What is a high strength bolt

This type of fastening has several classifications, but the most significant characteristic is increased resistance to heavy loads. Thanks to this, the structures connected by bolted fasteners become highly strong and durable. High-strength bolts, nuts and washers are widely used for metal structures, construction work and in heavy industry and mechanical engineering.

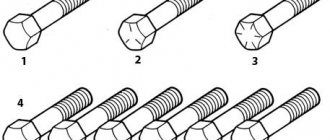

A bolt is a rod made of a metal alloy with an external thread applied to it and a head, usually in the form of a hexagon, for a wrench. Fastening is done by screwing on a nut of the required size. To distribute the load evenly, washers are used.

Bolt designation

For a long time, competing manufacturers used their own standards. This system has undergone a number of major changes, after which all parts began to meet certain parameters and be labeled according to them. This provision was necessary in a rapidly developing industry, in which the lack of standards complicated the production process.

At the moment, there are three unified standards, according to which markings are applied to bolts for ease of use:

- GOST;

- ISO;

- DIN.

The recommended designation scheme for bolts and screws according to GOST is used in the CIS countries. Quality standard requirements apply to food, manufactured goods, clothing, etc. ISO is an international metric system adopted in 1964. Currently, this standard is used in many countries around the world. DIN is accepted and used in Germany. This system has several standards.

Application area

High-strength bolted connections are designed for the installation of complex building structures that will be subject to:

- high temperature changes;

- precipitation;

- strong and frequent winds;

- contact with chemicals.

Since the dimensions of fasteners provided for by GOST vary, the scope of application of hardware is extensive:

- machines, equipment;

- agricultural machinery, mechanical engineering;

- construction of bridges, buildings;

- shipbuilding;

- industry, production.

Friction connection with high-strength bolts perfectly copes with the task of strong and reliable installation of structures subject to dynamic loads and vibrations.

This fastener is widely used in everyday life. It is ideal for renovating apartments and balconies; it will securely fasten any structures to concrete walls. Car enthusiasts cannot do without such bolts when repairing their car, especially wheel fastenings.

Description

There is an official current GOST 52644-2006 for high-strength bolts. This act regulates:

- bolt dimensions;

- thread length of such fasteners;

- variations of structural elements and designs;

- twist coefficients;

- theoretical weight of each product.

They are also subject to the DIN 6914 standard. By default, this product has a hexagonal socket head. It is intended for highly stressed steel connections. The diameter of the fastener can be from M12 to M36. Their size ranges from 3 to 24 cm.

Such bolts can be used in mechanical engineering and engine building. They are also useful for areas where there is strong vibration; they can finally be used in various types of building structures. However, the correct tightening force plays an important role. Too little pressure often leads to premature failure of the connection; too much pressure can damage the fasteners or the structures being connected.

Classification by strength and marking

This fastener is manufactured strictly in accordance with GOST and is marked accordingly. It's easy to decipher:

- In terms of the strength class of the coating of the top layer of fasteners, bolted hardware occupy the best positions on a scale from 6.8 to 12.9. Marking of high-strength bolts starts from 8.8. To make it better visible, the designation of high-strength bolts is placed on the head of the fastener.

- The additional letters ХЛ on the marking next to the strength class of the bolts mean that the fasteners can be used in conditions of very low temperatures down to -60 ° C.

- Marking with the letter U limits the low temperature regime - not lower than - 40°C.

- English S informs about the increased dimensions of the bolt head.

Thanks to the markings on the head of the hardware, you can quickly select the required fastener.

Scope of application of VPB

For the most part, VPBs are used in the manufacture of cars, machine tools, in the engineering industry, in the construction of particularly important objects - bridges, tunnels, railways and are used for joining structural parts.

VPB are designed for operation in aggressive environmental conditions - with sudden temperature changes, in humid conditions, in areas near the sea. In everyday life, for household needs, VPB is used for anchoring in concrete, brick, and stone.

Steels for making bolts

For the manufacture of high-strength fasteners, alloy carbon steel of increased strength and durability is used. Special manufacturing technologies include hot or cold heading of blanks, which significantly increase the level of strength. Mandatory heat treatment in electric furnaces gives the product anti-corrosion properties, greatly increases strength, and extends service life.

Dimensions

The dimensions of high-strength bolted connections exactly correspond to GOST 52644 standards:

- Diameter of hardware in ascending order: from bolt M10 (smaller) to M48 (larger).

- Length from 40 to 300 mm.

- The weight of 1000 pieces depends on the diameter and length. It can be determined from the corresponding tables according to GOST. The mass of M16 fasteners, for example, will be 115-515 kg, M20 - 200-800 kg, and M48 - from 2500 to 5000 kg.

- The thickness of the additional coating is also regulated by GOST, depending on the diameter of the hardware. Thus, high-strength bolts M24 have a coating thickness of 40 microns, and M16 - 25 microns.

Material

The strength of the fastening element is one of the most important parameters characterizing hardware. The strength of the fastening directly depends on the type of material from which it is made. Depending on the strength characteristics, the metal for production and the mode of its heat treatment are selected.

Most often, standard bolts are made of alloy and non-alloy steel.

But in some cases they can be made of other metals, such as copper, aluminum, which are used in cases where there is no need to achieve high fastener strength.

For jewelry making, fasteners can be made from precious metals such as gold, silver and others.

Depending on the type of material used, the designation of the bolts, called assortment, depends, by studying which you can understand what the bolts are made of.

Very often, to improve the technical characteristics of hardware, a special coating is used that protects the fastening element from environmental influences (humidity, water, temperature range, chemicals).

Among the most common coatings are the following varieties:

- Zinc. The thickness of the zinc coating can vary depending on the requirements. For bolts used in household appliances, the thickness is usually small. But for industrial fasteners it is usually up to 25 microns.

- Cadmium-plated. Not a very common type of bolt, due to the toxic properties of cadmium. Therefore, they are used in rare cases when coatings made of other materials do not allow achieving the desired performance characteristics.

- Nickel. Typically used for fasteners used in furniture production. Nickel only improves decorative characteristics and practically does not change operational characteristics.

- Phosphating and oxidation. They are used to create a protective layer on the surface of bolts due to oxidation of the base metal.

- Zinc lamellar. They are becoming widespread because they can increase the service life of fasteners several times.

Strength

Strength is strictly regulated by GOST, since in some cases this affects human safety and the safety of equipment or buildings. To achieve accurate strength characteristics, high-strength bolts are calculated. The production of high-strength bolts is regulated by GOST 7798-70.

Based on their strength characteristics, bolts are divided into 11 classes. Each category has its own labeling, based on which you can clearly determine which class it belongs to and what load it can withstand.

It should be noted that each hardware has a certain margin of safety to the indicators indicated in the marking. Therefore, you should not worry that the safety margin of the bolt will be used for future use.

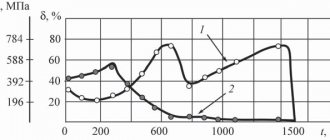

The strength of bolts depends not only on the type of material used, but also on the manufacturing technology. Based on the strength characteristics of fastening elements, we can distinguish the classification of bolts by strength:

- 3.6 – fasteners made of non-alloy steel, without additional hardening;

- 4.6 – products made of carbon steel (carbon less than 0.55%);

- 5.6 – from steel without tempering (carbon more than 0.15%);

- 6.6 and 6.8 – bolts made of carbon steel without additional additives;

- 8.8 – steel with additional components (chrome, manganese, boron) is used, which after hardening is tempered at a temperature of more than 400 degrees;

- 9.8 - practically no different from class 8.8, having an increased strength index;

- 10.9 - steel with additives is used, which is tempered in the temperature range from 340 to 425 degrees.

- 12.9 – alloy steel with a minimum content of phosphorus and sulfur is used for the manufacture of fasteners.

Based on their purpose, the following types of bolts can be distinguished:

- Ploughshare – designed for fastening heavy suspended structures. Based on the name, you can understand that it is widely used in agriculture, usually for attaching shares to tillage equipment.

- Furniture - differs from other types in that the thread is not cut along the entire length of the rod. The third part remains the usual integral part. The head of such fasteners is usually smooth, which is necessary so that the bolt does not protrude above the surface of the furniture. Despite the names, such elements are also used in other areas, especially often in construction.

- Road – widely used when installing fences. It is distinguished by a semicircular head, under which there is a square headrest. This design allows the fencing elements to be firmly fixed to the posts. It is used in all areas where there is a need to fix thin sheets of metal, wood, plastic and other materials.

- Mechanical bolts are the most common type of bolts used in mechanical engineering. It is characterized by increased strength properties and resistance to aggressive external environments.

- Track - used in the railway sector, most often for connecting individual parts of the rails. They differ in that the thread can be less than half the length of the rod.

High strength bolt technology

One of the important components in fastening technology is the clear recording of the time period after preparation and lubrication of the thread before the direct use of the fastener. This period should not exceed 10 days, which should be indicated in a special journal for installing high-strength bolts after their delivery from the manufacturer. If the preparation was carried out independently, then the data is also recorded by filling out a log. An example of the order of fastening a bolted connection:

- Prepare the entire structure for docking and installation.

- Prepare the necessary fasteners according to standards.

- Carry out installation and installation of the structure.

- Tighten the bolts.

- The joints of all fasteners are sealed.

- Carry out quality control of the assembly of the object.

Preparing High Strength Bolts, Nuts and Washers

Before installation into the structure, high-strength bolts, nuts and washers must be prepared. It includes:

- Technological cleaning of preservative factory lubricants, as well as dust and dirt. It is performed in a heated alkaline solution at a temperature of 80-100 ° C, which includes water, detergents, soda ash and caustic soda, liquid glass and trisodium phosphate. The ratio is strictly observed according to GOST. The fasteners in a special container are dipped into the solution for 20 minutes, after which they are washed 3-5 times in a washing solution.

- Drying is carried out hot for several minutes, blowing with compressed air.

- Perform running on a lathe or wrenches, checking and lubricating the threads.

- Mandatory lubrication of fastener threads is carried out by immersing it in a solution of special gasoline GOST 2084 and mineral oil GOST 0799 in a ratio of 9 to 1.

- Purified hardware is collected and stored in closed containers. When assembled, each bolt is equipped with a nut and two washers.

- Carry out quality control.

Product 2M12x1.50LH-5gx50.66.A.047 GOST 7798-70

- Product. The name of the part is written in this place: bolt, screw, stud, etc.

- The quality class is dictated by GOST, so it may not be indicated. There are three classes - A, B and C, where the designation A indicates the highest accuracy of the part.

- The number 2 indicates execution. There are only four types of execution. Execution 1 is not specified by default.

- M is a designation for the type of thread. The first letter of its name is indicated: metric, conical or trapezoidal.

- 12 - bolt diameter in millimeters.

- 1.5 - thread pitch, may not be specified if it is the main one for a thread of a given diameter.

- LH - designation that this bolt has a left-hand thread. If the product is made with a main (right-hand) thread, this will not be indicated.

- 5g indicates to what accuracy class the thread was cut. Classes can be designated by numbers from 4 to 8, with 4 being the most accurate class.

- 50 - bolt length (designation in millimeters).

- 66 — product strength class. On the head of the bolt, these indicators are placed with a dot between the numbers. There is no dot in the symbol.

- A is a characteristic of the steel used for manufacturing. In this case, it is indicated that the bolt was cast from machine gun steel. The letter C indicates that the part was made of mild steel. This parameter characterizes the strength class of the bolt. This means that the class is higher than 8.8.

- 047 indicates the type of coating and its thickness on the product. There are several types of coating - from 01 to 13. In this case, the type of coating is 04, and its thickness is 07 microns.

The symbol for fastening bolts allows you to most accurately fulfill the requirements for a particular product and design. Meeting quality standards is the key to successfully reproducing project requirements. The mark that the product complies with GOST allows you to study the properties of the part according to these documents and means its full compliance with the standards. GOST standards correspond to other unified systems. To convert from one system to another, it is enough to use the metric conversion table.

Rules for tightening BVP

Tensioning of high-strength bolts is carried out in two stages:

- Align the holes of the parts for high-strength bolts and fix the position of the structural parts using mounting plugs.

- At the first stage, bolt fasteners are inserted and plugs are removed. Next, using wrenches, the bolt fasteners are tightened only to 50-90%. At the beginning of tensioning, the fastener head must be held from turning. If it is impossible to eliminate the scrolling, the element is replaced.

- At the second stage, fastening is carried out completely, using torque wrenches. The tension of the bolts is carried out after checking the compliance of the geometry of the entire structure with respect to standards and rules, and checking the tightness of the structure's screed.

Excellent technical characteristics of connections made with high-strength bolts ensure the strength of the entire structure. If all instructions are followed, the structure will last for many decades.

Did you manage to solve your problem using the recommendations from the article?

Yes!

45.45%

No. More answers required. I'll ask in the comments now.

38.29%

Partially. There are still questions. I'll write in the comments now.

16.25%

Voted: 363

4.5. Acceptance and sealing of connections subject to their complete disassembly

4.5.1. Regardless of the tensioning method, the inspector must, first of all, carry out an external inspection of all supplied high-strength bolts and make sure that all bolts have the established markings, washers are installed under all heads and nuts; parts of the bolts protruding beyond the nut have at least one turn of thread above the nut and two below the nut; the assembled unit bears the mark of the team that performed this work ().

4.5.2. The number of bolts in the assembly that are subject to control is indicated in table. 3.

Table 3

| Number of bolts in the connection, pcs. | Number of bolts to be inspected |

| Up to 5 | 100 % |

| 6-20 | 5 pieces. |

| 21 or more | at least 25% |

4.5.3. If the control results do not comply with the requirements of clause 3.5.1. for at least one bolt, double the number of bolts is controlled. If in this case a defective bolt is detected, all bolts of this connection are checked.

Rice. 3

4.5.4. The control results, regardless of the tension method, must be entered in a special journal ().

4.5.5. The manufacturer is responsible for the quality of installation of bolts.

4.5.6 The tightness of the package tie is checked with a thickness probe. 0.3 mm against the tightened bolt in the area limited by the washer. The probe should not pass between the assembled parts into the area limited by the washer (later formed by the washer).

4.5.7. On each connection, as a rule, the mark of the team that performed the connection and the person who carried out the control is applied with a core. The mark number is assigned by order to the unit performing the connections. If the bolts are prepared by waxing, the letter “P” is placed next to the mark.

4.5.8. After acceptance of the connection by the inspector, all joints along the contour must be primed. If there is no brand of primer in the project design, it is allowed to use primers FL-03K, GF-021 with the addition of dry pigment to a consistency that prevents the primer from flowing into the bag.

4.5.9. Tools for tensioning bolts and preparing surfaces are adopted in accordance with the “Guidelines for the use of a tool kit for installing high-strength bolts.” MMSS USSR Moscow 1985 ().