Toilet sealant - installation, types and applications

In the toilet and bathroom, where the level of humidity constantly increases, fungal colonies and mold often appear on the floor surface. To reduce the risk of the latter, you should use sealant for the bathtub and toilet. A product such as toilet sealant reliably seals all holes and joints, protects the floor from leaks and the formation of pathogenic microscopic organisms.

Depending on the properties and composition, all sealants can be divided into several types, although there are also gels and combined pastes.

Acrylic. Typically, such products are marked with the presence or absence of resistance to water. If the adhesive-sealant does not have the ability to withstand moisture, it can only be used in dry rooms. Waterproof acrylic sealants can withstand high air humidity, but usually do not tolerate constant contact with water. The advantages of the compositions include safety for human health, excellent adhesion, and a large selection of shades. It is recommended to use them for repair work on furniture, doors, windows, but cannot be used in the bathroom.

When is sealing of sewer pipes required?

Often the sewer riser or outlet parts of a cast iron pipe receive serious damage. An inspection shows that a piece of the cemented patch is falling off, and the pipe itself may fail. In this case, the master decides to use sealant for cast iron sewer pipes or PVC plastic pipes. During the work, the recommendations specified in SNiPs and technical regulations, pipe wear, hydraulic effects and the possibility of leaks are taken into account.

Sealant for sewer pipes must be selected taking into account the fact that this external sewer has a significant diameter and a large length.

Sealing PVC sewer pipes is necessary to prevent sewage from entering the apartment and eliminating unpleasant odors in residential areas.

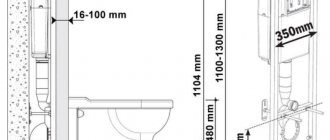

Scheme for sealing a pipe joint

Solving the problem of sealing joints must be taken quite seriously.

Having identified the cause of the malfunction that is interfering with the operation of the cast iron pipe, the owner can carry out the entire cycle of necessary work to eliminate it.

The causes of pipe leaks are varied:

- defect in the material used to install the sewer;

- improper laying of cast iron sections;

- the presence of cracks and holes in the riser.

Quality of corrugated pipe

Replacement of corrugation.

Modern plumbing stores have a large selection of corrugated pipes for toilet repairs, varying in price and quality. But is it worth shelling out for expensive products or can you get by with cheap ones? Research by experts in the field of plumbing equipment will help answer this question. The experiment was carried out as follows: cuffs from corrugations from different manufacturers were put on a regular pipe one by one.

Related article: Plasterboard ceiling in the bathroom: whether to do it, and if to do it, then how

It turned out that cheap, low-quality corrugation does not fit tightly to the inner walls of the pipe and forms waves, which (according to experts) intensify over time, which inevitably leads to leakage. In addition, during the repair process, with minor bends, the corrugation can easily become deformed. It was also noticed that the cuff skirt of some products is not straight, but cone-shaped, which is completely unacceptable. More expensive products, especially imported ones, are considered to be of higher quality, so they are necessary for a good repair.

To carry out repair work, you should call a specialist. When replacing pipes, knowledgeable people advise monitoring the actions of the plumber, because good specialists are rarely found in this matter. However, even with correct and careful installation, low-quality corrugation still very quickly becomes unusable. It follows from this that there is no need to save on materials, otherwise you will have to make repairs again and again. It is important to note that when calling a plumber, it is advisable to ask not only about the cost of the material, but also about its manufacturer. A qualified master will always give a specific and detailed answer to any question related to his field of activity.

Types of sealants

Sealing of sewer pipes can be done with the following materials:

- reinforced aluminum adhesive tapes;

- silicone sealants;

- mastics from various manufacturers;

- polymer cement solutions;

- sanitary winding;

- epoxy resin;

- technical sulfur.

To choose the right sealant for sewer pipes, you need to know the material from which the drain is made. Silicone compounds and reinforced tapes are suitable for lightweight plastic pipes PVC, PEX, HDPE, etc. If you have to work with metal (steel or cast iron), you need to use something serious. It is also important to consider for what work the solution is purchased.

The joints of PVC plastic pipes are sealed with lightweight silicone, which is unlikely to cope with an emergency leaking sewer. It is also important to follow the instructions. It describes the optimal conditions under which sewer pipes should be sealed. For example, let's take the optimal conditions for curing silicone sealant (this is room temperature, at which it dries for about 4 minutes). When working in cold weather, the hardening time is significantly longer.

There is a need to purchase another type of sealant - frost-resistant silicone. We'll talk about the nuances of using different materials below.

Advice from the experts

Corrugation device.

Experts advise placing the toilet (if possible) at a minimum distance from the sewer pipe, since in this case the corrugation stretches less and, therefore, sag less. A stretched pipe becomes deformed, deposits accumulate on its walls, which pull it down - this leads to potential blockages. There are times when it is impossible to dismantle a sanitary fixture. In this case, you can simply cut off the old plastic pipe with a knife and replace it with a new one.

Some disadvantages of a corrugated toilet pipe should be noted: it is easy to damage from the outside and inside. In the first case, this can happen from any mechanical impact, and in the second, from a sharp object, such as a piece of glass, being flushed down the toilet. Despite the fact that plastic is considered resistant to aggressive environments, exposure to various chemicals that are part of cleaning products still destroys it over time. From an aesthetic point of view, the corrugation does not look very nice, because unpleasant deposits inside are visible through its walls.

Article on the topic: Cross stitch works: finished gallery, manufacturing technology, photos and videos, paintings and diagrams, hand-stitched work

Self-adhesive tapes and their properties

The structure of the sealing tape

This type of sealing can be used both to seal and protect joints, and to strengthen sealing plugs, fittings, taps, corners and elbows. The main advantage of the tape is its ease of use. It is wrapped in several layers around the pipe on the desired section of the sewer. This ensures reliable and long-term operation of the system, protection against corrosion and the effects of currents, and waterproofing of joints. Depending on the composition, adhesive tape can be used both on cast iron sewer pipes and on plastic, such as PVC or PE (HDPE) pipes.

The tape must be applied to a dry surface. Before winding, the pipe is cleaned of dirt and liquid and degreased. Next, we wrap the problem area with an overlap so that the previous round overlaps the new one by half the width. We keep the tape under tension and do not create folds.

As for the choice of insulating material, special anti-corrosion tape coatings should be used. They are used to seal joints between pipes, seal coupling units, tie-ins, and bends related to the sewer system.

What is a sealing tape that insulates a sewer pipe? The product is based on a bitumen-rubber mixture and a protective film.

The peculiarity of the material is that it has a high degree of strength, is used to work with various compositions, and does not collapse for a long time.

You can avoid the unpleasant consequences of a leaking sewer riser by sealing the joints with a silicone compound. For work, 2 types of materials are used:

- acid insulation;

- neutral sealant.

Repairing defects using a neutral compound will cost the owner much more than working with acidic insulation.

The use of silicone is economically beneficial, since the material has significant adhesion.

As for the use of other sealing compounds, here you can choose the following types:

- bitumen mastic;

- cement mortar;

- asbestos cement composition.

Do-it-yourself toilet corrugation replacement

Replacing corrugations with your own hands.

If you decide to install an accordion pipe with your own hands, then you need to take into account some parameters: the corrugation varies in length and degree of rigidity. In addition, it can be reinforced or unreinforced. It is best to purchase corrugation reinforced with stainless steel, as it is considered the most durable. In the manufacture of this product, steel threads are used, which help increase the density of the pipe and protect it from cracking.

In stores you can also find different types of corrugated pipes: angular, offset, with and without an outlet. If we are talking about a regular replacement that excludes remodeling the bathroom, you should purchase the same pipe (in size and shape) as was installed previously, only of better quality.

For installation you will need:

- corrugation;

- plumbing sealant;

- sharp knife;

- gloves;

- rag.

Related article: Septic tank “Tank”: comparison of septic tanks, negative reviews, reasons

Corrugation replacement diagram.

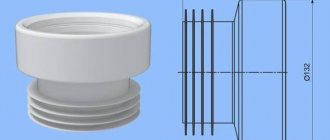

The corrugation has a simple design: it is a tube, one end of which (with internal membranes) is intended for attachment to the toilet, and the other (with O-rings) to the sewer pipe. Before proceeding with installation, you need to turn off the water and dismantle the sanitary fixture. Then you should remove the old tube and thoroughly clean the toilet and sewer outlet from residual waste and mucus. The old sealant is scraped off with a sharp knife. The internal and external surfaces of the sockets must be not only clean, but also smooth, without small debris. To seal the connection and reduce unpleasant odors, they are lubricated with silicone sealant.

Next, you need to put one end of the pipe onto the toilet drain hole, and push the other into the sewer hole until it stops and seal the joints again. Place the toilet in place and tighten the mounting screws (if any) until it stops wobbling. It is important not to overdo it in this matter, otherwise you may split the base of the toilet. If the floor is uneven, then it is lubricated with cement mortar (or sealant) so that the structure stands firmly and does not tilt under the user’s weight. When the sealant has dried, you need to check the quality of the work done: pour water into the toilet - if it doesn’t flow anywhere, then the installation process can be considered successfully completed.

Silicone sealant

Sealing of joints is carried out using silicone adhesives made in accordance with TU 6-15-1822-95, GOST 6-02-4-53-96.

All plumbers have a weakness for this type of sealant. Meanwhile, silicone compounds have good sealing ability, allow you to seal seams and cracks in plastic and cast iron pipes, dry quickly and are easily removed from the surface.

There are two types of silicone compounds.

- The first type, neutral , allows you to work with any surface and does not come into contact with water and other substances. Features a higher price tag.

- The second sealant, acidic , is used only for PVC pipes and other plastics. Although it is a cheap substitute, it destroys metal and cement-containing materials. In the presence of water, it breaks off acetic acid, which can damage the inside of pipes. Therefore, for cast iron and steel pipes we choose only neutral sealant.

Silicone insulating material is a rubber-based composition consisting of a filler, a hardener and a catalyst. The vulcanization temperature of the material ranges from +60 to +200˚С.

Stages of sealing cast iron pipes with sealant

Silicone sealant for repairing PVC pipes in the sewerage system has a density of 2.0 g/cm³, dries at a temperature of +20˚C in 150 minutes. The tensile strength characteristics are even more varied, ranging from 16 to 20 kgf/cm² and depending on the grade of material.

The peculiarity of the sealant is that the vulcanizer has high adhesion to steel, copper, aluminum, silicate glue, and concrete. Silicone sealant is resistant to adverse weather conditions, solvents, synthetic and mineral oils.

When repairing a pipe, there is no pollution of the environment with toxic substances, since silicone materials belong to class 4 of low-hazard products. The sealant is used for gluing and sealing joints and connectors when repairing sewer pipes.

Details

Features of silicone type sealants

To glue the toilet to the floor and seal its base, you should buy a silicone-type compound. This is a one-component, one-pack type product that seals cracks, seams, holes and defects as reliably as possible. Silicone sealants can be divided into several types.

Sour or vinegar

Such products can be classified as “economy” sealants - they are accessible, quite cheap and reliable. Among the disadvantages, we highlight the sour aroma, which indicates the presence of acid in the composition, and therefore sealants cannot be used on the surface of aluminum or marble due to the risk of damage.

Neutral

To seal the toilet with a sealant, you should use a product. Such compositions are based on alcohol components, as well as metal oxides, which make them much stronger. They are suitable for any type of material, do not cause damage, but are much more expensive than others.

Sanitary

Sanitary products include a group of silicone sealants that are used in residential areas. They do not contain toxic components, and they have a minimal shrinkage percentage, and therefore the seams will remain tight and durable for a long time. Due to the fact that the product is elastic, it is useful for moving units and joints. Often, plumbing-type devices are installed on them, including a toilet, a substrate is installed, and the joints are sealed.

Please note that, among other things, sealant can be used to fill the seams between tiles where they are exposed to water, close the joints between structures and walls, fix small glass items without bolts, and additionally attach mirrors.

Advantages of silicone sanitary sealant

A huge advantage of silicone-based sealant is the ease of working with it and the ability to install plumbing fixtures yourself. The product is universal, suitable for a huge range of actions in the kitchen, bathroom, bathhouse, sauna and swimming pool. Other advantages:

- Resistant to ultraviolet radiation and does not fade in light.

- Suitable for all types of materials that are suitable for the manufacture of sanitary ware - earthenware, cast iron, acrylic and ceramics.

- Resistance to high and low temperatures, humidity, changes, excellent tolerance to direct contact with water.

- The presence of a fungicide in the composition, and also protects surfaces from mold and fungal colonies.

- Enormous strength, and also high adhesion force to the base.

- A shiny and smooth surface of the seam after drying, and also a beautiful appearance.

- Elasticity and the ability to stretch/shrink along with the main material.

- Resistant to household chemicals and other aggressive substances that can get on the seams.

- Safety for people and environmental friendliness.

How to choose the right product?

Right choice

Silicone sealants are available for sale in various packages - tubes, cartridges and sprays. The cheapest ones are the usual formulations in tubes, which have elongated spouts. Cartridge sealants require the additional purchase of a special gun. They are usually purchased for processing huge rooms.

Please note that silicone sealant must not only be used correctly, but also purchased with a serious approach to the issues. To begin with, you should choose a composition that is suitable in shade, although usually masters prefer white or transparent products. There are still some factors to consider.

Best before date

Sometimes silicone toilet sealant with an expiring shelf life is sold at a huge discount. You should not be fooled by tempting offers - usually the products are very thick, have less elasticity and tend to partially lose other useful characteristics, and even more so fungicidal.

Undamaged packaging

If there is even a very small crack on the sealant body, it will quickly dry out from contact with air. When purchasing, you need to make sure that the integrity of the tube or other packaging is completely preserved. After uncorking, you should cover all the necessary places literally 3-4 days in advance, since otherwise the sealant will begin to dry out.

Manufacturer

Proven and reliable brands produce high quality products. Products such as “Titan”, “Moment”, and “Knauf” have proven themselves best. The disadvantage will be the higher cost, because a popular brand always has an inflated price for the product.

Place of purchase

Sealants are sold everywhere, even in supermarkets. You should not buy them at the market from hand; for this there are special departments at the market or construction/hardware stores, where the goods are definitely not expired.

Application when installing a toilet

To install a toilet with sealant, you need to perform the entire sequence of actions correctly. First, buy all the most necessary materials, prepare consumables and equipment:

Direct sealant.- Laundry soap.

- Solvent for silicone (if you need to tear off and remove excess sealant or remove the old layer of the compound).

- Marker.

- Glass drill and door.

- Stationery knife.

- Construction tape.

- Rubber or plastic spatula.

- Cotton napkin.

- Degreasing agents - acetone and alcohol.

Now the preparatory stage.

Preparatory stage

Most often, toilets with an oblique, vertical or even horizontal outlet are installed on laid tiles. For this reason, you will need to carry out the work carefully so as not to damage or break the tiles. To choose the correct position for the plumbing, you should connect the corrugation to the drain in advance. Before installation you need:

- Shut off access to water.

- Clean the entire area.

- Wash the bottom of the toilet, wipe the joint with alcohol to degrease.

Let's consider the next stage.

Marking

To glue the toilet with sealant, you need to mark the entry areas of the anchors on the floor with a marker that can be easily erased from the tile, and then trace the outline of the toilet. Next, remove it and cover the areas around the contour with construction tape. This will make it possible to keep the surface clean.

Hole preparation

The door requires making holes in the floor where bolts will need to be placed. It is important to turn off the impact mode of the drill in advance so that cracks do not form on the surface of the tile. Such a drill will not work for a concrete floor, and you will need to buy a Pobedite one. After the holes are ready, clean them from dust using a vacuum cleaner or dry rag.

Application of the product

Pour a little product inside the holes so that the anchors hold much stronger. The sealant will also serve as waterproofing, and water will not get into the holes. The order of work is as follows:

- Apply sealants in a thick layer along the intended contour.

- Mount the toilet and press it as best as possible.

- Attach the device to the anchors, and place a rubber gasket under the mounting cap.

- Wipe off excess sealant or immediately remove it with a napkin.

- Remove construction tape.

Please note that if cracks have formed on the toilet legs, they can also be sealed with sealant. Cover up the entire flaw or break from below, completely hiding it and extending slightly beyond the edges. You need to level the product with a spatula, and then immediately wash the tool in a soapy solution, otherwise the product will stick tightly. Using the same soap solution, treat the crack over the applied product and level it with your fingers until smooth, if there is no spatula available.

Application of sealant in old sanitary units

Silicone paste can be used for partial repairs of an old toilet, the joint of which with the floor surface has already lost its strength. To do this you need to proceed as follows:

- Prepare the base - remove dirt, rust, old sealant and plaque.

- Degrease the surface.

- Buy sealant in a cartridge and insert it into a construction gun.

- Swipe the product over the seam so that it gets deeper under the device, making the line continuous.

- Remove excess composition with a rag.

- After a few minutes, start forming the seam using a rubber spatula (you can do everything with your hands wearing rubber gloves) - the goal will be to level the silicone to the level of the surface that has been treated.

- After hardening, the drops and uneven seam need to be cut off with a stationery knife.

It happens that the cuff on the toilet, which is placed on the sewer pipe, has lost its seal. It can also be replaced using sealant. To do this, remove the adapter with the cuff from the rubber pipe seal, and also remove the latter, clean and dry. Buy new elements 0 cuff, seal and adapter. Apply silicone sealant to the pipe, insert the rubber band, then lubricate the cuff with a similar compound and secure it in place.

Recommendations for application

In order for the seam to last for a long time, you must follow the rules when working with toilet sealant:

- The maximum permissible joint width is from 0.5 to 3 cm.

- The thickness of the seam can be up to 1 cm.

- Possible application depth up to 6 cm.

- For very large defects, additional plumber's tape should be used.

Following the advice and algorithm of actions helps to do the work efficiently yourself without the involvement of specialists and unnecessary expenses.

Technical sulfur

Sealing an old cast iron drain can be very difficult. Technical sulfur was often used to repair cast iron pipes. But to apply it, it was necessary to heat the composition to a plastic state. A special vessel was used (bath for heating sulfur).

The material is pre-melted in an electric furnace at a temperature of 130-135˚C, and then poured into the socket. Unfortunately, the repair may be of poor quality if it was not possible to fill it at once.

Observing special precautions will help you avoid unpleasant consequences when working with sulfur, since the sealant easily spills, and careless handling leads to a chemical burn.

In addition to the high temperature and risk of fire, there was another risk factor during such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Nowadays, pipes can be sealed in safer ways, so technical sulfur is practically not used.

Application when installing a toilet

To install the toilet on the sealant, you need to correctly carry out the entire sequence of actions. To begin, purchase the necessary materials, prepare consumables and tools:

- silicone sealant;

- solvent for silicone (if you need to tear off and remove excess sealant or remove the old compound);

- laundry soap;

- marker;

- drill, glass drill;

- construction tape;

- stationery knife;

- plastic or rubber spatula;

- degreasing agents – alcohol, acetone;

- cotton napkin.

Preparation

Most often, a toilet with a vertical, oblique or horizontal outlet is mounted on already laid tiles. Therefore, you will have to work carefully so as not to spoil or break the tiles. To choose the correct position for the toilet, you must first connect the corrugation to the drain. Immediately before installation you should:

- block access to water;

- clean the area around;

- wash the bottom of the toilet, wipe the future joint with alcohol to degrease.

Marking

On the floor you need to mark the entry areas of the anchors using a marker that can be easily erased from the tiles, then trace the outline of the toilet. Next, remove it and cover the areas around the contour with construction tape. This will keep surfaces clean.

Hole preparation

Using the door, you need to make holes in the floor where you will have to put the bolts. It is important to first turn off the impact mode in the drill so that cracks do not appear on the tiles. This type of drill is not suitable for a concrete floor; you will have to buy a Pobedite one. After the holes are ready, they need to be cleaned of dust with a vacuum cleaner or a dry cloth.

Applying sealant

You should pour a little sealant inside the holes so that the anchors stay in them more tightly. The sealant will also serve as waterproofing and water will not get into the holes. Then the order of work is as follows:

- Apply a thick layer of sealant along the drawn contour;

- install the toilet, press well;

- secure the device with anchors, place a rubber gasket under the fastener head;

- Wipe off excess sealant or immediately remove with a napkin;

- remove construction tape.

If a crack appears on the toilet leg, it can also be sealed with sealant. Cover the entire defect or break from below, completely hiding it and extending slightly beyond the edges. Use a spatula to smooth out the sealant, then immediately wash the tool with soapy water, otherwise the product will stick tightly. Treat the crack over the applied composition with the same soap solution and smooth it out with your fingers if there is no spatula available.

Epoxy resin (glue)

PVC sewerage equipment that is significantly worn out, with numerous damages, is repaired using epoxy resin. The material is necessary to eliminate leaks when repairing PVC pipes.

Through cracks discovered after inspection of the equipment are sealed using a two-component adhesive composition. The mixture is prepared immediately before use, following the manufacturer's recommendations.

Fragile types of sewerage (cast iron, ceramics) can also be sealed using epoxy resin. Such pipes require a stronger and more reliable connection, which epoxy glue does well.

Fixing a leak is quite easy if you use epoxy resin . The composition is used in combination with a hardener, and the ratio of components to form the working mixture is 1:2 or 1:1.

To seal seams and emergency areas, epoxy resin is mixed with a hardener and applied to the break site. The mass dries quickly, serves for a long time and reliably, and is resistant to aggressive acids and alkalis.

The polymerization reaction proceeds much faster when the temperature increases by 10˚ C. The sealing of the resulting cracks is quite strong, since the epoxy composition has minimal shrinkage, high resistance to adverse factors, and stable physical and mechanical characteristics.

Epoxy adhesive is obtained by mixing resin and hardener in a ratio of 1:10, and distilled water is used to form a composition with water-borne resin.

Epoxy resin is a common material for connecting PVC sewer pipes. The joint is sealed by pouring resin into the gap, and to obtain a lasting result it can be used in hot and cold conditions.

Toilet crack

Causes

Remember what was said a few paragraphs above about toilets and boiling water? It is hot water poured into the toilet that most often causes cracks in them. Flushing the batteries in winter by flushing water into the toilet also makes its contribution. In third place of honor is the fall of various objects from the toilet cabinet.

Solution

- If the crack is located on the visible part of the bowl, and you don’t want to replace the toilet, epoxy resin or any imported equivalent will help. Drill two holes at the ends of the crack with a thin tile drill bit to prevent the crack from expanding. Sand the outer surface of the toilet near the crack with a turbine or sandpaper. Be careful not to completely crack the toilet. Then apply the resin so that the crack is securely sealed and the holes are filled. Wait for the resin to dry - and go into battle.

- If the base of the toilet is cracked, only replacing it will help.

A crack in the toilet base means a move to the trash heap.

Advice: in the second case, do not try to cement the base of the toilet in the hope that the leak will stop. Water will still pour through the ceiling onto the neighbors' heads, and dismantling the old toilet when replacing it will become much more difficult.

Cement

Sealing the joint with cement

When sealing a cast iron socket, Portland cement can be used. This substance dries quickly and provides reliable protection against leaks and accidents. For sealing, a high-quality grade of Portland cement is used. When working with Portland cement, it is necessary to apply the mixture over the joint.

A plumber's wrap is applied to the end of the pipe, and resin strands can be used for thick channels. The end is inserted into the socket, compacted and filled with Portland cement. This design will last for many years.

True, when dismantling it, your followers will have a lot of difficulties. But that is another story.

Leak at the connection between the toilet shelf and the tank

Cause

A design with a shelf that is part of the toilet is a much more sensible solution compared to a separate shelf. However, it can also create some problems. If the bolts are tightened loosely and/or skewed, leaks along the gasket between the tank and the shelf are possible when flushing.

In addition, the bolts themselves can also be a source of leakage. If the sealing gaskets are not pressed tightly, water will flow through the bolts.

Solution

Do not try to tighten the bolts immediately.

So there is a high chance of making a mistake and, increasing the distortion, splitting the tank.

- Turn off the water to the tank and rinse;

- Loosen both bolts until the nuts rotate by hand;

- But after that, start tightening them - strictly symmetrically, first by hand, then, if necessary, with an adjustable wrench or pliers. Tools may not be needed - many kits are assembled with bare hands, they are equipped with hand-friendly plastic wings.

The photo clearly shows that water was flowing down one of the bolts

Which glue to choose?

It is known from practice that to securely fasten ceramic fragments, you can use so-called liquid nails.

If you need to restore the drain tank, then the gluing technology is exactly the same. Sanitaryware and porcelain adhere well to ready-made compounds, which are freely sold in the retail chain.

Among them, we must mention the BF-2 glue, which has proven itself for a long time and has proven itself. The abbreviation BF stands for “butyralphenol”.

The numerical value indicates the percentage of polyvinyl buteral. The higher the number, the higher the elasticity of the adhesive joint. Therefore, BF-6 is not suitable for gluing a toilet bowl.

In order to glue a toilet bowl or cistern, you can use epoxy resin. It glues reliably, but handling it is not very convenient.

It is preferable to use Rapid or Unicum glue. Any of these compounds can also be used to glue the toilet seat together.

In the process of choosing an adhesive composition, each master has to rely on his own experience and advice from those closest to him.

Often you have to prepare such a composition yourself from individual components.

Using liquid nails, you can prepare a high-quality adhesive mixture by adding chalk and a little quicklime. At the same time, you need to know that this composition “sets” very quickly.

It is prepared immediately before gluing. During the gluing process, excess composition must be immediately removed using a rag or soft cloth.

As practice shows, cracks or chips on the toilet often occur. No one living in the apartment is insured against such a nuisance.

Video:

If the seat is cracked, it is easier to replace it than to glue it. The glued toilet will, of course, still serve for some time.

At the same time, we must remember that the restored plumbing fixture (including the tank) no longer has its original strength.

And after some time it will have to be replaced with a new one.

How to repair a crack with glue

The method is relevant in the case when a fragment that is not responsible for the tightness has broken off from the toilet. This usually happens at the junction of the bowl and the cistern (the eyelet or the edge of the base) or on the cistern itself, sometimes along the rim of the toilet. Regular all-purpose glue is suitable for this purpose. It is important to buy a reliable one, because there are many models on the market, many of which do not differ in quality.

Attention! Good glue won't be cheap. It is better to purchase a product from a well-known brand. For example, Henkel. Among the domestic ones, Mars and Rapid have proven themselves well.

The process of gluing a broken ceramic element consists of the following steps:

Restoring a small crack with glue

- Clean the surfaces of the fragment and the toilet bowl at the fracture site from mechanical debris and ceramic chips.

- After drying, degrease the surfaces using acetone or gasoline.

- Apply glue and press the broken element. The time and force of pressing must correspond to the recommendations in the instructions for the glue.

Attention! No matter how good the glue is, it cannot restore the toilet to its former strength. Therefore, do not put stress on the glued fragment.