Stainless steel pipes occupy a significant part of the pipe rolling market. They combine strength and fire resistance at a relative low cost, which neither expensive copper pipes nor fire-hazardous plastic can boast of. Large volumes of manufactured products have made it possible to bring technological processes to near perfection, so in most cases the finished products are distinguished by high quality and a wide range of applications.

The production of stainless steel pipes is based on the requirements of GOST and technical specifications. Standards determine production technology, assortment, tolerances, acceptance rules, test methods and other factors that must be taken into account when manufacturing stainless steel pipes. Let's take a closer look at the types of pipes and their areas of application, as well as the factors that determine the market price for this type of product.

GOST 9941-Cold-formed stainless steel pipes

The interstate standard GOST 9941-81 regulates the range, technical requirements, acceptance rules, test methods, marking, packaging, transportation and storage of seamless cold- and heat-deformed pipes made of corrosion-resistant steel for general use.

Assortment

According to GOST 9941-81, seamless stainless steel pipes are manufactured with a diameter from 5 to 273 mm with a wall thickness from 0.2 to 22 mm . The table below shows the maximum possible length for each size. The first column indicates the outer diameter, the header indicates the wall thickness.

See table. (opens in a new window)

There are a number of notes to this table:

If the ratio of diameter to thickness is greater than or equal to 40, the pipe is considered thin-walled . The requirements for such a pipe in terms of technical characteristics and maximum dimensional deviations are established by regulatory and technical documentation.

There are restrictions on the range depending on the steel used for production. If the product is made of steel grades 12Х17, 08Х17Т, 15Х25Т, the outer diameter should not be less than 21 mm. For alloy 06ХН28МДТ, the outer diameter should be in the range from 14 to 85 mm and the wall thickness from 1 to 5 mm.

Limit deviations

The process of producing pipes on a rolling machine is technologically complex. The blank has to be molded to the size of a hollow sleeve and therefore often the nominal dimensions stated in the documentation do not correspond to the actual ones. GOST 9941-81 determines which deviations are acceptable. They are:

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | ||

| ordinary | increased | high | |

| By outer diameter | |||

| with a diameter from 5 to 10 | ±0.3 mm | ±0.2 mm | ±0.15 mm |

| with a diameter of St. 10 to 30 | ±0.4 mm | ±0.3 mm | ±0.2 mm |

| with a diameter of St. 30 to 95 | ±1,2% | ±1,0% | ±0,8% |

| with a diameter of St. 95 | ±1,0% | ±1,0% | ±0,8% |

| According to wall thickness | |||

| at wall 0.2 | ±0.05 mm | ±0.03 mm | – |

| with a wall from 0.3 to 0.4 | ±0.07 mm | ±0.05 mm | – |

| with a wall from 0.5 to 0.6 | ±0.10 mm | ±0.07 mm | – |

| with a wall from 0.7 to 1 | ±0.15 mm | ±0.10 mm | – |

| at the wall of St. 1 to 3 | +12,5% -15% | ±12,5% | +12,5% -10% |

| at the wall of St. 3 to 7 | ±12,5% | +12,5% -10% | ±10% |

| at the wall of St. 7 | +12,5% -10% | ±10% | – |

Pipes, highlighted in dark yellow in the table , are produced in only two accuracy categories: normal and high. Other maximum deviations are established for them:

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| By outer diameter | ±1,2% | ±1% |

| According to wall thickness | ||

| with a wall from 1.5 to 2.5 | ±15% | 12,5% -15% |

| at the wall of St. 2.5 to 4 | 12,5% -15% | ±12,5% |

Also, unique maximum deviations are established for pipes made from steel 06ХН28МДТ . They are listed in the table below.

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| By outer diameter | ||

| with diameter up to 30 | ±0.45 mm | – |

| with a diameter of St. thirty | ±1,2% | – |

| According to wall thickness | ||

| at wall up to 3 | ±15,0% | – |

| at the wall of St. 3 | ±12,5% | – |

Typically, pipes are manufactured based on outer diameter and wall thickness. But if the consumer wishes, GOST allows manufacturing according to the internal diameter and thickness. In this case, permissible deviations are specified separately.

If the product turns out to be slightly oval, the ovality should not bring the diameter beyond the maximum deviations in the outer diameter.

Deviations in curvature are also established. The curvature on any section 1 m long should not exceed:

- 1 mm – with a diameter of 5 mm or more, with a wall thickness of 0.5 mm or more;

- 2 mm – with a diameter of 15 mm or more, with a wall thickness of less than 0.5 mm.

- not regulated - with a diameter of less than 15 mm, with a wall thickness of less than 0.5 mm. These pipes should not have sharp bends.

This is interesting: Range of profile pipes - GOST, parameters and application

Assortment

According to GOST 9941-81, seamless stainless steel pipes are manufactured with a diameter from 5 to 273 mm with a wall thickness from 0.2 to 22 mm . The table below shows the maximum possible length for each size. The first column indicates the outer diameter, the header indicates the wall thickness.

| Diameter | Maximum length with wall thickness | |||||||||||||||||||||||||||||||||||||

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.8 | 1 | 1.2 | 1.4 | 1.5 | 1.8 | 2 | 2.2 | 2.5 | 2.8 | 3 | 3.2 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 8.5 | 9 | 9.5 | 10 | 11 | 12 | 14 | 16 | 18 | 20 | 22 | |

| 5 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||||||||

| 6 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 7 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||||

| 8 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 9 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||||

| 10 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 11 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 12 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 13 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||||

| 14 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 15 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 16 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 17 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 18 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 19 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 20 mm. | 5 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 21 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 22 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 23 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 24 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||

| 25 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 27 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 28 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 30 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 32 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 34 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 35 mm. | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 36 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||

| 38 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 40 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 42 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 45 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||

| 48 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 50 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 51 mm. | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 53 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 54 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 56 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 57 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 60 mm. | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 63 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 65 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 68 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 70 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 73 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 75 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 76 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 80 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 83 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 85 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 89 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 90 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||||||||

| 95 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||||||||

| 100 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 102 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 108 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||||

| 110 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 120 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||||

| 130 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 140 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 150 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | ||||||||||||

| 160 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 170 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 180 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||

| 200 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||

| 220 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 250 mm. | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | 7 | |||||||||||||||||||

| 273 mm. | 6.5 | 6.5 | 6 | 6 | 5.5 | 5.5 | 5 | 5 | 5 | 4 | 4 | |||||||||||||||||||||||||||

There are a number of notes to this table:

If the ratio of diameter to thickness is greater than or equal to 40, the pipe is considered thin-walled . The requirements for such a pipe in terms of technical characteristics and maximum dimensional deviations are established by regulatory and technical documentation.

There are restrictions on the range depending on the steel used for production. If the product is made of steel grades 12Х17, 08Х17Т, 15Х25Т, the outer diameter should not be less than 21 mm. For alloy 06ХН28МДТ, the outer diameter should be in the range from 14 to 85 mm and the wall thickness from 1 to 5 mm.

Standards

The standard to which a pipe is produced depends primarily on the method of its manufacture. The pipe production technology itself has already been covered many times, and we will not focus our attention on it; Let us mention only the main points.

Welded pipes

Stainless steel pipes: GOST 11068-81 are made from flat billets. A narrow endless tape is formed from it, which is wound onto a drum and fed to the line as needed.

There, the future pipe is bent into a cylinder, the edges of which are welded using one of several methods:

- High frequency currents;

- Electric arc in an inert gas environment;

- Laser;

- Plasma;

- Electron beams.

The latter method is used extremely rarely due to its high cost: all technological operations take place in a vacuum.

The assortment determined by GOST includes pipes from 8 to 102 mm with walls ranging from 0.8 to 4 mm thick.

Seam quality control is a mandatory stage in the production of welded pipes

Seamless pipes

The raw material for them is a round billet obtained by casting or pressing. Production includes several stages of processing with rollers: the pipe acquires the required diameter and wall thickness, is calibrated, and then cut into pieces of the required length.

Based on the temperature at which the workpiece is processed by the rollers, the following are distinguished:

- Cold-deformed pipes;

- Heat deformed;

- Hot-deformed.

Cold-deformed and heat-deformed pipes GOST 9941 81 are manufactured with an outer diameter from 5 to 273 mm and wall thickness from 0.2 to 22 mm.

Stainless steel pipe: GOST 9941-81 has the following permissible deviations from the specified dimensions:

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | ||

| ordinary | increased | high | |

| By outer diameter | |||

| with diameter: from 5 to 10 | ±0.3 mm | ±0.2 mm | ±0.15 mm |

| St. 10 to 30 | ±0.4 mm | ±0.3 mm | ±0.2 mm |

| St. 30 to 95 | ±1,2% | ±1,0% | ±0,8% |

| St. 95 | ±1,0% | ±1,0% | ±0,8% |

| According to wall thickness | |||

| at wall: 0.2 | ±0.05 mm | ±0.03 mm | — |

| from 0.3 to 0.4 | ±0.07 mm | ±0.05 mm | — |

| from 0.5 to 0.6 | ±0.10 mm | ±0.07 mm | — |

| from 0.7 to 1 | ±0.15 mm | ±0.10 mm | — |

| St. 1 to 3 | +12,5 15,0% | ±12,5% | +12,5 -10,0% |

| St. 3 to 7 | ±12,5 % | +12,5 -10,0 % | ±10% |

| St. 7 | -10,0% | ±10% | — |

For hot-deformed pipes, a different standard is used: they are produced according to GOST 9940 81. They provide pipe sizes from 57 to 325 millimeters with wall thicknesses from 3.5 to 32 mm.

Important: actual pipe production is not limited by the standard. By agreement with the customer, no one bothers to produce, say, a thicker-walled or larger diameter pipe.

This standard also limits the maximum permissible deviations:

| Pipe sizes | Maximum deviations for manufacturing accuracy, % | |

| ordinary | high | |

| By outer diameter | ± 1,5 | ± 1,0 |

| By wall thickness, mm: | ||

| 8 or less | +20,0 | +12,5 |

| -15,0 | -15,0 | |

| more than 8 to 20 | ± 15,0 | +12,5 |

| -15,0 | ||

| more than 20 | +12,5 | |

| -15,0 | ± 12,5 | |

Before us is a blank for a seamless pipe. She has a long way to go through countless rollers

The difference between pipes GOST 9940 and 9941

Seamless products are produced from steel 12Х18Н10Т in accordance with GOST 9940-81. It applies to hot-deformed pipe products made from corrosion-resistant general-purpose alloys.

Stainless steel pipes according to GOST 9940 are manufactured:

- with diameter (external) from 57 to 325 mm;

- with wall thickness from 3.5 to 32 mm;

- standard maximum length from 3 to 8.5 m

In terms of manufacturing precision, pipes are produced with normal and high precision. Other geometric dimensions and physical and mechanical properties, which are described below, determined GOST 9940 for pipes 12Х18Н10Т and other tolerances for wall thickness, diameter and curvature.

The chemical composition of steel for seamless products of this standard is subject to the same requirements as those produced according to GOST 9941. And their mass is calculated using the same formula. The requirements for the ends and surface of the pipes are also identical.

Products are manufactured in accordance with the submitted order, heat-treated or without heat treatment and resistant to intergranular corrosion.

At the request of the customer, pipes are subjected to the same tests as those produced in accordance with GOST 9941, and using similar methods and conditions for their conduct.

The only difference here is that for hot-deformed pipes according to GOST 9940, their heat treatment is not a prerequisite for achieving the required physical and mechanical properties and conducting the necessary tests. After all, the method of manufacturing these products already presupposes the necessary heat treatment, which cannot be said about cold- and heat-deformed products according to GOST 9941.

Hot-deformed ones have greater flexibility and ductility, but are significantly inferior to cold- and heat-deformed ones in terms of strength and resistance to the physical impact exerted on them.

| pipes 12Х18Н10Т GOST 9940 | pipes 12Х18Н10Т GOST 9941 | |

| tensile strength | > 54 kgf/mm2 (529 N/mm2) | 56 kgf/mm2 (549 N/mm2) |

| relative extension | > 40% | 35% |

In addition, for hot-deformed pipes 12Х18Н10Т with a diameter to wall thickness ratio equal to or less than 8, a reduction in tensile strength by 2 kgf/mm2 (19.6 N/mm2) is allowed.

GOST 9941 products must withstand the rated load regardless of the geometric parameters of their cross-section. Only the yield strength of hot-deformed pipes is the same - 22 kgf/mm2 (216 MPa).

But this is due to the fact that the same stainless alloy is used for manufacturing - 12Х18Н10Т.

Due to their greater strength, GOST 9941 pipes are manufactured with smaller wall thicknesses and diameters than products of the 9940 standard. If we compare, for example, products with a diameter of 273, then cold- and heat-deformed ones are produced with walls of 3–14 mm, and hot-deformed ones with walls of 11–20 mm .

Accordingly, the areas of application of GOST 9941 and 9940 products are somewhat different.

The first is used where high strength of the pipeline or product is needed with its relative lightness, and the second, when during the installation and operation of a stainless network or part, the flexibility and ductility of the pipe from which they are made is more important.

When preparing the text, materials from the site https://tutmet.ru were used

Source: https://rospnk.ru/truba-nerzhaveyushchaya/faq/otlichie-mezhdu-trubami-gostov-9940-i-9941.html

Areas of use

Stainless steel pipe has a unique set of properties:

- Highest mechanical strength;

- Resistance to corrosion and aggressive environments;

- High melting point;

- When treated with surface it creates an attractive appearance.

The properties determine the areas in which the pipe marked “stainless” is used in the price list position:

- Water supply and heating systems;

- Pipelines in the food industry in contact with various products;

- The chemical industry with its extremely aggressive substances, which are often conveyed through pipes at high temperatures and pressures;

- Energy. What is needed here is the strength and heat resistance of stainless steel;

- Decor of interiors and buildings. Still, polished stainless steel pipes are not only wear-resistant, but also a very beautiful material;

- Medicine;

- Shipbuilding;

- Automotive industry;

- Heavy engineering. What else can hydraulic cylinders be made of where pressures amount to thousands of atmospheres?

Let's take a closer look at some of the areas.

Plumbing and heating systems

Made from stainless steel, they are almost eternal.

The list of advantages is long:

- The stainless steel pipe is not subject to corrosion and does not overgrow;

- pipe erosion by suspensions and microparticles is theoretically possible, but in practice it will take much longer than the lifespan of any building;

- A polished pipe looks very presentable and, with carefully made threaded pipe connections, may not be hidden under decorative boxes.

The most simple threaded fittings for water supply can be used. However, stainless steel water pipes are often assembled using welding.

Tip: When using threaded connections, do not use synthetic sealing tapes or threads. TO

In fact, the old-fashioned method, proven over decades, will be more reliable: ordinary linen winding soaked in paint or drying oil.

The only downside to using stainless steel pipe when creating your home plumbing is how difficult it is to machine. Trying to thread it by hand is simply futile; making pipes and bends on a lathe will require especially durable tools.

Fittings for threaded connections are also made of stainless steel

Recently, corrugated stainless steel pipes for water supply systems using threaded clamp fittings have appeared on sale. Reviews for them have been rather mixed so far, so you should probably refrain from using them for now.

Use in the food industry

Stainless steel food pipe is, as a rule, a seamless pipe. The food industry can also use welded pipes, but only those produced by TIG welding - a tungsten electrode in an inert gas environment. This limitation is due to the strength of the seam and its tightness .

In addition, in the food industry, only polished pipes are used, and, of course, the inner surface is also polished. This is due to the fact that bacteria do not multiply on a perfectly smooth pipe: there is simply nothing for them to eat there. There are no, so to speak, folds of the terrain in which the remains of organic matter get stuck.

At food processing enterprises, a significant part of the equipment is made of stainless steel. Of course, pipelines are no exception.

Chemical industry

But here the strength of stainless steel and, most importantly, its ability to work in aggressive environments come first. Pipes made of steel 12x18n10t can withstand temperatures up to 350C in solutions of acids and alkalis!

Of course, here we see exclusively seamless pipes: after all, leakage of even a few molecules of the contents of the water supply is sometimes unacceptable. And the pressures can be enormous.

A stainless steel pipe leads to the dismantled chemical reactor. The reactor vessel is made from it

Energy

And here, too, you need the strength of stainless steel and its resistance to temperatures. Heat-resistant grades of stainless steels are capable of operating at temperatures up to 1100 C. They are used, for example, to create cooling circuits for nuclear reactors.

Decorative Applications

And in this area, the spectacular appearance of stainless steel pipes and its wear resistance are in demand. Of course, only pipes with a treated surface are used here; Often the use of profile pipes is also used.

In particular:

- polished oval pipe is often used for railings and decorative fences;

- square polished pipes 10 10, 20 20 and 40 40 can be found as frames for chairs, bookcases and other furniture;

- larger pipes - 50 50 and 60 60 - are popular as beautiful, extremely reliable handrails that do not lose their shine over time in supermarkets and sports facilities.

Furniture made from profile pipes turns out to be very impressive

Often made from stainless steel:

- Shelving and other commercial equipment;

- Furniture stands and legs;

- Frames for canopies and cornices;

It turns out beautifully, doesn't it?

- Mufflers for cars and motorcycles and much, much more.

Medicine

The absolute chemical stability of stainless steel makes it an ideal material for a variety of implants, prostheses implanted into the body and other medical equipment.

The most popular and well-known products made from stainless steel pipes are ordinary medical syringes. Or rather, needles for them.

From a production point of view, any needle in the hands of a surgeon is a thin seamless stainless steel tube

Stainless steel pipe GOST 9941-81

Corrosion-resistant pipes are widely used in the energy, food and chemical industries, construction and design. Pipes made from steels that are resistant to electrochemical corrosion are also called stainless steel.

According to manufacturing technology, stainless steel pipes are divided into:

- hot-deformed seamless pipes GOST 4490 81;

- cold- and heat-deformed seamless (GOST 4491-81) and welded (GOST 11068-81).

Stainless steel pipe GOST 9941-81, as well as hot-deformed stainless pipe GOST 9940-81, is made from high-chromium steels of type 08Х13, 10Х13, 12Х13, 14Х17Н2; austenitic type 08Х18Н9Т, 12Х18Н10Т; austenitic heat-resistant type 20Х23Н18, 20Х25Н20С2, 06ХН28МТ; sparingly alloyed high-manganese types 10Х13Г18Д, 10Х14Г14Н4Т, 10Х14AG15, 12Х17Г9AN4.

Each alloying system has its own purpose: to work in solutions of acids and alkalis, organic acids, in an oxidizing atmosphere at temperatures up to 650-11000C; at negative temperatures down to -1960C, etc.

The general rule is the following: the more expensive nickel in the steel, the higher the properties and capabilities of the steel, but also the higher the price. Naturally, special areas of application of stainless steel pipes are indicated. Any of them can be successfully used as a decorative material.

The choice is determined only by the cost of the steel grade.

Stainless steel pipe GOST 9941-81: features of manufacturing technology

Features of the production of seamless steel and stainless steel pipes:

- hot-deformed - by piercing and rolling a pipe blank;

- cold-deformed - in addition to hot rolling - by drawing or cold rolling of a hot-rolled billet (sleeve).

Alloying affects the temperature-time parameters of deformation and the features of surface preparation before reduction.

Unlike hot-deformed pipes GOST 9940-81, cold-deformed pipes have a better surface condition, higher dimensional accuracy, a uniform fine-grained steel structure with fewer defects.

Stainless steel cold-deformed pipes must undergo heat treatment. Goals: removal of internal stresses (softening) after cold deformation and homogenization (leveling of composition and structure) of steel.

High-chromium ferritic class steels of type 14Х17 (AISI 430) are subjected to annealing at 740-7800С, chromium-nickel austenitic steels of type 12Х18Н10Т (AISI 321) are quenched in water from 1050-10800С.

For austenitic steels, high-temperature heating is necessary to increase resistance to intergranular corrosion (ICC).

Pipe weight calculation

Often the consumer is faced with the need to calculate the weight of a linear meter of pipe . This can be done using special rolled metal calculators, which can be found on our website or on many other specialized sites on the Internet. The standard specifies the following formula for calculating weight:

Weight=3.14/1000*((Diameter – Thickness)*Thickness*Density)

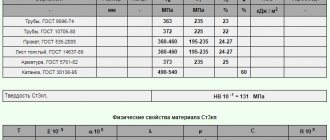

The mass of a meter is usually measured in kilograms. For calculations, the steel density must be taken from the following table.

| steel grade | Temporary resistance | Relative extension | Density |

| no less | |||

| 08Х17Т | 372 (38) | 17 | 7,70 |

| 08Х13 | 372 (38) | 22 | 7,70 |

| 12Х13 | 392 (40) | 22 | 7,70 |

| 12Х17 | 441 (45) | 17 | 7,70 |

| 15Х25Т | 461 (47) | 17 | 7,60 |

| 04Х18Н10 | 490 (50) | 45 | 7,90 |

| 08Х20Н14С2 | 510 (52) | 35 | 7,70 |

| 10Х17Н13М2Т | 529 (54) | 35 | 8,00 |

| 08Х18Н12Б | 529 (54) | 37 | 7,90 |

| 10Х23Н18 | 529 (54) | 35 | 7,95 |

| 08Х18Н10 | 529 (54) | 37 | 7,90 |

| 08Х18Н10Т | 549 (56) | 37 | 7,90 |

| 08Х18Н12Т | 549 (56) | 37 | 7,95 |

| 08Х17Н15М3Т | 549 (56) | 35 | 8,10 |

| 12Х18Н10Т | 549 (56) | 35 | 7,95 |

| 12Х18Н12Т | 549 (56) | 35 | 7,90 |

| 12Х18Н9 | 549 (56) | 37 | 7,90 |

| 17Х18Н9 | 568 (58) | 35 | 7,90 |

| 08Х22Н6Т | 588 (60) | 20 | 7,60 |

| 06ХН28МДТ | 490 (50) | 30 | 7,96 |

All calculated values for stainless steel seamless pipes in our database are made taking into account these requirements using the above formula! The steel density for basic calculations was taken equal to 7.85, which corresponds to GOST standards.

Main grades of stainless steel for seamless pipes

GOSTs 9940 and 9941 contain 20 grades of alloys that can be used for the manufacture of stainless steel seamless pipes. Of these, the most used are presented below.

Steel 12x18n10t

The steel has excellent anti-corrosion properties, is resistant to oxidation at temperatures up to 900 degrees C, and has high heat resistance.

Properties of pipes made from steel 12x18n10t by cold/hot rolling:

- resistance, kgf/sq.mm: 56 / 54;

- elongation,%: 35 / 40;

- density, g/cc: 7.95 / 7.9.

Tubular products made from this steel are used for transporting oxidizing media, organic solvents and some types of organic acids in cryogenic technologies at temperatures close to absolute zero.

Steel grade 08x18n10t

Stainless steel of this brand is characterized by even better properties for transporting aggressive media than the previous type. It finds its application in the chemical industry as it exhibits high resistance to intercrystalline corrosion.

Mechanical properties of pipe products made from steel 08x18n10t by cold/hot rolling:

- resistance, kgf/sq.mm: 54 / 52;

- elongation,%: 37 / 40;

- density, g/cc: 7.9.

Pipes made of this type of steel can be operated at any pressure and temperature up to 600 degrees C.

Steel 10x17N13M2T

The type of steel contains 3% molybdenum, which gives it additional properties that steel 12x18 and 08x18 lack. Pipes made from 10x17N13M2T are resistant to chlorine. In acidic environments, depending on the type of acid, its concentration and temperature, the annual corrosion rate does not exceed 0.1 mm. The mechanical properties of products made from 10x17N13M2T by cold and hot rolling are the same and are:

- resistance, kgf/sq.mm: 54;

- elongation, %: 35;

- density, g/cc: 8

Steel grade 06xN28MDT

Stainless steel contains molybdenum (up to 3%), increased amounts of nickel (up to 29%) and chromium (up to 25%). Used in industrial installations requiring transportation of acids and other aggressive media. In accordance with the standard, this grade of steel is used in the production of pipes using the cold rolling method. The mechanical properties of the products are as follows:

- resistance, kgf/sq.mm: 50;

- elongation, %: 30;

- density, g/cc: 7.96

For cold-rolled pipes made of 06xN28MDT, special permissible deviations in diameter and wall are established (Table 8).

Table 8. Permissible deviations in diameter and wall for products made of steel 06xN28MDT

| Pipe sizes, mm | Limit deviations for manufacturing accuracy | |

| ordinary | high | |

| with diameter: up to 30 | ±0.45 mm | — |

| St. thirty | ±1,2% | — |

| at the wall: up to 3 | ±15,0 % | — |

| St. 3 | ±12,5 % | — |

Steel 10x23N18

Belongs to the group of heat-resistant alloys. Can be used to work with aggressive media with temperatures up to 1000 degrees C. At higher temperatures in the air it is subject to intense oxidation.

Properties of pipes made from 08x18n10t by cold/hot rolling:

- resistance, kgf/sq.mm: 54 / 50;

- elongation, %: 35 / 37;

- density, g/cc: 7.95.

Media transported under high pressure at temperatures up to 1000 degrees C lead to a reduction in the service life of products to 1-10 thousand hours.

Length

Often the buyer has a question regarding length . The standard on this matter states that the production of pipes is allowed:

- Measured length - within unmeasured length. In this case, the length should not exceed the values specified in Table 1 of GOST. The deviation in length should not exceed +15 mm. It is allowed to manufacture pipes with a length exceeding the specified values, but only with appropriate agreement between the manufacturer and the consumer.

- Length that is a multiple of the measured length – within the measured length. In this case, allowances of 5 mm are allowed for each cut. The deviation in length should not be more than 15 mm

- of unmeasured length with a wall thickness of up to 0.5 - it is allowed to manufacture pipes with a length of 0.75 meters up to the value indicated in Table 1. In this case, no more than 6% of products with a length of 0.5 to 0.75 meters are allowed in a batch.

- of unmeasured length with a wall thickness of 0.5 to 1 mm – it is allowed to manufacture pipes with a length of 1 meter up to the size indicated in Table 1. In this case, no more than 6% of products with a length of 0.75 to 1 meter are allowed in a batch.

- of unmeasured length with a wall thickness of more than 1 mm - minimum length 1.5 meters, maximum length 12.5 meters. At the same time, no more than 6% of products with a length of 0.75 to 1.5 meters are allowed in a batch.

It is possible to produce pipes longer than 12.5 meters, but only if agreed upon by the manufacturer and the buyer.

In case of approval for the production of pipes with a length exceeding those established in Table 1, it must be remembered that pipes with a diameter of up to 25 mm cannot be longer than 16 meters.

Difference from hot-deformed

In accordance with this standard, pipes are produced by cold or warm deformation. As you know, there are stainless steel seamless pipes manufactured according to GOST 9940-81 by hot rolling. The difference from cold-deformed ones is in the manufacturing method. In cold forming, the workpiece is formed without preheating to a high temperature. Since there is no heating, the resulting pipe is not subject to temperature deformation and, as a result, comes out more accurate and uniform.

The actual dimensions of pipes produced in accordance with GOST 9941-81 are much more accurate than with hot forming. Permissible deviations in size are usually smaller. Therefore, if the project requires increased manufacturing accuracy, choose cold-rolled products.

The main disadvantage of such pipes is their higher price. They are usually more expensive than hot rolled ones. However, some projects require just such products. Therefore, if manufacturing accuracy is not a critical factor for the project, it is more advisable to give preference to hot-deformed ones due to their lower price.

This is interesting: Aluminum corner - classification and application

Difference from hot-deformed

In accordance with this standard, pipes are produced by cold or warm deformation . As you know, there are stainless steel seamless pipes manufactured according to GOST 9940-81 by hot rolling. The difference from cold-deformed ones is in the manufacturing method. In cold forming, the workpiece is formed without preheating to a high temperature. Since there is no heating, the resulting pipe is not subject to temperature deformation and, as a result, comes out more accurate and uniform.

The actual dimensions of pipes produced in accordance with GOST 9941-81 are much more accurate than with hot molding. Permissible deviations in size are usually smaller. Therefore, if the project requires increased manufacturing accuracy, choose cold-rolled products.

The main disadvantage of such pipes is their higher price . They are usually more expensive than hot rolled ones. However, some projects require just such products. Therefore, if manufacturing accuracy is not a critical factor for the project, it is more advisable to give preference to hot-deformed ones due to their lower price.

GOST standards and types of rolled metal products

The production method in this case depends on the requirements of GOST. For example:

- GOST 9941 81 defines the production method that results in stainless steel electric-welded pipes.

A narrow ribbon is created from the raw material, and it is wound onto a drum shaft. In it, the future pipe blank is bent into a cylinder. Its extreme parts are welded using one of the welding methods.

This can be an electric arc, an electron beam, the use of high-frequency points, plasma or laser. The “bundles” option in the manufacture of electric-welded stainless pipes is not used very often, as it is quite expensive, because all technical processes are performed in a vacuum.

Electric-welded metal products are used for the manufacture of pipelines and various structures.

The length of electric-welded pipes is as follows: measured length - from 5 to 9 meters; unmeasured length - from 1.5 to 9 m. The limit deviation in the length of types of short and measured lengths cannot exceed +15 mm.

The specified regulatory document applies to types of electric-welded pipe assortment with wall dimensions from 0.7 to 5 mm.

- Seamless stainless steel pipes are also produced in accordance with GOST.

The raw material base for a seamless product is round blanks obtained by casting or pressing. Production according to the standards includes a couple of stages of “running” through rollers. In them, the pipe receives the required dimensions and volume. Next, the seamless products are calibrated and cut into pieces of the required size.

The following types are determined by temperature conditions: cold-deformed; heat deformed; hot-deformed. The first two types of seamless pipe materials are standardized by document - 9941 81.

These are options with an external volume from 0.6 to 27.4 cm, and wall dimensions from 0.3 to 21 mm. For the last type of seamless options, other standards are used, these are 9940 81. Such standards provide for volumes from 58 to 326 mm and wall thicknesses from 3.6 to 31 mm.

IMPORTANT! In practice, the production of stainless steel pipe products is not always limited by standards. By agreement with the client, products can be manufactured with other volume and wall dimensions.

Prices for stainless steel seamless pipes GOST 9941-81

The price varies depending on the wall thickness, please check the cost by calling 8

| Pipe Ø 6 | GOST | 9941-81 | 12x18n10t | 6 | from 4 to 6 | On request |

| Pipe Ø 8 | GOST | 9941-81 | 12x18n10t | 8 | from 4 to 6 | On request |

| Pipe Ø 10 | GOST | 9941-81 | 12x18n10t | 10 | from 4 to 6 | On request |

| Pipe Ø 12 | GOST | 9941-81 | 12x18n10t | 12 | from 4 to 6 | On request |

| Pipe Ø 14 | GOST | 9941-81 | 12x18n10t | 14 | from 4 to 6 | On request |

| Pipe Ø 16 | GOST | 9941-81 | 12x18n10t | 16 | from 4 to 6 | On request |

| Pipe Ø 18 | GOST | 9941-81 | 12x18n10t | 18 | from 4 to 6 | On request |

| Pipe Ø 20 | GOST | 9941-81 | 12x18n10t | 20 | from 4 to 6 | On request |

| Pipe Ø 21 | GOST | 9941-81 | 12x18n10t | 21 | from 4 to 6 | On request |

| Pipe Ø 22 | GOST | 9941-81 | 12x18n10t | 22 | from 4 to 6 | On request |

| Pipe Ø 25 | GOST | 9941-81 | 12x18n10t | 25 | from 4 to 6 | On request |

| Pipe Ø 27 | GOST | 9941-81 | 12x18n10t | 27 | from 4 to 6 | On request |

| Pipe Ø 28 | GOST | 9941-81 | 12x18n10t | 28 | from 4 to 6 | On request |

| Pipe Ø 30 | GOST | 9941-81 | 12x18n10t | 30 | from 4 to 6 | On request |

| Pipe Ø 32 | GOST | 9941-81 | 12x18n10t | 32 | from 4 to 6 | On request |

| Pipe Ø 34 | GOST | 9941-81 | 12x18n10t | 34 | from 4 to 6 | On request |

| Pipe Ø 35 | GOST | 9941-81 | 12x18n10t | 35 | from 4 to 6 | On request |

| Pipe Ø 36 | GOST | 9941-81 | 12x18n10t | 36 | from 4 to 6 | On request |

| Pipe Ø 38 | GOST | 9941-81 | 12x18n10t | 38 | from 4 to 6 | On request |

| Pipe Ø 40 | GOST | 9941-81 | 12x18n10t | 40 | from 4 to 6 | On request |

| Pipe Ø 42 | GOST | 9941-81 | 12x18n10t | 42 | from 4 to 6 | On request |

| Pipe Ø 45 | GOST | 9941-81 | 12x18n10t | 45 | from 4 to 6 | On request |

| Pipe Ø 48 | GOST | 9941-81 | 12x18n10t | 48 | from 4 to 6 | On request |

| Pipe Ø 50 | GOST | 9941-81 | 12x18n10t | 50 | from 4 to 6 | On request |

| Pipe Ø 51 | GOST | 9941-81 | 12x18n10t | 51 | from 4 to 6 | On request |

| Pipe Ø 56 | GOST | 9941-81 | 12x18n10t | 56 | from 4 to 6 | On request |

| Pipe Ø 57 | GOST | 9941-81 | 12x18n10t | 57 | from 4 to 6 | On request |

| Pipe Ø 60 | GOST | 9941-81 | 12x18n10t | 60 | from 4 to 6 | On request |

| Pipe Ø 65 | GOST | 9941-81 | 12x18n10t | 65 | from 4 to 6 | On request |

| Pipe Ø 68 | GOST | 9941-81 | 12x18n10t | 68 | from 4 to 6 | On request |

| Pipe Ø 76 | GOST | 9941-81 | 12x18n10t | 76 | from 4 to 6 | On request |

| Pipe Ø 89 | GOST | 9941-81 | 12x18n10t | 89 | from 4 to 6 | On request |

| Pipe Ø 95 | GOST | 9941-81 | 12x18n10t | 95 | from 4 to 6 | On request |

| Pipe Ø 102 | GOST | 9941-81 | 12x18n10t | 102 | from 4 to 6 | On request |

| Pipe Ø 108 | GOST | 9941-81 | 12x18n10t | 108 | from 4 to 6 | On request |

| Pipe Ø 114 | GOST | 9941-81 | 12x18n10t | 114 | from 4 to 6 | On request |

| Pipe Ø 121 | GOST | 9941-81 | 12x18n10t | 121 | from 4 to 6 | On request |

| Pipe Ø 127 | GOST | 9941-81 | 12x18n10t | 127 | from 4 to 6 | On request |

| Pipe Ø 133 | GOST | 9941-81 | 12x18n10t | 133 | from 4 to 6 | On request |

| Pipe Ø 159 | GOST | 9941-81 | 12x18n10t | 159 | from 4 to 6 | On request |

| Pipe Ø 168 | GOST | 9941-81 | 12x18n10t | 168 | from 4 to 6 | On request |

| Pipe Ø 219 | GOST | 9941-81 | 12x18n10t | 219 | from 4 to 6 | On request |

| Pipe Ø 273 | GOST | 9941-81 | 12x18n10t | 273 | from 4 to 6 | On request |

| Pipe Ø 377 | GOST | 9941-81 | 12x18n10t | 377 | from 4 to 6 | On request |

Steel grade AISI 321

The greatest demand is for seamless stainless steel pipes made from “food grade” steel. Imported steel AISI 321 is an analogue of Russian 12Х18Н10Т. This steel belongs to the class of chromium-nickel steels of the austenitic class.

Seamless pipes made of AISI 321 steel can withstand temperatures ranging from - 196 ° C to + 600 ° C under normal conditions, and when operating in aggressive environments, the temperature at which the operating condition will be maintained should not exceed 350 ° C.

Seamless pipes made of steel 12Х18Н10Т can be welded by any type of automatic or manual welding, which is due to the low carbon content in its composition.

The first digit in the name of steel indicates the percentage of carbon in it. 12Х18Н10Т contains 0.12% carbon. First of all, the difference between grade 12Х18Н10Т and other stainless steels is the presence of titanium “Ti” in its composition.

This element creates more stable compounds with carbon molecules than chromium. Alloying with titanium makes the alloy resistant to intergranular corrosion.

That is, alloys with titanium have a longer service life than other grades of stainless steel.

Assortment

According to current standards, seamless stainless steel pipes are produced according to the outer diameter and wall size (for diameter dimensions, see GOST 9941-81 and GOST 9940-81).

- Pipe length:

- According to the length of the pipe they are made:

- measure;

- multiple measure;

- limited length within the limits of measurement;

- LDL from 1.5 meters to 10 meters;

Cracks, films, sunsets, and flaws are not allowed on the inner and outer surface of a seamless stainless steel pipe. According to the standards, some of the defects can be removed by local grinding, grinding, turning or boring, if, as a result of the work carried out, the wall thickness or diameter does not go beyond minus deviations.

Profile stainless steel

Stainless steel profile pipe GOST 8642-68 is a type of rolled metal.

The profile pipe product differs according to the production method, these are the following options:

- electric welded;

- seamless;

- hot rolled;

- cold rolled.

Further division of these products occurs according to processing options, these are:

- matte assortment;

- polished types;

- products with a mirror surface.

The main application of profile products is the construction sector. This pipe is hollow inside, but has four stiffeners. This arrangement of profile options gives these products high elasticity.

Indicators for bending and twisting in this situation are not at all inferior to the characteristics of a metal bar of similar size. And at the same time, it should be noted that the material consumption and weight of the pipe are significantly reduced. Based on these facts, the benefits of using such materials are obvious.

The profile pipe is used in the construction of frames, partitions, and in the design of decorative structures. These durable products do not pose problems during welding work. They also do not require additional protective and decorative coating.

Watch the video

The beautiful appearance of the products in this range makes them a priority when choosing an option for architectural design and decoration.

Rectangular and square stainless steel

Rectangular stainless steel pipes manufactured in accordance with GOST are in great demand on the rolled metal market. Square stainless steel pipes GOST 8639 are in equally high demand.

They make rectangular and square products from different grades of authentic steel. According to the processing method, this assortment can be matte, polished and mirror.

The main characteristics of rectangular and square pipe materials, regardless of the type of surface part, are:

- long period of use;

- resistance to the influence of corrosive formations;

- ease of installation work.

To create any metal structures, it is difficult to find a better option than rectangular and square pipes. Various structures, supports, frames, towers, and much more are erected from it.

Such materials make it possible to significantly reduce the cost of building materials. In addition, square pipe products are widely used in the petroleum, medical and food fields.

The great popularity of rectangular and square pipe-rolling materials is dictated by their distinctive ability to maintain their original characteristics for a long period, and they are not lost at all when the products are used with aggressive substances.

The advantages of a rectangular stainless steel pipe manufactured in accordance with GOST are as follows:

- Rectangular products are convenient for transportation and storage.

- The rectangular grade is characterized by high corrosion resistance and specific characteristics due to alloying additives in the steel.

- The excellent quality of the rectangular surface gives the products a presentable appearance.

- The convenient rectangular hollow shape allows the assembled structure to be rationally positioned in the building.

Requirements for this range

Stainless steel pipes GOST 9941 81 are manufactured in compliance with the following requirements:

- The extreme parts of the finished product are cut at right angles, and they are carefully cleaned of burrs. This sometimes causes a slight roughness to appear on the surface and a chamfer is formed. The described standards allow the presence of such formations. Often, customers specifically discuss with the manufacturer the presence of a chamfer on a product that has a wall thicker than five mm, as this makes it possible to more effectively fasten the structure together by welding.

- On a meter-long piece, these pipes may have a slight curvature. This is two millimeters for a structure with a wall of 0.05 cm and a cross-section of 1.5 cm. It is also one millimeter for options with a wall of more than 0.05 cm and a cross-section of more than 0.5 cm.

- The steel grades taken for the work for these pipes may contain small inclusions of metals belonging to the rare earth group. But sulfur may contain no more than 0.02%.

- All finished products must undergo heat treatment. This is not carried out only by individual agreement with the consumer. In this case, the curvature and mechanical characteristics of the goods are discussed with each client separately.

- The presence of sunsets, both on the outside and on the inside of this assortment, is not allowed. There should also be no cracks or flaws. When removing these defects, the dimensions of these tubular products should not exceed the limits stated by the requirements.

How is finished goods accepted?

Stainless steel pipe GOST 9941 81 is accepted in batches. They are assembled according to the thermal finishing option, the original alloy and geometric shapes. One batch of stainless steel goods cannot contain more than 200 tubular products.

Quality control of stainless steel products includes the following procedures:

- Check for intergranular corrosion. For control, two pipe blanks are taken from the batch.

- Distributing and flattening. One tubular product is taken for testing.

- Stretching. Two blanks are taken for this test.

If all testing procedures were successful, then such a batch of stainless steel goods is considered to be of high quality. If the testing reveals unsatisfactory quality, then another check is carried out - this is an ultrasonic examination, hydrotesting and analysis of geometric dimensions. And the final size check is carried out on the entire batch of stainless steel products without sampling.

Products 19277

GOST 19277 73 defines seamless stainless steel pipes. In this case, there is no welding seam, therefore, the strength of the finished product is many times higher. GOST 19277 73 applies to the following options: cold-deformed, heat-deformed and hot-deformed.

Pipe metal products GOST 19277 73 show all the best indicators of types of steel products.

Pipe products GOST 19277 73 are produced:

- thin-walled options;

- thick-walled assortment;

- capillary pipe rolling.

The features in this case are as follows: with a similar external volume, this assortment has a greater wall thickness than options produced by the electric welding method.

Accordingly, these products are characterized by a higher strength index and the ability to withstand heavy loads. On larger walls of steel grade GOST 19277 73, you can make a threaded joint and use special reinforcement.

In terms of length, these options are produced in unmeasured form. Their size range ranges from 1.5 to 10 meters. Small volumes include options from 8.9 to 10.8 cm, they are made in segments of seven meters. Large-diameter species reach nine meters in length.

Stainless steel pipes GOST 19277 73 are used in conventional and nuclear energy, in aircraft and automotive industries. They can be found in the oil refining and gas industries. In addition, they are indispensable in various sectors of the national economy.

Dimensions

The dimensions and dimensions of stainless steel pipe assortments can be viewed in special tables that provide all the indicators in detail. Here are some of them:

- Stainless steel pipe GOST 9941 81 has the following dimensions: external volume from 5 to 273 mm. Seamless blanks according to the same standards have a wall thickness of 0.2 to 22 mm.

- This rolled pipe according to GOST dimensions is characterized by a weight that depends on the actual volume and dimensions of the walls, as well as the presence of a coating. For example, similar dimensions of the galvanized version will differ in heavier weight.

All products, which are distinguished by their compliance with standards, have precise dimensions and excellent characteristics. But, when choosing, you need to be able to navigate the wide range of offers from manufacturers. And consultants can help with this, ready to come to the client’s aid at any moment.

Watch the video

Areas of use

Stainless steel pipe GOST 9941 81 has unique characteristics that determine the use of these products. They can be seen:

- In the food industry.

- In the heating and water supply lines.

- In the energy industry.

- In chemical production.

- In medicine.

- When decorating the interior.

- Car structure.

- Sudo - mechanical engineering.

To what has been said, we can add that such communications last forever and look presentable. You can choose any fitting connections for such a water supply system, but most often welding is used for connection.

In the food industry, seamless types of pipe rolling are often used. In addition, the assortment must be polished not only on the outside, but also on the inside. All for the reason that a smooth surface is a bad option for the growth of bacteria and fungi.

Chemical production. In this case, the determining factor is the strength of the pipe assortment and its ability to withstand aggressive chemical substances.

The resistance of stainless steel structures to high temperatures is successfully used in the energy industry; here they can withstand loads exceeding a thousand degrees.

No less often you can find this rolled metal in decorative design. And here, presentable appearance and wear resistance come first. It is clear that only a range with a treated surface part is suitable for such purposes.

When talking about the use of this pipe range, we cannot ignore medicine. The chemical stability of this rolled metal has found its application here.

It is an excellent material for implants inserted into prostheses. By the way, it will be said that the most popular type of such tubular product is an ordinary medical syringe (i.e. its needle).

Stainless steel pipe GOST 8639 is actively installed in a wide variety of pipelines. This is facilitated by the excellent resistance of these products to corrosion processes and ease of use. This unique type of assortment has gained its popularity well deservedly.

Types of seamless pipes made of steel grade 12Х18Н10Т

The requirements of GOST 9941-81 cover not only 12Х18Н10Т pipes, but also seamless tubular products manufactured by cold and warm deformation methods from other grades of general-purpose stainless steels. According to the provisions of the specified GOST, the range of such pipes consists of products whose outer diameter is in the range of 5–273 mm, and the walls have a thickness from two tenths to twenty-two mm. The requirements of GOST 9941-81 concern not only the geometric parameters of seamless stainless steel pipes, but also the technical characteristics of such products.

The permissible length of stainless pipes transferred to warehouses or consumers, which is also specified by GOST, is determined by their outer diameter and wall thickness.

Length requirements for stainless steel pipes

In the standard version, this parameter can be in the range of 4–7 m, but GOST 9941-81 also allows that seamless stainless steel pipes can be supplied to consumers in the following lengths.

- Pipes, the wall thickness of which does not exceed half a millimeter, have an unmeasured length. In this case, the minimum length of such pipes cannot be less than 0.75 m, and the maximum should not exceed the largest standard value.

- Pipe products with a wall thickness in the range of 0.5–1 mm are made of unmeasured length, the value of which does not exceed 1 meter and the maximum standard value.

- Pipes with a wall thickness of more than 1 mm have an unmeasured length, the length of which is in the range of 1.5–12.5 m.

- They also produce stainless steel pipes of measured length, the minimum value of which does not exceed the lengths of unmeasured products, and the maximum value does not exceed the maximum length specified by GOST. For pipe products whose length corresponds to this category, the maximum maximum deviation of this parameter should not exceed 15 mm. The regulatory document allows that the length of measuring pipes may be greater than the parameters specified by the standard, but for the production of such products a preliminary agreement between the manufacturer and the consumer is necessary.

- There are pipes with a length that is a multiple of the measured length, and the smallest value of such a multiple, in accordance with the provisions of GOST 9941-81, is 300 mm. When producing such pipe products, it is allowed to leave an allowance on each side of the cut, the value of which should not exceed 5 mm. In addition, the standard stipulates the maximum deviation from the full length of such products, which should not exceed +15 mm.

- If the consumer needs stainless pipes whose length exceeds 12.5 m, GOST allows the possibility of their production, but this must also be previously agreed with the manufacturer.

- Tubular products, the outer diameter of which does not exceed 25 mm, by agreement between the customer of such products and its manufacturer, can be produced with a length of up to 16 m.

Stainless steel boiler pipe KVD 57x4, length 6.5 meters

GOST 9941-81 classifies pipes 12Х18Н10Т and products made from other steel grades, not only according to their lengths and other geometric parameters, but also according to their degree of accuracy. Thus, seamless pipes made of stainless steel alloys can meet normal, high and increased precision.

The geometric parameters of seamless pipe products are associated with the maximum deviations of their wall thickness, as well as their outer diameter. GOST 9941-81 also regulates the amount of permissible curvature of rolled pipes of the seamless category, which, if measured on a pipe section 1 meter long, cannot exceed:

- 1 mm – for pipes of any diameter, the wall thickness of which is half a millimeter or more;

- 2 mm - for pipes with a wall thickness of less than half a millimeter and an outer diameter exceeding 15 mm.

Visual inspection of the pipe surface is one of the stages of quality control

For stainless steel seamless pipes with an outer diameter of less than 15 mm, the wall thickness of which does not exceed half a millimeter, such a parameter as the amount of permissible curvature is not specified in the standard. The only requirement is that there should be no sharp kinks on their surface.

The ends of seamless pipes, according to GOST 9941-81, must be cut strictly at an angle of 90°, and after such cutting they must be cleaned of burrs. When cleaning, roughness and chamfer may form on the surface of the pipes, the presence of which is allowed by the standard. The consumer of pipes whose wall thickness exceeds 5 mm, if necessary, can specify that their cut ends must be specially chamfered for welding.

Pipe production methods

Stainless steel pipes are a derivative product of rolled metal. Based on the production method, the following types of stainless pipes are distinguished:

- Hot-deformed;

- Cold-worked;

- Heat deformed;

Products can be made from flat rolled products, which are subjected to technological bending and subsequent welding. Welded pipes are produced in this way. For seamless pipes, the starting material is a stainless steel circle, and in this case, piercing, rolling and calibration are used in the manufacture of the pipe. Stainless steel seamless pipe as a solid product has increased strength and high mechanical properties.

Scope of application of seamless steel pipes

Seamless technology is one of the main methods for producing thin-walled and thick-walled stainless steel pipes with a precise internal channel. They apply:

- in high pressure installations;

- in power plants;

- in mechanical engineering and aviation industry;

- in the chemical and food industries;

- in gas and oil pipelines.

The scope of their application is wide and covers highly specialized types of production and industry.

Classification

Stainless steel pipes vary in geometric characteristics depending on the diameter and cross-sectional shape of the pipe, as well as the type of surface treatment. The cross-sectional shape of the pipes can be round, square and rectangular. According to the type of processing, they are divided into:

- Matte

- Sanded

- Polished

The thickness of the pipe wall allows stainless steel pipes to be divided into thick-walled with great strength and thin-walled. Thin-walled pipes are characterized by high flexibility, so they are necessary for the manufacture of complex structures.

Requirements of GOST 9940-81

Stainless steel alloy grade 12Х18Н10Т is also used for the production of seamless pipes in accordance with GOST 9940-81. According to this regulatory document, seamless tubular products are manufactured by hot deformation, for which general purpose stainless steels are used.

Seamless pipes, which are produced in accordance with GOST 9940-81, can have diameters in the range of 57–325 mm and wall thicknesses of 3.5–32 mm. The standard length of such pipes, which can meet normal and high degrees of accuracy, can range from 3 to 8.5 meters. The provisions of GOST 9940-81 also stipulate the remaining geometric parameters of pipes of this category, the physical and mechanical properties of the material from which they are made, the maximum permissible deviations in the curvature of the surface of the products, their outer diameter and wall thickness.

Permissible deviations in the geometric dimensions of pipes depend on the manufacturing accuracy

In terms of the requirements for the chemical composition of the material for manufacturing seamless stainless steel pipes, GOST 9940-81 differs little from the provisions of the previous regulatory document. The mass of pipes can be determined using the same method presented above.

The state standard number 9940-81 stipulates that seamless pipes made of stainless steel, depending on the wishes of the customer, may or may not be subjected to heat treatment and meet additional requirements for their resistance to intergranular corrosion. In addition, consumers of pipes of this type can additionally negotiate with their manufacturer the testing methods for such products, which are carried out according to the methods specified by the provisions of GOST 9941-81.

Stainless steel seamless pipe is used most often for transporting various types of liquids and gases

A significant difference between GOST 9940-81 and the standard number 9941-81 is that its requirements do not provide for mandatory heat treatment of seamless stainless steel pipes. This is explained by the fact that pipes that meet this standard, as mentioned above, are produced by hot deformation, and this already implies that the material for their manufacture has been subjected to significant thermal effects. The latter is necessary to facilitate plastic deformation of the pipe material and at the same time gives it the required physical and mechanical properties.

It should be noted that the differences in the characteristics of seamless stainless pipes produced in accordance with GOSTs 9940-81 and 9941-81 are precisely explained by different manufacturing technologies. Thus, seamless stainless steel pipes produced by hot deformation are distinguished by good ductility and flexibility, but have less strength and resistance to mechanical stress than cold- and heat-deformed ones. For example, you can compare the following parameters of pipes made of stainless steel alloy grade 12Х18Н10Т, produced in accordance with GOSTs 9940-81 and 9941-81:

Comparison of stainless pipes produced using different technologies

Due to their increased strength, seamless stainless pipes manufactured by cold and warm deformation methods, regardless of their geometric parameters, must withstand the rated load specified by the requirements of the regulatory document. This is precisely why pipe rolls of this category can be produced with smaller outer diameters and wall thicknesses than products manufactured in accordance with GOST 9940-81. Thus, if we compare cold- and heat-deformed pipes with hot-rolled products of the same outer diameter (273 mm), made of stainless steel grade 12Х18Н10Т, then the former can be produced with a wall thickness of 3–14 mm, while for the latter this parameter should be 11–20 mm. Moreover, the yield limits of such products, since they are made of the same grade of steel, completely coincide and amount to 22 kgf/mm2 (216 MPa).

From all of the above, we can conclude that cold- and heat-deformed seamless pipes made from steel grade 12Х18Н10Т are more appropriate to use in cases where high strength with low weight of pipe structures is required, and hot-rolled products will be optimal when properties are especially important are the flexibility and ductility of the pipes used.

Characteristics of electric welded pipes

International standards: electric welded pipes made of austenitic steel grades ASTM A554, A270, A312, A249, A269, DIN 17457, 17455 Seam welding type - TIG, laser seam. Surface: • Matte • Sanded (180, 320, 400 Grit) • Mirror (400,600 Grit)

Symbols for determining the surface type of an electric-welded pipe

| Surface type | Designation | |

| Matte | Matt, Mill finish | Matte |

| Sanded | Brushed | Cleaned, primary grinding |

| Satin 180 Grit Satin 320 Grit Satin 400 Grit | Grinding degree | |

| Mirror | Mirror 400 Grit Mirror 600 Grit | Polishing degree |

Shape: • round • profile Length: 6 m (custom pipes of any length can be supplied to order). Standard sizes: • diameter from 6 mm to 325 mm • cross-section from 10x10mm to 300x300mm, 400x200mm Wall thickness: from 0.8 mm to 6 mm

Characteristics of seamless pipes

International standards:

- ASTM A312 - Seamless pipes (c/c) of austenitic stainless steel grades,

- ASTM A213 - Seamless Ferritic and Austenitic Alloy Boiler Parts,

- steam superheating and heat exchange pipes.

Surface: Matte Shape: round Length: 5-7m Standard sizes: diameter from 6 mm to 325 mm Wall thickness: from 1 mm to 13 mm

Hot rolled seamless steel pipes

The hot process gives finished products the following advantages:

- Ideal anti-corrosion properties.

- Durability and resistance to impact.

- Allows the production of products with walls up to 32 mm.

- Competitive price.

Standards for pipes according to GOST 9940-81

Hot-deformed pipes are cleaned of scale and have no external defects on both surfaces.

If products are subject to further welding, then the mass fraction of sulfur in the material is normatively limited to 0.02%. Table 5. Permissible deviations along the wall.

| Maximum deviations for manufacturing accuracy, % | |

| ordinary | high |

| ±1,5 | ±1,0 % |

Table 6. Permissible deviations in diameter.

| Pipe sizes, mm | Maximum deviations for manufacturing accuracy, % | |

| ordinary | high | |

| By wall thickness, mm | ||

| 8 or less | +20 -15 | +12,5 -15,0 |

| more than 8 to 20 | ±15,0 | +12,5 -15,0 |

| more than 20 | +12,5 -15,0 | ±12,5 |

The curvature of finished hot-deformed products is established normatively. This value is indicated relative to the wall thickness per 1 m of pipe and is:

- with a wall less than or equal to 10 mm: 1.5 mm;

- with a wall of 10-20 mm: 2 mm;

- with a wall more than 20 mm: 4 mm.

The standard's requirements for passing the hydraulic test, tensile test and others are similar to the tests established for products produced by the cold-deformed method.

Hot rolling steel technology

Unlike the cold rolling method, which involves heat treatment of blanks and products at some stages, the hot rolling method is completely carried out on heated metal. For this purpose, special furnaces with a so-called walking hearth are used, in which an excess pressure of up to 29.4 Pa is formed.

Next, the workpiece goes through several deformation stages:

- crimping machine;

- piercing mill, in which the workpiece becomes a pipe with walls;

- rolling on a continuous mill;

- induction heating and reduction mill.

After reduction, the finished pipes are cooled and cut into the required lengths.

Dimensions of seamless pipes GOST 9940-81 - table

GOST has introduced additional restrictions on the diameter of products for some steel grades:

- 108 mm - 08Х20Н14С2, 08Х22Н6Т, 08Х18Н12Б.

- 140 mm - 08Х17Н15М3Т.

- 168 mm - 10Х23Н18.

- 219 mm - 10Х17Н13М2Т, 15Х28, 08Х17Т, 12Х17.