seams are of high quality and durable.

But defects cannot be excluded:

- Burnout. In products, during the process of overheating of the material and drainage of steel, holes are formed and the fused edges are easily torn off. This occurs with high current, excessive compression force, or a prolonged pulse. To prevent burns, it is recommended to reduce the pliers pressure and current.

- Drip of molten metal. Molten material is able to escape from the core due to prolonged application of a weak pulse or strong squeezing of the tongs. When performing welding work, steel splashes out from points in the form of sparks. And with such a prolonged factor, the strength of the connection is significantly reduced.

- Lack of penetration. The reason that the core heats up weakly may be insufficient compression force and weak impulse. Lack of penetration occurs at close welding points, because the adjacent point is a shunt that passes some of the energy through itself.

Lack of penetration is a defect that occurs in the form of non-fusion of parts.

Also, due to a short pulse or a tight fit of the parts being connected, insufficient melt area may be obtained. In such cases, several microalloys are formed at one weld point, which together produce a weaker connection than a solid point.

Error correction

Spot non-contact or resistance welding is carried out according to the developed technology. But this technique has difficulties that can cause various defects. But rather complex diagnostics do not provide an accurate picture of the type and quality of the seam.

To eliminate defects, it is recommended to perform the following actions:

- drill the connection, repeat soldering using a semi-automatic device;

- weld the spot seam again;

- clean up external spills of material;

- install a blind or welded rivet;

- forging the heated point.

To avoid having to correct shortcomings, it is recommended to practice on rough blanks before performing work.

Common Defects

As with any work, various spot welding defects may occur. In order to prevent various defects from arising, you need to know them and pay additional attention to the place where they may appear. The most common defects include:

- Lack of penetration of the surface partially or completely. Most often, failure to cook occurs due to low-quality electrodes, low current, or excessive compression. Most often, the defect is visible during inspection; with the help of special instruments you can understand how poor the quality of the seam is. Also, using the device, you can determine the presence of unwelded areas even in a visually normal seam.

- Cracks. These are quite common defects that appear due to the use of high current or uncleaned parts.

- Tears at the edges. This defect is not very common, but can also occur. When calculating where the welding point will be, it is necessary to take into account the distance that will be enough to create a high-quality seam. For materials of different thicknesses this distance will be different.

- Internal splash. Such a defect cannot always be noticed immediately after cooking is completed. The defect is formed due to the fact that the liquid material leaves the core during cooking, causing a gap to appear between the parts. The main reason why such a defect occurs is the application of a long pulse at a high current, which leads to excessive melting of the core. If this is due to the fact that the device is completely new, then it is worth trying to make several points on a different material to adjust the tool.

- External splashes. A fairly obvious defect that appears due to poor clamping of metal parts. Due to the lack of forging torque, there is no possibility to connect the workpieces and the molten mass appears on the outside of the metal element.

- Dents appear. Excessive compression of the workpiece or the use of small-diameter electrodes leads to the appearance of dents. Also, due to these factors, the melting zone may increase, which leads to the occurrence of defects in the finished seam.

- Burn. This is the most common defect. There may be several reasons for the appearance of this defect, but most often the burn appears due to contaminated surfaces of the parts being welded or the tip of the conductor.

Homemade or factory device

A do-it-yourself spot welding machine allows you to save on body repairs and soldering of metal structures. Professional equipment is quite expensive. It pays off only when performing large volumes of work, i.e. in production.

But to build the device with your own hands, you need to know its design and assembly sequence. To do this, you will first have to study the technical documentation, diagrams and assembly instructions.

A homemade unit for welding steel parts is an indispensable tool in the garage. With its help, if necessary, you can weld your own car, assemble metal structures (for example, shelving), repair radio equipment, etc.

For frequent work, it is recommended to purchase factory-made devices with current regulation for connecting parts of different thicknesses and from different metal alloys.

Definitions, features and diagrams of spot and seam welding

Spot resistance welding

Spot welding is a type of contact welding in which welding of parts occurs in separate areas of contact at several points with a certain step.

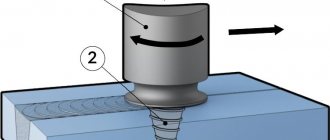

Figure a) on the left shows a spot welding diagram. The parts to be welded (item 1) are overlapped and placed between the electrodes (item 2) of the welding machine. One of the electrodes begins to move and acts on the part with a force Fst. After some time necessary to ensure reliable electrical contact, an electric current of 5-6 V is supplied to the electrodes from the secondary winding of the welding transformer (item 3) or rectifier. A short-term powerful pulse of welding current, lasting 0.01-0.1 s, provides very fast, almost instantaneous heating and the formation of a melting zone - a liquid core (item 4), common to both parts.

Heating is accompanied by plastic deformation of the metal during welding and a sealing belt is formed around the liquid core (item 5), which protects the liquid metal from splashing and interaction with the environment. Therefore, a special layer of protection, for example, as when welding in a carbon dioxide environment or in an argon environment, is not required.

After the current supply is stopped, the liquid metal quickly cools and crystallizes, and a strong metallic bond is formed between the parts. The force from the electrodes is not removed immediately, but after some time, which ensures crystallization under pressure - forging and the absence of defects in the weld (hot and cold cracks, shrinkage cavities, residual stresses). In some cases, the impact force at this stage of the process is increased by 2-3 times, i.e., in fact, forging force is used.

To increase welding productivity, a protrusion is preliminarily formed on one of the parts (item 6 in diagram b). The shape of the protrusion is semicircular or trapezoidal. This method is called spot relief welding. The protrusion limits the initial contact area, making it possible to increase the current density in the part-to-part contact area, using electrodes with a large surface area. As a result of heating, the protrusion is gradually deformed and at the end of the process a core is obtained, as in conventional spot welding. You can weld simultaneously on several protrusions.

If access of the electrodes to one of the parts is difficult, then it is advisable to use one-sided spot welding. Its diagram is shown in diagram c) of the figure on the left. In this case, the parts assembled for welding are installed on a copper lining (item 7) and the parts are pressed against it by two electrodes located on the side of one of the parts.

Seam (roller) resistance welding

Seam welding is a contact welding method in which current is supplied and parts are moved using rotating disk electrodes-rollers (item 8 in diagram d); the name roller welding is also common. As with spot welding, the metal is heated using short-term pulses of electric current, repeated at regular intervals. As a result, a series of points is formed. If the gap between pulses is small enough, the points overlap, forming a sealed weld.

There are continuous and step resistance welding. During continuous welding, the rollers rotate without stopping, and during step welding, the rollers stop at the moment the current pulse passes and the joint is forged, which reduces wear of the rollers, residual stresses and deformation during welding and reduces the tendency to form defects in the weld, especially hot cracks and shells.

In most cases, seam welding parts are assembled overlapping, but butt welding is also used, which provides greater strength to the welded joints (diagram e). For such welding, foil pads (item 9) are often used to obtain complete penetration of the parts being welded.

Plastic deformation in the welding zone

Plastic deformation of the metal being welded is one of the features of all types of resistance welding. At the first stage, mainly deformation of microroughness occurs, the degree of which in the contact of parts reaches up to 70%. This deformation is alleviated if increased crimping forces or additional electrical impulses are used at this stage to form good electrical contact. When current is applied, the metal rapidly heats up, its resistance to plastic deformation decreases, and the rate of microplastic deformation increases and by the time the metal begins to melt, the degree of its deformation approaches 100%.

From the moment of heating, volumetric plastic deformation of the metal begins to develop. The reason for its occurrence is external (welding) force and internally, associated with an uneven temperature field and unfree thermal expansion of the metal. These forces cause uneven volumetric compression of the metal in the welding zone.

At the stage of cooling and crystallization, a reduction in the volume of the metal occurs and residual tensile stresses are formed in the welding zone, which can lead to the formation of cold cracks in the metal and reduce the performance characteristics of the structure.

The peculiarity of metal deformation during cooling is that the volume of the metal contracts most quickly near the axis, as a result of which the pressure in the center decreases and the possibility of reverse deformation arises - from the edge of the joint to its center. Reverse deformation helps reduce stress and the tendency to form discontinuities, especially when increased forging forces are applied at this stage.

At the end of the welding process, dents remain on the surface of the seam, with a depth of 10-15% of the thickness of the metal being welded.

It is believed that one of the conditions for a stable welding process (no metal splash) is a certain degree of plastic deformation. The degree of this deformation increases with the use of increased welding forces, the use of soft modes, preheating of parts and other technological methods.

The most severe degree of deformation appears during projection welding immediately after turning on the current. In some cases, the flow of metal along the surface of the parts can ensure their strong connection without melting in the annular zone along the periphery of the contact (see diagram b in the figure above).

Plastic deformation during resistance welding does not remove oxide films from metal surfaces. Only at the initial stage does microplastic deformation contribute to the destruction of these films. The final removal of their parts occurs in the molten metal under the influence of electrodynamic forces.

Technological capabilities of spot and seam resistance welding

Spot and seam (roller) types of resistance welding have wide technological capabilities, as they allow connecting almost all structural materials with a wide range of thicknesses.

In practice, resistance welding of copper and copper alloys, titanium and magnesium welding, aluminum welding, welding of nickel and nickel alloys, and alloy steels are widely used. Some difficulties arise when welding refractory metals, for example, molybdenum, and they are associated with the low resistance of the electrodes due to the high temperature on their working surface.

In addition, it is possible to weld metals with anti-corrosion coating - galvanized, aluminized and nickel-plated steels and even metals with non-metallic insulating coatings, as well as composite materials. But, when connecting all of the listed dissimilar materials, it should be borne in mind that spot welding is allowed for welding only homogeneous materials or alloys on the same base, for example, welding low-carbon steel with corrosion-resistant steel. When welding dissimilar materials using this method, in particular magnesium with aluminum, a large amount of intermetallic compounds is formed in the weld, and the mechanical properties of the joint will be low.

The range of welded thicknesses is 20 µm - 30 mm for spot welding and 8-10 mm for seam welding. Most often, metals of the same thickness are welded, but it is possible to weld parts of different thicknesses, and the thickness of one of them can be 20 or more times greater than the other. Welded joints have very high strength values. At the same time, the tear strength of the points is 2-4 times less than the shear strength.