Sometimes brazing stainless steel is preferable to welding. Soldering is used for thin-walled products that are not subject to heavy loads, and in cases where they do not want to experience warping from heating.

It should be taken into account that some types of stainless steel require a certain approach, taking into account their composition and manufacturing technology. For example, cold-worked stainless alloys crack at high temperatures, so their soldering is carried out without loads, after first annealing the metal. There are other subtleties.

The main thing is a soldering iron!

Before you begin, consider whether you should actually solder rather than use other fastening methods. Soldering is advisable if metal parts cannot be drilled or the bolted connection is unreliable.

The main factors that influence the process: a good electric soldering iron and the right flux, which ensures the connection of surfaces for a long time.

Pay special attention to the following:

- The power of the soldering iron should be 60-100 W; if it is less, then it will not be possible to heat the metal well and melt it to the desired state. High power at home is not needed - it leads to excessive energy consumption.

- You need to purchase a soldering iron with permanent heating - it lasts a long time and saves energy.

- It is best to have a soldering iron with a tip that does not burn - this will work longer. It needs to be descaled periodically, and also sharpened for precise work.

- Tin is an almost ideal solder for stainless steel. It does not contain lead, like POS, and can be used with products in contact with food.

- Without the correct choice of flux, it is impossible to tin stainless steel, as an oxide film will form. The best flux in this case is phosphoric acid.

How to seal a stainless steel flask

How to solder stainless steel and hard soldering technology

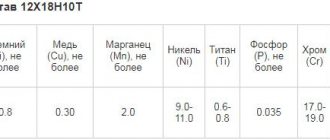

Soldering stainless steel is a rather labor-intensive process, but at the same time there are no great difficulties here. Alloys containing up to 25% nickel and chromium are alloyed together quite simply. Moreover, these alloys can create strong bonds with other metals, with the only exceptions being magnesium and aluminum alloys.

But you need to pay attention to the fact that some nickel-plated alloys when heated to a temperature of 500-700 degrees. Carbides can form; their level of release depends on the duration of soldering, so the procedure time must be reduced.

The resulting carbides significantly reduce the corrosion resistance of stainless steel.

In order to minimize the precipitation of carbides, titanium is added or additional heat treatment is carried out upon completion of soldering.

Under the influence of hot solder (tinol), the cold-hardened stainless material can crack, so soldering occurs after annealing, without using loads during soldering.

The choice of solder for stainless steel depends entirely on the following characteristics: steel composition, soldering conditions. It should be noted that products that are made in corrosive conditions must be soldered using silver tinols, which contain a small amount of nickel in the composition. Copper, silver-manganese, and chromium-nickel solders are used during oven soldering in dry conditions.

Today, borax is most often used as a flux for processing stainless steel. It is applied to the joint in powder or paste form. When the borax melts, the rest of the metal gradually heats up to a bright red heat (850 degrees). When this temperature is reached, solder is injected into the joint.

Removal of material adhering to the stainless surface upon completion of soldering is done by rinsing the soldered product in water or by sand blowing. Hydrochloric or nitric acid, which can be used in cleaning, are very undesirable at this stage of working with stainless steel, since they, along with the solder, will corrode the base metal.

Soldering stainless steel at home

Perhaps everyone knows that a home handyman is constantly faced with everyday difficulties that he needs to eliminate on his own.

But it often happens that you need to do the work associated with processing stainless steel yourself. Therefore, this will require certain skills, abilities and knowledge.

You will also need to acquire some materials and tools. Here is a list of everything you need:

- Soldering acid;

- Electric soldering iron 100 Watt;

- Tin solder for joining metals;

- File or sandpaper;

- A tube;

- Metal cable.

Now that you have decided on the soldering tool, you need to know the steps to perform the actions:

- To process stainless steel, you must initially ensure that you have flux and a 100-watt electric soldering iron. You need to know that there is no point in choosing a more powerful soldering iron for processing stainless steel. The flux is ordinary soldering acid. Also, do not forget to always have tin-lead solder on hand.

- When all the necessary tools and materials are ready for soldering, you can begin work. First you need to clean the stainless steel joint: this can be done using sandpaper or a file. Upon completion of cleaning the work areas, it is necessary to apply soldering acid followed by further treatment. If the treatment does not work (the solder does not stick to the surface of the stainless steel), then you need to re-manipulate the soldering acid on a thoroughly heated surface, then perform the treatment again.

- In the case when you made a second attempt, and it was not successful, and the solder lags behind again, then the working surface of the stainless steel needs to be cleaned with a special brush, which you can make your own: you will need a piece of pipe with a cross-section of 5 mm, where you place thin wires pulled from a metal cable . Now, apply acid to the soldering area, and then bring the brush and soldering iron here at the same time. Then start working with two tools. It should be noted that this process is very helpful in removing the oxide film from the surface of stainless steel.

- When the parts have been tinned, begin soldering stainless steel using a soldering iron and flux.

Soldering with a gas torch

The parts are heated using a gas torch or a tin-plated soldering iron tip.

When working with the burner, you must ensure that there is not too much oxygen in the flame, because this causes the stainless steel to oxidize.

This can be determined by the color of the fire (it should be blue); if the color is pale and the fire is weak, then this indicates an excess of oxygen. To warm up the connection, the burner must be moved smoothly.

By periodically touching the metal with solder, the quality of the temperature achieved is determined. Heating is sufficient when the solder melts not from the flame of the torch, but from touching the metal.

Then solder is immediately applied to the part where the joint needs to be made, while the parts continue to be heated so that the solder, melting, slowly fills the joint completely. If there is not enough liquid solder in some area, it is heated more strongly than other places, and the solder itself flows into it. A clear sign of high-quality soldering is the leakage of excess solder from the joint.

Working with hard solders

Stainless steel soldering works well using flowable, liquid, fluxed solder with a low melting point and high capillary characteristics. This solder is quite elastic and has excellent deoxidation properties, which are very useful when working with stainless steel.

It can also handle brass, copper and some other materials. Soldering with such hard solders is very suitable for stainless steel. Stainless steel does not contain cadmium, and the percentage of silver here is 30%. Processing the material with hard solders gives good results, making it possible to obtain durable and high-quality metal fastening.

HTS528 solder can cope with copper, brass, nickel, bronze, stainless steel, and other metals. Along with other hard solders today, this tinol is the most in demand. The solder looks like a rod treated with red flux. The rod size is about 45 cm and the weight is 20 g. The melting point is 760 degrees.

How to choose a flux for soldering

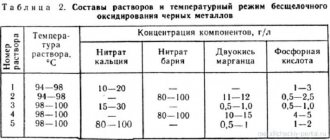

Small elements are soldered with adjustable gas-air burners (this method is more suitable for jewelry). Larger parts are best soldered with acetylene. The same applies when choosing a flux for stainless steel, since this metal is very demanding on flux. Flux for stainless steel consists of 10% calcium fluoride, 20% boric acid, 70% borax.

For small stainless steel parts, you can prepare a flux composition that includes 50/50% boric acid and borax. This flux must be diluted in water, then applied to the part; when it dries, the solder will adhere perfectly to the metal surface.

That is, the soldering area is not etched, but only cleaned using sandpaper. Copper does not spread well over the surface of steel, so it is better to use L 63 brass. For better soldering, you can also use silver and brass to make solder from them.

Recommendations from professionals

There are many people who, so to speak, “ate the dog” when working with soldering. And they share personal experience gained in practice, giving useful recommendations:

- It is best to choose a soldering iron with a non-burnable tip.

- An electric soldering iron needs a power of 60-100 watts. The most optimal soldering iron is 100 Watt. A less powerful soldering iron will not be able to heat the metal.

- Phosphoric acid works best as a flux.

- It is advisable to use tin-lead rods as solder. You can also use tin in its pure form. It must be said that it is better to solder utensils with tin, since pure tin does not contain lead.

- When working with soldering, it is necessary to use personal protective equipment.

- Soldering must take place in a well-ventilated and open area.

Basic mistakes during soldering

If an error is made during preparation, selection of materials, or during the soldering process, the solder may not spread over the surface and may not hold the parts together.

It happens that the parts were not properly cleaned before soldering or were not heated up properly. This often happens with large-sized products.

The tip of the soldering iron must be thoroughly cleaned after any session, and in order for jewelry work to be possible, its tip must be sharpened from time to time.

To obtain a high-quality connection, do not solder stainless steel with pure lead or use rosin. If the solder is made of tin, then working with it can be quite difficult due to its weak consistency.

If the tin does not melt more than to the state of warm plasticine, then most likely it will not hold the connection, constantly breaking and crumbling.

The optimal state of tin for fastening is if it looks like a liquid.

High-quality solder, which is laid according to all the rules, can only be scratched. but not separated from the stainless steel soldering area. In order not to damage the connection in the future, after soldering the product must be allowed to cool down at rest. When the joint has cooled, it is cleaned of any flux and solder that remains at the edges, and then washed thoroughly with soap.

Matveev Nikolay Ivanovich

He who doesn't work doesn't make mistakes

For soldering, the tin must reach the desired consistency - similar to water. Then the seam turns out to be of high quality, even and long-lasting.

Mistakes in achieving a good result are:

- the soldering iron has not reached the required temperature;

- poor heating of the parts being soldered. If they are large, then this can be done using a gas burner or on an electric stove;

- incorrect choice of flux, which cannot dissolve the oxide or fatty film on the metal.

All the above-described features must be observed when soldering stainless steel with tin. After finishing work, the connected surfaces should be washed with soap and water. The fact is that the acids used in the process are quite aggressive, they accelerate the destruction and corrosion of the metal, and soap neutralizes them.

Tips in the article “How an electronic dynamometer works” here.

Soldering stainless steel in the video:

Soldering stainless steel is a rather labor-intensive procedure, but it will not cause any special problems if you know all the features of its implementation. With significantly less labor, it is possible to solder stainless steel alloys that contain no more than 25% chromium and nickel. Moreover, soldering stainless steel with such a chemical composition allows you to obtain reliable connections of products from dissimilar metals, excluding alloys with magnesium and aluminum.

Solder repaired bicycle frame

Soldering stainless steel, which contains a significant amount of nickel, can be difficult. This is due to the fact that in such alloys, when heated to a temperature of 500–700°, carbide compounds appear. The intensity of the formation of such connections depends on the duration of heating, so soldering should be performed as quickly as possible.

To minimize the risk of the formation of carbide compounds in the stainless steel structure during soldering, titanium is added to the alloy composition, and after the joint is formed, the product is subjected to heat treatment. You should be very careful when soldering cold-worked stainless steels, the surface of which may become cracked under the influence of heated solder. To avoid such consequences, it is necessary to eliminate the load on the parts being connected during the soldering process. In addition, it is possible to pre-anneal the products being joined.

Use a gas torch for annealing.

The choice of solder with which to solder stainless steel is influenced by both the chemical composition of the alloy and the process conditions. So, if this process is carried out at high ambient humidity, then silver alloys should be used, which contain a small amount of nickel. Soldering in an oven, as well as in a relatively dry atmosphere, is performed using chromium-nickel and silver-manganese solders.

The most common type of flux used when soldering stainless steel is borax, applied to the future joint in the form of a paste or powder. Melting borax on the surface of the parts being joined contributes to uniform and most accurate heating of the area of the future seam to the required temperature - 850°. Only after the required heating temperature has been reached, which can be determined by the color change of the future joint to light red, is solder introduced into the joint between the parts.

The flux is applied in an even layer over the entire surface, which must first be cleaned.

After soldering is completed, flux residues are present at the joint, which are removed by washing with water or sandblasting. To perform this procedure, you cannot use nitric or hydrochloric acids, which, although they effectively clean the flux remaining on the surface of the parts, have a negative effect on both the base metal and the used solder.

Soldering brass and stainless steel

Soldering stainless steel is a complex and time-consuming procedure. The fact is that a number of nickel-plated alloys can release carbides when heated to 500 degrees. The amount of release depends on the duration of the soldering process.

The resulting carbides negatively affect stainless steel elements, as they can destroy its anti-corrosion properties. In order to prevent their appearance during soldering of stainless steel, it is necessary to add titanium or carry out additional temperature treatment of the elements.

Soldering of stainless steel must be done after annealing, since when reacting with molten solder, the hardened steel elements may begin to crack.

Soldering stainless steel with brass

Soldering stainless steel is a complex and time-consuming procedure. The fact is that a number of nickel-plated alloys can release carbides when heated to 500 degrees. The amount of release depends on the duration of the soldering process.

The resulting carbides negatively affect stainless steel elements, as they can destroy its anti-corrosion properties. In order to prevent their appearance during soldering of stainless steel, it is necessary to add titanium or carry out additional temperature treatment of the elements.

How to do soldering at home

Problems such as joining stainless steel parts using soldering and soldering stainless steel to copper are often encountered at home. Products made of stainless steel have been actively used in everyday life for many years, therefore, when for some reason they become unusable, any home craftsman has a natural desire to repair them himself. It should be said right away that soldering stainless steel parts is not so difficult, the main thing is to strictly adhere to the technology, as well as stock up on the appropriate tools and consumables.

Master the soldering technique on simple connections, and then try working with more critical parts

Before you start soldering stainless steel, it is very advisable not only to study the theoretical material on this issue, but also to become more familiar with the rules for its implementation using training videos.

To solder stainless steel products, you will need the following tools and consumables:

- a soldering iron powered by electricity with a power of at least 100 W;

- special soldering acid, which will be used as a flux;

- file or sandpaper;

- solder, specially designed for joining steel parts, based on tin and lead;

- cable made of steel;

- metal tube.

Soldering materials and tools

When choosing a soldering iron for working with stainless steel, you should opt for a tool with a power of 100 W. Using a more powerful device to perform such work is simply not practical.

The process of soldering stainless steel parts is carried out according to the following algorithm.

- First of all, it is necessary to thoroughly clean the area of the future connection, for which sandpaper or a file is used.

- After preparing the surfaces of the parts to be joined, it is necessary to apply flux to them, which, as mentioned above, uses soldering acid. The main task of the flux is to ensure high-quality tinning of the parts to be joined.

- After the surfaces of the parts to be joined are treated with flux, it is necessary to tinning them, which consists of applying a thin layer of solder consisting of tin and lead to them. If tinning was not successful the first time, then it is necessary to repeat this procedure, preheating the parts to be joined.

- Even after heating the products and re-processing them with flux, tinning may not be successful - the solder will simply roll off the surface of the parts, rather than lie on them as a thin film. In this case, you need to use a brush with metal wires, which can be easily made from a tube and steel cable. Before using such a brush, it is also necessary to apply flux (soldering acid) to the surface of the parts and only then, heating the future joint with a soldering iron, clean it with a metal brush. This simple technique allows you to effectively clean the surface of a stainless steel from an oxide film, which, as a rule, is the main obstacle to high-quality tinning.

- Once a thin layer of tin has been applied to the products to be joined, you can begin to solder them. This procedure is performed using a soldering iron and solder, which is used to fill the joint between the parts.

How to solder stainless steel with brass

Their skill amazes and enchants, they bring dreams to life, create masterpieces, and pass on their skills from generation to generation. These people are jewelers. To conquer metal and turn it into beautiful products requires skill, perseverance and time.

The main metals that specialists work with are gold, silver, and stainless steel. The main operation in the manufacturing technology of a unique product is metal soldering. Soldering technology has its own characteristics for each material. Brazing stainless steel is a complex process.

Soldering silver at home is a rather expensive operation . It is especially technologically difficult and economically expensive to solder two different metals. Special conditions, special solder and flux must be observed. Author's products are becoming popular among consumers. Many complex projects have a combination of silver parts and stainless steel.

Technology for joining stainless steel parts

Unfortunately, soldering stainless steel is not such a simple process, and ordinary solders in the form of tin or copper will not do the job well. Solder for soldering stainless steel must contain silver. The industry produces it coated with flux (contains 30% silver). You can use solder containing zinc, copper and nickel.

Sometimes they solder with brass, this is considered the most difficult work. To melt brass, a temperature of 950 degrees is required.

To ensure high-quality performance of work and reliable connection of parts into a single structure, it is necessary to use flux. For brass, the flux consists of boric acid and borax.

Parts can be soldered using this method only if they are small and well heated. Soldering massive parts at home is problematic.

What you need to solder stainless steel:

- gas-burner;

- solder containing silver and coated with flux;

- soldering acid.

Technological process of soldering stainless steel with hard solders:

- heating parts for degreasing;

- surface treatment with orthophosphoric acid;

- heating parts to a red glow;

- supply of solder followed by heating.

To solder a hole in a stainless steel sheet at home, you need to determine its size and prepare an appropriate patch . Soldering must be performed according to technology using solder containing silver.

Nanotechnology: welding pencil

The easiest way to carry out welding work is with a special welding pencil. It can weld any metal: aluminum, iron, stainless steel, copper, brass.

Moreover, there is no need to clean and degrease the surface. This is new. It works as follows. Light a pencil, bring the burning end to the object being welded and carefully roll the pencil over the surface to be welded.

The molten metal will adhere to the part and provide a reliable connection.

How to solder silver parts

You can't go anywhere without silver solder! Silver cannot be reliably soldered with tin. Although at first glance such a connection is strong, the metals react with each other, and the product crumbles after some time.

To ensure a high-quality connection of silver parts, you must use special silver solder. They come in three types: hard, soft and medium, differing in melting point (from 700 to 900 degrees).

Solder is selected depending on the type of metal and the requirements for joint strength. When manufacturing complex products in several stages, as well as when combining different structural elements, soft solders are used.

It should look like a small, very thin plate or wire. They cut it into small (millimeter) pieces. Soldering silver at home is done on a refractory brick, a piece of charcoal or a special ceramic tile. It is not recommended to perform soldering on a material that conducts heat well - it absorbs heating energy, and the soldered object does not heat up well.

You cannot use a simple wet brick, which crumbles under the influence of temperature due to the moisture it contains. Superheated steam will send a piece of brick straight into your face with great force.

To solder a part to an object, it is necessary to lubricate the cleaned and thoroughly degreased area with flux (ready mixture: boric acid, borax) or soldering acid. Removing grease, oxides and other contaminants is important. The degreased surface ensures a reliable connection with the solder. Jewelers, as a rule, use a weak acid solution for this purpose.

Solder Types

Stainless steel products can be soldered with both soft solders made on the basis of tin and lead, and hard types of filler material, which includes more refractory metals.

Soft solder, due to the fact that it is based on tin, is a low-melting material characterized by high ductility and fluidity in the molten state. What is especially important when soldering stainless steel products is that it has good deoxidizing ability.

Properties of soft solders

More reliable connections both in production and at home can be achieved by soldering using hard solders. The metals from which they are made melt at a higher temperature than tin, which makes it possible to obtain reliable and durable connections with their help. Very often, materials of this type are produced on the basis of technical silver, which can contain up to 30% in their composition.

Main brands of silver solders

One of the popular types of hard solder is the HTS-528 material, which is successfully used for soldering not only stainless steel, but also copper, brass, bronze, nickel and other metals. Conveniently, it is produced in the form of a rod, the surface of which is already covered with a layer of flux. When working with such solder in a production environment or at home, you should keep in mind that its melting point is 760°.

HTS-528 solder is a rod coated with red flux. In addition to stainless steel, it is suitable for cast iron and non-ferrous metals

Connection with other metals

The connection of two different metals, for example, the soldering of copper and stainless steel, must be approached from the position of studying their properties. Metals have different melting points, so the soldering process is considered one of the most difficult.

Joining copper and stainless steel at home includes processing the workpieces, tinning the edges and the soldering process itself.

It should be noted that copper and stainless steel can be soldered with a soldering iron or torch. The first tool is low-power, so it cannot work with hard solders.

The soldering iron is also not used for soldering large contact areas due to the length of the process. In addition, the flux will oxidize even before it has time to fully warm up.

A burner is the best option. With its help you can solder not only stainless steel with copper, but also with brass.

By the way, when choosing solder, you need to pay attention to brass rods.

It is primarily the most common material for soldering stainless steel and can even be used in a joint without flux. It should be taken into account that brass is inferior to silver in many respects. But it is cheaper. It should only be used for soldering simple non-critical connections.

To obtain high-strength connections, it is better to use copper-phosphorus solder. It is more expensive, but this is a guarantee of high-quality soldering. But the best are silver alloys.

The process of soldering copper or brass to stainless steel is no different from others. It is necessary to clean the edges of the two metals, degrease them, and tinning each edge separately.

Next, you need to place two workpieces on the workbench so that there is a gap of no more than 3 mm between them. Flux is applied, heated, and then solder is fed into the soldering zone.

It should melt and spread along the border of the workpieces. As soon as the gap is completely filled, soldering stops. Metals cool naturally. The remaining flux is washed off with water.

Flux preparation

When soldering stainless steel, you should be very careful about choosing a ready-made flux or the recipe for making it yourself. The classic flux composition, which can be prepared at home, includes the following components:

- borax (70%);

- boric acid (20%);

- calcium fluoride (10%).

For soldering small-sized products, you can prepare a flux that will consist only of borax and boric acid mixed in equal proportions. Having mixed the components of the flux in dry form, it must be diluted with water and treated with the resulting solution at the site of the future connection.

Flux selection

As for flux for soldering stainless steel, the best option here is borax. It can be used in paste or powder form. Borax powder is poured into the soldering zone of two workpieces and heated to a temperature of +850 ℃. This is the so-called light red heat temperature.

Once the flux has melted, solder is added to the area. If you follow the standards, then to work with silver solders, use flux No. 209 or 284 according to GOST, and for solders containing copper and nickel - No. 200 or 201.

Remains of flux after soldering are removed with water (cold or hot) or blown with sand. It is not recommended to use hydrochloric or nitric acid for this. This is a potent material that corrodes the solder layer and the stainless steel itself.

Useful tips

To perform stainless steel soldering efficiently, you should use the recommendations of experienced specialists.

- The power of a soldering iron, which must effectively heat the metal being joined, is in the range of 60–100 W, but it is better to opt for a 100-watt device. To solder large parts, such as stainless steel pipes, you will need a gas torch rather than an electric soldering iron.

- When choosing an electric soldering iron, it is better to opt for models equipped with tips that do not burn.

- The most economical and universal type of solder, which makes it possible to obtain high-quality connections for stainless steel products, is tin-lead rods. If you are soldering dishes that will come into contact with food or liquids, it is better to use pure tin as solder, which does not contain harmful impurities.

- The room in which soldering work is carried out must be well ventilated.

- When performing soldering, be sure to use personal protective equipment so as not to harm your health.

What else you should know about soldering stainless steel

In cases where special requirements are imposed on soldered joints of stainless steel products, special grades of solders can be used, which include materials based on nickel and phosphorus, as well as nickel, chromium and manganese. Solders of the second group are used, in particular, in cases where soldering is performed in a protective gas environment consisting of a mixture of argon and boron trifluoride. When performing soldering using this technology, pure copper can be used as solder, which wets the metal well and forms a reliable connection.

When using copper solder, the soldering area will differ from stainless steel in a characteristic yellow color

Nickel-based solders make it possible to obtain joints with high strength. However, such materials also have disadvantages, which include low ductility. That is why such filler material is not used to connect stainless steel structural elements that will be subject to shock and vibration loads during their operation. In addition, a soldered seam made of such a material is very critical to low temperatures. Soldering with nickel group solders, which melt at temperatures exceeding 1000°, can be performed in dry hydrogen, argon and vacuum.

Thus, soldering stainless steel products (large pipes operated under pressure, dishes, pieces of furniture or interior design) has its own nuances, which must be taken into account when choosing both soldering modes and consumables. There are many reference books, guided by which, you can optimally select all the necessary materials and obtain a high-quality, reliable and beautiful soldered connection.

Soldering stainless steel is quite a complex and difficult job. To make a high-quality connection, you need to comply with many conditions - both in the choice of materials and in the soldering modes. It is somewhat easier to solder alloys containing up to 25% Ni or Cr. They can also be soldered to other metals and alloys, with the exception of Al and Mg. DIYers most often use tin solders.

Can you solder stainless steel with copper?

To begin with, it must be said that this process has an increased level of complexity. But despite this, it is possible to solder stainless steel using copper. Most often, joints are made of parts made of one metal, that is, if you connect parts only from stainless steel or only from copper, the quality of the seam will be high. But sooner or later a situation will arise when you need to solder these two materials together, and in this case you have to give in to the quality of the final result.

To perform this manipulation, special solders were created; with their help, it is possible to create connections of sufficiently high strength and it is quite enough to use the item in standard mode. If when soldering any other material there is no mandatory need to use flux, then complete preparatory procedures are required, including tinning.

Like any other soldering method, this one has its advantages and disadvantages.

.

First, it’s worth considering the advantages of using

:

- using this soldering method it is possible to solve quite complex technological problems;

- there is simply no alternative to this method that would allow joining copper with stainless steel at the same level;

- The soldering process itself does not take much time; it does not require highly specialized tools; a regular torch will be sufficient;

- modern technologies make it possible to create solders that cope quite well with joining dissimilar metals;

- Stainless steel can be soldered to copper both on an industrial scale and at home.

- the quality of the final result is at a fairly low level compared to other soldering methods;

- Certain difficulties arise when selecting the right type of solder;

- the flux used is very quickly subject to the oxidation process, so you need to start soldering immediately, without delaying the heat treatment;

- in most cases, “light” solder is used for soldering, which significantly increases the complexity of the procedure due to the fact that there is a need for precise adjustment of the temperature regime used.

Features of stainless steel soldering

Using tin and compounds based on it, you can repair stainless steel products, as well as assemble homemade structures that are small in size and not subject to heavy loads. Kitchenware and other household items can be repaired with a regular soldering iron and tin solder.

Soldering of stainless steel in production is performed using a more complex technology. For soldering of critical structures, special industrial mixtures containing Cr are used. Equipment used

In order to properly repair products, you need to prepare materials, equipment and study technology. To solder stainless steel in a workshop at home, you will need:

- electric soldering iron with a power of 100 W (portable propane torch);

- flux;

- degreaser (solvent);

- abrasive paper, wire brush, needle file;

- tin solder;

- rags;

- protective equipment: gloves, respirator, safety glasses or transparent face shield.

Portable propane torch

In addition, for the initial heating of massive workpieces, a more powerful soldering iron may be needed. Phosphoric acid provides high-quality surface cleaning and rapid coagulation.

Advantages

- This method allows solving complex technological operations;

- This is one of the few ways to achieve such a connection;

- The procedure itself occurs quite quickly and does not require additional tools, since an ordinary burner is sufficient for this;

- Modern developments of solders provide relatively high compatibility of metals during soldering;

- The process is available for both home and industrial needs.

Solder Types

Solders for stainless steel are divided into two main groups:

- soft;

- solid.

Soft ones are the usual compositions based on Pb and Sn grades POS. Sufficient tin content increases ductility and fluidity, allowing it to penetrate into all micro-irregularities of the surface and significantly improving adhesion. In addition, tin is a good deoxidizer, which is especially important when working with stainless alloys. The disadvantage of such soldering compositions is the low strength of the resulting joint.

To obtain stronger solder joints on stainless steel, hard solders are used. They are used both in industrial conditions and in the home workshop. Up to 30% technical silver is added to solid compositions. They are produced in the form of thin rods and are designated by the letters PSR.

Solder HTS – 528

If you need to solder together dissimilar products made from materials such as stainless steel, copper alloys, nickel, cast iron, use the HTS-528 composition. It already contains flux, and the melting point is not less than 750 ° C

How to choose solder?

The final result of the quality of the work performed largely depends on the choice of a certain type of solder. It ensures complete filling of the treated surface. The most common and affordable method is to use brass solder to solder stainless steel to copper. In some particular situations it can be used even without using flux.

Important: the use of this type of solder is in many ways inferior in physical properties to other methods, however, due to its availability and simplicity, it can be used for soldering simple connections that will not incur a high level of responsibility.

In addition to the above method, you can also use solders from the following materials:

- copper-phosphorus material - it can significantly improve the quality of the final connection, but the cost of this solder is quite high;

- tin-silver material - the use of this type of solder is best suited for joining stainless steel with copper, however, the use of this method is associated with high financial costs;

- To create the simplest connections, you can use ordinary radio consumables, but it is best to choose specialized material.

Flux preparation

Corrosion-resistant alloys are very sensitive to soldering conditions, so the correct choice of flux for soldering stainless steel is extremely important.

The most widely used flux contains:

- 7 parts technical borax;

- 2 parts boric acid;

- 1 part calcium fluoride.

Making flux at home

For soldering small workpieces, the composition of the flux is simplified - equal parts of borax and boric acid are taken. The mixture is diluted in water and applied to the soldering area. Once it dries, it will provide excellent adhesion to the surface of the alloy.

Before applying flux, it is necessary to thoroughly mechanically treat the soldering area with sandpaper, a wire brush or a needle file.

Why do you need flux?

This substance will ensure uniform spreading of solder over the surface of the soldering zone and create conditions for high-quality adhesion of the material to the metal coating. Fluxes are currently classified according to the degree of impact on the following varieties:

- Inactive (neutral), which do not contain acids. In addition, they almost do not conduct electricity.

- Active (acid) fluxes.

- Protective (anti-corrosion), the purpose of which is to protect the soldering zone of the finished joint from corrosion and destruction.

If the question arises why flux is needed for soldering, then the answer can be this: this substance is necessary to comply with the technology, since it will definitely be needed during soldering work. However, the method of application of the composition depends on its initial state:

- if the flux is in a solid state, the soldering iron tip must first be dipped into the reagent, and then grab a little solder with it;

- the finished liquid mixture will have to be applied to the soldering area using a brush;

- The surface should be treated with a paste-like substance using a regular stick.

In addition, flux is sometimes sold in special tubes.

Advantages of soldering stainless steel with tin

The use of soft tin-based compounds provides the following advantages:

- ease of soldering operations for small objects;

- short preparation;

- availability of soldering materials;

- Sufficient soldering quality for not the most critical parts.

Soldering stainless steel with tin

Soldering with soft tin compounds can be quickly mastered by a home craftsman.

Preparation of equipment and necessary materials

When preparing equipment, it is important to pay attention to the characteristics and design features of the soldering iron. Its power is at least 80-110 watts; weaker devices will not be able to provide sufficient heating of the working area. The sting must be fireproof. You can work with a soldering iron using soft, low-melting solders - rods made of pure tin or from mixtures like POS. Pure tin will be needed when repairing kitchen utensils and vessels that come into contact with food or drinking water. It does not contain harmful components. The most suitable flux for such dishes is phosphoric acid.

For hard solders you will have to use a gas torch.

Selection of solder and auxiliary materials

The correct choice of composition allows high-quality soldering of stainless steel parts. Such a connection will be reliable and durable. The most common types of soldering compounds are tin-lead POS grades. For soldering work on stainless steel, experts recommend:

- POS50Kd18 (with the addition of cadmium);

- POS-61;

- POS-40.

Only clean tin should be used to repair items that come into contact with food. Not every flux is suitable for stainless steel.

- soldering acid;

- orthophosphoric acid ;

- zinc chloride.

It is necessary to apply flux immediately before soldering, so that the oxide film does not have time to re-form.

Interesting: Phosphoric acid is part of Coca-Cola. A good reason to think about whether you should drink it.

Food solders

There are no differences in food soldering technology from standard operations. You cannot use materials and alloys that contain lead, for example, POS (tin-lead). Lead is toxic and there is a trend towards a sharp reduction in its use in soldering operations.

When phosphoric acid is used, the soldering itself must be carried out faster. The thing is that after 10-15 seconds a phosphate film will appear on the surface of the parts being joined.

It will make soldering difficult; you will have to clean the stainless steel again, removing this layer. So it is optimal if the flux is applied right before the operation.

Technology of soldering stainless steel with tin

It is very important to carry out the preparatory operations correctly and carefully. Their purpose is to remove oxide film and other contaminants from the surface of the stainless steel that prevent the formation of a strong and durable solder joint. First, the surface is protected with sandpaper, a wire brush or a file. Next, after removing sawdust and abrasive particles, degreasing is carried out. To do this, take a special degreaser. It can be successfully replaced by any organic solvent - acetone, white spirit, numbered solvents (646, 657), etc.

Immediately after degreasing, the soldering area is coated with a flux compound. (If flux is included in the solder rod, this step is not performed.)

Now the actual tin soldering begins. First, the soldering area is heated using a soldering iron tip or a gas torch. When soldering with a torch, the oxygen content should be monitored, since if it is in excess, oxidation processes will begin, deteriorating the quality of the connection. When the permissible oxygen concentration is exceeded, the flame acquires a light blue tint.

The principle of soldering stainless steel

The entire soldering area should be heated to the melting temperature of the solder.

Important! The solder should melt not from the tip of a soldering iron or the torch of a gas burner, but from the heat stored in the parts being soldered.

Solder must be supplied to the working area until it begins to appear from the working gaps between the workpieces. This will ensure optimal adhesion.

Features of alloys

Stainless steel cannot be soldered with aluminum and magnesium alloys. With other metals the process goes well, while the joint itself is characterized by increased strength.

Some stainless steel alloys, especially those containing more than 25% nickel, begin to release carbides at temperatures of +500-700 ℃. These chemical compounds reduce the corrosion resistance of the metal.

And the longer the soldering process at this temperature, the more intense the carbides are released. Therefore, soldering time must be reduced. Soldering at home is carried out with a soldering iron or a gas torch, and a soldering iron is used more often.

Soldering stainless steel at home

It often happens that a home handyman needs to repair household utensils and stainless steel dishes. To do this, it is necessary to prepare a certain set of equipment, as well as working and auxiliary materials. In order to quickly and efficiently repair stainless steel products, you will also need to acquire a certain skill. Therefore, you should not immediately take on the repair of complex or large-sized products. To get better at “feeling metal and fire,” it’s better to practice on spoons, mugs, or just scraps of stainless steel.

Soldering stainless steel at home

To work, you will need to equip a workplace. The work table must be metal or have a non-flammable coating. Exhaust ventilation must be equipped - both the fumes from the soldering compound and the flux and degreaser are harmful to the respiratory system. The parts to be soldered must be securely fastened with inventory fastening devices - vices, clamps, clamps, spacers.

The work area should not be cluttered; only parts to be soldered may be contained in it.

Containers with working fluids should be tightly closed immediately after use and stored in a cabinet or bedside table.

It is necessary to carefully follow the technology for performing the work. If the processing is carried out poorly and the solder does not stick to the surface of the parts, it is necessary to stop soldering and repeat mechanical processing and degreasing. After degreasing, you can handle parts only with thick gloves - even a small sweat stain left by your fingers can ruin the work.

You can make your own wire brush for stripping. To do this, wires obtained from a piece of metal cable must be tightly inserted into a piece of pipe with a diameter of 5-10 millimeters and a length of about 10 cm. They should protrude from the tube by a few millimeters. For small soldering areas of stainless steel, and especially in narrow and hard-to-reach places, such a homemade product is much more convenient and effective than purchased brushes with a wooden handle.

This brush can be used to work in close proximity to a soldering iron or burner flame, minimizing the time between stripping and the start of soldering.

Soldering with a gas torch

The burner is moved smoothly, heating the metal evenly. The solder rod should melt not from the flame of the burner, but from the heat of the workpiece - only then will a strong and reliable connection be obtained. After applying the rod to the joint area, it is necessary to further heat the workpieces so that it completely penetrates into all the gaps and fills them. Heating is continued until excess soldering compound begins to flow out of the joint.

The most common mistakes

There are a number of mistakes that a person can make when carrying out work:

- Solder may not adhere to the material due to poor cleaning of the work surface.

- Contamination of the part with greasy fingers before applying flux.

- Insufficient heating. Solder does not always have time to fill the seam for reliable bonding.

It is important to remember to clean the soldering iron tip.

It is advisable to refrain from using solders with a high percentage of lead. Soldering stainless steel is a difficult process, but it can be done. To successfully connect parts, you need to choose the right consumables and use high-quality tools.