Due to their high reliability and simplicity, threaded connections are widely used in various building structures, machines and mechanisms. Since the basic geometric parameters of threads are generally accepted, it is enough to have a small set of standard tools to create new connections and repair worn units.

Creating a Thread

The concept of helical surfaces has long been known to mankind, dating back to ancient times.

The Archimedes screw is widely known and used to move liquids, bulk products, plastics, etc. Archimedes is far from the only genius of the ancient Greek land. There are probably some legal documents (patent), but it is believed that the first screw was invented by Archytas of Tarentum (philosopher, mathematician, mechanic), who lived in the fifth century BC.

Screw fasteners were used in ancient Rome, but were naturally very expensive and were therefore used in medical instruments, jewelry and luxury goods.

You can imagine a helical surface by winding a rope around a cylindrical object, such as part of a log. Approximately the same technology was used to mark screw elements, after first covering the rope with paint or chalk.

The thread itself, of course, was cut by hand.

STAYER “PROFESSIONAL” pipe die with replaceable cutters, 28261-5/4

The production of taps (a tool for cutting threads) has been known since the fifteenth century, but screw elements were adjusted by hand and interchangeability was, of course, not known in those days.

If there is a lead screw, then cutting a thread on a cylindrical surface, that is, making another lead screw, is not a problem, but where to find this very first lead screw?

Henry Maudsley worked on the problem at the turn of the eighteenth and nineteenth centuries.

The first lead screw and nut (for his lathe) were made by hand. Using these imperfect elements, he made a more accurate lead screw. By replacing a more accurate lead screw on his lathe, he was able to produce an even more accurate lead screw (and so on several times in a row until the accuracy stopped increasing).

Precision manufacturing is the basis of interchangeability. Thank you, Henry.

For those times, this was space technology.

The standardization of threads and the concept of interchangeability remained for a long time within individual engineering companies, until in 1841 Joseph Whitworth proposed a system of fastening threads, which became the national standard for Great Britain (BSW).

There were many national thread standards, and we still see echoes of technical, national revolutions (for example, the fasteners of American cars differ from European ones).

The International Congress for the Standardization of Threads, held in Zurich in 1898, defined new standards for metric threads based on the American Sellers standard, but with metric dimensions.

At the state level, there was no standardization of threads in the Russian Empire and machine-building enterprises used foreign ones.

The Soviet standardization system leaned either towards the German or towards the American, until in 1947, the International Organization for Standardization (ISO) was created, the standards of which are generally accepted throughout the world.

Traces of the struggle between national standards are still found today, for example, pipe sizes in Russia are measured in both the metric and inch systems, the connecting squares of tools (sockets) are designated in inches, etc.

How to choose a tool?

When choosing a tool for cutting threads on pipes, the master is guided by the design features of the pipeline, its technical characteristics and functionality.

The choice of hand or power tool depends on what material will be used for threading and how much work needs to be done. An important factor remains the price of threading tools and components. Expensive electrical plugs are bought by craftsmen who regularly cut external and internal threads. If the job is one-time, you should consider buying inexpensive hand tools.

A thread-cutting tool requires the presence of direct cutting elements - these are dies, taps, and cutters. For more advanced products designed for high-precision productive cutting, the working tool is a prefabricated adjustable thread-cutting head, including several cutting combs.

Metric thread

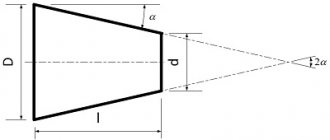

It is widely used with a nominal diameter from 1 to 600 millimeters, in increments of 0.25 to 6 millimeters. The metric thread profile is an equilateral triangle (with an apex angle of 60 degrees and a theoretical profile height H = 0.866..P (pitch)).

All metric thread parameters are measured in millimeters. When marking, a metric thread is designated by the letter M (metric) with the numerical value of the outer diameter of the rod (cylinder) on which this thread is cut.

A fine pitch and designation (LH) for left-hand threads may also be indicated.

Thread geometry

Depending on the purpose and operating conditions, the geometry of the threads can be:

- trapezoidal (Tr) (lead screws, weight screws, screw presses, etc.);

- thrust (sawtooth) (artillery systems, pressure screws of rolling mills, etc.);

- round with radii at the tops and bottoms (valves, water taps, etc.)

- inch, British Standard (BSW) with a vertex angle of 55 degrees, etc.

Threading

The thread direction can be left or right, external or internal.

In the mass production of fasteners, automated lines are used, with minimal human intervention.

For the production of small-scale and unique fasteners, threads are cut manually using a thread-cutting tool.

In the manufacture of external threads, dies (daggers) and dies are used; for internal threads, taps are used.

The thread cutting process is faster and easier when using classic, universal equipment, that is, a lathe.

Typically, thread-cutting tools are made of high-speed steel and hard alloys, but threads can also be cut with high-carbon tools, with appropriate lubrication and cooling.

Manufacturing methods

- cutting (cutter on a lathe);

- abrasive processing;

- rolling (plastic deformation);

- extrusion by pressing;

- casting;

- electrochemical processing, etc.

Some of the most versatile thread cutting methods include:

- cutting external threads with dies;

- cutting internal threads with taps;

- cutting internal and external threads with cutters and combs;

- cutting external and internal threads with threading heads, etc.

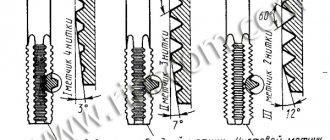

Threaded dies for increased productivity

Some thread cutting tools are characterized by high efficiency when used. An example is thread dies, which can be used to produce threads of almost any size. Their advantages include the following:

- Simple design.

- Versatility in use.

- High efficiency.

- Manufacturability.

Thread dies

The combs are represented by multi-filament shaped cutters, which are of prismatic, round and rod type. Most often they are used for cutting threads with fine pitches and low profile heights.

Die (die)

Die BISON "EXPERT" machine-manual, 4-28023-12-1.75_z01

The term “die” was previously used to refer to adjustable and stackable threading tools.

Currently, the concepts of lerka and die are considered equivalent.

Structurally, the die is a nut with manufactured cutting edges and corners.

This universal threading tool is designed to produce threads from 1 to 52 millimeters in one pass.

Depending on the size, 3-6 holes are formed in the dies to create cutting surfaces and remove chips.

The intake part of the thread is made in the form of an internal cone, and the thickness of the die itself is 8-10 turns, including 2-3 intake turns.

The material used for the manufacture of dies can be:

alloy steel (9ХС, ХВСГФ);

high-speed steel (R18, R6M5, R6M5K5, R6M5K8);

hard alloy.

Structurally, the dies may differ:

- solid;

- split (with the ability to compensate for wear of the cutting surface);

- sliding (clupp).

In die holders (collars), the dies are secured with locking screws using conical recesses and a groove.

If there is significant wear, the groove is cut and the die becomes adjustable (within limited limits).

Using Electric Tapping Power Tools

Using an electric pipe threader, you can significantly speed up the work and improve its quality; standard threading heads have sizes of 1/2, 3/4, 1 and 1.1/4 inches. In addition to the heads, the set includes a power tool and a clamp; cutting is carried out in the following sequence:

- Fix the clamp on the surface of the workpiece with a screw, put the head from the electric socket together with the power tool onto the workpiece and fix its handle in the side tube of the clamp.

- Press the electrical device to the end, turn on the reverse (counterclockwise) rotation of the head until it securely grips the pipe edge, then switch the direction of movement of the device to direct to apply the profile. When performing thread-cutting operations, the cutters are coated with a special oil, which facilitates cutting and prevents chips from getting under the knives.

- After a direct pass over the entire length, the reverse and forward strokes are alternately turned on in order to free the channel from chip inclusions. The reverse is switched several times, after which the thread cutter head is removed from the workpiece.

In this case, it is necessary to ensure that the chips do not fall under the knives - to do this, remove them with a brush and periodically lubricate the knives with a special oil that prevents them from sticking.

Tap

A tap is a tool for cutting internal threads, it is a bolt made of tool metal, with formed cutting edges and chip grooves.

To produce internal threads in viscous materials, several taps (2-5) can be used, which differ in profile height (to reduce cutting force).

Taps for cutting threads in through and blind holes have design differences (taps for blind holes have a shorter lead).

Modern taps are made from high-speed steel or carbide.

In ductile metals, it is possible to form threads using the method of plastic deformation, without cutting; accordingly, such taps are called rolling taps.

A tap is the primary tool for cutting internal holes by hand.

To reduce friction and prevent jamming of the tap, its thread is made with reverse taper (relief).

Machine taps

If the thread is cylindrical or conical, has a pitch of up to 3 mm, and it must be placed in a blind or through hole, then it is recommended to use a machine or mechanical device. Although hand cutting is also possible. Machine taps have very large shanks and tap sizes.

If the threading process is carried out on a part made of high strength steel, then a set of two sets of taps will be required. For workpieces made of structural steel, the use of one tap is permissible. This also applies to cast iron parts.

This type of tool is distinguished by the profile of the grooves, designed for quick removal of chips, and the shape of the shank, convenient for mounting in a spindle or chuck.

Klupp

Klupp (German: Kluppe), a tool for manual threading, is a mandrel in which thread-cutting dies (dies) are placed.

Since threads are cut only by elements made of expensive alloy steel, there is no need to make the entire unit from it, but only replaceable comb cutters.

To create a cutting force (quite large), the clamps are equipped with massive levers (possibly with a ratchet).

There's enough muscle power to cut 2-inch pipe threads, and a good ratchet can make the job easier.

The operation of the die, in its main part, is very similar to cutting a thread with a die (only with a very large die and the efforts there are corresponding).

How to correctly determine the hole diameter

Before cutting internal threads, it is necessary to make a hole in the workpiece in advance. Its dimensions must be selected strictly, since exceeding the optimal value will not allow you to create a strong bolt connection, and reducing it will increase the likelihood of damage to the tool during operation.

To determine the diameter of the hole for a standard thread, you will need to use reference books. To create non-standard threads, you need to make simple calculations: subtract the pitch size from the diameter.

Creating a Thread

The concept of helical surfaces has long been known to mankind, dating back to ancient times. The Archimedes screw is widely known and used to move liquids, bulk products, plastics, etc.

Archimedes is far from the only genius of the ancient Greek land. There are probably some legal documents (patent), but it is believed that the first screw was invented by Archytas of Tarentum (philosopher, mathematician, mechanic), who lived in the fifth century BC.

Screw fasteners were used in ancient Rome, but were naturally very expensive and were therefore used in medical instruments, jewelry and luxury goods.

You can imagine a helical surface by winding a rope around a cylindrical object, such as part of a log. Approximately the same technology was used to mark screw elements, after first covering the rope with paint or chalk.

The thread itself, of course, was cut by hand.

The production of taps (a tool for cutting threads) has been known since the fifteenth century, but screw elements were adjusted by hand and interchangeability was, of course, not known in those days.

If there is a lead screw, then cutting a thread on a cylindrical surface, that is, making another lead screw, is not a problem, but where to find this very first lead screw?

Henry Maudsley worked on the problem at the turn of the eighteenth and nineteenth centuries.

The first lead screw and nut (for his lathe) were made by hand. Using these imperfect elements, he made a more accurate lead screw. By replacing a more accurate lead screw on his lathe, he was able to produce an even more accurate lead screw (and so on several times in a row until the accuracy stopped increasing).

Precision manufacturing is the basis of interchangeability. Thank you, Henry.

For those times, this was space technology.

The standardization of threads and the concept of interchangeability remained for a long time within individual engineering companies, until in 1841 Joseph Whitworth proposed a system of fastening threads, which became the national standard for Great Britain (BSW).

There were many national thread standards, and we still see echoes of technical, national revolutions (for example, the fasteners of American cars differ from European ones).

The International Congress for the Standardization of Threads, held in Zurich in 1898, defined new standards for metric threads based on the American Sellers standard, but with metric dimensions.

At the state level, there was no standardization of threads in the Russian Empire and machine-building enterprises used foreign ones.

The Soviet standardization system leaned either towards the German or towards the American, until in 1947, the International Organization for Standardization (ISO) was created, the standards of which are generally accepted throughout the world.

Traces of the struggle between national standards are still found today, for example, pipe sizes in Russia are measured in both the metric and inch systems, the connecting squares of tools (sockets) are designated in inches, etc.

Adaptations

To apply carvings with your own hands, use small devices:

- dies (they are also called dies) for applying turns from the outside (usually onto a pipe or metal rod (pin);

- taps - for internal ones (you first need to make a hole for them).

This is interesting: Grades and types of tool steel: description of carbon, alloy and high-speed

Tap (top) and die (bottom)

All these devices are made of alloys characterized by increased strength and abrasion resistance. Grooves and grooves are applied to their surfaces, with the help of which their mirror image is obtained on the workpiece.

Any tap or die is marked - they have an inscription indicating the type of thread that this device cuts - diameter and pitch. They are inserted into holders - collars and die holders - and secured there with screws. Having clamped the thread cutting device in the holder, it is put on/inserted into the place where you want to make a detachable connection. By turning the device, turns are formed. How correctly the device is positioned at the beginning of work determines whether the turns will “lay down” evenly. Therefore, make the first revolutions, trying to keep the structure level, avoiding shifts and distortions. After a few turns, the process will become easier.

You can cut small or medium diameter threads by hand. Complex types (two- and three-way) or working with large diameters by hand are impossible - too much effort is required. For these purposes, special mechanized equipment is used - lathes with taps and dies attached to them.

Metric thread

It is widely used with a nominal diameter from 1 to 600 millimeters, in increments of 0.25 to 6 millimeters. The metric thread profile is an equilateral triangle (with an apex angle of 60 degrees and a theoretical profile height H = 0.866..P (pitch)).

All metric thread parameters are measured in millimeters. When marking, a metric thread is designated by the letter M (metric) with the numerical value of the outer diameter of the rod (cylinder) on which this thread is cut.

A fine pitch and designation (LH) for left-hand threads may also be indicated.

Thread geometry

Depending on the purpose and operating conditions, the geometry of the threads can be:

- trapezoidal (Tr) (lead screws, weight screws, screw presses, etc.);

- thrust (sawtooth) (artillery systems, pressure screws of rolling mills, etc.);

- round with radii at the tops and bottoms (valves, water taps, etc.)

- inch, British Standard (BSW) with a vertex angle of 55 degrees, etc.

Threading

The thread direction can be left or right, external or internal.

In the mass production of fasteners, automated lines are used, with minimal human intervention.

For the production of small-scale and unique fasteners, threads are cut manually using a thread-cutting tool.

In the manufacture of external threads, dies (daggers) and dies are used; for internal threads, taps are used.

The thread cutting process is faster and easier when using classic, universal equipment, that is, a lathe.

Typically, thread-cutting tools are made of high-speed steel and hard alloys, but threads can also be cut with high-carbon tools, with appropriate lubrication and cooling.

Manufacturing methods

- cutting (cutter on a lathe);

- abrasive processing;

- rolling (plastic deformation);

- extrusion by pressing;

- casting;

- electrochemical processing, etc.

BISON tap "Expert" machine-hand, 4-28005-18-2.5

Some of the most versatile thread cutting methods include:

- cutting external threads with dies;

- cutting internal threads with taps;

- cutting internal and external threads with cutters and combs;

- cutting external and internal threads with threading heads, etc.

Internal thread

The internal thread is cut into the hole using taps (1). They are metal rods with hardened teeth. Manufactured from tool or high-speed steel.

Types of taps

Taps are distinguished by purpose. They can be used for cutting metric, inch, tapered, pipe, and trapezoidal threads. According to the relevant technical specifications, as well as GOST 3266-81, the table shows the limits of applicability of this tool.

| Thread name | Nominal diameters |

| Metric | 1 - 52 mm |

| Inch | 1/4” - 2” (inches) |

| Conical | 1/16” — 2” |

| Pipe | 1/16” — 6” |

| Trapezoidal | 5.6 - 90 mm |

Taps for cutting metric and inch threads are manufactured in sets. The set can consist of either two, finishing and roughing, or three - roughing, medium and finishing taps. The roughing tap is designed to remove the bulk of the chips. Finishing is used for the final, precise shaping of the thread profile and calibration.

To identify the tap in the kit, its tail part is marked with one, two or three ring marks. It is also possible to designate using a number: I – rough, II – medium, III – finishing.

Nut taps are designed to cut threads in one pass. They are single-set, that is, sold individually.

To rotate the taps, use knobs (2). They can be non-adjustable with square holes for a fixed size shank, or adjustable. In addition, there are wrenches with a ratchet mechanism, providing ease of work in hard-to-reach places.

Die (die)

The term “die” was previously used to refer to adjustable and stackable threading tools.

Currently, the concepts of lerka and die are considered equivalent.

Structurally, the die is a nut with manufactured cutting edges and corners.

This universal threading tool is designed to produce threads from 1 to 52 millimeters in one pass.

Depending on the size, 3-6 holes are formed in the dies to create cutting surfaces and remove chips.

The intake part of the thread is made in the form of an internal cone, and the thickness of the die itself is 8-10 turns, including 2-3 intake turns.

The material used for the manufacture of dies can be:

alloy steel (9ХС, ХВСГФ);

high-speed steel (R18, R6M5, R6M5K5, R6M5K8);

hard alloy.

Structurally, the dies may differ:

- solid;

- split (with the ability to compensate for wear of the cutting surface);

- sliding (clupp).

In die holders (collars), the dies are secured with locking screws using conical recesses and a groove.

If there is significant wear, the groove is cut and the die becomes adjustable (within limited limits).

Tap

A tap is a tool for cutting internal threads, it is a bolt made of tool metal, with formed cutting edges and chip grooves.

To produce internal threads in viscous materials, several taps (2-5) can be used, which differ in profile height (to reduce cutting force).

Taps for cutting threads in through and blind holes have design differences (taps for blind holes have a shorter lead).

Modern taps are made from high-speed steel or carbide.

In ductile metals, it is possible to form threads using the method of plastic deformation, without cutting; accordingly, such taps are called rolling taps.

A tap is the primary tool for cutting internal holes by hand.

To reduce friction and prevent jamming of the tap, its thread is made with reverse taper (relief).

Removing a Broken Tool

Even mechanics with many years of experience, for various reasons, sometimes break taps when cutting internal threads by hand. The question is how to remove a piece of the product, because the problem cannot always be solved by making another hole. If the fragment sticks out even slightly above the surface, you should try to grab it with pliers or jaws of a hand vice and try to turn it out naturally. As a rule, this gives a successful result.

When a piece of the working part is completely seated in the hole, drastic measures are needed. One of them is to try to turn it out with a left-hand rotation drill, working the drill at the lowest speed. Nothing works? You will have to find a drill with a carbide tip or diamond and simply drill out the stuck piece of the tool.

The broken working part of the tap can sometimes be very difficult to remove, so the work must be done scrupulously, especially if you lack experience. Use a well-sharpened tool, follow all the recommendations suggested above, and you will 100% get the result in the form of a reliable threaded connection.

Klupp

Klupp (German: Kluppe), a tool for manual threading, is a mandrel in which thread-cutting dies (dies) are placed.

Since threads are cut only by elements made of expensive alloy steel, there is no need to make the entire unit from it, but only replaceable comb cutters.

To create a cutting force (quite large), the clamps are equipped with massive levers (possibly with a ratchet).

There's enough muscle power to cut 2-inch pipe threads, and a good ratchet can make the job easier.

The operation of the die, in its main part, is very similar to cutting a thread with a die (only with a very large die and the efforts there are corresponding).

Types of tapping

Metric cutting type. The cut element of such a thread has the shape of an isosceles triangle, the entire value is measured in millimeters, such taps are marked with the letter (M). To select the right tool during cutting, a special reference table of taps is used.

Tapping table:

The inch working part of the tool has a conical shape. The diameter of such a tool is measured in inches, and the pitch is measured in the number of threads per inch.

Pipe. Cylindrical and conical taps are used for cutting threads on pipe connections.