Nuances of choosing fasteners

The choice of fasteners should be treated with great responsibility. This is due to the fact that their strength indicator may differ significantly. The selection is made taking into account which grade of steel bolts has more suitable performance properties. The key points include the following information:

- Type of material used in manufacturing.

- Accuracy class.

- Applied methods of thermal and chemical treatment.

High-strength bolts can be made from a variety of metals. Let's call the key points:

- In most cases, the following metals are used: 10KP, 20KP, steel 10, steel 20, 20G2R, 40X. These metals meet all established requirements for physical and mechanical properties.

- To improve performance, heat treatment can be carried out. To perform this operation, special electric ovens are used. By creating a special protective environment, the required performance qualities are ensured.

- Carbon steels are the most widely used. This is due to their relatively low cost, as well as high performance.

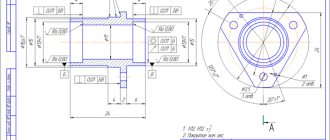

The diameter of the bolts is also an important selection criterion. Diametrical dimensions can vary over a fairly large range. With an increase in the cross-sectional area, the strength and reliability of the connection increases. The length of the bolts is considered the most important geometric indicator that must be taken into account. The materials used can have very different characteristics. For example, attention is paid to the hardness of the bolts.

Too low a value can cause deformation of the threaded surface when a longitudinal load occurs.

Before choosing the most suitable fastener, you need to take into account the features of connecting parts when using this fastening material:

- The conducted studies indicate that with the correct choice of strength class and tightening torque, the highest quality connection can be ensured. In addition, it provides protection against spontaneous unscrewing and long service life of the product.

- High-quality fasteners can withstand transverse and axial loads. In the manufacture of fasteners, special metals and alloys are used that effectively withstand loads acting in any direction.

- The installation and dismantling process is greatly simplified. It is worth considering that some metals can oxidize, and after some time it will be difficult to dismantle the structure. However, the task can be simplified by using a special substance.

- It is possible to obtain detachable connections. Very often you can encounter a situation where in order to perform various works it is necessary to disassemble the structure. To carry out dismantling work, simple tools are required, and the work usually takes little time to complete.

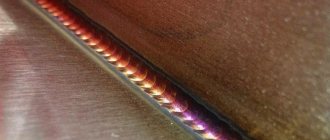

- The cost of the resulting product is significantly reduced. Welding a joint is expensive, as it requires the use of a special welding machine.

Read also: How to choose a screwdriver for home use

The quality of connections can be significantly improved by using additional various elements. For example, washers and locknuts are used, which significantly improve the quality and reliability of the connection. However, threaded connections also have several significant disadvantages:

- Stress concentration at the root of the thread profile. It is worth considering that the use of special metal can significantly increase the reliability of the threaded surface.

- There is a possibility that the nut will unscrew under strong mechanical stress. Of course, to exclude such a possibility, various fixation methods can be used.

In addition, there are several types of threaded fastening. An example is a bolted and screwed connection. Some connections can be made using studs. The choice of a more suitable fastening element is carried out taking into account what qualities the product should have.