Stainless steel, or corrosion-resistant steel, is an alloy of iron and carbon. It contains chromium, from which chromium oxide is formed with the help of oxygen, and due to this, an oxide film is created on the surface, protecting the product from corrosion. In this article we will talk about the properties of this type of steel and find out whether stainless steel is magnetic.

What is anti-corrosion steel?

Steel that does not become rusty during use is popularly called stainless steel. It is obtained from an alloy of iron with carbon and various alloying additives: nickel, chromium, niobium, titanium. Each of these components enhances or reduces certain properties of the alloy - magnetism, strength, hardness, ductility, corrosion. The main quality of stainless steel is corrosion resistance. It just depends on the chromium content in it.

The more of this metal in the alloy, the less susceptible it is to corrosion. Therefore, all steels that are resistant to rust contain at least 10.5% chromium. The uniqueness of this metal is that when it reacts with oxygen, it creates an oxide film on the surface of the product, which prevents the alloy from reacting with aggressive environments. Moreover, if the surface is damaged, the film forms again after the oxidation of chromium with oxygen.

This is interesting: Types of pipeline fittings - classification, use

What affects the price of stainless steel, how to determine stainless steel

Scrap of non-ferrous, rare earth metals, battery, cable scrap.

Stainless steel or stainless steel is part of the group of alloy steels and may include impurities that are designed to improve its characteristics: hardness, resistance to aggressive environments, corrosion and high temperatures.

What can be scrapped?

Stainless steel scrap collection centers are ready to accept:

- pipes;

- sheets;

- shavings;

- dishes;

- cutlery;

- metal scraps;

- springs and other metal parts, and finished stainless steel products.

What affects the price of scrap?

The main evaluation criterion in the process of accepting stainless steel scrap is the percentage of nickel and chromium. The more nickel there is in a metal, the more expensive it is.

The price of scrap is also affected by:

- Appearance and condition of the metal. The presence of rust will reduce the initial cost of scrap. And loose rust is the first sign of low quality metal.

- Magnetic properties. Products that are not magnetic will cost more.

- Density and durability of paintwork. A strong paint layer complicates the metal cleaning procedure, therefore reducing the cost of scrap.

- Number of metal layers. Multilayer steel is less in demand, so its price will be lower.

How to quickly determine the quality of stainless steel

The cost of stainless steel directly depends on its quality. You can determine the quality of steel:

- on low-quality stainless steel, a drop of water leaves a yellowish stain;

- Salt will also help check the quality of the metal. On the surface of high-quality alloys, salt leaves no traces after drying;

- high quality metal produces a short, direct spark.

nickel in various metal objects

The percentage of nickel in stainless steel is classified:

- nickel 2-5% - may be contained in sanitary waste objects;

- nickel 10% - present in kitchen utensils;

- nickel 12% - found in plates, metal scraps, construction waste and other heat-resistant materials;

- nickel 30-85% - metal alloys (matte);

- nickel 95% - present in construction and plumbing rings, connectors, wire, powder, scrap and other high-alloy steel.

How to distinguish stainless steel from other metals

Taking into account the fact that stainless steel may or may not have this property, there is no need to focus on this indicator. Therefore, in order to distinguish stainless steel from scrap of other metals, you need to clean a small area of the surface of the object being tested until the metal shines, then use a few drops of concentrated copper sulfate applied to the scrap

Therefore, in order to distinguish stainless steel from scrap of other metals, you need to clean a small area of the surface of the object being tested until the metal shines, then use a few drops of concentrated copper sulfate applied to the scrap.

Stainless steel under the influence of vitriol will become covered with a coating of red copper. It is almost impossible to determine whether a stainless steel belongs to the food category without special devices.

How to hand over stainless steel in Moscow

The procedure for accepting stainless steel in Moscow is aimed at maintaining the interest of the donating party:

- collection points are located in different parts of the city;

- We provide pick-up service at any convenient time;

- We provide free consultations;

- We are considering the possibility of dismantling the facility ourselves.

Our scrap metal collection center tries to offer the most favorable prices for receiving stainless steel.

Use in medicine

Due to its high hygienic properties, rigidity, wear resistance and ease of cleaning from various contaminants, including bacteriological contamination, this alloy…

Architectural and construction elements

Today, stainless steel, due to its hygienic properties, high strength and corrosion resistance, is used everywhere, including in architecture...

Bar equipment

In bars, like in any dining room, there is a kitchen where you can find a lot of different stainless steel equipment. But this article will talk about equipment for...

Is stainless steel magnetic?

Among the main properties of a metal, the degree of magnetism is distinguished. Recently, there is simply a huge number of stainless steels, the performance characteristics of which can differ significantly. In many ways, the property under consideration depends on the chemical composition of the alloy. It is quite difficult to independently check the degree of magnetism, since it can vary depending on operating conditions.

Is stainless steel magnetic?

Stainless steel classification

And yet, is stainless steel magnetic or not? Depending on the composition of chemical elements and internal structure, it can be magnetic or not, and is divided into the following types:

- Ferritic - contain more than 20% chromium, are resistant to aggressive environments, are endowed with magnetic properties, are affordable, and are widely used.

- Austenitic - do not corrode, contain large amounts of nickel and chromium, are flexible and durable. Easy to weld, belong to non-magnetic alloys.

- Martensitic - anti-corrosion alloys can be exposed to high temperatures, do not emit harmful fumes, and have increased wear resistance and strength.

- Combined - special stainless steels that combine the properties of all the above groups. Produced according to individual customer requests. The greatest demand is for austenitic-martensitic and austenitic-ferritic alloys.

It should be noted that the magnetic properties of steel do not affect its corrosion properties.

How to identify a stainless steel product?

Many consumers often try to determine on their own what metal a particular household item is made of. Visually, ordinary steel cannot be distinguished from stainless steel, so it is customary to use a magnet to check. There is an opinion that real anti-corrosion steel is not magnetic. Can stainless steel be magnetic or not? Anything can happen. Therefore, this method of verification does not give a reliable result. Sometimes it happens that a product is attracted to a magnet, but serves for a long time without changing its qualities.

And vice versa, which does not react to it in any way, upon contact with water it becomes covered with rust. Corrosion resistance can be correctly determined by examining its chemical composition, which is impossible to do at home. To protect yourself from counterfeits, it is better to purchase household products in branded stores.

Magnetic or not

St. Petersburg Regions

We make most of our products from stainless steel. The second bottom of the chimney must be made of stainless steel - this part absorbs hot smoke from the chimney, so the requirements for anti-corrosion protection are increased here.

Sometimes our clients try to check the quality of stainless steel using a magnet - there is a “folk way”. But do not rush to accuse the supplier of deception if you suddenly discover the magnetic properties of “stainless steel”. In fact, more than 250 grades of steel are now produced, which have the general name “stainless”, but are very different in composition and properties and may well be magnetic.

Modern classification of stainless steel

Stainless steel is a type of alloy steel that is resistant to corrosion due to its chromium content. In the presence of oxygen, chromium oxide is formed, which creates an inert film on the surface of the steel, protecting the entire product from adverse influences.

Not every grade of stainless steel demonstrates the resistance of chromium oxide film to mechanical and chemical damage. Although the film recovers when exposed to oxygen, special grades of stainless steel have been developed for use in aggressive environments.

The first conditional type of division into groups:

- Food

- Heat resistant steel

- Acid resistant steel

The second type of classification is by microstructure:

- Austenitic

- non-magnetic steel with the main components of 15-20% chromium and 5-15% nickel which increases corrosion resistance. It is well suited to heat treatment and welding. It is the austenitic group of steels that is most widely used in industry and in the production of fasteners. - Martensitic steels

are significantly harder than austenitic steels and can be magnetic. They are hardened by quenching and tempering like simple carbon steels, and are used mainly in the manufacture of cutlery, cutting tools and general engineering. More susceptible to corrosion. - Ferritic steels

are much softer than martensitic steels due to their low carbon content. They also have magnetic properties.

Stainless steel markings

In Russia and the CIS countries, an alphanumeric system has been adopted, according to which numbers indicate the content of steel elements, and letters indicate the name of the elements. The designations common to all are the letter designations of alloying elements: H - nickel, X - chromium, K - cobalt, M - molybdenum, B - tungsten, T - titanium, D - copper, G - manganese, C - silicon.

Standard stainless steel, according to GOST 5632-72, is marked with letters and numbers (for example, 08Х18Н10Т). In the United States, there are several systems for naming metals and their alloys. This is due to the presence of several standardization organizations, these include AMS, ASME, ASTM, AWS, SAE, ACJ, ANSI, AJS. It is quite clear that such marking requires additional clarification and knowledge when trading metal, placing orders, etc.

| Europe (EN) | Germany (DIN) | USA (AISI) | Japan (JIS) | CIS (GOST) |

| 1.4021 | X20Cr13 | (420) | SUS 420 J1 | 20Х13 |

| 1.4028 | X30Cr13 | (420) | SUS 420 J2 | 30Х13 |

| 1.4031 | X39Cr13 | SUS 420 J2 | 40Х13 | |

| 1.4016 | X6Cr17 | 430 | SUS 430 | 12Х17 |

| 1.4510 | X3CrTi17 | 439 | SUS 430 LX | 08Х17Т |

| 1.4301 | X5CrNI18-10 | 304 | SUS 304 | 08Х18Н10 |

| 1.4541 | X6CrNiTi18-10 | 321 | SUS 321 | 08Х18Н10Т |

| 1.4401 | X5CrNiMo17-12-2 | 316 | SUS 316 | 08Х17Н13М2 |

| 1.4404 | X2CrNiMo17-12-2 | 316 L | SUS 316 L | 03Х17Н14М2 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316 Ti | SUS 316 Ti | 10Х17Н13М2Т |

| 1.4435 | X2CrNiMo18-14-3 | 316 L | SUS 316 L | 03Х17Н14М2 |

| 1.4878 | X12CrNiTi18-9 | 321H | 12Х18Н10Т | |

| 1.4845 | X12CrNi25-21 | 310 S | 20Х23Н18 |

Of the variety of brands, we use three main ones in our production - AISI 304, AISI 316 and AISI 430.

Read more about the stainless steel grades we use

- Stainless steel AISI 430 (Russian standard 12X17);

Due to the low carbon content, it is the most flexible and bends relatively easily. A high percentage of chromium provides a high level of protection.

Tests for determining the grade of stainless steels

How to distinguish one steel grade from another if, for example, AISI 304 and AISI 303 sheets were stored together? A number of simple, inexpensive and non-damaging tests can help solve this problem. It should be noted right away that such tests have a number of serious limitations.

For example, such tests will not help determine which of two sheets of steel of the same grade has been heat treated and which has not. Additionally, there is no easy way to distinguish certain grades of steel from each other. For example, it is impossible to distinguish steel AISI 304 (08Х18Н10) from AISI 316L (03Х17Н14М3), or 304 (08Х18Н10) from 304L (03Х18Н11).

A molybdenum content test will help determine whether molybdenum is present in steel, but without additional information the grade of steel cannot be correctly determined. For example, AISI 316 (10Х17Н13М2) steel, based solely on the results of this test, can be defined as 316L (03Х17Н14М3), 2205 or 904L.

Often, only with the help of more complex tests, in which the metal is exposed to chemical reagents, strength or heat resistance is checked, can the grade of steel be reliably determined. If simple tests do not help, then a full spectral or chemical analysis in the laboratory cannot be avoided.

Reaction to magnet

This test will help determine that austenitic steels (for example, AISI 300 series) do not react to a magnet when approaching it. Other stainless steels, such as ferritic, martensitic and duplex, react to magnets. When performing this test, it should be remembered that some austenitic steels, for example, 304 (08Х18Н10), can be attracted by a magnet if they were produced by cold rolling.

Reaction to nitric acid

Helps differentiate carbon steel from stainless steel. First, you need to place a steel sample in a solution of nitric acid (from 20-50%) at room temperature, or drop the solution onto a clean steel surface.

A reaction will begin on the surface of the carbon steel, releasing caustic brown vapor. This reaction does not occur with stainless steel.

When working with nitric acid, you must be extremely careful, and you should not inhale the vapors released during the reaction.

Molybdenum content test

Helps determine whether steel contains molybdenum. Steel containing sufficiently molybdenum, for testing as follows: 316 (10x17n13M2), 316L (03x17N14M3), 444, 904L, 2205, all "super -duplicate" alloys (S32760, Zeron 100, S32750, 2507, S32550, S32520, UR52N+).

The test can also determine molybdenum in other steels containing approximately 2% Mo. When conducting a test, it is best to compare an unknown steel with a control sample, for example, AISI 304 (08Х18Н10) and AISI 316 (10Х17Н13М2) steels.

For the test you will need an acid-based reagent (you can use either the American “Decapoli 304/316” or “Moly Drop 960”, or domestic analogues, although they are quite difficult to find). First, it is necessary to prepare the surface of the test sample by cleaning it with sandpaper.

For example, some steels containing about 0.5% molybdenum in impurities may react positively to the test at low temperatures. During the test, you should be careful when working with the reagent and follow the requirements for safe work with acids.

Sulfur content test

Sulfur is a harmful impurity that causes brittleness of steel during hot forming. This test helps determine the level of sulfur in steel. For this test, control samples of AISI CS1020, S1214, 304 or 303 steels will be needed, comparison with which will help in determining the degree of sulfur content.

To carry out the test, it is necessary to clean the surface of the test sample using sandpaper, and control samples should be prepared in the same way.

Next, you should soak the photographic paper in a 3% sulfuric acid solution for 3 minutes, apply the photographic paper face to the surface of the test sample, hold for 5 seconds and compare the results of the tested steel and the control samples. A dark brown stain indicates high sulfur content.

When testing, it should be taken into account that the reliability of the result is seriously influenced by the density and duration of contact of the paper with the surface

When performing this test, also remember to be careful when working with acid.

Tweet

Properties of corrosion-resistant steel

The alloy contains at least 10.5% chromium. In addition to its anti-corrosion properties, it adds some positive qualities to fame:

- easy processability by cold forming;

- high resistance to atmospheric corrosion and various chemical influences;

- sufficiently high strength;

- durability in use without loss of their qualities and performance properties, the average service life of such alloys is approximately 40-50 years;

- decent appearance, smooth surface;

- It is quite easy to clean from contamination with household detergents, which makes its maintenance more economical than that required by products made from ordinary steel;

Currently, more than 250 types of stainless steel have been created, which contain not only chromium, but also nickel, cobalt, titanium, molybdenum, and niobium. The performance properties and scope of application of the steel depend on what chemical element and in what quantities is added to the alloy. Carbon is an essential element in stainless steel. Thanks to it, the alloy acquires hardness and strength.

This is interesting: Square stainless steel pipe: production, application, GOST

Magnetic properties of stainless steel

It is impossible to distinguish between the stainless steel in front of you and ordinary steel by eye. It is believed that stainless steel should not be magnetic, but it is quite difficult to obtain a reliable result. It happens that steel, which is not magnetic, perfectly resists rust, and vice versa, a product that has the ability to magnetize rusts. The magnetic properties of stainless steel depend on the chemical composition of the alloy.

Bodies that are in a magnetic field have the ability to be magnetized and are divided into:

- paramagnetic materials have a magnetic susceptibility coefficient greater than zero;

- diamagnetic materials have a magnetic susceptibility coefficient below zero;

- ferromagnets have increased sensitivity to magnetic fields and are intensely magnetized even in the presence of weak magnetic radiation. They are used as additives to stainless steel, improving its performance characteristics.

Price

The cost of a men's bracelet made of surgical steel will be the same, and a sheet of AlSl316L alloy will be different. For source codes they ask from 10 rubles. At the same time, the sheets from the factory differ in thickness. As a rule, they offer samples from 0.1 to 999 millimeters.

The sheets are also damaged when they are cut. For example, 1 by 2 meter plates are offered for 140, 218, 240 rubles. Depends on the manufacturer and the nuances of the alloy formula.

Some sellers set a price tag per kilogram or ton. For example, one of the companies in Nizhny Novgorod sells 1,000 kilograms of 316L steel for 416 rubles. On the jewelry market, this amount can be asked for a bracelet weighing about 30 grams. It all depends on the brand, the complexity of the design, and its compliance with the latest fashion trends.

Regarding jewelry, people most often ask about the cost of piercings. Surgical steel , being in the body, will not cause allergies or other negative consequences. Gold rods can bend, and are not accessible to everyone. As a rule, having made one puncture on the body, people tend to come to the salon again.

It is more profitable to purchase 20 steel jewelry than one precious one. For one barbell made of improved iron you will have to pay only 50-100 rubles. We are talking about 19 mm models without additional elements, for example, stones.

The photo shows a men's bracelet made of surgical steel

Surgical steel remains exotic only among wedding rings. Experts say it's a matter of time. The first samples for weddings have already been released. Newlyweds resort to them because of their special strength.

The wedding ring is worn without taking off. Gold is a soft metal. You have to constantly polish the symbol of love, getting rid of scratches.

Silver rings are covered with niello and do not tolerate moisture. But steel models are the true embodiment of durability and strength of relationships. There is also something sterile in the new trend, indicating the purity of feelings, it’s not for nothing that the alloy is medical.

What determine the magnetic properties of materials?

A magnetic field with a certain level of its intensity (H) acts on bodies placed in it in such a way that it magnetizes them. In this case, the intensity of such magnetization, which is designated by the letter J, is directly proportional to the field strength. The formula by which the intensity of magnetization of a certain substance is calculated (J = ϞH) also takes into account the coefficient of proportionality Ϟ - the magnetic susceptibility of the substance.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Depending on the value of this coefficient, all materials can be included in one of three categories:

- paramagnetic materials – coefficient Ϟ is greater than zero;

- diamagnetic materials – Ϟ is equal to zero;

- ferromagnets are substances whose magnetic susceptibility is significant (substances, which, in particular, include iron, cobalt, nickel and cadmium, are capable of actively magnetizing, even when placed in weak magnetic fields).

Directions of action of magnetic moments of neighboring atoms in substances of different magnetic nature

The magnetic properties that stainless steel has are also associated with its internal structure, which can include austenite, ferrite and martensite, as well as combinations thereof. At the same time, the magnetic properties of stainless steel are influenced both by the phase components themselves and by the ratio in which they are found in the internal structure.

Useful

Designation of alloying elements in stainless steels

- In the initial part of the stamp there are numbers (two or one) showing the carbon content.

- Two numbers indicate its average content in the alloy in hundredths of a percent, and one – in tenths. There are also steels that do not have numbers at the beginning of the brand name. This means that the carbon content in these alloys is within 1%.

- The letters that can be seen behind the first digits of the brand name indicate what the alloy is made of.

- The letters that give information about a particular element in its composition may or may not have numbers. If there is a number, then it determines (in whole percentages) the average content of the element indicated by the letter in the composition of the alloy, and if there is no number, then this element is contained in the range from 1 to 1.5%.

X - chromium N - nickel K - cobalt M - molybdenum B tungsten T - titanium D - copper G - manganese C - silicon F - vanadium P - boron A - nitrogen B niobium E - selenium C - zirconium U - aluminum

The influence of the main alloying elements on the properties of stainless steels

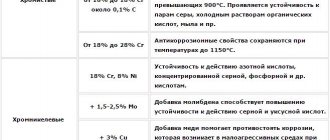

Chromium (Cr):

- is the main element of steel, determining its resistance to oxidation (corrosion). Chromium sharply increases the corrosion resistance of steel when it increases in the alloy above 12.5%, starting from this concentration a dense oxide film of Cr2O3 is formed on the surface (chromium actually makes steel stainless, for example, steels 20Х13, 30Х13, 40Х13, etc.) ;

- when the chromium content in steel is 12-14%, the thermal conductivity of steel is 2 times less than pure iron, and the electrical resistance increases 3 times;

- provides increased strength at elevated temperatures, the addition of chromium increases the hardness and strength of steel without reducing its ductility;

- reduces the impact strength of steel.

Nickel (Ni):

- The main function of nickel is to stabilize the austenitic structure of steel; such a structure is especially strong and elastic. The minimum amount of nickel capable of stabilizing the austenitic structure is 8% (this is exactly how much nickel is found in the most common imported steel AISI 304);

- the presence of 8-10% nickel in steel provides it with good ductility and good forming properties;

- improves the weldability of steel and further increases the resistance of steel to oxidation (corrosion) in the weld area;

- nickel increases the heat resistance of steel (especially in relation to resistance to deformation);

- Thanks to nickel, stainless steel polishes better and is more scratch resistant than conventional steels (brushed and mirrored surfaces).

Molybdenum (Mo):

- increases the resistance of steel to oxidation (corrosion) at high temperatures, reduces the resistance of steels to pitting corrosion;

- increases red resistance, elasticity, tensile strength;

- provides additional thermal strengthening.

Titanium (Ti):

- increases the strength of steel;

- Titanium is added to stainless steels to prevent intergranular corrosion.

Carbon (C):

- with an increase in carbon to 0.8%, the hardness and strength of the steel increases, but leads to an increase in the threshold of cold brittleness (for example, steels 40Х13 and 95Х18 are used for the production of knives);

- the more carbon there is in the steel, the more difficult it is to process by cutting, the worse it deforms and the worse it welds (for example, the most common commercially available imported steels of the 300 series AISI304/321/316 have 0.8% carbon in their composition, which gives them a wide range of applications compared to domestic steel 12x18n10t).

Compliance of foreign standards with Russian GOST.

Currently, almost all stainless steel products supplied to our country are marked according to AISI, DIN, or EN standards. Let's consider the compliance of these standards with Russian GOST.

AISI (American Iron and Steel Institute), American Institute of Iron and Steel

The designation of standard stainless steels according to AISI includes three numbers followed by one, two or more letters in some cases. The first digit of the designation determines the steel class. Thus, the designations of austenitic stainless steels begin with the numbers 2XX and 3XX. While ferritic and martensitic steels are defined in class 4XX. Moreover, the last two digits, unlike carbon and alloy steels, are in no way related to the chemical composition, but simply determine the serial number of the steel in the group.

The additional letters and numbers following the numbers used to designate AISI stainless steels mean:

xxxL – Low carbon standards adopted by the European Committee for Standardization (CEN) In them, the steel grade is presented as 1.XXXX, where:

- 1. determines that this material belongs to steel;

- The next two digits after 1 determine the number of the steel group, and the last two – the serial number of the steel in the group.

By the group number you can unambiguously determine what type a particular steel belongs to.

1.40ХХ – 1.45ХХ – stainless steels 1.46ХХ – 1.49ХХ – heat-resistant and acid-resistant steels

1.4016 - AISI 430 (12Х17) 1.4301 - AISI 304 (03Х18Н10) 1.4541 - AISI 321 (08х18Н10Т) 1.4842 - AISI 410S (10Х23Н18)

Table of correspondence between GOST steel grades and standards of other countries.

Why is one brand of stainless steel magnetic and another is not?

A little theory: A magnetic field with a certain level of its intensity acts on bodies placed in it in such a way that it magnetizes them.

Ferromagnets are substances that, in particular, include iron, cobalt and nickel, which are capable of actively magnetizing, even when placed in weak magnetic fields. We are used to identifying stainless steel using a magnet. It is believed that “real stainless steel” should not be magnetic, but in practice this diagnostic method does not always allow obtaining a reliable result. Why is this happening?

The term “stainless steel” refers to various materials, the composition of which may contain ferrite, martensite or austenite, as well as their various combinations. The characteristics of stainless steel depend on the phase components and their ratio. So, which stainless steel is magnetic and which is not?

Anti-corrosion magnetic steels

Alloys that are resistant to rust but are strongly attracted to a magnet include:

- Martensitic - the material has high strength, can be ground and polished well, is very resistant to corrosion, and can be easily processed by stamping, cutting and welding. In addition to the manufacture of industrial equipment, it is used for the manufacture of cutlery. Therefore, the question of whether stainless steel is magnetic or not can be answered positively.

- Ferritic – the most popular grade of steel with magnetic properties is AISI 430, used for the production of food equipment.

Martensitic

Stainless steels are similar to ferritic steels in their chromium content, but have higher carbon levels, up to 1%. This allows them to be hardened. They are used where high strength and moderate corrosion resistance are required. They are more commonly found in products such as blades, knives, scissors, razors and medical instruments. Martensitic stainless steels also have moderate corrosion resistance, are heat treatable and magnetic, but are very difficult to weld.

Use of chromium-nickel steel

Anti-corrosion steel 12Х18Н10Т is an environmentally friendly and durable material. The composition of the chromium-nickel alloy, in addition to the main component - iron, includes up to 19% chromium, which provides it with strong anti-corrosion properties, and 11% nickel, which transfers it to the class of austenites and imparts flexibility, strength and heat resistance. Due to its characteristics, it is widely used. Many people are interested in whether steel grade 12Х18Н10Т is magnetic or not? It is non-magnetic, like all austenitic alloys, and is used in the following industries:

- Chemical - aggressive acids: acetic, nitric, phosphoric are transported through pipes made of this grade of steel.

- Food – dairy, meat, alcohol.

- Mechanical engineering – production of parts in contact with acids and alkalis, production of welded equipment, exhaust system manifolds.

- Petroleum - for the manufacture of pipes.

In addition, chromium-nickel alloys are used in the fuel and energy sector. Furnace fittings and heat exchangers are made from them.

Stainless steel that is magnetic

Ferritic alloys

They contain chromium in large quantities, approximately 20%. They have high magnetic properties and resistance to corrosion. They acquire greater softness due to a decrease in carbon composition and are easily amenable to various types of processing. Most often, such alloys are used in heavy industry, at food industry enterprises, and elements of heating systems are also made from them. They are cheaper than austenitic alloys.

Some features of ferritic alloys allow them to be used to replace more expensive materials:

- low level of thermal expansion and thermal conductivity;

- increased temperature resistance and fluidity;

- resistance to deformation and corrosion.

This allows these alloys to be used in the manufacture of electromagnetic drives and actuators.

Martensitic alloys

They have increased strength and are not inferior to carbon steels, thanks to hardening and tempering. These are absolute ferromagnets. They are rare because it is difficult to maintain a pure composition. Alloys with a high chromium content are resistant to humidity and aggressive environments. Excellent weldability, both hot and cold stamping can be used.

Martensites are heat-resistant and capable of self-hardening. They are used in mechanical engineering for the production of abrasives, in the production of cutlery, elements of pumping systems, springs, surgical and various cutting instruments. Among stainless steels, martensitic alloys have the highest magnetizability.

Martensitic-ferritic alloys

They have good performance characteristics and are easy to heat treat. But when welding they tend to form cold cracks. They are used when surfaces that are often exposed to heating are required, such as collectors, boilers, and pipelines.

Where is food grade steel used?

In the food industry, there is a need to select a material that will come into contact with food. This choice must be approached with special responsibility. Negative interactions are possible during food storage and transportation. Even high-quality stainless steel does not in all cases have the ability to withstand the effects of materials. In such cases, it is possible to use special food alloys that have special requirements.

Alloys are used in the food industry and are capable of not reacting to aggressive influences. Every kitchen has stainless steel cookware, which pleases its owners with reliability and practicality. The surface of the electrical equipment is made of stainless steel. All this is convenient to use, has a long service life and excellent quality.

List of sources

- svarkalegko.com

- truehunter.ru

- steelfactoryrus.com

- vchemraznica.ru

- DedPodaril.com

- martensit.ru

- prompriem.ru

- obrabotkametalla.info

- lkmprom.ru

Stainless steel markings

In Russia and the CIS countries, an alphanumeric system has been adopted, according to which numbers indicate the content of steel elements, and letters indicate the name of the elements. The designations common to all are the letter designations of alloying elements: H - nickel, X - chromium, K - cobalt, M - molybdenum, B - tungsten, T - titanium, D - copper, G - manganese, C - silicon.

Standard stainless steel, according to GOST 5632-72, is marked with letters and numbers (for example, 08Х18Н10Т). In the United States, there are several systems for naming metals and their alloys. This is due to the presence of several standardization organizations, these include AMS, ASME, ASTM, AWS, SAE, ACJ, ANSI, AJS. It is quite clear that such marking requires additional clarification and knowledge when trading metal, placing orders, etc.

| Europe (EN) | Germany (DIN) | USA (AISI) | Japan (JIS) | CIS (GOST) |

| 1.4021 | X20Cr13 | (420) | SUS 420 J1 | 20Х13 |

| 1.4028 | X30Cr13 | (420) | SUS 420 J2 | 30Х13 |

| 1.4031 | X39Cr13 | SUS 420 J2 | 40Х13 | |

| 1.4016 | X6Cr17 | 430 | SUS 430 | 12Х17 |

| 1.4510 | X3CrTi17 | 439 | SUS 430 LX | 08Х17Т |

| 1.4301 | X5CrNI18-10 | 304 | SUS 304 | 08Х18Н10 |

| 1.4541 | X6CrNiTi18-10 | 321 | SUS 321 | 08Х18Н10Т |

| 1.4401 | X5CrNiMo17-12-2 | 316 | SUS 316 | 08Х17Н13М2 |

| 1.4404 | X2CrNiMo17-12-2 | 316 L | SUS 316 L | 03Х17Н14М2 |

| 1.4571 | X6CrNiMoTi17-12-2 | 316 Ti | SUS 316 Ti | 10Х17Н13М2Т |

| 1.4435 | X2CrNiMo18-14-3 | 316 L | SUS 316 L | 03Х17Н14М2 |

| 1.4878 | X12CrNiTi18-9 | 321H | 12Х18Н10Т | |

| 1.4845 | X12CrNi25-21 | 310 S | 20Х23Н18 |

Of the variety of brands, we use three main ones in our production - AISI 304, AISI 316 and AISI 430.