What kind of material is this?

Ordinary steel is a combination of iron and carbon and a number of impurities.

The definition of “alloy steel” (AS) means a special alloy, which is obtained by introducing a certain amount of chemical elements. This is done in order to obtain the necessary physical and chemical properties of the metal. As a rule, the following elements of the periodic table are added, which are difficult to do without depending on the specific situation:

- Nickel – H (Ni).

- Copper – M (Cu).

- Niobium – B (Nb).

- Chromium – X (Cr).

- Manganese – G (Mn).

- Silicon – C (Si).

- Vanadium – F (V).

- Tungsten – B (W).

- Molybdenum – M (Mo).

- Titanium – T (Ti).

- Aluminum – A (Al).

- Zirconium – C (Zr).

- Cobalt – K (Co).

But besides them, molybdenum and aluminum are used. Moreover, each of these elements is added for a specific purpose. And their quantity directly affects the obtaining of the necessary qualities. Now it becomes a little clear what alloy steel is.

What is steel

An alloy based on iron (at least 45%) is called steel. Depending on the percentage of the second initial component - carbon, alloys are distinguished into high-carbon (0.6-2.14% C), medium-carbon (0.25-0.6% C), and low-carbon (no more than 0.25% C) . The higher this indicator, the more durable and elastic the steel, but at the same time with reduced ductility and impact resistance.

Alloy steel example

The required components of the alloy are deoxidizing agents - manganese and silicon. These chemical elements are present in small quantities and do not affect the properties. Their goal is to neutralize the harmful effects of oxygen.

Even high-quality steel contains harmful impurities that cannot be eliminated. This:

- sulfur, which causes cracks;

- phosphorus, which increases fragility (cold brittleness);

- nitrogen, oxygen, hydrogen – disintegrants of steel structure;

- oxides and nitrides leading to ruptures.

In addition to the listed components, carbon alloys always contain other substances that come along with the starting materials during smelting: copper, zinc, chromium, nickel, lead. The level of their content is so insignificant that they have neither a positive nor a negative effect.

Historical path

The foundation for the development of alloying was laid by the justification of the crucible method of melting steel in Europe in the 18th century. In a more primitive version, crucibles were used in ancient times, including for the smelting of damask and Damascus steel. At the beginning of the 18th century, this technology was improved on an industrial scale and made it possible to adjust the composition and quality of the starting material.

- The simultaneous discovery of more and more new chemical elements pushed researchers into experimental smelting experiments.

- The negative influence of copper on the quality of steel has been established.

- Opened brass containing 6% iron.

Experiments were carried out from the point of view of the qualitative and quantitative influence of tungsten, manganese, titanium, molybdenum, cobalt, chromium, platinum, nickel, aluminum and others on the steel alloy.

The first industrial production of steel alloyed with manganese was established at the beginning of the 19th century. It has also been developed since 1856 as part of the Bessemer smelting process.

Doping and impurities - is there a difference?

From a formal point of view, some chemical elements contained in ordinary steels, both structural and ordinary quality, can also be called alloying. These include, for example, copper (up to 0.2%), silicon (up to 0.37%), etc.

Phosphorus and sulfur are constant companions of any steel. However, metal scientists mostly classify them not as alloying additives, but as impurities, although sometimes the percentage of another alloying element may be even smaller.

The reason is that any impurity is a consequence of either the purity of the original ore (manganese) or the specific metallurgical smelting processes (sulfur, phosphorus). Theoretically, steel smelted without copper, phosphorus and sulfur would have the same mechanical properties. Alloying has as its ultimate goal precisely the improvement of certain technical characteristics of steel. At the same time, phosphorus and sulfur are clearly classified as harmful but inevitable impurities. The presence of copper increases ductility, but promotes the adhesion of the surface of a metal having an excessive (more than 0.3%) concentration of copper onto the surface of an adjacent part. When the structure operates under conditions of intense friction, this is a major drawback.

The presence of a chemical element with a concentration of more than 1% provides grounds for introducing its symbol into the steel grade. In addition to the aforementioned 65G steel, aluminum (present, in particular, in O8Yu steel) also receives a similar honor. In this case, aluminum is introduced into ordinary O8 structural steel in order to deoxidize it, and the fact that its ductility slightly increases is only a fortunate accompanying circumstance. Boriding steel provides it with increased subsequent deformability, therefore even microadditives of boron to the chemical composition of steel are marked accordingly by changing its markings (for example, in 20P steel there is only 0.001...0.005% boron).

In general it is accepted that:

- Steels containing only one element intentionally introduced into the composition;

- Steels containing chemical elements other than carbon and manganese in an amount not exceeding 1%

If the percentage of iron in the melted alloy does not exceed 55%, then such material can no longer be called alloy steel.

Designation of elements in alloy steel grades

| Designation of alloying elements | ||

| A – nitrogen (in the middle of the mark) B – niobium C – tungsten D – manganese D – copper E – selenium | M – molybdenum N – nickel P – phosphorus P – boron C – silicon T – titanium | F – vanadium X – chromium C – zirconium H – rare earth elements and yttrium Y – aluminum |

Particularly high-quality

steels and alloys are designated at the end of the grade through a dash with the letters VI (vacuum-induction remelting), VD (vacuum-arc remelting), Ш (electroslag remelting), ShD (vacuum-arc remelting of steel electroslag remelting).

According to the specified rules, structural components

steels (alloyed and high-quality carbon), steels and alloys

for specialized engineering purposes

, steels with

special chemical properties

and certain groups of steels

with special physical properties

, for example, alloys with high electrical resistance.

When designating individual groups of steels, there are deviations from the general marking rules:

1. Experimental steels not included in the standards and supplied according to technical specifications are designated by the letters EI or EP, ChS, ZI, DI and the following numbers, which are a serial number, for example: EI276, ChS36, DI37.

2. Carbon steel of ordinary quality has a different marking principle.

3. At the beginning of steel grades, letters are sometimes placed indicating their use: A - automatic, E - magnetically hard (deformable), P - high-speed, Ш - ball bearing, C - steel for building structures.

4. The designation of tool, ball bearing and automatic steels has its own characteristics.

5. Steels and alloys with special physical properties

(special alloys), depending on their properties and operational capabilities, are divided into groups, each of which has its own method of designation.

Structural quality carbon

steel (GOST 1050–88), containing no more than 0.6% carbon, is supplied with guaranteed chemical composition and mechanical characteristics. These steels are used, for example, for deep drawing (steel 05kp, steel 08ps), in elements of pipe connections (steel 15kp, steel 15ps, steel 20), for the manufacture of parts with high strength and wear resistance (steel 55, steel 50R).

Structural alloy

steel (GOST 4543–71), depending on alloying elements, is divided into groups: chromium (for example, steel 15Х), manganese (10G2), chromium-nickel (30ХНА), chromium-silicon (40ХС), chromium-manganese (35ХГ2); chromium-manganese with vanadium (35ХГФ), with molybdenum (38ХГМ), with titanium (18ХГТ); chromium-manganese-silicon (35ХГСА); chromium-nickel with molybdenum (30ХН2МА), with vanadium (20ХН4ФА), etc. Alloy steels have higher strength properties compared to carbon steels, and they are used for the manufacture of critical parts with appropriate heat treatment.

Spring steel

(GOST 14959–79) can be carbon (steel 65...85) or alloyed, for example: 65G, 55S2, 50KhFA, 65S2VA, 70S2ХА. These steels are used for the manufacture of car springs, torsion shafts, springs of various mechanisms, etc.

Steels of especially high strength and toughness ( maraging-aging

) have a tensile strength of up to 2500–3000 MPa, retain ductility (more than 10%) and impact strength at low temperatures (400–500 kJ/m2 at –196 °C). Alloying with chromium (more than 12%) gives them resistance to corrosion in aggressive environments (sea water, acids). Heat-resistant (up to 500 °C) steels are also produced for parts of chemical equipment, thermal power plants, etc. The most common grades of maraging steels are: 03N18K9M5T, 03N10Kh12D2T, 03N4Kh12K15M4T, 04Kh11N9M2D2TYu.

Heat resistant

and

heat-resistant

steels and alloys (GOST 5632–72) are materials that operate at high temperatures. Heat-resistant steels are resistant to corrosion in air, furnace gases, including sulfur-containing gases, and combustion products at temperatures up to 900–1200°C. Typical grades of heat-resistant steels: 15Х6СУ, 20Х20Н14С2, 30Х13Н7С2, 40Х9С2, 12Х17, 15Х28.

Heat resistant

steels are used for long-term operation under load in parts and installations operating at temperatures above 400–450 °C. Heat-resistant alloys are divided according to operating temperature. For operation at temperatures of 400–500 °C, for example, steels are used: 20Kh1M1F1BR, 12Kh1MF, 25Kh1MF, 18Kh3MV, 20Kh3MVF; at a temperature of 500–600 oC – steels 20Х13, 15Х6СУ, 40Х10С2М; at a temperature of 600–650 oC – steels 45Х14Н14В2М, 10Х11Н23Т3МР, 12Х18Н9Т and others. Nickel-based alloys, for example: KhN60VT, KhN70Yu, KhN75MBTYu, KhN77TYUR are used at temperatures of 700–750 °C, and alloys such as KhN62MVKYu, KhN56VMKYu - up to 850 °C. Alloys based on iron-nickel, for example: KhN35VT, KhN45Yu, KhN28VMAB, 03KhN28MDT, 06KhN28MT are used at temperatures from 650 oC to 900 oC. In grades of nickel or iron-nickel based alloys, the absence of a number at the beginning of the grade means that the carbon content in the alloy does not exceed 0.1%. When marking nickel-based alloys, for example, N70MFV, KhN77TYUR, numbers indicating the percentage composition of alloying elements, as a rule, are not written behind the letters. The chromium content in nickel-based alloys is 10–29% (9–12% when alloyed with cobalt, tungsten, molybdenum and aluminum), and in iron-nickel-based alloys it ranges from 14 to 18%.

Cold-resistant steel

and

wear-resistant

(GOST 977–88, GOST 21357–87), for example, 08G2DNFL, 12KhGFL, 20GL, 25Kh2NML, 30KhG2STL, 30KhL, 35KhMFL, 110G13L, 110G13KhBRL are used in cast or forged condition.

Corrosion-resistant steels and alloys

(GOST 5632–72) are distributed according to the type of operating environment. Steels 12Х13, 20Х13, 20Х17Н2, 30Х13, 40Х13, 95Х18 are resistant to mildly aggressive environments (air, water, steam); steels 15Х28, 12Х18Н10Т and similar ones are resistant to more aggressive environments (sea water, organic acids); steels 10Х17Н13М3Т, 09Х15Н18У, 08Х21Н6М2Т are capable of working in concentrated and hot acids.

Structural carbon steel of ordinary quality

(GOST 380–94) are designated by the index “St” and a serial number, for example: St0, St1ps, St4kp, St5Gps, St6sp.

In the designation of grades, the letters “St” mean “steel”, numbers from 0 to 6 are the serial number of the grade depending on the chemical composition. Moreover, the higher the number, the more carbon there is in the steel. The numbers added at the end of the grade designation indicate the category of steel, depending on the standardized indicators for long and shaped (GOST 535–88), for thick sheet (GOST 14637–89) and thin sheet (GOST 16523–97) rolled products.

Tool carbon

steel (GOST 1435–99) retain high hardness, strength and wear resistance up to temperatures of 190–225 °C. The letter U at the beginning of the brand means that this tool steel is high-carbon, containing carbon from 0.65 to 1.3%. The following numbers mean the average carbon content in tenths of a percent, and the letter G means an increased manganese content (up to 0.58%), for example: U8G, U12. High and especially high quality steels are designated respectively by the letters A and Ш, which are placed at the end of the steel grade, for example: U7A, U10A-Sh.

When designating instrumental alloyed

steels (GOST 5950–2000), for example: 9ХС, 5ХНМ, 3Х2В8, 5Х3В3МФС, the average carbon content is indicated at the beginning of the grade in tenths of a percent. When the steel contains more than 1% carbon, the number at the beginning of the grade is not indicated, for example: KhVG, Kh12M, Kh12F1. The number after the letters indicates the average content of the alloying element in whole percent.

In brands of high-speed tool

steels (GOST 19265–73), for example: R18, R6M5, R9M3K5, R10K5F5, the number after the letter P corresponds to the average tungsten content as a percentage. Other elements are designated in the same way as in alloy tool steels. Carbon in high-speed tool steels is not indicated; its content is in the range of 0.73–1.12%.

Ball bearing

steel (GOST 801–78 and GOST 21022–75) are designated at the beginning of the grade with the letters ШХ, then the chromium content is indicated in tenths of a percent, for example: ШХ4, ШХ15, ШХ20СГ, ШХ15СГ–Ш. The carbon content in ball bearing steels is about 1%. For high-quality steels made with vacuum, the letter B (ШХ15–В) is indicated at the end of the grade through a dash.

Automatic

steels (GOST 1414–75) are marked as follows: in the mark, before the numbers indicating the carbon content, the letter A is indicated (for steels with sulfur and phosphorus), for example, A11, A40G, the letters AC (for steels with lead), for example, AS12ХН , AS40KhGNM or ATs (for steels with calcium), for example, ATs35G2, ATs20KhN3. Automatic steel is intended mainly for producing fasteners for non-critical purposes: bushings, nuts, terminals, etc.

Examples of designation and decoding

:

1. Steel 15kp – structural steel, carbon, high-quality, containing 0.15% carbon, boiling cast.

2. Steel 38Х2МУА – structural steel, alloyed, high quality, containing 0.38% carbon, 2% chromium, less than 1% molybdenum, 1% aluminum.

3. Steel 60S2KhFA – spring steel, alloyed, high quality, containing 0.6% carbon, 2% silicon, up to 1.5% chromium and less than 1% vanadium.

4. Steel 03N18K9M5T-VI - steel of especially high strength and toughness, maraging-aging, high-alloy, especially high-quality, containing 0.03% carbon, 18% nickel, 9% cobalt, 5% molybdenum, about 1% titanium, produced by vacuum induction remelted.

5. Steel 08Х16Н13М2Б – heat-resistant, corrosion-resistant, high-alloy, high-quality steel, containing 0.08% carbon, 16% chromium, 13% nickel, 2% molybdenum and less than 1% niobium.

6. Steel 110G13L – cast steel, wear-resistant, high-quality, containing 1.1% carbon, 13% manganese.

7. St5ps1 – structural carbon steel of ordinary quality, number 5, semi-quiet casting, first category (supplied with guaranteed mechanical characteristics).

8. Steel U9A-Sh – tool steel, high-carbon, especially high-quality, containing 0.9% carbon, produced by electroslag remelting.

9. X12M steel – tool steel, alloyed, high quality, containing 1% carbon, 12% chromium and 1% molybdenum.

10. Steel R10K5F5 – tool steel, high-speed, alloyed, high-quality, containing about 1% carbon, 10% tungsten, 5% cobalt, 5% vanadium.

11. Steel ШХ15-ШД – ball-bearing steel, alloyed, especially high-quality, containing up to 1.0% carbon, 1.5% chromium, produced by remelting in a vacuum arc furnace from electroslag remelted metal.

12. Steel AS45G2 – automatic steel, leaded, alloyed, high quality, containing 0.45% carbon, 0.15–0.3% lead, 2% manganese.

Steels and alloys with special physical properties

, acquired as a result of special alloying and heat treatment, do not have general labeling rules. As an example, consider the designation of some magnetic alloys.

Structure of marking of deformable magnetic-hard

alloys (TU 14-1-4487-88) is similar to the marking structure of tool alloy steels. For example, steel EX5K5 stands for magnetically hard, high-quality steel, containing 1.0% carbon, 5% chromium, 5% cobalt, and the rest iron.

Electrical soft magnetic

steel (GOST 3836–83, GOST 11036–75) (thin-sheet, high-quality, cold- and hot-rolled, forged) with carbon content up to 0.04% and silicon up to 0.3% are marked with a five-digit number, for example: 10864, 21880.

The first digit corresponds to the class according to the structural state and type of rolled product (1 - hot-rolled isotropic, 2 - cold-rolled isotropic); the second - silicon content (0 - unalloyed steel, without normalized aging coefficient, 1 - unalloyed steel with normalized aging coefficient); the third - to the group according to the main standardized characteristic (8 - coercive force); the fourth and fifth - the quantitative value of the coercive force in whole units, A/m.

steels (silicon

) (GOST 21427.1–83, GOST 21427.2–83, GOST 21427.4–83) are marked with four numbers, for example: 1511, 1212, 2011, 3404.

In the brand designation, the first digit means the class according to the structural state and type of rolled product (1 - hot-rolled isotropic, 2 - cold-rolled isotropic, 3 - cold-rolled anisotropic with rib texture in the [100] direction). The second figure is equal to the total mass fraction of alloying elements (silicon) (0 - up to 0.5% inclusive; 1 - 0.5-0.8%; 2 - 0.8-1.8%; 3 - 1.8-2 .8%; 4 — 2.8–3.8%; 5 — 3.8–4.8%). The third digit is the group according to the main standardized characteristic (0-2 - specific losses, 6-7 - magnetic induction). The fourth digit is the serial number of the steel type (code of the numerical value of the standardized parameter).

Features of alloying

Modern capabilities make it possible to smelt alloyed metals of any composition. Basic principles of the technology under consideration:

- Components are considered alloying only if they are introduced purposefully and the content of each exceeds 1%.

- Sulfur, hydrogen, phosphorus are considered impurities. Boron, nitrogen, silicon, and rarely phosphorus are used as non-metallic inclusions.

- Bulk alloying is the introduction of components into a molten substance as part of metallurgical production. Surface is a method of diffusion saturation of the surface layer with the necessary chemical elements under the influence of high temperatures.

- During the process, additives change the crystal structure of the “daughter” material. They can create penetration or exclusion solutions, and can be placed at the boundaries of metallic and non-metallic structures, creating a mechanical mixture of grains. The degree of solubility of elements in each other plays a big role here.

General classification of alloying elements in steels

Metals have a predominant position in the list of alloying elements. The exceptions are silicon and boron.

The presence of alloying elements has a predominant influence on the appearance of the phase diagram of the iron-carbon system, and on the presence/absence of chemical compounds in the final product (nitrides, carbides and more complex components). The latter, in turn, significantly modify the microstructure of steel.

In this regard, steel alloying metals are divided into two groups:

- Metals that increase the region of γ-iron solid solutions (austenitic region on the phase diagram), which leads to increased diversity in the final microstructure of the alloy steel after its strengthening heat treatment). These elements include nickel, manganese, cobalt, copper, and nitrogen.

- Metals and chemical elements, the presence of which narrows the γ-region, but increases the strength of steel. These include chromium and tungsten. vanadium, molybdenum, titanium.

In the process of producing alloy steels, the following patterns in its properties change.

As is known, different elements have different crystal structures (for metals this is face-centered and body-centered). Iron itself has a body-centered lattice.

This is interesting: VGP pipe - decoding, description, advantages and scope of application

When a metal with a similar type of lattice is introduced into steel, the region of existence of an α-solution (ferrite) increases due to a corresponding decrease in the austenitic region. As a result, the microstructure is stabilized, which allows for a wider choice of technological processes for subsequent heat treatment. On the contrary, if the steel contains a metal with a different type of lattice, the austenitic region narrows. Such steel will be more ductile during subsequent machining. Alloying steel with some metals is generally impossible. This occurs if the difference in the atomic diameters of the elements exceeds 15%.

It is for this reason that a metal such as zinc is introduced as an alloying additive only into non-ferrous metals and alloys. Chemical elements that are unable to form stable chemical compounds with carbon, iron and nitrogen during smelting are also of limited use for steel alloying purposes.

The dependence of the characteristics of steel on its saturation with certain chemical elements has not yet been fully studied. This is explained by the fact that with complex doping, each component can interact differently with others, and such changes often cannot be explained naturally. Therefore, questions about the appropriateness of using one or another alloying element are resolved experimentally.

The following provisions are considered proven:

- The efficiency of the process increases with increasing solubility of nitrogen and carbon in the alloying additive and in the main iron;

- The stability of the final properties of steel increases with increasing size of the austenitic zone;

- The quality of steel alloyed with metals and elements with a lower serial number than iron (in D. Mendeleev’s table of chemical elements) is worse than in the opposite case;

- Metals that are more refractory than iron increase the strength of steel in any variant of its further heat treatment.

However, secondary interactions, which strongly depend on the method of steel smelting, can significantly correct these provisions. Therefore, at this stage we can speak with confidence only about the influence of specific alloying elements on the properties of steel.

Nickel

Nickel increases the ductility, toughness, and heat capacity of the alloy, increases its resistance to cracking and corrosion, and improves heat treatment capabilities. In this regard, ferronickel is one of the most common and sought-after ferroalloys in the global metallurgical industry. World standards define five grades of ferronickel containing 20-70% nickel, plus a small amount of carbon (C), sulfur (S), phosphorus (P), silicon (Si), chromium (Cr), copper (Cu).

Nickel-alloyed heat-resistant alloys typically contain 8-25% nickel, and some contain up to 35% or more. However, due to the fact that nickel reduces the hardness of the alloy, it is usually used for alloying not in its pure form, but in combination with iron, chromium, molybdenum, titanium, niobium and other elements. As an example, we can cite alloys of grades 12Х18Н9Т (Fe – about 61%) and 10Х17Н13МЗТ (Fe – about 67%) with a nickel content of 8-9.5% and 12-14%, respectively.

Molybdenum and tungsten

Tungsten and molybdenum have a similar effect on the physical characteristics of steels and alloys, significantly increasing the limit of long-term mechanical strength at temperatures up to 1800°C (in vacuum). It is enough to introduce 0.3-0.5% of these elements into the alloy to significantly enhance its creep resistance, strengthen the interatomic bonds of the crystal lattice, and increase the temperature limit of recrystallization. For the steelmaking and foundry industries, alloying ferroalloys are produced from molybdenum and tungsten with iron: ferromolybdenum (55-60% Mo) and ferrotungsten (65-85% W).

For alloying, relatively small amounts of molybdenum (about 0.2-20%) and tungsten (up to 10-12%) are usually introduced into alloys, since an excess of these elements can increase the brittleness of the alloy when heated. An example of an alloy alloyed with molybdenum and tungsten is heat-resistant low-alloy steel 12Х1МФ (Fe - about 96%) with a Mo content of 0.25-0.35 percent. In the same series is the heat-resistant relaxation-resistant steel 20Kh3MVF (Fe - about 93%) containing Mo 0.35-0.55% and W 0.3-0.5%, as well as the nickel-based alloy KhN57MTVYu (Mo 8.5-10%, W 1.5-2.5%, Fe 8-10%, etc.)

Vanadium

For alloying, relatively small amounts of molybdenum (about 0.2-20%) and tungsten (up to 10-12%) are usually introduced into alloys, since an excess of these elements can increase the brittleness of the alloy when heated. An example of an alloy alloyed with molybdenum and tungsten is heat-resistant low-alloy steel 12Х1МФ (Fe - about 96%) with a Mo content of 0.25-0.35 percent. In the same series is the heat-resistant relaxation-resistant steel 20Kh3MVF (Fe - about 93%) containing Mo 0.35-0.55% and W 0.3-0.5%, as well as the nickel-based alloy KhN57MTVYu (Mo 8.5-10%, W 1.5-2.5%, Fe 8-10%, etc.)

In order to improve the heat resistance characteristics, the composition of alloying elements becomes more complex; molybdenum, chromium, nickel, etc. are often introduced into the alloy along with vanadium. An indicative example of such an alloying technology is a heat-resistant alloy based on iron grade 12Х2МФСС (Fe - about 95%) with a content of V 0.2-0.35%, Mo 0.5-0.7%, Cr 1.6-1, 9%, Ni up to 0.25%, etc. Another example of multi-alloying of an alloy using vanadium is heat-resistant steel 15Kh2M2FBS, including V 0.25-0.4%, Mo 1.2-1.5%, Cr 1.8-2.3%, Ni up to 0. 3%, etc.

Special ferroalloys

All ferroalloys used in the foundry production of heat-resistant alloys are conventionally divided into two groups: the first is ferroalloys for mass use, the second is special ferroalloys. The second group includes compounds of iron with titanium, cobalt, niobium and a number of other elements. Special ferroalloys are used in small proportions of 4–6%, and not only to increase the operating temperature of heat-resistant alloys, but to give them special properties.

For example, ferroniobium is used to alloy heat-resistant chromium-nickel steels, since niobium effectively prevents intergranular corrosion, which destroys grain boundaries and leads to loss of strength of the material. In turn, ferrotitanium is introduced into heat-resistant alloys to enhance the overall anti-corrosion characteristics. In addition, titanium improves the weldability of stainless steels. Alloying heat-resistant alloys with ferrocobalt has a positive effect on their relaxation resistance, especially for chromium steels.

Steel grades. Decoding. Letter designations of alloying elements. Groups of steel grades

// Useful information / Reference information / Steel grades

Specialists are ready to answer all your questions

Request prices

Pipeline parts Shut-off valves Pipeline insulation

Steel is a deformable (malleable) alloy of iron with carbon and other elements, the carbon content of which does not exceed 2.14%. Carbon gives strength to iron alloys.

Steel classification

According to the chemical composition, steels are divided into carbon and alloy;

according to carbon content - low-carbon, medium-carbon and high-carbon;

Based on the content of alloying elements, alloy steels are divided into low-alloy, medium-alloy and high-alloy.

Carbon steel, along with iron and carbon, contains manganese (0.1-1.0%), silicon (up to 0.4%). Steel also contains harmful impurities: phosphorus, sulfur, gases - unbound nitrogen and oxygen.

Phosphorus imparts brittleness (cold brittleness) to steel at low temperatures and reduces ductility when heated.

Sulfur causes cracking at high temperatures (red brittleness). For the manufacture of welded structures, carbon steel of ordinary quality, corresponding to GOST 380-71 is mainly used

To impart any special properties to steel - mechanical, electrical, magnetic, corrosion resistance, etc. – so-called alloying elements are introduced into it, usually metals: chromium, nickel, molybdenum, aluminum, etc. Such steels are called alloyed. The properties of steel can be changed using various types of processing: thermal (quenching, annealing), chemical-thermal (cementization, nitriding), thermo-mechanical (rolling, forging). Combinations of letters and numbers give characteristics of alloy steel. If there are two numbers in front of the brand, they indicate the average carbon content in hundredths of a percent. One number in front of the mark indicates the average carbon content in tenths of a percent. If there is no number in front of the brand, this means that it contains either 1% carbon or higher than 1%. The numbers behind the letters indicate the average content of this element as a percentage; if there is no number behind the letter, then the content of this element is about 1% (no more than 1.5%). The letter A at the end of the grade, both in carbon and alloy steel, denotes high-quality steel, i.e. steel containing less sulfur and phosphorus.

This marking system covers most existing alloy steels.

The exception is certain groups of steels, which are additionally designated by a specific letter: P - high-speed, E - magnetic, Ш - ball-bearing, E - electrical.

- nitrogen (N) – A

- aluminum (Al) – Yu

- beryllium (Be) – L

- boron (B)–P

- vanadium (V)–F

- bismuth (Bi) – Vi

- tungsten (W) – B

- gallium (Ga) – Gl

- iridium (Ir) – I

- cadmium (Cd)–Cd

- cobalt (Co)–K

- silicon (Si)–C

- magnesium (Mg) – Ш

- manganese (Mn) – G

- lead (Pb) – AC

- copper (Cu) – D

- molybdenum (Mo)–M

- nickel (Ni)–H

- niobium (Nb) – B

- selenium (Se)–E

- titanium (Ti) – T

- carbon (C)–U

- phosphorus (P) – P

- chromium (Cr) – X

- zirconium (Zr) – C

Groups of steel grades:

- Carbonaceous: st. 20, 09G2S

- Corrosion resistant: Art. 20FA, 13HFA, 09GSF, 20A, 20S, 10Х17Н13М2Т

- Stainless steel (food grade): art. 08Х18Н10Т, 12Х18Н10Т

- Cold resistant: Art. 10G2FBU

- Heat resistant: Art. 15Х5М

Corrosion resistance group 1 – all types of corrosion steels with strength class K 52 Strength classes:

K42 – st. 20 K48 – art. 09G2S K52 – st. 20FA, 13HFA, 20A, 20C K56-60 – art. 10G2FBU

Characteristics of alloy steels

Alloy steel is steel that, in addition to the usual impurities, is also equipped with additional additives that are necessary for it to meet certain chemical and physical requirements.

Ordinary steel consists of iron, carbon and impurities, without which it is impossible to imagine this material. Additional substances are added to alloy steel, which are called alloying substances. They are used to ensure that steel has the properties that are necessary in certain situations.

In most cases, the following are added to iron, impurities and carbon as alloying elements: nickel, niobium, chromium, manganese, silicon, vanadium, tungsten, nitrogen, copper, cobalt. It is also not uncommon for such materials to contain substances such as molybdenum and aluminum. In most cases, titanium is added to add strength to the material.

This is interesting: What is cold welding for metal? Its features, pros and cons

This type of steel has three main categories. The relationship of alloy steel to a particular group is determined by how much steel and impurities it contains, as well as alloy additives.

Types of Alloy Steel

There are three main types of steel with alloying elements:

- Low alloy steel. It is characterized by the fact that it contains about two and a half percent of alloying additional elements.

- Medium alloy steel. This material contains from 2.5 to 10 percent of additional alloying substances.

- High alloy steel. This type includes steel materials, the amount of alloying additives in which exceeds ten percent. The amount of these components in such steel can reach fifty percent.

Purpose of alloy steel

Alloy steel is widely used in modern industry. It has a high level of strength, which allows it to be used to manufacture equipment for cutting and chopping rolled metal of various types.

According to their purpose, alloy steels can be represented by a large number of groups.

The main ones are:

- structural alloy steel,

- tool alloy steel,

- alloy steel with special chemical and physical properties.

The characteristics of alloy steels can be varied. They acquire them due to the ratio of the basic elements. Steels of this type are in any case more durable and resistant to corrosion.

Composition and application of alloy steels

The use of alloys is determined by their chemical composition. Thus, construction low-alloy steels are used for metal structures with a uniformly distributed load between all elements. The only requirement is good weldability.

Types of structural steels:

- Improved, high chromium content, enriched with boron, nickel, molybdenum, manganese. Designed for heat treatment.

- Spring-spring. These alloys are alloyed with silicon, cobalt, manganese, boron, and titanium. Used in the production of transport.

- Bearing. They have increased hardness and wear resistance. Be sure to contain chromium and a minimum of non-metallic additives.

- Heat resistant. Used for the production of steam heaters.

Tool steels for milling cutters, cutters, and taps are alloyed with chromium, vanadium, titanium and other additives. These are very expensive high-speed alloys, so they are used only in cutting planes. For measuring instruments, steel is alloyed with chromium, tungsten and manganese. This ensures hardness and retention of original dimensions.

Steels with special properties:

- Highly durable. These are high-alloy steels with a specially selected composition. They are used for the manufacture of critical components of mechanisms.

- Stainless steel, with additions of manganese and chromium. Used for work in chemically aggressive environments. Used to make pipes.

- Wear-resistant, high manganese content. They are used to make railway switches, tracks, mining equipment, and excavator buckets.

This group also includes heat-resistant, heat-resistant, magnetic, non-magnetic, rheostatic, and high electrical resistance alloys.

Low-alloy steel, high-quality structural

Regulatory document: high-quality structural low-alloy steel is manufactured in accordance with GOST 19281-89.

Low-alloy steel - alloy steel with a total mass of alloying elements less than 2.5% of the total mass of steel.

Low alloy steel grades

Steel grades: 09G2, 09G2S, 0KHSND, 17G1S, 16G2AF, 10KHNDP, 15KHNDP, 0KHSND, 15KHSND, etc.

Low-alloy steel grades 10KhNDP, 15KhNDP, 0KhSND, 15KhSND are atmospherically corrosion-resistant (AKS).

Substitutes for some grades of steel:

- 09G2S - 09G2, 09G2DT, 09G2T, 10G2S;

- 10HSND - 16GAF.

Application of low alloy steel

Low-alloy steel is used for the manufacture of railway, metro and tram car bodies, load-bearing structures of locomotives, agricultural and other field machines and engineering structures operating under conditions of variable dynamic loads and seasonal and daily heat changes.

Weldability: low-alloy steel can be welded without restrictions.

Tool alloy steels

Tool alloy steels

This type of low-carbon iron has other priority parameters, focused on high levels of hardness and wear resistance. Both characteristics improve with increasing carbon concentration in the metal.

The primary issue affecting alloy steels is the use of this type of metal. The area of use, as stated earlier, corresponds to the name of the category. Such steel is a material for the production of three main groups of tools:

- cutting;

- measuring;

- stamps.

The first category combines cutters, cutters, and cutters. This also includes a class of high-speed steel, characterized by red resistance, as well as preservation of cutting characteristics when heated to a temperature of 700 0C. Another distinctive feature of high-speed steel is the metal processing speed, which is five times higher than that of conventional tool grades. High-speed grades are marked with the letter “P”, where subsequent numbers indicate the percentage of tungsten.

The document describing tool alloy steels is GOST 5950 – 73. This type has improved heat resistance, the range of values of this parameter is transferred to the range 250 – 300 0C. An increase in this characteristic affects the cutting speed, increasing its value by 20 - 40%.

Considering how alloying elements influence the properties of steel, we will focus on several elements.

Silicon, grade – 9ХС. The introduction of the element into the composition of tool steel increases its hardenability to 40 mm. An additional effect is associated with improved martensite resistance during tempering. However, the element also brings negative nuances to the alloyed metal. Steels containing silicon are difficult to cut.

Alloy structural steel products

Manganese, grades – KhVG, 9KhVSG. Alloying with this metal leads to a decrease in tool deformation during the hardening process. This type of alloying is most effective for broaches - tools with a large ratio of length to cross-sectional diameter.

Medium alloy steel grades

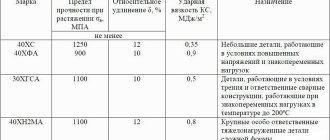

Medium-alloy steel grades whose designations contain letters and numbers have striking differences, so it is important to understand how steels of this type are marked. The marking principle is as follows: the letter shows the name of the alloying element in the steel, and the number shows its average content as a percentage. Thus, grades 9Х5ВФ, 8Х4В3М3Ф2 have high wear resistance, as well as calcination temperature. Medium alloy steels grades 9ХС, ХВГ, ХВСГ are widely used for the manufacture of drills, broaches, and reamers. 30KhGSA, 30KhGSNA have a high carbon content (0.35-0.5%) and this gives high strength to the steel. For the use of medium-alloy steel under conditions of frequent friction, high pressure, and shock loads, grades 40ХС, 40ХФА, 50ХВ are used. The chromium contained there gives special hardness and wear resistance to abrasive effects.

Alloyed scrap metal

The review of the alloy scrap market concerns not only steel, but also cast iron. Indeed, the share of advertisements for the purchase of alloyed cast iron scrap is not particularly inferior to the demand for secondary low-carbon iron. Acceptance of alloyed scrap is carried out by almost all points working with ferrous metal, but at a significantly higher cost.

It is worth understanding: for scrap metal collection points there is no such division by alloy steel (as in the directory) - for them there is black scrap, stainless steel scrap and high-speed cutter scrap. If everything is clear with stainless steel and quick-cutting steel, then black scrap can include steels such as: 09G2s and other grades that are in demand in this particular region. Some enterprises specifically purchase scrap steel from 09g2s.

Naturally, taking into account the specifics of alloy waste and alloy steel scrap, the price of such scrap per kilogram is determined by the inclusion of certain metals - alloying elements. For example, recycled steel with a nickel content of more than 9.3% can be accepted at up to 60 rubles per kg, while a lower concentration of Ni equates the waste to ordinary black steel scrap - 11,000 per ton.

Alloy scrap

Of particular value are high-speed grades, the value of which even in the form of scrap metal is significantly higher. However, many receivers divide the waste of high-speed cutters into two categories. The first group includes grades R6M5, R18, used for processing metals, including alloyed structural steels. The second includes grades P9 and P12, used for working on stone and less hard materials - see the article high-speed steel scrap.

Thus, the cost of alloy steel scrap is determined mainly by a couple of parameters: the content and type of additive, as well as the quality of the steel itself. On the other hand, high-speed cutter scrap, unlike other steel waste, can be used for business purposes. Many tools, even after completing their service life, remain attractive for further use. The scope of their application may include both the household sector and small private enterprises.

Carbon steels

Carbon, while increasing hardness, also makes the alloy more brittle. The percentage content of the element is reflected in the marking - you can use it to determine what material is in front of you. Please note that the first two digits reflect the presence of hundredths of a percent of the element, one – tenths. If the carbon content is up to 0.25%, then the steel is low-carbon, and therefore inexpensive, easy to weld. If from 0.3 to 0.55%, then the alloy is medium carbon; these are actively used in mechanical engineering. The amount of the element in the range of 0.6-2% shows that the material is high-carbon, therefore its weldability and fluidity are low, but its hardness is high.

The structure of low-carbon alloys provides plasticity, but relatively low strength of the material. An increase in carbon content leads to a loss of ductility, but significantly increases strength. Thus, high-carbon steel is a very hard, durable alloy, for which they try to avoid the use of welding whenever possible. Wire, bearings, springs, and stamped parts are produced from it.

This is interesting: Characteristics of food grade stainless steel. What grades of stainless steel are food grade?

What does the steel marking mean?

It has become quite easy to decipher the brand; you just need to have certain information. Structural steels of ordinary quality and not containing alloying elements are marked with the letter combination “St”. By the number following the letters in the name of the brand, you can determine how much carbon is in such an alloy (calculated in tenths of a percent). The numbers may be followed by the letters “KP”: from them it becomes clear that this alloy has not completely gone through the deoxidation process in the furnace, and accordingly, it belongs to the boiling category. If the brand name does not contain such letters, then the steel corresponds to the calm category.

Chemical composition of carbon structural steels of ordinary quality

Structural unalloyed steel, which belongs to the quality category, has two numbers in its designation; they are used to determine the average carbon content in it (calculated in hundredths of a percent).

Before we begin to consider the grades of those steels that include alloying additives, you should understand how these additives are designated. Marking of alloy steels may include the following letter designations:

List of alloying additives used

Why label?

Alloys are marked according to GOST. The brand indicates their purpose, basis, and the presence of impurities. For example, they can be instrumental (used to make working parts of various tools), structural (used to create metal structures, car bodies). Additional letters may denote materials that have special physical properties (magnetic, heat-resistant, corrosion-resistant).

The quality of the alloy is determined by the percentage of additives in the composition. For example, the content of phosphorus and sulfur should be minimal. The components are indicated by capitalizing the element letters.

Decoding

Steel is marked according to certain rules. The first numbers indicate the carbon content. For example, 5 indicates 0.05%. If there is no number at the beginning, the amount of carbon is up to 1%.

The letters that follow the first numbers indicate the name of the additional components.

There are different types of steels that differ in technical characteristics and properties. They depend on the presence of additional impurities contained in the composition. To avoid confusion among numerous products made from different types of materials, special markings are used.

CIS countries standards

When designating alloy structural steel, the percentage of carbon mass fraction is marked with the first two digits without using a letter designation. Next, alloying components and their share in the alloy in average equivalent are indicated in decreasing order. The letter designations of chemical elements are indicated in Table 1. Alloying additives, the amount of which is less than 1.0%, are indicated only in the deciphered nomenclature, since the designation would then take on a very cumbersome form.

Given the extensive assortment, the steel grade may also include additional symbols, since the designation would then take on a very cumbersome form that more broadly describes the properties or features: A - automatic, E - magnetic, F - stainless, P - cutting, X - chromium , Ш - ball bearings, E - electrical, I - chromium-nickel. Labeling may also involve exceptions to the general designation rules. So, depending on the chemical composition, structural alloys are divided into high-quality and high-quality. For example, at the end of the marking, the letter “A” indicates that the alloy is especially pure in terms of phosphorus and sulfur content, and the letter “W” classifies them as high-quality.

Marking of alloy steels for river and sea shipbuilding is often carried out in accordance with GOST 5521-86 and the requirements of the International Association of Classification Societies. This means that such alloys are classified into categories A, B, D and E, taking into account their yield strength, strength, brittleness and impact resistance.

European standards

EN 10027 defines the designation procedure for all steels. Alloy alloys are marked 1.20ХХ - 1.89ХХ, where the first digit determines that the material belongs to steel, the second and third digits determine the number of the steel group, and the last two determine the serial number of the alloy in this group. For example, the category of tool steels is identified as 1.20ХХ - 1.28ХХ, and stainless steels as 1.40ХХ - 1.45ХХ.

North American ASTM/ASME and AISI standards

The USA has the most extensive steel marking system. For example, ASTM marking implies the designation of the main chemical elements, tensile strength and shape of the rolled product. The AISI system uses 4 digits, where the first two indicate the group number, the next two indicate the percentage of carbon. Letter symbols indicate the presence of the corresponding additives.

Designation of steels with alloying elements

As mentioned above, the classification of steels with alloying elements includes several categories. The marking of alloy steels is compiled according to certain rules, knowledge of which allows one to quite simply determine the category of a particular alloy and the main area of its application. In the initial part of the names of such brands there are numbers (two or one) indicating the carbon content. Two numbers indicate its average content in the alloy in hundredths of a percent, and one – in tenths. There are also steels that do not have numbers at the beginning of the brand name. This means that the carbon content in these alloys is within 1%.

Example of alloy steel marking

The letters that can be seen behind the first digits of the brand name indicate what the alloy is made of. The letters that give information about a particular element in its composition may or may not be followed by numbers. If there is a number, then it determines (in whole percentages) the average content of the element indicated by the letter in the alloy, and if there is no number, it means that this element is contained in the range from 1 to 1.5%.

At the end of the marking of certain types of steel there may be the letter “A”. This suggests that this is high quality steel. These grades may include carbon steels and alloys with alloying additives in their composition. According to the classification, this category of steels includes those in which sulfur and phosphorus amount to no more than 0.03%.

Examples

To learn how to decipher symbols, you need to consider several labeling options:

- U8GA - contains 0.8% carbon.

- St3sp5 is a structural metal that is not alloyed. Often used for the manufacture of metal structures.

- 30ХГСА - contains up to 0.3% carbon. Additional components - silicon, manganese, chromium. The letter A indicates high quality material.

- R6M5F2K8 - high-speed steel. The composition contains about 8% cobalt, 5% molybdenum, 2% vanadium.

- HVG - consists of manganese, chromium, tungsten, the amount of which does not exceed 1%.

Examples of marking steels of various types

Determining the grade of steel and assigning an alloy to a certain type is a task that should not cause any problems for a specialist. You don’t always have a table at hand that gives a breakdown of brand names, but the examples given below will help you figure it out.

Content of elements in common steel grades (click to enlarge)

Structural steels that do not contain alloying elements are designated by the letter combination “St”. The numbers following are the carbon content, calculated in hundredths of a percent. Low-alloy structural steels are marked somewhat differently. For example, 09G2S steel contains 0.09% carbon, and alloying additives (manganese, silicon, etc.) are contained within 2.5%. 10KhSND and 15KhSND, which are very similar in their markings, differ in different amounts of carbon, and the share of each alloying element in them is no more than 1%. That is why there are no numbers after the letters indicating each alloying element in such an alloy.

20Х, 30Х, 40Х, etc. – this is how structural alloy steels are marked; the predominant alloying element in them is chromium. The number at the beginning of such a mark is the carbon content in the alloy in question, calculated in hundredths of a percent. The letter designation of each alloying element can be followed by a number, which is used to determine its quantitative content in the alloy. If it is not there, then the specified element in the steel contains no more than 1.5%.

You can consider an example of the designation of chromium-silicon-manganese steel 30KhGSA. According to the labeling, it consists of carbon (0.3%), manganese, silicon, and chromium. It contains 0.8–1.1% of each of these elements.

Have a question?

Our services

Welding alloy steels: features

Alloy alloys have good ductility, so complex structures can be made from them by welding. Due to the different content of additives, each type of alloyed products has its own characteristics.

Welding alloy steels

Alloy alloys have good ductility, so complex structures can be made from them by welding. Due to the different content of additives, each type of alloyed products has its own characteristics.

Welding low alloy steels

The peculiarity of welded joints of low-alloy steels is their high resistance to cold cracks and brittle fracture. But, such properties of the connecting seam can only be achieved with proper welding.

If the preheating process is disrupted or the weld is subjected to too rapid cooling, the metal may receive microscopic damage at the joints, which will significantly reduce the strength of the entire structure.

Low-alloy steels 10G2SD, as well as 14KhGS and 15KhSND are welded using a direct current machine with reverse polarity. Electrodes for welding must have a calcium fluoride coating.

The amount of welding current must exactly match the type of electrode, the thickness of the metal and the type of alloy.

Failure to comply with this requirement will also affect the quality of the weld and, as a result, the strength of the manufactured structure.

Welding of low-alloy steel must be carried out without interruption so that the entire seam is made without a metal temperature of at least 200 degrees. The average welding speed is 20 m/h, with a voltage of 40 V and a current of 80 A.

Welding of medium alloy steels

When manufacturing structures from medium-alloy steels, it is necessary to use welding materials in which the content of alloying elements should be less than in the material being welded.

Only by using such materials can a seam with high resistance to deformation be achieved. If, in the manufacture of products from medium-alloy steels, the sheet thickness does not exceed 5 mm, then high quality joints can be achieved using argon arc welding.

If gas welding is used to connect parts, then acetylene mixed with oxygen should be used as a combustion source.

Welding of high alloy steels

If high-alloy steel is used for the production of metal parts, then welding equipment with minimal thermal entrainment of the material should be used. This is necessary to reduce the likelihood of metal warping during welding, due to the high content of various impurities in the metal composition.

Electric welding of high-alloy alloys is carried out using calcium fluoride coated electrodes. In this case, it is possible to achieve high levels of mechanical and chemical strength of the weld.

The use of gas welding in the manufacture of structures made of high-alloy steels is undesirable. In exceptional cases, it is possible to use gas welding to connect heat-resistant high-alloy steel sheets with a thickness of no more than 2 mm.

Sources

- https://www.syl.ru/article/365687/chto-takoe-legirovannaya-stal—sostav-svoystva-marki-gost-naznachenie-obrabotka

- https://FB.ru/article/275232/legirovannyie-metallyi-opisanie-spisok-i-osobennosti-primeneniya

- https://www.m-deer.ru/tehnologiya/legirovanie-stalej.html

- https://www.metotech.ru/art_garsplavy_2.htm

- https://intehstroy-spb.ru/spravochnik/legirovannye-stali-klassifikaciya-i-markirovka.html

- https://xlom.ru/spravochnik/legirovannyj-stali-vidy-xarakteristika-legirovannyj-metallolom

- https://msmetall.ru/metalloobrabotka/klassifikaciya-legirovannyh-stalej.html

- https://metalloy.ru/stal/markirovka-legirovannoy-stali

- https://metinvest-smc.com/ru/articles/legirovannaya-stal-osobennosti-klassifikatsiya-i-kharakteristiki/

- https://plavitmetall.ru/obrabotka/legirovannaya-stal-primenenie.html

- https://regionvtormet.ru/stanki-i-oborudovanie/harakternye-osobennosti-legirovannoj-stali-i-sfera-ee-primeneniya.html