A typical example of final metal processing is steel tempering. It involves heating a part for a certain time with slow cooling. This helps eliminate internal defects of the alloy, which negatively affect stability, strength, and ductility. But what defects does this heat treatment method help eliminate? Is it possible to temper steel at home? Is it true that improper heating can degrade the physical properties of the metal?

Process description

Steel tempering (STE) is a type of heat treatment in which the metal is gradually heated and then cooled. In most cases, the tempering procedure is performed at the final stage immediately after hardening. OS can be performed both before and after the formation of a part from a semi-finished steel product. Allows you to eliminate internal stresses inside the metal, which negatively affect its physical structure and properties.

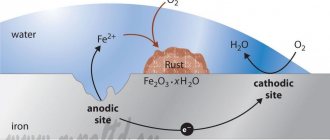

Internal stresses at the chemical level are violations of the crystalline structure of the metal. Because of them, there is an uneven distribution of carbon and alloying additives throughout the metal alloy. Vacation allows you to redistribute these elements more evenly. This improves the physical and chemical properties of the material (ductility, strength, shape retention, chemical inertness). Heating is carried out using special furnaces in a protective environment (oil, saltpeter or alkaline baths). The method of cooling parts after heating is air (usually) or liquid (rarely).

The quality of steel tempering depends on the following physical parameters of the thermal procedure:

- Heating temperature. OS can be performed at temperatures from 100 to 700 degrees, and the higher the heating temperature, the higher the quality of processing. This dependence is explained by the fact that at higher temperatures a deeper change in the structure of the crystal lattice occurs. Mainly due to the processes of polygonization and recrystallization.

- Heating duration. OSes typically last between 1 and 3 hours, although longer formats exist. All main processes in the material take place in the first 20-40 minutes. Additional exposure is needed for uniform distribution of carbon atoms, iron, and alloying additives throughout the entire thickness of the material.

- Cooling speed. The rule here is extremely simple - the slower the cooling, the higher the quality of the material. To slow down cooling, metallurgists use various tricks and tricks. The main trick is to place the material in an oil, saltpeter or alkaline environment, which slows down the cooling of the material. Theoretically, cooling can be performed without the use of liquid media, but the cooling rate will be high, which will negatively affect the quality of the OS.

Types of steel tempering

The main technical parameter of the OS is the heating temperature. There are 3 types of OS - high, medium and low. Of course, high-temperature tempering is the optimal means of processing, since the higher the heating temperature, the more actively recrystallization of the metal will occur. However, low- and medium-temperature processing methods also have practical benefits that should not be underestimated. Below we will look at each type of OS separately.

High

High tempering of steel is a variant of tempering treatment at temperatures from 500 to 700 degrees. This method is the most effective, since with such heating, polygonization and recrystallization of the material occurs, which eliminates all stress inside the metal. Usually lasts from 2 to 3 hours. In the case of processing complex structures, the recommended time can increase to 6 hours.

The main disadvantage of high-temperature tempering is a slight decrease in the strength of the material. Therefore, the technique is not suitable for processing parts that will experience extremely high loads during operation. The high temperature technique applies to all types of steel, but note that in the case of some alloy alloys, so-called reversible high temperature embrittlement may occur during processing.

Average

The main feature of medium tempering is the active diffusion of carbon without polygonization and recrystallization of the alloy. In the case of medium-temperature treatment, the elasticity of the material improves and its relaxation resistance increases. The steel tempering temperature in this case ranges from 350 to 500 degrees. The average processing time is 2-4 hours. The optimal environment is oily or alkaline. Medium processing is well suited for durable parts of complex shapes - springs, springs, impact structures. However, in practice this technology is rarely used due to a number of limitations:

- In the temperature range from 250 to 300 degrees there is a so-called island of brittleness of the first kind, which should be avoided. At the same time, at temperatures above 500 degrees, there is another island of fragility of the second type (it is also recommended to avoid it). We will discuss the features of these islands below. A slight deviation in temperature up or down during the holidays can lead to fatal consequences.

- The technique has no advantages in comparison with alternative technologies (low and high). At the same time, weak processing furnaces usually cannot heat the working environment to such temperatures, and stronger furnaces can reach higher temperatures, which is inconvenient from a practical point of view.

Short

Low tempering of steel is a method of processing a steel alloy or product in which heating is carried out to a temperature of 100 to 250 degrees. The processing time is usually 1-3 hours depending on the type of part and its dimensions. During low-temperature processing, diffusion of particles of carbon components occurs without polygonization and recrystallization of the atomic lattice. This allows you to increase some of the physical characteristics of the material - strength, ductility, hardness, chemical inertness.

Low tempering is a universal technology, but in fact it is used mainly for tempering products made from low-alloy and high-carbon steels (knives, utensils, simple parts). You also need to avoid heating the material above a temperature of 250 degrees (otherwise it will fall into a type I island of fragility, which can lead to irreversible damage to the metal).

Pivot table

| Vacation type | Time | Steel tempering temperature | Brief Features |

| Short | 1-3 hours | 100 to 250 degrees | Only partial diffusion of carbon occurs. Avoid overheating the material above 250 degrees. |

| Average | 2-4 hours | 350 to 500 degrees | Complete diffusion of carbon occurs without polygonization or recrystallization. In practice it is rarely used due to a number of limitations. |

| High | 2-3 hours | 500 to 700 degrees | Complete diffusion of carbon, polygonization, and recrystallization occurs. Slightly reduces the strength of the material, so it is not used for heavy-duty parts. |

Additional leave with pay

What a vacation . For rest of workers with hazardous and irregular work. This is the same annual leave, only extended. Basis - art. 116 Labor Code of the Russian Federation.

Duration . Workers with hazardous working conditions of 2, 3 and 4 degrees or dangerous according to the results of a special assessment are given a minimum of 7 days. Annual leave is 28 + 7 = 35 calendar days.

For irregular working hours, add a minimum of three days. It turns out 28 + 3 = 31 calendar days. An irregular day is when an employer occasionally asks you to stay late after your shift. And this must be written down in the employment contract.

In the Far North, an additional 24 calendar days are added to the additional vacation. And in areas equivalent to them - 16 calendar days.

Documents for registration . Employee application, order, entry in a personal card.

Processing of tool alloys

High, medium and low steel tempering are only suitable for heat treatment of alloys containing less than 0.7% carbon. For alloys with a higher carbon content (called tool alloys), other methods are used. Let's look at the main technologies:

- It is not recommended to temper high-speed tool alloys because they contain molybdenum, cobalt, tungsten, and vanadium. These elements are resistant to heat, so they do not change their physical and chemical properties during tempering heating. Instead of tempering, it is recommended to do multi-stage hardening: for this, the material is gradually heated to 800, 1050 and 1200 degrees - after which the alloy is sharply cooled in an oil environment.

- It is recommended to process conventional tool alloys in two stages. First, the material is hardened in molten salts at a temperature of 450-500 degrees. After this, the second stage is performed - double tempering at a temperature of 550-600 degrees (no more than 1 hour). Please note that when tool alloys are heated, the possibility of the occurrence of tempering ability of the second type is excluded.

Low steel tempering

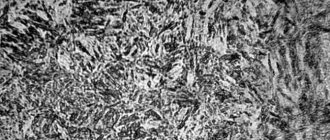

Low tempering of steel is done at temperatures up to 250°C. During this process, some of the excess carbon is released from martensite to form tiny carbide particles (ε-carbides). ε-carbides precipitate in the form of plates or rods and they are coherently bonded to the martensite lattice. The decomposition of retained austenite during low tempering occurs according to the mechanism of bainite transformation: a heterogeneous mixture of low-carbon martensite crystals and dispersed carbides is formed. The product of low tempering is tempered martensite, which differs from quenched martensite by its lower carbon concentration and the presence of carbides (ε-carbides) in it, which are coherently bonded to the martensite lattice.

At a temperature of about 250°C, the transformation of carbide into cementite begins; in this case, the coherence of the lattices of the α-solid solution of martensite and carbides is disrupted.

Iron-carbon tool materials (cutting and measuring tools), as well as steels that have been carburized or nitrocarburized, are subjected to low tempering. Low tempering is often done for steels after heat treatment with high frequency currents.

What is temper brittleness

The release temperature affects the quality of processing - the higher the temperature, the higher the quality of processing. However, metallurgical scientists have found that this rule has 2 exceptions, when an increase in temperature does not lead to an improvement, but to a deterioration in the quality of the material. These two exceptions are often called temper brittleness islands in practice. Fortunately, several effective, safe ways to bypass these islands have been developed, so the issue of tempering ability is not significant in modern metallurgy. Let's look at each of the islands separately + learn how to get around them.

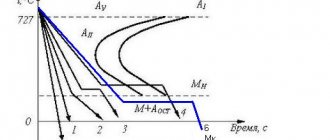

Irreversible low temperature embrittlement

Another name is fragility of the first kind. It occurs during prolonged processing of the material at temperatures from 250 to 300 degrees, and this fragility extends to all types of steel alloys. Explanation of the phenomenon: when heated in a given temperature range, carbon begins to actively distribute over the surface of the crystal lattice. However, the distribution of carbon is extremely uneven - this leads to disruption of the crystalline structure of the metal, which leads to a serious increase in fragility. As the name implies, this fragility is irreversible (that is, the islands remain stable for an unlimited time, and damaged material is only suitable for remelting). The method of dealing with this fragility is trivial - you need to use either low or medium heat treatment - but not “intermediate” between them.

Reversible high temperature embrittlement

Another name is fragility of the second kind. It occurs only when three factors are combined simultaneously. The first factor is that the metal is heated above a temperature of 500 degrees (that is, this fragility is characteristic of high tempering processing). The second factor is that steel is an alloy with a high content of chromium, manganese or nickel. The third factor is a very low cooling rate. Explanation of the phenomenon: with a combination of three factors, an uneven distribution of carbon, chromium, manganese and nickel atoms also occurs, which leads to disruption of the crystal lattice of the alloy. There are many ways to combat this fragility - let's look at two of them:

- Method No. 1: after the formation of brittleness, the material is reheated to a given temperature - only heating is carried out in an oil environment, and the metal is cooled after tempering very quickly.

- Method No. 2: during tempering, tungsten (about 1% of the total mass) or molybdenum (0.3-0.4%) is additionally added to the alloy - after this, high tempering is performed using standard technology.

High holiday

During high tempering (450-550°C and above), structural changes occur in carbon steels that are not associated with phase transformations: the shape, size of carbides and ferrite structure change. With increasing temperature, coagulation occurs - the enlargement of cementite particles. The shape of the crystals gradually becomes spherical - this process is called spheroidization.

Coagulation and spheroidization of carbides begin to occur more intensely at a temperature of 400°C. The ferrite grains become large and their shape approaches equiaxial. The ferrite-carbide mixture, which is formed after tempering at a temperature of 400–600 ° C, is called tempering sorbitol. At a temperature close to point A1, a fairly coarse ferrite-cementite mixture is formed - pearlite.

High tempering at temperatures of 450-550°C is used for most structural steels. It is widely used in the heat treatment of various bushings, supports, fasteners operating in tension-compression and other products that experience static loads.

Temper brittleness phenomenon

When tempering some steels, processes may occur that reduce the impact strength of the steel without changing other mechanical properties. This phenomenon is called temper brittleness and is observed in the tempering temperature ranges at 250–400ºС and 500–550ºС. The first type of brittleness is called type 1 temper brittleness and is irreversible, so tempering steels at these temperatures should be avoided. This type is inherent in almost all steels alloyed with chromium, magnesium, nickel and their combination, and is due to the heterogeneous precipitation of carbides from martensite. The second type of temper brittleness, temper brittleness of the ΙΙth kind, is reversible. Temper brittleness of the ΙΙ-th kind manifests itself when alloy steel is slowly cooled at a temperature of 500–550°C. This brittleness can be eliminated by repeated tempering at a high cooling rate (in water or oil). In this case, the cause of this brittleness is eliminated—the precipitation of carbides, nitrides, and phosphides along the boundaries of former austenite grains. It is possible to eliminate the temper brittleness of alloy steels by introducing small additions of molybdenum (0.2–0.3%) or tungsten (0.5–0.7%) into them.

Graphically, these types of fragility look as shown in the figure.

Manifestation of temper brittleness in steels during tempering

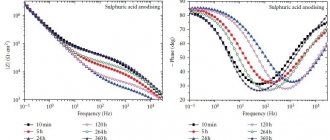

Almost all steels obey the law: an increase in tempering temperature leads to a decrease in strength characteristics and an increase in plasticity, as shown in the figure below.

Effect of tempering temperature on the mechanical properties of steel

This pattern does not apply to high-speed tool steels alloyed with carbide-forming elements.

Is it possible to temper steel at home?

Most often, heat treatment applies to various simple parts, household utensils - knives, forks, metal cups, car parts, and so on. However, home metallurgy has many limitations that the common man may not be aware of. Let's consider the main problems that a person may encounter during a steel holiday at home:

- Most home ovens cannot reach high temperatures. Therefore, at home you can only make a low or medium vacation. Theoretically, you can try to re-equip or “strengthen” your stove to increase the heating temperature, but this will be difficult for a person without experience.

- To carry out heat treatment, it is necessary to use a protective medium (oil, alkali, saltpeter). But each substance has its own temperature characteristics. A simple example: saltpeter-based compounds can explode when heated to high temperatures, which can be dangerous to the life and health of the home metallurgist.

- Tempering without the use of a protective environment can be fatal to the metal itself. The fact is that without the use of a protective environment, the metal will cool quickly, which can affect the quality of the steel (increased brittleness, bending, plastic deformation, rust).

- Also, do not forget about low-temperature brittleness of the first type (from 250 to 300 degrees). If the temperature is incorrect, the quality of the metal can be seriously affected, up to the complete destruction of the alloy.

Vacation at your own expense

What a vacation . When an employee cannot go to work for family reasons or other valid reasons. For example, caring for a dying relative. The list of circumstances is unlimited. Basis - art. 128 Labor Code of the Russian Federation.

Salaries are not paid for this time, and vacation pay before leaving is not given.

It is impossible to force an employee to go on leave without pay.

Duration . The employer is obliged to grant leave without pay to:

- WWII participants - for 35 calendar days a year;

— old-age pensioners — for 14 calendar days a year;

- parents and spouses of deceased military personnel, police officers, firefighters, and correctional service employees - for 14 calendar days a year;

— disabled people — for 60 calendar days a year;

- at the birth of a child, wedding or death of loved ones - for 5 calendar days, possibly several times a year.

In all other cases, the duration of the vacation is agreed upon at one’s own expense. There is no lower or upper limit; you can apply for either three days or a year.

Documents for registration . Employee application, order, entry in a personal card. Plus - documents that confirm that the employee cannot work. For example, a death certificate for a relative. If the deadline has passed and the employee still cannot leave, he writes a statement again, and the employer again issues an order.