For reference, table 10 (coarse thread pitch) and table 11 (fine thread pitch) show the breaking loads for nuts and bolts of various strength classes. For bolts of low strength classes, the expected failure will be stripping of the bolt threads, while for bolts of high strength classes, stripping of the nut threads can be expected.

Table 10 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(large thread pitch)

| Nut strength class | Test load voltage nuts, N/mm2 | Minimum stress in the bolt shaft when the thread breaks, N/mm2, for bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | ||

| 04 | 380 | 260 | 300 | 330 | 350 |

| 05 | 500 | 290 | 370 | 410 | 480 |

Table 11 - Breaking loads for nuts with a nominal height of 0.5 d

up to 0.8

d

(fine thread pitch)

| Nut strength class | Minimum stress in the bolt shaft when the thread is broken, %, stress from the test load of bolts of strength class | |||

| 6.8 | 8.8 | 10.9 | 12.9 | |

| 04 | 85 | 65 | 45 | 40 |

| 05 | 100 | 85 | 60 | 50 |

8.1 Proof load test

A proof load test should be carried out whenever the testing equipment used allows, and this test is decisive for nuts with a thread diameter of M5 and larger.

The nut is screwed onto a hardened mandrel, as shown in Figures 1 and 2. In cases of dispute, the tensile test is decisive (see Figure 1).

1) D11 - according to GOST

25346

Figure 1 - Axial tensile test

Figure 2 - Axial compression test

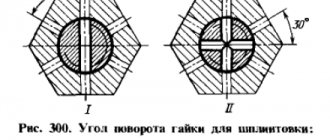

The test load is applied to the nut in the axial direction and held for 15 s. The nut must withstand the load without breaking or stripping the thread and can be unscrewed by hand after the load is removed. If the thread of the mandrel is damaged during the test, the test is considered invalid. When unscrewing a nut, it is permissible to use a wrench to turn the nut 1/2 turn, and then it must be unscrewed by hand.

The hardness of the test mandrel must be at least 45 HRC.

The tolerance field of the mandrel thread is 5h6g, with the exception of the tolerance of the outer diameter of the thread, which should be 1/4 of the tolerance field 6g in its lower part.

MATERIALS FOR MANUFACTURING HIGH-STRENGTH NUTS GOST R 52645-2006

Hex nuts in accordance with GOST R 52645-2006 can be made of carbon or alloy steel of such grades as: 35, 40, 35Х, 38ХА, 40Х, 40Х Select, 45, 45Г, 40Г2, 30ХГСА, 35ХГСА. It is allowed to produce nuts without applying an anti-corrosion coating or with metal and non-metallic coatings made in accordance with GOST R 9.306 or GOST R 9.316 with a thickness of 25 to 50 microns.

Depending on the modification, the product can be coated by thermal diffusion galvanizing, galvanic galvanizing, galvanic nickel plating, galvanic chromating, or in the form of a black oxide film with a thin residual oil coating. The latter is a normal coating for this type of nut, obtained as a result of heat treatment. Among arbitrary types of coating, the most widely used method is thermal diffusion galvanizing: in a special container - a retort, which is then placed in a muffle furnace, a steel nut and a zinc-containing powder mixture are subjected to uniform heating to 290-400 ° C (depending on the steel grade), as well as mixing in rotation process. As a result, due to the transition of zinc atoms into the vapor phase and penetration into the iron substrate, a zinc coating is formed on the surface of the hardware in the form of an iron-zinc alloy with a complex phase structure. Thus, the product becomes more wear-resistant and heat-resistant, and becomes resistant to aggressive atmospheric influences, corrosion in sea or fresh water. This coating is less susceptible to peeling or chipping due to impacts, mechanical loads and deformations.

The absence of a coating for hardware, as a rule, implies the use of the product for painting or in fastening work that does not have requirements for aesthetic content or special conditions of corrosion resistance, for example, in industrial construction or mechanical engineering.

To avoid hydrogen embrittlement, it is not recommended to apply coatings using the electrolytic method and the hot-dip method.

8.2 Hardness test

When inspecting nuts, the hardness test is carried out on one of the supporting surfaces of the nut at three points shifted relative to each other by 120°, and the hardness values are determined as the arithmetic mean of three measurements.

In controversial cases, hardness is checked on a longitudinal section passing through the axis of the nut, at points located as close as possible to the outer diameter of the nut thread.

The Vickers hardness test is decisive and, where possible, a load of 30HV should be applied.

If Brinell and Rockwell tests are used, conversion tables should be used.

Vickers hardness test - according to GOST 2999.

Brinell hardness test - according to GOST 9012.

Rockwell hardness test - according to GOST 9013.

Markings

If you are not a professional builder, you should not delve into the jungle of bolt classifications. It is important to know that, as already mentioned, the numbers on the head of the bolt indicate the strength class. Usually these are two numbers written with a dot, for example, 3.6 or 10.9.

The first number indicates the load on the threaded connection that the hardware can withstand. More precisely, this is one hundredth of the nominal value of the tensile strength of the hardware. The measurement is carried out in MPa.

Example: if you see 8.8 on a bolt, this means that the tensile strength of the bolt will be 8×100 = 800 MPa.

The next figure indicates the ratio of the yield strength to the tensile strength multiplied by ten. From two numbers you can calculate the yield strength of the material. To do this, they are multiplied by each other, and then by another ten.

Example: we return to the same 8.8. 8×8 x 10 = 640 N/m.

It is important to understand that the maximum working load limit of a bolt is the yield strength. When calculating a bolt connection for a given load, use a coefficient of 0.5-0.6 from the yield strength. For example, if an M14 bolt of strength class 8.8 has a cross-sectional area of about one square centimeter and a body diameter of about 12 mm, then its tensile strength will be 8 tons, its yield strength will be 6.4 tons, and its design load will be 6.4× 0.5 = 3.2 t.

Stainless steel bolt markings

Among the markings on a bolt made of stainless steel, the marking of the steel itself, A2 or A4, comes first. Next comes the tensile strength, for example 50, 60, 70, etc. These numbers also indicate one tenth of the tensile strength of carbon steel, measured in MPa.

9.1 Notation

Markings are given in tables 12 and 13.

Table 12 - Markings of nuts by strength classes in accordance with 3.1

| Strength class | 4 | 5 | 6 | |

| Alternative markings | or designation symbol | 4 | 5 | 6 |

| or code symbol (dial system) | ||||

End of

table 12

| Strength class | 8 | 9 | 10 | 121) | |

| Alternative markings | or designation symbol | 8 | 9 | 10 | 12 |

| or code symbol (dial system) | |||||

| 1) At the 12 o'clock position, the marking dot cannot be replaced by the manufacturer's mark. | |||||

Table 13 - Marking of nuts by strength classes in accordance with 3.2

| Strength class | 04 | 05 |

| Marking |

Hex nuts, Nuts GOST 5915-70, 5927-70

GOST 5915-70 hex nut (analogous to DIN 934) is used in construction and mechanical engineering for connecting parts together, for all sectors of the national economy and for assembling bolts.

They are made from steels 20G2R, 35, 40X, 09G2S, sizes from M4 to M42.

The zinc coating is made to order. Accuracy class: A, B. Strength class: 5; 6; 8, 10. Thread tolerance range: for 6H, 7H nuts. Nut GOST 5915-70 hexagonal

| NTD | GOST 5915-70 DIN 555 |

| Size range | M4-M30 |

| Nut accuracy class | B A |

| Nut thread tolerance range | 6h 7h |

| Nut strength class | 6 8 10 |

| steel grade | 10kp 20kp |

It is possible to supply nuts in accordance with GOST 5915-70 with fine thread pitches and in a high-strength version (strength classes 8.0 and 10.0) made of 20G2R steel.

Hex nut GOST 5915-70 produced by OSPAZ

| Diameter, d | 4 | 5 | 6 | 8 | 10 | 12 |

| S | 7 | 8 | 10 | 13 | 17 | 19 |

| e,no less | 7,5 | 8,6 | 10,9 | 14,2 | 18,7 | 20,9 |

| m | 3,2 | 4 | 5 | 6,5 | 8 | 10 |

| thread pitch | 0,7 | 0,8 | 1 | 1,25 | 1,5 | 1,75 |

Nut GOST 5915-70 hexagonal

| d | 16 | 20 | 22 | 24 | 27 | 30 |

| S | 24 | 30 | 32 | 36 | 41 | 46 |

| e,no less | 26,2 | 33 | 35 | 39,6 | 45,2 | 50,9 |

| m | 13 | 16 | 18 | 19 | 22 | 24 |

| thread pitch | 2 | 2,5 | 2,5 | 3 | 3 | 3,5 |

Can be supplied:

- with strength classes 6.0, 8.0, 10.0* from steels 20, 35, 20G2R;

- galvanized zinc coated

An example of a nut symbol GOST 5915-70

Nut with thread diameter d=12 mm, with a large thread pitch, with a thread tolerance of 6H, strength class 5, uncoated:

Nut M12-6N.5 GOST 5915-70

The same, with a large thread pitch with a tolerance range of 6H, strength class 6, made of steel grade A12, without coating:

Nut 2M12-6N.6.A GOST 5915-70

The same, with a fine thread pitch with a tolerance range of 6H, strength class 12, made of steel grade 40X, with a coating of 01 6 microns thick:

Nut 2М12X1.25-6Н.12.40X016 GOST 5915-70

Theoretical weight of 1000 pieces of nuts GOST 5915-70, kg

| Diameter, mm | Theoretical weight of 1000 pieces of nuts, kg |

| 6 | 2.441 |

| 8 | 5.130 |

| 10 | 11.370 |

| 12 | 15.400 |

| 14 | 28.480 |

| 16 | 33.17 |

| 18 | 47.03 |

| 20 | 62.60 |

| 22 | 76.77 |

| 24 | 107.0 |

| 27 | 161.40 |

Nut GOST 5927-70 hexagonal

GOST 5927-70 hex nut is used in construction and mechanical engineering for connecting parts together, for all sectors of the national economy and for assembling bolts.

Made from steel grades: 20G2R, 10 kp; 20kp; 35. Accuracy class: A, B. Strength class: 5; 6; 8, 10. Thread tolerance range: for 6H, 7H nuts. Nut GOST 5927-70 hexagonal

| NTD | Nut GOST 5927-70 DIN 934 |

| Size range | M4-M30 |

| Nut accuracy class | B A |

| Nut thread tolerance range | 6h 7h |

| Nut strength class | 6 8 10 |

| steel grade | 10kp 20kp |

It is possible to supply nuts in accordance with GOST 5927-70 with fine thread pitches and in a high-strength design (strength classes 8.0 and 10.0) made of 20G2R steel.

Nuts according to this GOST made of steels 35, 40Х, 09G2S sizes from M4 to M42, nuts with zinc coating are made to order.

Hex nut GOST 5927-70 produced by OSPAZ

| Diameter, d mm | Nut 6 | Nut 8 | Nut 10 | 12 | 14 |

| S | 10 | 13 | 17;16 | 19;18 | 22;21 |

| e,no less | 11,1 | 14,4 | 18,9;17,8 | 20,9;19,9 | 24,5;23,4 |

| m | 5 | 6,5 | 8 | 10 | 11 |

| thread pitch | 1 | 1,25 | 1,5;1,25 | 1,75;1,25 | 2;1,5 |

Hex nut GOST 5927-70 produced by OSPAZ

| Diameter, d mm | 16 | 18 | 20 | 22 | 24 | 27 |

| S | 24 | 27 | 30 | 32;34 | 36 | 41 |

| e,no less | 26,8 | 30,1 | 33,5 | 35,7;37,7 | 40 | 45,6 |

| m | 13 | 15 | 16 | 17 | 19 | 22 |

| thread pitch | 2;1,5 | 2,5;1,5 | 2,5;1,5 | 2,5;1,5 | 3;2 | 3;2 |

Can be supplied:

- with strength classes 6.0, 8.0, 10.0* from steels 20, 35, 20G2R;

- galvanized zinc coated

An example of a nut symbol GOST 5927-70

Nut with thread diameter d=12 mm, with a large thread pitch, with a thread tolerance of 6H, strength class 5, uncoated:

Nut M12-6N.5 GOST 5927-70

The same, with a large thread pitch with a tolerance range of 6H, strength class 6, made of steel grade A12, without coating:

Nut 2M12-6N.6.A GOST 5927-70

The same, with a fine thread pitch with a tolerance range of 6H, strength class 12, made of steel grade 40X, with a coating of 01 6 microns thick:

Nut 2М12X1.25-6Н.12.40X016 GOST 5927-70

Theoretical weight of 1000 pieces of nuts GOST 5927-70, kg

| Diameter, mm | Theoretical weight of 1000 pieces of nuts, kg |

| 6 | 2.573 |

| 8 | 5.548 |

| 10 | 10.220 |

| 12 | 15.670 |

| 14 | 25.33 |

| 16 | 37.61 |

| 18 | 52.27 |

| 20 | 71.44 |

| 22 | 103.15 |

| 24 | 122.87 |

| 27 | 175.28 |

Production of nuts at a factory: how and what steel is made from, equipment for the production of nuts

LOOK EVERYONE!

A nut is a fastener with a thread inside, usually in the shape of a hexagon according to GOST for use with a wrench. It is connected using a bolt, stud or screw.

Types of nuts

There are many types of this product:

- Crown - equipped with additional protrusions at one end.

- Body nuts are a square nut with a counterplate that are used in the automotive industry.

- Wing - have at least two blades and are designed to be twisted by hand.

- Slotted - used for flush screwing using a fork screwdriver.

- Push-type - used in the instrument-making industry and tightened by hand.

- Cap-shaped ones are decorative, as they are made in the shape of a cap at the top.

- Square - designed for screwing in bolts. This type is fixed in the socket until installation begins.

- End - made in the form of the letter T and used in the machine tool industry.

- Flanged - have notches on one side that replace a washer.

- Self-locking - prevents self-unwinding. Used under increased vibration loads.

- An eye nut is a ring-shaped connection that is used for rigging work.

- Riveted - they have a threaded connection at one end, and at the other they resemble a regular rivet.

- Connecting nuts are a regular elongated nut. You can screw two bolts into it.

- Welded - additionally have excess metal at the edges for welding.

- Blind - closed on the top side.

Cap nut

Eye nut

In addition to the above types, there are various forms: low and high, wide and narrow.

What are nuts made of?

It should be noted that the composition of nuts is very diverse and depends on the strength class and scope of application. Today the most common material is steel. It is suitable for cold stamping using presses. Low-carbon steel is also used, but hardening is used during the production process. Additionally, bronze, titanium and brass can be used. Duralumin and magnesium alloy are not very widely used.

2. MATERIAL

2.1. Nuts must be made from steels whose chemical composition corresponds to that indicated in Table 3.

Table 3

| Nut strength class | Limit value of element content (control analysis), % | |||

| C, no more | Mn, not less | R, no more | S, no more | |

| 4*; 5*; 6* | 0,50 | — | 0,110 | 0,150 |

| 8; 9; 04* | 0,58 | 0,25 | 0,06 | 0,150 |

| 10**; 05** | 0,58 | 0,30 | 0,048 | 0,058 |

| 12** | 0,58 | 0,45 | 0,048 | 0,058 |

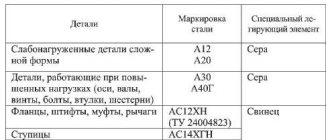

________________ * Nuts of the indicated strength classes can be made from free-cut steel by agreement between the manufacturer and the consumer. In this case, the allowed content of sulfur, phosphorus and lead is no more than:

S - 0.34%,

P - 0.12%,

Pb - 0.35%.

** If necessary, improve the mechanical properties of nuts of the specified strength classes. For their manufacture, steels with additions of alloying elements can be used.

2.2. Nuts of strength class 05; 8 (M16); 10 and 12 must be quenched and tempered.

Note. It is allowed that nuts of strength classes 8 and 10 with a height of at least 0.9 are not subjected to heat treatment.

(Changed edition, Amendment No. 2).

2.3. Recommended steel grades and technological processes for manufacturing nuts are given in the appendix.

Strength classes of nuts and bolts with metric threads from 1 to 48 mm according to GOST 1759.5

In table 4 shows the recommended combinations of strength classes of mating parts for various thread diameters. In special cases, fasteners can be made from corrosion-resistant, heat-resistant, heat-resistant steels, as well as non-ferrous alloys. The strength class of the nuts is indicated by a number which, when multiplied by 100, gives the value of the stress from the test load in MPa.

As a rule, nuts of high strength classes can replace nuts of low strength classes. This replacement is recommended for bolt-nut connections, the stress in which will be higher than the yield strength, or the stress from the test load of the bolt.

Related Pages

- Cylindrical threads

- Tapered threads

- Metric thread

- Runs, undercuts, grooves and chamfers according to GOST 10549

- Thread persistent

- Trapezoidal thread

- Symbols of fasteners according to GOST 1759.0 (ST SEV 4203)

- General Purpose Hex Head Bolts

- General purpose screws

- Captive screws

- Set screws

- Special purpose bolts and screws

- Self-tapping screws for metal and plastics

- Locking the nut against the bolt with additional elements

- Locking the nuts relative to the body

- Locking the nut relative to the bolt due to additional friction, welding and plastic deformation

- Locking bolts. Preventing screws and nuts from being lost

- Locking screws

- Flange connection parts

- Flange connections for pipes and cylinder heads

- Flange connections for metal structure pipes

- Application examples for set screws

- Terminal connections

- Friction screw clamps

- Ties and stops

- Fastening machines to bases