Which solder should I choose?

When soldering copper pipes, two main types are used:

- soft, with a melting point of up to 425°C;

- solid, with a temperature range of 460-560°C.

The use of silver-containing alloys is recommended as solders . They provide high quality connections, but are expensive. Copper-phosphorus compounds are more accessible and suitable for soldering less critical connections.

Copper-phosphorus

The melting point of copper-phosphorus solder is low. Copper solder allows you to do without flux compounds . The phosphorus contained in the composition will protect the work area from exposure to atmospheric oxygen.

The suture material, formed on the basis of copper-phosphorus solder, is very durable and resistant to vibration. Therefore, phosphorous compounds are widely used when soldering heat exchanger components.

Why do solders sometimes use copper solder when soldering steel parts, but copper cannot be soldered with steel solder? The reason is the difference in the melting temperatures of steel and copper. The copper blanks will already melt, but the steel will still heat up.

At the same time, copper-phosphorus solder is sensitive to overheating , so measures must be taken to cool the joint. The product is produced in the form of a rod. Copper soldering tape is also available . Copper-zinc low-temperature solders are also used for soldering.

Silver

Pure silver composition is not suitable for soldering copper products. They mainly use silver with the addition of iron, bismuth and other elements.

Silver-based copper solder has high wettability towards workpieces and penetrates perfectly into the narrowest gaps between them. The connections do not corrode and withstand large static and periodic dynamic loads.

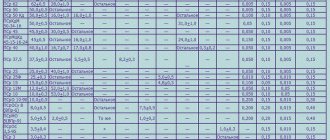

Ag content

The chemical composition of solders for soldering copper and silver workpieces is described in GOST 19738-74. They are designated by the letters PSR XX, where the numbers determine the percentage of silver

Practical use

Compositions with a high percentage of silver (50-72) have high electrical and thermal conductivity . They are used in electrical engineering and electronics.

Alloys with a medium percentage are cheaper and are used for soldering joints that are not subject to temperature stress.

Compositions with low percentages (5-15) are used in mechanical engineering.

Features of tinoles

A characteristic feature of silver-containing compounds is their low operating temperature. High fluidity allows the melt to penetrate into gaps and pores and create high-quality seams.

Brazing

Brazing alloys are used for joints of larger diameter tubes and pipelines. In this case, a paste-like flux, a gas burner for heating and the necessary auxiliary equipment and tools are used.

Low temperature

Low-temperature solders melt at temperatures up to 450°C . The low temperature avoids annealing of the base material of the pipe and preserves its physical and chemical properties. Solders are prepared on the basis of tin or zinc alloys. Lead is also used as a component.

High temperature

High-temperature solder for soldering copper is prepared on the basis of silver or copper, which has a high melting point. At temperatures above 450°C, the workpieces are annealed, leading to a decrease in their strength.

Copper soldering methods

There are two ways to independently connect a copper pipe line:

- Low temperature. This method is the simplest and most commonly used at home. In this case, soft solder is used from tin, lead or alloys of these metals with the addition of some silver. During low-temperature processing, the melting point of copper-phosphorus solder is no more than 450 degrees.

- High temperature (solid). Such soldering is quite difficult and expensive to organize at home, since in this case the melting temperature of the material should be from 600 to 900 degrees.

Physicochemical characteristics

Properties depend on the chemical composition of the alloy. Thus, low-temperature ones have less strength, but do not reduce the strength and elastic characteristics of the material of the parts.

High-temperature ones, on the contrary, create high-strength joints that can withstand static and dynamic loads. But when using them, great care is required so as not to burn or weaken the base material.

Specifications

temperature compositions lies in the range of 645-815 ° C. The seam can withstand tensile loads up to 250 MPa. The operating temperature of the compound, depending on the composition, is 150-250°C. In addition to copper itself, such solders allow you to join brass, red bronze, cast iron, steel and nickel. They also solder aluminum. In addition, they are used to connect copper and stainless steel parts.

Types of solders for copper

The following materials are suitable for processing pipes made of this material:

- 102. This three-component copper and phosphorus solder contains no more than 2% silver. Due to reduced plasticity, the composition spreads slowly. Suitable for soldering elements that do not experience strong shock or vibration loads.

- 105. Copper-phosphorus solder with silver (5%) also spreads quite slowly, but has higher ductility. The seam obtained with its help can withstand minor loads from vibrations.

- 115. Another three-component solder, which in addition to copper and phosphorus contains 15% silver. This is a fairly plastic material with which you can create seams on highways that experience fairly heavy loads.

Having selected all the necessary components, all that remains is to get to work.

Methods

There are two main methods of soldering copper blanks:

- High temperature . Silver or copper based refractory solder creates a rigid and durable connection. The seam is called solid and can withstand mechanical and temperature loads. To prevent annealing from leading to a deterioration in the strength of the main parts, the finished soldering should be cooled exclusively naturally, without blowing with cold air or immersing it in liquid.

This soldering is used for pipes ranging in size from 12 to 159 mm, operating at ambient temperatures up to 125°C.

- Low temperature . This type of soldering is called soft soldering. Solders are prepared on the basis of metals with low melting points. The low temperature avoids annealing and there is no reduction in the strength of the pipes. The method forms seams with a width of 7 to 50 mm, on pipes from 6 to 100 mm in diameter.

Soft connections cannot be used when installing gas pipelines.

What will be needed in the process?

For soldering you will need:

- flux for surface treatment of the workpiece;

- solder corresponding to the selected soldering method;

- device for chamfering the end of a pipe;

- wire brush and brush for cleaning workpieces;

- pipe expander;

- measuring instrument: tape measure, measuring gauge, square, spirit level;

- burner.

A portable propane torch makes it possible to heat a joint in a few seconds . In places where the use of an open flame is unacceptable, the joints are heated with an electric soldering iron with replaceable clamps and electrodes for different pipe diameters

Soft soldering

Low-temperature soldering is suitable for installing a heating or water supply network if the temperature of the coolant does not exceed 130 degrees and the diameter of the copper pipes is no more than 10 cm.

To perform soldering you need:

- Clean the surfaces to be joined.

- Apply flux to them.

- Insert elements into each other.

- Heat the connection area with a burner to 200-250 degrees.

- Apply solder to the very edges of the parts.

- Constantly moving the burner, heat the connection for 15-20 seconds.

- When the flux darkens, you need to place a little more solder on the soldering area. As soon as the material is on the hot surface, it will immediately begin to melt and fill the space between the pipe and the socket.

Technology

After the accessories and tools are prepared, proceed to the soldering itself:

Cut the part to the required length

To cut pipe blanks, pipe cutters with manual or electric drive are used. To ensure an even cut, after each revolution the pressure-regulating flywheel should be tightened by a third of the stroke. The edge should be treated with a chamfer remover and cleaned with a brush. If the connection is butt, one of the pipes should be expanded. Next, the surfaces are degreased and the quality of their mating is checked.

Apply flux to the surface of the pipe

Flux paste is applied to the inner surface with a brush built into the lid of the jar. It should be completely covered with flux, but at the same time no excess should accumulate on it.

Connecting

The parts are inserted into each other with a slight twist in both directions . This helps distribute the flux evenly.

Excess flux must be wiped off with a clean rag.

When low-temperature soldering, the turned on torch is directed towards the joint . The joint must be heated evenly, smoothly moving the torch .

The coil of solder is taken in the left hand. The wire touches the gap, the solder melts and fills it. At this point, the flame is pulled slightly to the side, allowing the solder to flow into the gap.

The soldered joint must be cooled in the usual way, by blowing or wetting with liquid. This will avoid the annealing effect.

High temperature requires a hotter flame. It is obtained by burning a mixture of propane with oxygen or acetylene with air . The joint should be heated evenly and quickly, avoiding overburning. The required temperature of the workpiece (750°C) can be determined by the dark cherry color. The soldering compound, heated but not melted by the torch, is fed into the joint area.

Experienced craftsmen immediately heat the joint exactly enough to melt and flow the soldering compound. Beginning shareholders will have to practice on training blanks. Excess melt is removed with copper tape designed for removing solder. The soldered seam should cool naturally, without blowing cold air.

After cooling, use a clean, dry rag to remove any remaining flux paste.

Hard soldering

Solid soldering agents are used for capillary joining and connection of pipeline fittings, which are used to supply water.

Example of soldering with 1% silver solder

When soldering copper pipes, special paste, gas, auxiliary tools and technological equipment are used.

When connecting copper parts with hard solder, all necessary safety precautions must be observed.

How to solder pipes

To connect pipes made of copper and its alloys, it is necessary to use certain materials and tools.

So, to complete the work, you will need:

- device for cutting copper pipes;

- gas burner;

- composition for soldering copper pipes;

- flux.

The soldering process is as follows:

- Clean the treated area.

- The fitting is installed manually; this operation may require a special tool.

- Using a gas heating tool, heat the area being treated until the color of the surface changes.

- The composition for soldering copper pipes is placed on the heated place.

If you find an error, please select a piece of text and press Ctrl+Enter.

Everyone knows that copper is quite easy to solder. This statement is true only if the correct consumables and technology for the entire process are selected when working with this material. The most popular filler material for copper welding at the industrial level is copper-phosphorus solder. Its main purpose is to use copper, brass, and bronze parts in the soldering process. It can also be used without problems with almost all alloys of the metals described above.

Oddly enough, despite the fact that the name of the filler material mentions two chemical elements, its composition consists of three. The last one is silver. Due to its presence in the composition, this modification of the filler material can be used in the refrigeration industry; also, due to the low temperature at which the substance begins to undergo a melting process, it can be used in the process of soldering copper pipes.

This material has an increased flow property, which can significantly improve the quality of the final joint result. Thanks to this property, the material is able to penetrate even the smallest cracks and, accordingly, completely fill the working space. The high level of fluidity of the substance can significantly increase the level of strength of the finished joint, and the product also has the ability to resist the processes of corrosion and erosion.

Due to the presence of phosphorus in the chemical composition of the consumable, working with it does not require the use of additional flux. This chemical element has properties that can easily act as a flux during the soldering process.

Most often, this type of solder is used in the refrigeration industry during repair and installation of equipment. In addition, it can be used when working with products whose operating activity is directly related to minor vibrations and mechanical stress. If the proportion of silver in the chemical composition of the material decreases, then the final result significantly increases the level of the material’s plasticity property.

If you have to work with parts that are deprived of the property of heat resistance, then before starting soldering manipulations they must be pre-cooled. Performing this procedure allows you to minimize the chance of critical overheating of the material, which can negatively affect its integrity.

The most popular models of copper-phosphorus solder

There are many models of this type of solder on the market from various manufacturers and brands. It’s worth paying attention and taking a closer look at the most popular ones.

1. Felder CuP6 - most often this solder from a German manufacturer is used in working with air conditioners, ventilation systems, pipelines and gas pipelines. In specialized retail outlets you can find this substance in two forms: rods or granules. The material begins to melt when the temperature reaches 300 degrees Celsius.

2. Harris 0 – the main purpose of this model is to work with copper parts. The chemical composition of the substance does not contain silver. The material begins to melt when it reaches a temperature of 755 degrees Celsius. The composition of the substance consists of two components and looks like this (values are indicated as percentages):

3. Castolin rb-5246 - a hard version of solder from a popular German brand. It is distinguished by its high level of wettability, which makes it possible to achieve an almost perfectly smooth final joint result. The working activity of the soldered product can be carried out at temperatures up to 150 degrees Celsius. Solder begins to melt when heated from 715 degrees Celsius.

4. F2 – domestic model of universal-type copper-phosphorus solder. The fairly solid structure of the filler material allows the creation of compounds with relatively good physical properties and mechanical characteristics. It is also worth noting the fairly good fluidity of the material in the molten state.

5. PMF 7 - another model of solder from a domestic manufacturer with a seven percent flux content in the composition. Due to its fairly high fluidity, this consumable material can be used to create a strong and tight connection. When working with all metals and alloys, with the exception of copper, it is necessary to use additional flux to improve the quality of the final result. The substance should not be used with all types of steel and cast iron. Solder begins to undergo a melting process when it reaches a temperature of approximately 750 degrees Celsius.

Physical and chemical properties of the material

Soldering filler material, whose chemical composition is based on copper and phosphorus, obtains all its properties precisely due to the presence of one or another additional element in the composition. Most often in specialized stores you can find models designed for soldering copper, bronze and brass. Accordingly, the chemical composition is as close as possible to the composition of the material for which the solder is intended.

If we consider in general, then almost all models from absolutely all brands have a fairly high level of wettability. Thanks to this, it is possible to significantly increase contact with the working surface of the product, and therefore improve the quality of the final connection result.

Certain models can begin to melt only when the temperature reaches 800 degrees Celsius, which significantly increases the danger of the work being carried out, but allows achieving the maximum possible strength of the connection. Most models have the property of protection against the effects of corrosion and erosion. You can also find models containing flux in the composition, which eliminates the need to use it.

How to choose?

If you want to purchase a copper-phosphorus filler material for soldering, then first of all you need to decide on its specific chemical composition. Basically, the choice is made between two broad groups, which differ from each other in the presence of silver in the composition.

Options with silver allow you to achieve higher strength for the final result of the connection than models without it. Also, models with silver should be used if the product operates at negative air temperatures. To do this, you need to purchase solder with a silver content of at least fifteen percent. However, there is one peculiarity. As the percentage of silver in the substance increases, the ductility of the compound decreases. Therefore, if a part requires constant bending in operation, then it must be soldered using solder with a silver percentage of less than two.

There is a rule that states that the thinner the metal, the lower the melting point of the filler material should be. In addition, the low melting point significantly increases the ability of the material to spread evenly over the working surface. It is worth noting that some models have fluxes of the same name; when used together, it is possible to achieve a high quality connection.