Interesting facts about stainless cookware

Already in 1913, the world learned about the unique properties of steel and its resistance to corrosion. Harry Brearley, having added 10% chromium to steel, realized that the alloy was now resistant to elevated temperatures, but society did not accept the new material, since it considered all these properties to be completely unfavorable. Brearley tried his best to convince him otherwise and released the first ever batch of chrome steel knives. The knives quickly became dull and this significantly affected the popularity of the products. Only ten years later, Brearley's successor, Hartfield, managed to correct this flaw. He discovered that by adding nickel, any mechanical stress on the material does not affect the material and thereby ensures long service life of kitchen appliances. It is interesting that the alloy developed for the manufacture of knives subsequently began to be actively used in the oil production, engineering and even military industries.

Steel and stainless steel (differences)

There are many types and grades of steel. Sometimes analog brands can have huge differences in strength, corrosion resistance and other parameters. A common service is electrochemical polishing, which gives stainless steel characteristics suitable for certain applications:

- Making tableware;

- Pipelines;

- Mechanical engineering, etc.

For example, stainless steel 316, the characteristics of which are close to AISI 304, thanks to molybdenum (an alloying additive), has received greater resistance to high temperatures, chemical influences (alkali and acid), and rust. This grade of steel performed well even with constant use in cold and salty sea water. In the post-Soviet space, an analogue is produced, marked 08Х17Н13М2.

No less interesting is stainless steel 321, the characteristics of which allow it to be used in the manufacture of pipes, fittings for furnaces and boilers, and welding equipment. The material shows high resistance to temperatures and exposure to particularly aggressive environments.

Explanation of the marking “steel 18/10”

Steel itself is an alloy. The composition necessarily includes iron (about 50%), and carbon is added to increase its strength (no more than 0.8%). On the bottom of any high-quality cookware you can find markings (several numbers). It could be 18/8, 18/10, 18/0, etc. Just two numbers carry a large block of information for the consumer. The first number indicates the percentage of chromium in the steel. The larger it is, the more reliable the protective layer of the dishes. 0, 8 and 10 are percentages of nickel. It is this that creates an attractive external shine and also performs protective functions. The 18/10 marking is considered the best, and is actively used in professional kitchens. Steel of this marking is also called food grade.

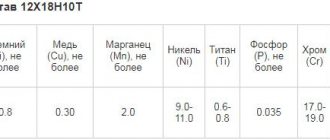

Chemical composition in % of steel 08Х18Н10

The main element in stainless steel is carbon, but in this steel its percentage is reduced. But such important alloying additives as silicon (0.8%), manganese (up to 2.0%), nickel (9.0–11.0%), titanium (up to 0.5%) and chromium ( 17–19%).

Full chemical composition 08Х18Н10

| C | Si | Mn | P | S | Cr | Mo | Ni | V | Ti | Cu | W | Fe |

| <0,08 | <0,8 | <2,0 | <0,035 | <0,02 | 17,0-19,0 | <0,3 | 9,0-11,0 | <0,2 | <0,5 | <0,3 | <0,2 | Rest |

The influence of chemical composition on the properties of steel

All characteristics 08Х18Н10

determines the chemical composition. The optimal ratio of chromium and nickel content in alloy 08Х18Н10 provides products made from it with high resistance to aggressive environments, including acidic and acidic salt environments. The introduction of other alloying elements improves the properties of steel. It is thanks to the compounds of chromium with oxygen that an oxide film is formed on the surface of the stainless alloy - reliable protection against corrosive deposits.

Carbon provides high hardness and strength.

Why is food grade steel a great choice for cooking?

- It has a smooth, shiny surface with no pores and creates an attractive appearance.

- The dishes are very durable, do not deform or scratch, so you can safely use metal spoons, forks or spatulas.

- It is hygienic because it does not form micropores and crevices in which food debris can accumulate and provoke the development of microbes.

- Durability of use is guaranteed, so with proper care and storage, such cookware will serve you for decades.

- The presence of a multi-layer bottom prevents burning and accumulates heat well, so food cooks faster.

- Such cookware easily functions on all types of stoves, even induction. And as you know, such cooking surfaces may not come into contact with every material.

- Easy to clean and even seriously sanitize. It is not for nothing that the alloy is also used in medicine.

- Food-grade steel has anti-corrosion properties, so it does not emit alkalis and acids, thereby guaranteeing the safe preparation of tasty and healthy food without impurities.

- The material is completely environmentally friendly, as it has no artificial components. It is easy to recycle and create new products. In this way, producers reduce their consumption of natural resources.

- The range of stainless steel products available today is simply huge, from pots, saucepans to knives and forks.

no one thinks that this is just one of the many advantages of such dishes.

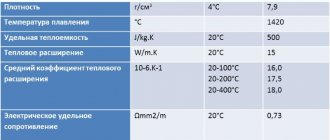

Performance properties of the alloy

Steel 08Х18Н10 belongs to high-alloy alloys of the austenitic type. The presence of chromium, nickel and titanium in the composition determines the main advantages of this brand of material: resistance to high temperatures and corrosion, strength.

Performance characteristics of steel 08Х18Н10:

- Corrosion resistance: the alloy structure is not subject to intergranular and atmospheric corrosion. The material is used in salts, alkalis, phosphoric, acetic and nitric acids. In sea water, steel retains its structure.

- Heat resistance: steel products are designed for use at temperatures up to 800°C; when operating in aggressive chemical environments, the maximum heating temperature is 600°C. However, stainless steel grade 08Х18Н10 is also effective when cooled to -196°C.

- Strength: the alloy can withstand constant mechanical loads, shocks, and vibration.

- Low-magnetic material: After heat treatment, steel is practically non-magnetic.

- Good weldability: without restrictions, used for contact and spot welding, manual and automatic, in carbon dioxide.

- Ease of processing: used for the production of rolled metal, steel parts and elements.

Given the performance properties that stainless steel 08Х18Н10 has, the price is reasonable, which explains the high demand for this alloy.

Application of high-alloy steel 08Х18Н10

Steel grade 08Х18Н10 has found application in various industries, architecture, mechanical engineering, and in the manufacture of consumer goods. The alloy serves as the basis for the production of heat-resistant and corrosion-resistant rolled metal:

- sheets;

- wires;

- pipes;

- ribbons;

- stripes

Excellent weldability and easy processing make it possible to produce steel parts of complex shapes and in various configurations. In construction, round steel pipes are used to construct balconies, load-bearing structures, railings, and staircases. The polished surface looks aesthetically pleasing, which is why designers use stainless steel parts to decorate facades and interiors.

Stainless steel is used to make tanks, reservoirs, refrigeration chambers, and racks that are used in the food industry. We also produce elements of pipeline equipment, furnace fittings, and instrument components for the chemical industry, which are designed to operate in aggressive environments, with the exception of sulfur-containing substances.

Stainless steel 08Х18Н10: buy wire and mesh

Rolled metal products made from steel 08Х18Н10 are widespread here and in other countries. TRADE HOUSE OF NETS offers meshes and wire: you can buy certified products (stainless steel 08Х18Н10 - based) on our website. The range of products is presented above on the page. Delivery throughout Russia and other countries is carried out by courier and postal services.

Interesting facts about stainless cookware

Already in 1913, the world learned about the unique properties of steel and its resistance to corrosion. Harry Brearley, having added 10% chromium to steel, realized that the alloy was now resistant to elevated temperatures, but society did not accept the new material, since it considered all these properties to be completely unfavorable. Brearley tried his best to convince him otherwise and released the first ever batch of chrome steel knives. The knives quickly became dull and this significantly affected the popularity of the products. Only ten years later, Brearley's successor, Hartfield, managed to correct this flaw. He discovered that by adding nickel, any mechanical stress on the material does not affect the material and thereby ensures long service life of kitchen appliances. It is interesting that the alloy developed for the manufacture of knives subsequently began to be actively used in the oil production, engineering and even military industries.

Hardening of austenitic chromium-nickel steels.

Carbon in the composition of austenitic chromium-nickel stainless steels without titanium and niobium additives affects the hardening temperature of the steel. When hardening, it is necessary to heat the steel above the dissolution temperature of chromium carbides; subsequent rapid cooling is intended to fix the homogeneity of the solid solution. Thus, with an increase in carbon content, a higher heating temperature for quenching is required. In general, the heating temperature range during hardening of austenitic chromium-nickel stainless steels ranges from 900 to 1100 ºС.

Long-term holding of austenitic chromium-nickel stainless steels upon reaching the hardening temperature is not required. For sheet stainless steel, the total heating time to 1000-1050 ºС and holding time is 1-3 minutes per 1 mm of sheet thickness.

But cooling should be fast. For austenitic chromium-nickel stainless steels with a carbon content of more than 0.03%, which are classified as “unstabilized,” cooling in water is used. Stainless steels with lower carbon content and small cross-sections can be cooled in air.

Explanation of the marking “steel 18/10”

Steel itself is an alloy. The composition necessarily includes iron (about 50%), and carbon is added to increase its strength (no more than 0.8%). On the bottom of any high-quality cookware you can find markings (several numbers). It could be 18/8, 18/10, 18/0, etc. Just two numbers carry a large block of information for the consumer. The first number indicates the percentage of chromium in the steel. The larger it is, the more reliable the protective layer of the dishes. 0, 8 and 10 are percentages of nickel. It is this that creates an attractive external shine and also performs protective functions. The 18/10 marking is considered the best, and is actively used in professional kitchens. Steel of this marking is also called food grade.

Resistance of stainless steel against intergranular corrosion

The ability to resist intergranular corrosion in chromium-nickel austenitic stainless steels primarily depends on the carbon content of the solid solution. Carbon promotes the release of carbide phases in the solid solution, thereby accelerating the manifestation of intergranular corrosion with increasing temperature.

Chromium-nickel austenitic stainless steels, when held in the range of 750-800 ºС, lose their ability to resist intergranular corrosion:

- with a carbon content of 0.084% - within 1 minute;

- with a carbon content of 0.054% - within 10 minutes;

- at a carbon content of 0.021 5 – after more than 100 minutes.

The nitrogen content in the composition of chromium-nickel austenitic stainless steels also affects the susceptibility to intergranular corrosion, but to a much lesser extent. the presence of nitrogen in the composition may even be useful for increasing strength.

An increase in the concentration of nickel in the composition of chromium-nickel austenitic stainless steels helps to reduce the solubility of carbon, but negatively affects the impact strength of chromium-nickel steel after tempering and promotes intergranular corrosion.

The solubility of carbon in the solid solution of chromium-nickel austenitic stainless steels also occurs with increasing chromium content. In this case, the impact toughness of the steel also decreases, but at the same time the resistance to intergranular corrosion increases.

Why is food grade steel a great choice for cooking?

- It has a smooth, shiny surface with no pores and creates an attractive appearance.

- The dishes are very durable, do not deform or scratch, so you can safely use metal spoons, forks or spatulas.

- It is hygienic because it does not form micropores and crevices in which food debris can accumulate and provoke the development of microbes.

- Durability of use is guaranteed, so with proper care and storage, such cookware will serve you for decades.

- The presence of a multi-layer bottom prevents burning and accumulates heat well, so food cooks faster.

- Such cookware easily functions on all types of stoves, even induction. And as you know, such cooking surfaces may not come into contact with every material.

- Easy to clean and even seriously sanitize. It is not for nothing that the alloy is also used in medicine.

- Food-grade steel has anti-corrosion properties, so it does not emit alkalis and acids, thereby guaranteeing the safe preparation of tasty and healthy food without impurities.

- The material is completely environmentally friendly, as it has no artificial components. It is easy to recycle and create new products. In this way, producers reduce their consumption of natural resources.

- The range of stainless steel products available today is simply huge, from pots, saucepans to knives and forks.

Types of stainless steel corrosion

Even though stainless steel is considered corrosion-resistant, this does not mean that it cannot be destroyed under certain conditions. Listed below are the main types of corrosion and the conditions under which it occurs.

Electrochemical (galvanic).

Occurs when steel and another material come into contact in an electrically conductive environment. At the same time, they form a galvanic couple in which the element with a higher electrochemical potential acts as a cathode, and with a lower one - as an anode. The latter dissolves, that is, it corrodes.

Spot (pitting).

The most common type is electrochemical. It is formed due to local destruction of the oxide layer and lack of oxygen in this place. Small in diameter but deep cavities (pittings) are formed.

Slit.

A type of electrochemical, the second most widespread. It appears if there is a small gap between elements made of steel and another material, into which an aggressive liquid, for example, with chloride ions, enters. First they accumulate and displace oxygen. An anode of steel and a cathode of another material are then formed in the slot. The passivating film is destroyed and can no longer be restored.

Intergranular (intergranular).

Occurs at high temperatures, for example during welding. The reason is that, under certain conditions, a solid becomes stratified. Along the grain boundaries, phases are formed in which there is a lot of one of the components of the material. And in areas adjacent to these borders there is little of it. Corrosion can penetrate to great depths. In an aggressive environment, either enriched or depleted areas are destroyed. This type is dangerous because the product usually retains its presentation, but, under load, unexpectedly falls apart.

Sensitization

(weld corrosion, if in the joint area, or knife corrosion, if in the form of a narrow strip). A type of intercrystalline. Crystals fall from the surface of the material. It begins due to the loss of chromium at the boundaries between grains due to intermetallic carbides. 6 carbon atoms remove 23 Cr atoms from stainless steel, as a result of which the percentage of the latter can decrease by one and a half times. In an aggressive environment, the center of the crystal is the cathode, and the boundary between the grains is the anode. Because of this, after some time, the bonds weaken and the crystals fall out.

Contact.

Occurs when stainless steel comes into contact with carbon steel. Particles of the latter remain on the surface, forming anodes, and rust.

General.

Formed when the protective layer is destroyed over the entire surface. Halogens (chlorine, fluorine, iodine, bromine) penetrate the film and cause corrosion. For this reason, cleaning stainless steel with chlorine-containing products is not recommended.

Erosive.

Appears when an abrasive liquid falls on the surface of the steel at high speed and destroys the protective layer.

When talking about stainless steel corrosion, there are two important points to note. Firstly, the smoother the surface of a material, the better it resists destruction, all other things being equal. The absence of crystal defects and internal stresses is also of great importance. Secondly, if the oxide film is damaged in some place, but the part is in favorable conditions (primarily in the presence of a sufficient amount of oxygen), then the protective layer can restore itself. This should be taken into account when using stainless steel products in an oxygen-poor environment.

How to choose such dishes correctly?

Despite all the undeniable advantages, the dishes you purchased may demonstrate the opposite. This indicates that you purchased low-quality products. But such embarrassments can be avoided by following several rules:

- You should always buy dishes in specialized stores;

- such dishes cannot be very cheap, since high quality and complex manufacturing technology require certain financial costs;

- you need to pay attention to the thickness of the walls and bottom: the former should not be less than 0.5 mm, and the bottom should not be less than 3 mm;

- the surface grinding, both inside and outside, must be flawless - without dents or roughness;

- information about the composition of the material on the bottom should also be present, this indicates that the dishes are branded.

Taking into account all this data, you can purchase good products that will provide you with healthy and nutritious food, will be easy to use and will not let you down for many years.

Today there are many companies that produce high-quality stainless cookware, so you have every chance to find the right one. There are products with different wall and bottom thicknesses, ratios of metals and additional attributes such as a lid, built-in thermometer, etc. In any case, food grade steel has deservedly gained worldwide popularity and has been actively used for almost 100 years.

Stainless steel characteristics

Does your company produce various stainless steel tools? Then you need specialized material. These can be carbon hot-rolled and cold-rolled steels, as well as their alloyed analogs with the addition of chromium, manganese, vanadium, molybdenum and tungsten. Depending on the alloying material, it is possible to achieve heat resistance at temperatures up to 700 - 800°C, as well as wear resistance.

Each brand has its own characteristics. For example, AISI 304 has special characteristics. It is capable of withstanding short-term temperature increases of up to 800 - 900 ° C, which is inaccessible to many analogues. It also does not react with liquid media, including food products (milk, sour cream, honey, etc.). This allows it to be effectively used in the food industry, medicine, and pharmacology. There is a thin oxide film on the surface of the material.