The material for knives must have certain properties. Be soft enough to sharpen, hard enough to not become dull when cutting. Do not rust, withstand temperature changes, safe enough for the food industry. The required qualities are achieved by composition and processing. A popular alloy for the production of knives is stainless steel 40X13 . It is used in everyday life, industry, fishermen, and hunters. This steel differs from others in its low cost and ease of maintenance. The quality of the material depends on the country of origin and the purity of the alloy.

Characteristics of steel

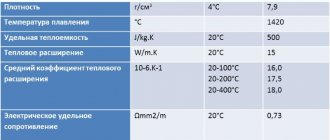

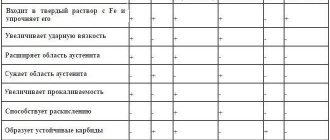

Steel - martensitic class, intended for parts operating at temperatures up to 450 degrees , as well as in corrosive environments. Belongs to group X13 . The absence of nickel reduces the formation of carbides, which contributes to the stability of mechanical properties. The quantitative composition of additional alloying elements is the same throughout the group. This allows you to have a number of mechanical and chemical properties as a result of the use of heat treatment technology:

- Corrosion resistance.

- Heat resistance.

- Heat resistance.

- Wear resistance.

Corrosion resistance is ensured by the content of martensite , carbides and retained austenite in the hardened state of the microstructure. It is characterized by increased resistance to vibration and alternating loads that occur in products operating at temperatures above 300 degrees Celsius .

For a material of this class, obtaining a combination of strength and hardness is not easy. The higher the hardness, the more brittle the parts become, and under impact loads they will be prone to cracking.

Heat treatment is used depending on the operating conditions of the product. For shafts and axles operating under conditions of mechanical and corrosive wear in a humid environment, normalization with exposure and high tempering is used. For products subject to shock loads during operation, stepwise hardening with high tempering is used, the number of cycles depends on the required surface hardness.

Surface hardness index for a knife is 40-60 HRC . Operating range 52-58 HRC . Steel 40X13 is difficult to harden . But you can achieve 57 HRC . The delivery condition ensures the hardness of the rolled products up to 229 HB .

It is well subjected to hot deformation - forging under slow heating and cooling conditions. Cold deformation is limited.

The alloy is produced in hot-rolled form. There are sheets, shapes, long products, calibrated rods, strips, tapes, and wires.

Let's get acquainted - Steel grades for knives!

To make it more convenient and easier to understand what kind of alloy we are dealing with, it was proposed to designate a set of chemical and mechanical components that characterize steel by steel grades for knives. Depending on the country of origin, they have their own markings and characteristics. Let's get acquainted with popular stainless steel grades, foreign and domestic production:

|

Russia is also one of the countries that produces high-alloy and high-quality carbon steel. Most Ukrainian manufacturers of cutting tools use alloys exclusively of domestic production.

Steel analogues and scope

4X13 is the old name. There are foreign analogues that differ in the purity of the alloy, the absence or presence of impurities.

Foreign analogues from different suppliers: American AISI420, Japanese SUS420J2, French X40Cr14, English 420S45, Italian X40Cr14, Spanish F.3404, Chinese 4C13, Polish 4h23, Czech 17024. All analogs have similar characteristics.

Application area:

- Measuring tool.

- Cutting tool.

- Household items.

- Medical instruments.

- Shafts.

- Springs.

- Bearings.

- Measuring devices for forging production.

- Details of compressor units.

- Cutting knives of devices for hot stamping.

Disadvantages of use

The disadvantages of parts made from 40X13 include:

- Instability to aggressive environments.

- Poor weldability of parts.

- To achieve the required hardness, it is necessary to use multi-stage hardening and tempering.

- Do not use on hard surfaces.

- It is not recommended to store in damp conditions; the part is subject to pitting corrosion.

The appearance of corrosion points due to improper storage will be removed by repeated sharpening, which is considered one of the disadvantages and advantages of steel.

Application

Previously, this material was used to make Soviet and inexpensive kitchen knives . Unfortunately, due to their low cost, they were of relatively poor quality (due to the factories that manufactured the knives, not the steel), but they were excellent for ordinary household and kitchen purposes. With such a knife you could easily cut chicken and other meat dishes, but the most important advantage was safety for health. There is simply no risk of contracting any chemical disease using 40x13 steel.

A separate area of application is aircraft modeling. In aircraft manufacturing, it is impossible for the material from which important components are made to be highly electrified and subject to various types of corrosion, because human lives are at stake. The designers would not use low-quality steel, so this fact will be another plus. But the most common method of use is the manufacture of various components. High strength and the ability to be used in mechanisms subject to wear make the material the main component .

It is worth noting that medical scalpels are made precisely from the above alloy, which confirms the information about safety for the human body. This steel is also used to produce various technical devices: bearings, springs, elements for measuring systems, compressor parts and many things necessary in everyday life.

One of the main disadvantages is the fact that it is absolutely forbidden to use this steel for welding . With a sharp change in temperature, it loses many of its properties, begins to rust, and the crystal lattice is destroyed.

How to make a knife from steel 40X13

The technology for making a knife from steel 40X13 is the same as for other grades of steel. If you are making your first blade, then you need 40X13 steel to master the technological process .

The workpiece must be forged, preferably to a given configuration . The forging process strengthens the structure, which will have a good effect on the properties of the cutting part.

A template of the future blade is applied to the forging and cut along the contour. Cutting is carried out only in the tempered state of the workpiece, with simultaneous cooling. Avoid overheating when cutting.

The edges and planes are pre-processed and sharpened to the required dimensions, and holes are drilled in the handle to install fastening pins. Heat treatment (hardening, tempering) is carried out to impart hardness and ductility.

The workpiece is polished with mandatory cooling. Overheating will weaken the steel and reduce its strength. Polished to a shine.

The manufactured wooden handle is mounted on pins. It is glued with epoxy glue, sanded until smooth so that it fits well in the hand, and treated with oil. The oil protects against moisture and gives the wooden handle a beautiful look. Final grinding of the cutting edge of the blade. A convenient and practical knife is ready.

Carbon steel alloys

An analogue of Russian steel X12MF is grade D-2, which contains approximately 12% chromium, which is not enough to effectively cope with corrosion. However, of all carbon steels, this alloy is the most corrosion-resistant. Although D-2 is the least durable of the high carbon steels, it still holds an edge well.

The domestic brand 95Х5ГМ or A-2, used for the production of combat knives, is harder than the previous one, but inferior in wear resistance. In addition, when making products from it, it is not possible to carry out additional hardening and tempering, since it “self-hardens” in air. This steel is used in particular by Chris Reeve and Phil Hartsfield.

U8 is excellent for forging large knives with increased strength requirements. Can only be used in conditions where there is no heating of the edge. Carbon content – 0.78-0.83%, chromium – no more than 0.2%. Low chromium content causes poor corrosion resistance. Hardness ranges from 61-63HRC. With proper upsetting, a hardness of up to 67HRC can be achieved. Its analogue is steel 1095.

Russian analogues of steel 50 and 60 are steel 1060 and 1050, which are more often used in the production of swords. Steel grades starting with 10 (1095, 1084, 1070, 1060, etc.) with a decrease in carbon, the amount of which corresponds to the last numbers (95.84...) become less durable, hold an edge worse and are more tough.