Exhaust system material

Typically, the release device is made of austenitic stainless steel, which is caused by a number of operational factors. Firstly, the exhaust gases of a car engine have an extremely high temperature, which places certain demands on the heat resistance of the metal. Secondly, the structure is located under the bottom of the car, so it is constantly exposed to moisture and dirt that are on the road surface.

Ordinary steel, when working in such conditions, very quickly begins to corrode and deform. Therefore, exhaust systems are manufactured from austenitic stainless steel, which is a heat-resistant material and can be exposed to high-temperature exhausts for a long time. Structural defects and cracks, if they occur, can be easily eliminated using the correct welding technology.

The issue of choosing a material and gas environment is relevant for tuning companies that manufacture exhaust gas systems for foreign cars, because customers can order welding of a unit not only from stainless steel, but also from titanium alloys.

example of a tuning studio's products, AISI304 stainless steel

Our prices:

- Stainless steel exhaust from 22,000 rubles

- Exhaust system made of aluminized steel from 18,000 rubles

- Sports exhaust system (forward flow) from 35,000 rubles

- Muffler from 3000 rubles

- Corrugation from 400 rubles

- Sports catalyst from 4500 rubles

- Equal-length collector from 10,000 rubles

- Middle resonator from 3800 rubles

Important! More expensive does not mean better. A budget system may not be inferior to one assembled from expensive and exclusive materials. The only difference is the absence of the emblem of an expensive company, such as Supersprint or Akrapovi č.

Welding a stainless steel exhaust system

You can order a stainless steel exhaust system from us

Stainless steel is the best material for exhaust systems

You can see even more photos of exhaust systems in our gallery!

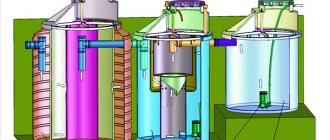

How exhaust systems are manufactured

Work with “stainless” mufflers and devices is carried out using the TIG method - this is welding with a non-consumable tungsten electrode in a protective gas atmosphere. Typically, high-purity argon is used for such purposes, which not only creates the necessary inert environment to protect the seam, but also makes the arc very stable.

The amount of welding current depends on the specifics of the work being performed. To connect thin-walled pipes, a small current is needed, which allows the use of compact torches, which are very convenient to use and enable the welder to easily weld elements with a complex structure. If it is necessary to fasten flanges and thick-walled pipes, the current requirements increase. Increased arc power forces the use of a torch with a large nozzle, since a small torch in this case will overheat greatly.

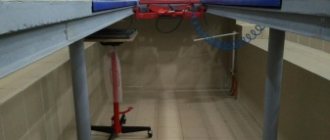

The use of nozzles of different diameters leads to the need to divide the production of the exhaust system into several technological operations. For example, one welder joins thin pipes using a small torch, while the second welder works with thick metal that requires increased arc power. Although this approach does not affect the quality of the final result, it does make the process somewhat drawn out.

example of an inconspicuous high-quality connection

Manufacturing of exhaust systems, intake systems and components

Manufacturing of exhaust systems and components

| Making a cold intake | from 15750 rub. | |||||

| Manufacturing the exhaust manifold | from 42,000 rub. | |||||

| Manufacturing of a component (muffler, resonator) | from 5250 rub. | |||||

| Manufacturing a stainless steel exhaust system | from 21,000 rub. | |||||

| Manufacturing an exhaust system from titanium | from 52500 rub. | |||||

The topic of various upgrades and improvements is becoming more and more popular. And the exclusive exhaust system with completely individual, custom-designed components can rightfully be considered a source of pride. In addition, the exhaust is not only a way to make a statement on the road with an excellent deep sound, but also a way to add some muscle under the hood! The same effect occurs with the intake system.

| Manufacturing of an Audi A6 C7 exhaust system with electric dampers (switching between quiet/loud modes) |

In the sections on exhaust repair (without welding, using welding) we have already mentioned the main components of the exhaust system, but repair is something simpler than the development and production of elements. And the ShedSkills workshop not only deals with the full range of work on the manufacture of exhaust systems and intake systems, but also with the production of individual components, including for production needs (For example: accessories for welding processes, etc. (More details in our Catalog)). Now let's look at some of the operating features of the exhaust gas exhaust system elements and outline some of the differences between their types.

1.An exhaust manifold.

In addition to exhaust gas removal, the manifold design provides better purging of the engine combustion chambers and also helps the piston remove gases from the cylinder. This happens for one simple reason: the pressure in the manifold is lower than in the cylinder, so a wave is formed in the manifold pipes, which, reflected by the flame arrester (resonator) or catalytic converter, goes through the channels back to the combustion chamber, and at the time of the next exhaust cycle they help remove gases and better cylinder purging. The whole variety of collectors can be divided into solid and tubular. Solid, usually used on low-power engines and cast from cast iron. Tubular ones are made of welded pipes, which are connected to the block using flange connections. Now let's move on to the manifold layout options. Surely many have heard of such things as collector 4-1, 4-2-1, etc. So, 4-1 corresponds to 4 pipe-channels that go (connect) into one common pipe. 4-2-1 in this way, 4 pipes are first connected 2 pipes each, for cylinders operating in pairs (on the same stroke), and then go into one common one. The length of the collector is also a very important value. And if the channel pipes are too small, then the energy of the exhaust gas flows will be enough to enter the channels of neighboring cylinders. However, do not forget that increasing the length of the collector will entail an increase in temperature in the engine compartment. Therefore, it is worth taking care of insulation. There are also manifolds with equal lengths of all channels (equal length), such designs are most often used on sports cars and make it possible to achieve uniform exhaust in all cylinders and improve the synchronization of the engine and exhaust system.

2.Reception pipe.

Used to connect the exhaust manifold to the catalytic converter and combine multiple gas streams into one. Many people also call this element “pants”. To connect to the manifold, the pipe has a connecting flange. Gradually, moving from the collector, two or more pipes will turn into one. In order to dampen vibrations from gases, a corrugation . Essentially, a corrugation is a shock absorber that, thanks to its design, dampens engine vibrations and allows further parts of the muffler to be attached, of course, through rubber elements, but to the car body. There are two-layer and three-layer corrugations. Nowadays, corrugations in 3 layers are mainly used and they are already divided into Innerbraid (metal braiding on the inner layer) and Interlock (inner layer of metal plates forming a sleeve). Let's say right away that Interlock is more reliable, but more expensive. The corrugation is replaced when worn out using a welding machine. But let's return to the exhaust pipe. The material from which it is made can be varied. However, there are a number of standard options. For example, stainless steel, aluminum alloy, ferrous metal alloys.

3. Resonator.

Depending on the presence and number of chambers, the device allows the device to narrow and expand gas flows that flow in jerks. Thanks to this, the pulsations are smoothed out and the flow becomes more uniform. To further reduce energy, the resonator is equipped with reflectors, which are a perforated sheet of metal.

4.Catalytic converter.

For its correct and complete operation, high temperatures are required (over 300 degrees). It consists of a body and the neutralizer itself, which is made in the form of sections with many holes. These holes are obtained thanks to a special tape made, which is wound around the central rod (one of the main types of catalysts). A chemical composition is applied to the resulting holes, the basis of which consists of platinum group metals, as well as rhodium and palladium, which react with exhaust gases and reduce the toxicity of most hazardous elements. Catalysts, according to the number of reactions carried out, are: - One-, two- or three-sided. In the first reaction, carbon monoxide is converted into carbon dioxide, in the second, fuel elements are oxidized and burnt out (breaking down into carbon dioxide and steam), and in the third, nitric oxide is separated into oxygen and nitrogen. This is where the catalysts that are directly in the exhaust system end, but many distinguish several more types that directly affect the mixture before it burns. — Fuel (combustion) catalyst. In fact, this is a special solution or composition that contains plant components, lithium, copper and polyhydric alcohols and is added directly to the fuel. — Magnetic-strictive. Which also affect the fuel mixture and not the exhaust gases. Also, catalysts may differ in honeycomb structure and density.

5.Muffler.

Regarding the power, volume and other characteristics of the engine, the design of this device may vary, but basically, it consists of several chambers with partitions and perforated tubes of various diameters. Plus, a compartment filled with a special porous absorbent material can be added. In order to withstand even the most severe operating conditions of the engine, the part is made of stainless steel, which has excellent resistance to temperature fluctuations, and it also perfectly removes excess heat.

6. Flanges, dampers, crossovers, nozzles.

So, above we looked at the main elements. Now it’s worth focusing on the auxiliary ones. If we talk about dampers, they help separate several exhaust lines. Usually it has two positions. One for quiet engine operation, the second for sporty driving, racing from traffic lights and sharp pressure on the gas pedal. Flanges are an integral part of the manifold-cylinder block connection or other system connections. Crossovers are designed to divide the flow in the right place. And the attachments emphasize the bright appearance and sporty character. All of these components can be custom made at ShedSkills for any vehicle.

However, you won’t be satisfied with individual elements, which is why it is possible to manufacture a complete exhaust system or some of its parts!

| Manufacturing of exhaust system for Audi A6 C7 |

| Car exhaust system resonators |

| Exhaust system Audi RS5 |

| Installing exhaust tips |

| Electric damper in the muffler area on the exhaust system of the Audi RS5 |

Welding mixture as an alternative to argon

One of the most effective methods for solving the problem of overheating of a working tool due to increased current is to replace pure Ar with a combination of Ar - H. One of our regular customers, the Turbo-V company, appreciated this transition, which we will discuss below.

So, according to its characteristics, hydrogen is an active gas, so adding such a component leads to an increase in arc power (while the operating current decreases), which is perfect for connecting parts made of austenitic steels. By the way, you can read about what welding mixtures are used for other types of metals and their alloys here.

As a rule, welders almost immediately feel the benefits of switching from argon to argon-hydrogen, including:

- reduction in operating current by 1.5-2 times while maintaining penetration depth;

- the ability to weld both thin and thick metal with a small torch;

- higher concentration of energy;

- no overheating;

- increasing process productivity;

- obtaining a neat seam of small thickness;

- less chance of pore formation.

Perhaps the only drawback of adding hydrogen is a decrease in arc stability, so the qualifications of the welder must be quite high. Otherwise, you can get a crooked seam and poor quality of connection. If you pay attention to the seams of exhaust systems manufactured by Turbo-V, you will notice high precision and quality.

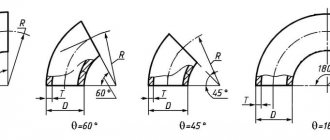

bends

Determining the correct proportion of gases

In order for the welding process to have maximum efficiency, it is important to calculate the optimal ratio of argon and hydrogen, taking into account specific conditions. Usually the best concentration is determined experimentally by gradually adding the active component to the inert gas and observing how these changes affect the arc and weld. In particular, for the production of automobile “exhausts” in Turbo-V, the best performance can be achieved with the composition “95% Ar – 5% H”. This combination was selected exclusively experimentally thanks to constant feedback from the client.

Argon-hydrogen allows you to obtain aesthetically pleasing compounds (see the bottom of the photo)

and larger version

Thus, it should be noted the importance of correct selection of the composition of the gas mixture, especially in cases where high quality welding and weld precision are required. A monogas working environment may not meet all requirements, but mixtures are more flexible in this regard. There is almost always an opportunity to improve the result of the work due to the supplier's full understanding of the buyer's needs and their feedback.

In addition to technological advantages, the use of such mixtures as a protective medium also has economic implications. In this case, gas consumption is significantly reduced, so delivery and refilling of cylinders is carried out less frequently. You can learn more about the described gas products by following the link N-MIX H5.