Main characteristics of the mechanical properties of non-ferrous metal alloys

- E - modulus of elasticity - proportionality coefficient between normal stress and elongation;

- G - shear modulus (tangential elastic modulus) - proportionality coefficient between shear stress and relative shear;

- μ - Poisson's ratio - the absolute value of the ratio of transverse to longitudinal deformation in the elastic region;

- σт — yield strength (conditional) — the stress at which the residual deformation after removing the load is 0.2%;

- σв - temporary resistance (tensile strength) - tensile strength;

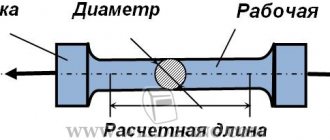

- δ - relative elongation - the ratio of the absolute residual elongation of the sample after rupture to the initial calculated length;

- hardness (HB, HRC, HV).

Mechanical properties of aluminum alloys

To designate the states of deformable alloys, the following designations are accepted: M - soft, annealed; P - semi-hardened; N - hard-worked; T - hardened and naturally aged; T1 - hardened and artificially aged for high strength; T2 - hardened and artificially aged in a mode that provides higher values of resolution viscosity and stress corrosion resistance compared to mode T1; T3 - similar to T2 with improved properties. The letter “h” in the designation of the alloy grade indicates increased purity of the alloy (in terms of impurity content). Deformable aluminum alloys are divided into non-hardening and hardening by heat treatment.

Mechanical properties of aluminum wrought alloys

E = 70...72 GPa, G = 27...28 GPa, Poisson's ratio μ = 0.31...0.33.

| Alloying system | Alloy, condition | Semifinished | Tensile strength σв, MPa | Yield strength σт, MPa | Hardness HB, MPa |

| Al-Mg | AMg5M | Rod, stamping | 300 | 160 | HB 650 |

| Al-Mg | AMg6M | Forging | 300 | 150 | — |

| Al-Mg | AMg6N | Sheet | 400 | 300 | — |

| Al-Cu | D16 and D16P | Sheet | 440 | 290 | — |

| Al-Cu | D16 and D16P | Profiles | 420-500 | 400-440 | — |

Rules for marking aluminum alloys

It is quite difficult to determine the grade of material, so aluminum alloys are marked in such a way that it is clear that this is what they are. A number is assigned to each train. It has an alphanumeric designation.

There are several features inherent in marking:

- At the beginning of the number there are several letters indicating the composition of the material.

- Then comes the digital ordinal code.

- The ending is a number indicating the peculiarities of the treatment (for example, thermal).

To better understand the marking process, consider the example of the D17P alloy. According to the rule, the first letter tells us about the composition of the alloy. D – duralumin. The chemical composition of all duralumin is the same; the differences lie in the concentration of its main elements. The number 17 following the letter D indicates the serial number of a material that has certain qualities. The last letter, in this case P, indicates a semi-hardened alloy. That is, the method of processing the material is pressure without preheating it. Consequently, the strength of the material obtained during such processing will be two times lower than the maximum.

Mechanical properties of titanium alloys

Titanium has the following advantages over other structural metals: low specific gravity, high mechanical properties over a wide temperature range, lack of cold brittleness and good corrosion resistance. The strength and plastic properties of unalloyed titanium are determined by the content of impurities of oxygen, nitrogen and, to a lesser extent, carbon, iron and silicon. Particularly strong titanium has a tensile strength of 251 MPa, a yield strength of 104 MPa, a relative elongation of 72% (at a gauge length of 13 mm) with a transverse contraction of 86.2%. Based on their structure, titanium alloys can be divided into four groups. 1) Alloys with α-structure, which include technical titanium and alloys based on it of the titanium-aluminium system. In addition to aluminum, these alloys may contain neutral elements such as tin and zirconium. The advantages of these titanium alloys are their excellent fusion weldability, good ductility and high strength at cryogenic temperatures. 2) Two-phase alloys with a predominance of α-structure, containing approximately 2% of elements from the group of β-stabilizers; These alloys have higher technological ductility. 3) Two-phase alloys containing more than 2% β-stabilizers have good ductility after annealing or quenching and high strength after quenching and aging. They weld worse than the alloys of the first two groups; after welding, annealing is required, which can be combined with the aging regime. These titanium alloys have higher strength at room and elevated temperatures than the alloys of the first two groups. 4) Alloys with a predominant β-structure due to the cubic lattice are very plastic at room temperature, not much inferior to technical titanium. Another advantage of alloys in this group is the ability to achieve extremely high levels of strength through heat treatment.

E = 110...120 GPa, G = 42...45 GPa, Poisson's ratio μ = 0.31...0.34.

| Alloying system | Alloy | Semifinished | Tensile strength σв, MPa | Yield strength σт, MPa |

| VT1-1 | 99.04% Ti | Low strength alloy after annealing. | 450-600 | 380-500 |

| Ti—Al | VT5 | Medium strength alloy after annealing. | 750-950 | 650-700 |

| Ti - Al - V | VT6 | High-strength alloy after hardening and aging. | 1150 | 1050 |

Mechanical properties of copper alloys

Copper alloys are divided into two main groups: brass and bronze. Brasses are alloys alloyed with zinc. There are simple and special brasses. Plain brasses (dual alloys) are marked with the letter L, followed by the percentage of copper content. In the designation of special brasses, the letter L is followed by capital letters of alloying elements and the percentage of copper content, then through a dash - the percentage of each alloying element. Bronzes are alloys alloyed with various elements except zinc. Bronze is marked with the letter Br, otherwise the marking system for brass is repeated. Alloys in which the main alloying element is nickel are called copper-nickel and have special names. Wrought copper alloys are supplied in soft (annealed and hardened), semi-hard (compression 10-30%), hard (compression 30-50%) and extra-hard (compression more than 60%) states. Alloys based on tin or lead - babbits , are marked with the letter B, followed by a number indicating the tin content in the alloy.

Nuances of choosing aluminum alloys

The choice of aluminum alloy to be used as a structural material must ensure the strength of the structural element produced from it. But different properties of the structural material are responsible for the strength of different types of parts of the product.

An example would be “thick” and “thin” columns. In the first, the strength largely depends on the yield strength of the alloy. And for the second - from the modulus of elasticity of the metal. Aluminum alloys have a yield strength comparable to that of ordinary structural steels. And they, in principle, could compete with the latter for the manufacture of “thick” columns. But aluminum and alloys have an elastic modulus equal to about a third of that of steel, which does not give them the opportunity to replace steel in “thick” columns.

The performance characteristics of a structure include not only its strength. Corrosion resistance, easy processing (weldability and compressibility), relative elongation (plastic fracture), elastic modulus (product rigidity), fatigue strength, product density (its weight), and cost are also important. All of them, to one degree or another, influence the choice of structural material.

Mechanical properties of wrought brasses

E = 105…115 GPa.

| Brass type | Brass grade | State | Tensile strength σв, MPa | Yield strength σт, MPa | Relative elongation δ, % | Hardness HB, MPa |

| Simple | L96, L90 | Soft condition | 240-260 | 120 | 50 | HB 550 |

| Simple | L96, L90 | Solid state | 450-470 | 400 | 2,5 | HB 1350 |

| Aluminum | LAZ60-1-1 | Soft condition | 450 | 200 | 50 | HB 550 |

| Aluminum | LAZ60-1-1 | Solid state | 700 | — | 8 | HB 1700 |

| Tiny | LO90-1 | Soft condition | 240-260 | 85 | 45 | HB 570 |

| Tiny | LO90-1 | Solid state | 520 | 450 | 4,5 | HB 1450 |

| Lead | LS74-3, LS64-2, LS63-3 | Soft condition | 300-400 | 120 | 40-60 | HB 500-700 |

| Lead | LS74-3, LS64-2, LS63-3 | Solid state | 550-700 | 500 | 2-6 | HB 1000-1200 |

| Lead | LS59-1 | Soft condition | 400 | 140 | 45 | HB 900 |

| Lead | LS59-1 | Solid state | 650 | 450 | 16 | HB 1400 |

Disadvantages of aluminum wires

To understand what aluminum cable products actually are, let’s consider its main disadvantages:

- electrical conductivity. If we take the silver index as 100, then the electrical conductivity of aluminum is 55 (copper – 94). This value is not bad, but remember that the purity of the metal content in the conductor is quite difficult to achieve, and the presence of all kinds of impurities seriously reduces the conductivity. An important point is the fact that the value of this indicator directly affects the cross-section of the product that is selected for a specific electrical project (i.e., an aluminum cable will be much thicker than a copper one). This feature partially offsets the weight advantage of aluminum,

- oxidation. Upon contact with air, a layer of refractory dielectric is formed on the surface of aluminum conductors, especially at the joints, in the form of a dark-colored film, which protects the wire from further chemical destruction, but increases resistance and heatability, and also reduces the value of the useful cross-section and worsens the contact. The consequences are not encouraging: melting of connections, electrical circuit breakage and decreased reliability of power supply. The problem area needs to be found, tighten the contact or change the clamp, every second risking damage to the heated conductor. Then the cable will generally need to be replaced, which is not always technologically possible,

- the mechanical strength of aluminum conductors is significantly less than that of copper (Brinell hardness 25 and 45-110 kgf/mm2, respectively), which means that the aluminum conductor cannot be clamped too tightly or bent frequently. Those who have independently replaced a socket, switch or chandelier remember that an aluminum electrical core often breaks “at the root”,

- The flexibility of aluminum wire is also not very high, therefore, given its relative fragility, the laying of such wires always requires special care. When buying an aluminum cable in a store, you can try to bend it 4-5 times and look at the exposed core - if it is covered with cracks, then the conductor material is of very poor quality,

- Installation difficulties begin when, in order to achieve the required conductivity parameters, you have to choose an aluminum cable with a much larger cross-section. Thick wires are known to be much more difficult to work with, especially on difficult routes full of sharp corners and narrow places,

- heat. The specific heat capacity of aluminum is 0.9 kJ/kg*K (0.39 for copper), so aluminum conductors overheat much faster, deteriorate and become even more brittle, and the insulating layer of cables dries out and ceases to perform its functions. As a result, the electrical network may short out and a fire may occur. It should be remembered that under a screw clamp, aluminum has the property of thermal expansion, which can lead to its further deformation, and therefore to weakening of the contact, up to burning out,

- specific electrical resistivity. And according to this indicator, aluminum is inferior to copper. Its value for aluminum conductors is 0.27 Ohm*mm2/m, while for a copper conductor it is almost 2 times less - 0.017,

- service life is one of the main criteria by which the material for electrical wiring is selected. Aluminum cables can function effectively and relatively trouble-free for 20-25 years, while copper conductors can operate for 30-50 years in similar conditions.

For a more clear idea of what these metals are, watch the video What is the difference between aluminum and copper? The topic is covered quite well in the video Copper and aluminum electrical wiring. Let's debunk the myths.

Mechanical properties of wrought bronzes

E = 92…130 GPa.

| Bronze | State | Tensile strength σв, MPa | Yield strength σт, MPa | Relative elongation δ, % | Hardness HB, MPa |

| BrAMts9-2 | Soft condition | 450 | 200 | 30 | HB 1100 |

| BrAMts9-2 | Solid state | 800 | 500 | 4 | HB 1800 |

| BrAZH9-4 | Soft condition | 450 | 220 | 40 | HB 1100 |

| BrAZH9-4 | Solid state | 700 | 350 | 4 | HB 2000 |

Mechanical properties of copper-nickel alloys

E = 120…145 GPa.

| Name | Alloy | State | Tensile strength σв, MPa | Relative elongation δ, % |

| Cupronickel | MNZHMts30-0.8-1 | Soft condition | 400 | 45 |

| Cupronickel | MNZHMts30-0.8-1 | Solid state | 600 | 4 |

| Cupronickel | MH19 | Soft condition | 350 | 40 |

| Cupronickel | MH19 | Solid state | 550 | 4 |

| Kopel | MNMts43-0.5 | Soft condition | 420 | 38 |

| Kopel | MNMts43-0.5 | Solid state | 650 | 3,5 |

| Constant | MNMts40-1.5 | Soft condition | 430 | 28 |

| Constant | MNMts40-1.5 | Solid state | 670 | 2,5 |