HARDENABILITY AND HARDENABILITY OF STEEL

Hardenability and hardenability - these two concepts characterize the important properties of steel.

Hardenability refers to the ability of steel to obtain maximum hardness when hardened.

Hardenability is understood as the ability of steel to obtain a hardened layer with a martensitic or troostite-martensitic structure to a certain depth.

DK is considered to be a characteristic of hardenability

, i.e. the largest diameter of a cylinder made of a given steel, which will obtain a semi-martensitic structure in the center of the sample as a result of hardening.

This structure contains 50% martensite and 50% troostite. In this case, DK

is designated D50 However, it is often important to know the diameter value where the martensite content is significantly higher: 95% and 99.9%.

In these cases , DK

is designated D95 and is designated D99

.

The question of hardenability arises because the cooling rate across the cross section of the part being hardened is different: it is maximum on the surface, decreases in layers deeper from the surface, and is minimal in the central part of the part, Fig. 22.

Naturally, the hardness across the cross section of a part that does not have through hardenability will be different, for example, for steel with 0.8% C it can be HRC 65 on the surface up to HKS 15 in the center. After tempering, when it is possible to level the hardness over the cross-section, a number of other properties ( especially

and at) in the non-calcined sections of the cross-section are obviously reduced.

| Figure 22.- Change in hardness along the cross section of a hardened cylindrical part |

For engineering parts for critical purposes that operate under severe loading conditions (tension and, especially, impact), as well as for parts such as springs, springs and the vast majority of tools, it is required that after hardening the structure over the entire cross-section consists of 100% martensite, which will provide a uniform structure after tempering.

For machine parts operating under less severe loading conditions (mainly bending and torsion), 100% martensite at a depth of 0.5 part radius has recently been taken as the hardenability criterion.

Thus, for a designer choosing a material for a part, knowledge of hardenability (critical diameter Dk)

have become quite important.

The determination of hardenability by the end hardening method is discussed below. With this method, a standard sample (1 = 100 mm and d = 25 mm) of the steel under study is subjected to cooling with a stream of water only from the end. Naturally, the cooling rate will decrease with distance from the end (and accordingly, the hardness will decrease).

Hardenability is influenced by many factors: a) the composition of austenite (all elements that dissolve in austenite with the exception of Co increase the stability of austenite, shift the C-shaped decomposition curves of austenite to the right and increase hardenability); b) with the growth of austenite grains, hardenability also increases; c) an increase in austenite heterogeneity and the presence of insoluble particles (oxides, carbides) in austenite accelerate the decomposition of austenite and reduce hardenability.

a) b)

Fig. 22 Curves of changes in hardness of carbon steel with 0.3% C (a) and alloy steel with 0.3% C, 1.27% Si and 0.87% Cr (b) depending on the distance of the cooled end.

Fig.23. Dependence of the hardness of the semi-martensitic structure HRC 50 on the carbon content in steel.

Fig.24. Diagram for determining the critical diameter D50 of steel using an accelerated method.

Practical part

Work order

To complete the task you must:

1. Obtain from the teacher the number of the individual assignment option and write it out from Table 9.

2. Draw the state diagram to be analyzed to scale.

3. Determine the hardness of the semi-martensitic structure HRC50M depending on the carbon content in the steel.

4. Determine the depth of hardening.

5 Determine the critical diameter Dk.

6. Write the results in a table.

7. Write the practical part of the work report in accordance with the above points of the assignment.

Table 9

Individual tasks to determine the hardenability of steel.

| Option No. | |||||||

| steel grade | 18kp | 20ps | 30ХГСА | VSt5ps | VSt6sp | 35ХН2М | 25Х2НМЛ |

| Option No. | ||||||

| steel grade | 35ХГС | 40ХНМА | 40G2 | 45ХН2МФА | 36Х2Н2МФА | A40G |

2.2.An example of completing a task.

In Fig. Figure 22 shows the hardness values depending on the distance from the end of two steels: c ~ 0.3% C, curve a, and c 0.3% C, 1.27% Si and 0.87% Cr, curve b.

Next, the curve determines h the distance from the end of the sample to the semi-martensitic zone: i.e., the region where the structure consists of 50% martensite and 50% troostite.

To do this, in Fig. Figure 23 shows a curve showing the hardness of the semi-martensitic structure of HRC50M versus the carbon content of the steel. (HRC50M of alloy steel with equal carbon content is higher by no more than 5 units). From Fig. 23 we determine for steel with 0.3% C HRC50M = 37, for steel ZZHS HRC50M = 42. Plotted along the ordinate axis in Fig. 22 hardness values HRC50M = 37 and HRC50M = 42, draw horizontal lines until they intersect with the curves HRC = f(h). Projecting the obtained intersection points onto the distance axis, we find that the distance to the semi-martensitic zone for carbon steel is ~4 mm, for alloy steel ~ 10 mm. To determine D50 we use the diagram in Fig. 24. Let us plot the found distances along the abscissa axis and, from the obtained points, restore the perpendiculars to the “water” curve.

From the intersection points obtained, we draw horizontal lines until they intersect with the ordinate axis and find that when quenching in water, Dk of carbon steel with C = 0.3% is about 20 mm, for alloyed steel Dk = 40 mm. Enter the results in table 10.

Table 10.

Determination of the hardenability of steel.

| Var. no. | steel grade | Chemical composition | HRC50M | h,mm | D50 (Dcr), mm |

| WITH,% | Harmful impurities, % | Dr. comp., % | |||

| 0,3 | S-0.35 P-0.35 | — | |||

| 30ХС | 0,3 | S-0.35 P-0.35 | Cr-0.87 Si-1.27 |

Practical lesson No. 6

Hardenability and hardenability of steel

Hardenability is the most important characteristic of steel, which determines the choice of steel grade depending on the size of the workpiece being hardened.

The hardenability of steel characterizes the hardness of properly hardened steel and is measured in hardness units. The higher the carbon content in steel, the greater the distortion of the martensite lattice and the higher the hardness. Alloying elements have little effect on hardenability.

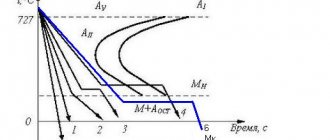

Hardenability is the ability of steel to obtain a hardened layer of a certain depth. The cooling rate decreases from the surface of the part to the center, therefore, with a large thickness of the part, it may turn out that in its core the cooling rate is less than critical (Fig. 49). In this case, only the surface layer of the part will be hardened to martensite, and the core will be unhardened, with a soft ferrite-pearlite structure.

Rice. 49. Changing the cooling rate along the cross section of the part

Hardenability is the distance from the surface to the place where 50% martensite and 50% troostite are observed in the structure (semi-martensitic zone). The hardness of the semi-martensitic zone depends on the carbon content in the steel (Fig. 50). Hardenability is expressed in mm and depends on the composition of the steel, or more precisely on the value of the critical hardening rate. With an increase in the content of carbon and alloying elements, the critical hardening rate decreases and the depth of hardenability increases.

Rice. 50 Hardness of the semi-martensitic zone of carbon steel.

To characterize the hardenability of steel, reference books give the value of the critical diameter.

The critical diameter is the maximum diameter of a cylindrical rod that is calcined through in a specific cooling environment.

The more hardenable the steel, the better. Carbon steel, when cooled in water, has a critical diameter of only 10-15 mm. The hardenability of steel depends mainly on the content of alloying elements, which hinder the diffusion decomposition of austenite, thereby reducing the critical cooling rate during hardening. The more alloying elements in steel, the higher its hardenability. The larger the workpiece size, the more alloyed steel should be used. In addition, hardenability is greater with increasing austenite grain size and increasing its chemical homogeneity.

The hardenability and hardenability of steels is determined experimentally. The values of these characteristics for various steels are given in reference books.

To determine hardenability, the standard end-hardening method is used. After heating in a furnace, a standard cylindrical sample is quickly transferred to a special installation in which it is cooled with a stream of water under pressure only from the end. After complete cooling, hardness is measured along its generatrix, starting from the end, and a hardenability curve is plotted. The value of hardenability is determined by the distance from the end to the semi-martensitic zone (Fig. 51), the hardness of which is known in advance from experimental data, and is determined mainly by the carbon content.

Rice. 51. Change in hardness along the length of the sample after end hardening.

Determination of the critical diameter for products of simple shape (ball, cylinder, parallelepiped) can be carried out with fairly high accuracy using a special nomogram (Fig. 52). The initial physical characteristic is the distance to the semi-martensitic zone, obtained experimentally as a result of end hardening. This value is plotted on the scale at the top of the nomogram. From this point a perpendicular descends to the line of ideal cooling and a horizontal line is drawn from it until it intersects with the line of cooling in water, oil, or air. And from these points, perpendiculars are lowered to the body scales of a certain shape located at the bottom of the nomogram.

Rice. 52. Determination of the critical diameter based on end-hardening data

Hardenability is an important characteristic of steel

Numerous studies have established that hardenability is an important characteristic of steel. It is believed that the degree of alloying is determined by hardenability. It was noted that the interchangeability of improved structural steels should be assessed by hardenability, and in production conditions it is necessary to determine the hardenability of steels for each heat. A classification of steels according to their hardenability is proposed. The best steel in terms of hardenability will be one in which austenite has a low rate of decomposition both in the pearlitic and intermediate regions. The initial temperature of the martensitic transformation should be quite high. In addition, when cooling in the pearlitic region, the precipitation of excess ferrite, which reduces the hardness and fatigue limit of the steel, should be avoided. Ferrite inclusions reduce toughness after tempering and create stress concentrations in products.

It is known that hardenability is determined by the distance from the surface of the hardened part to the layer with a semi-martensitic structure (50% martensite and 50% troostite). The hardness of such a semi-martensitic zone depends mainly on the carbon content. The “critical” diameter during quenching is determined from the condition of the presence of a semi-martensitic structure in the core of the workpiece. However, the best properties can be achieved with 100% martensite in the structure, which is quite difficult to obtain in practice.

Through hardenability is needed for products that work in tension and also experience significant elastic deformation. It is proposed to determine hardenability by the depth of the hardening layer with a structure of 90% martensite and 10% hardened troostite or 95% martensite. In the latter case, the difference between the “semi-martensitic” and “martensitic” diameters increases with increasing product size. However, a hardened layer containing 90-95% martensite can only be obtained in products with a small cross-section. Therefore, taking into account the distribution of bending and torsion stresses over the cross-section of parts, a condition has been proposed under which the depth of the layer containing 90% martensite should be at a distance of about a radius from the surface.

A method was presented for determining hardenability for improved structural steels by the type of fracture of impact samples after quenching and high tempering, which eliminates the appearance of temper brittleness. The critical section is considered to be the maximum thickness of the product with a completely fibrous fracture. The disadvantage of this method is that in complex alloy steels, determining the percentage of the fibrous component presents significant difficulties and does not always give accurate results.