Areas of use

Gas mixtures are widely used for welding and surfacing of both ferrous and high-alloy steels, as well as MIG-MAG welding of some non-ferrous metals. In addition, they are used when it is necessary to weld galvanized metals to minimize zinc burnout. Welding mixtures are used in all areas of mechanical engineering and construction, but their role is especially important for the production of industrially hazardous objects (shipbuilding, bridges, pipelines, cranes, elevators, etc.), where it is necessary to ensure increased reliability of welded joints.

Application benefits

When using correctly selected and high-quality gas mixtures for semi-automatic welding (MIG-MAG), you can provide the following advantages:

- high welding speed, increasing the productivity and efficiency of the welder;

- reduction of harmful smoke and carbon monoxide emissions. Improving working conditions;

- high impact strength and reliability of welded joints;

- reduction of welding deformations;

- reduction in the number and size of splashes; SIGNIFICANT REDUCTION IN CLEARING WORK

- improving the appearance of welded products;

- less risk of burning through thin-walled products;

- saving expensive welding wire;

- high arc stability. Larger permissible range of adjustments.

- no gearbox heating required;

- less splashing of the welding helmet;

Advantages of gas protection when welding

Welding gas mixtures provide:

- increasing labor productivity by speeding up the welding process;

- easy automation of the process of joining workpieces;

- reduced cost of work;

- reducing the volume of harmful emissions into the atmosphere due to the absence of flux in the technological process;

- possibility of welding in any spatial positions;

- improvement of the mechanical characteristics of the metal in the joint area (impact strength and tensile strength);

- reduction of thermal deformations of the workpiece material and seam;

- the ability to visually control the quality of metal at the joint during a mechanized welding process;

- reducing the amount of metal and bath splashes, which simplifies the procedure for cleaning the joint;

- improving the appearance of the structure by obtaining smooth connection lines without traces of metal ejection;

- reducing the risk of burning thin sheets and reducing the consumption of welding wire;

- simplification of ignition and stabilization of arc combustion while simultaneously expanding the range of welding equipment settings;

- no additional equipment preparation (no nozzle or reducer heating is required before gas supply);

- reducing the amount of small metal splashes falling on the welder’s protective suit and mask.

We recommend reading: Types of welding stations and information about them

Composition and areas of application

There are many types of gas compositions for MIG-MAG welding. The most widely used mixtures are argon and carbon dioxide. They are widely used both for working with low-carbon steels and for high-alloy (stainless, heat-resistant, etc.) steel grades.

Less common are mixtures with the addition of oxygen, which work better in the presence of rust or surface contamination, but are characterized by greater metal waste and smoke emissions. In addition, mixtures with oxygen are not suitable for welding high-alloy steels.

The choice of operating modes for MIG-MAG welding allows for different types of transfer of molten metal to the welding wire. A distinction is made between droplet transfer, when the molten metal from the welding wire passes into the weld pool, causing the formation of spatter and irregularities in the weld. With forced MIG-MAG welding modes, the formation of jet transfer of molten metal is possible. There is virtually no spattering.

The most popular mixture compositions for semi-automatic welding (MIG-MAG):

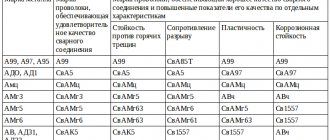

- 98%Ar+2%CO2 – for semi-automatic welding of high-alloy (stainless) steels + for conventional semi-automatic welding of galvanized parts and welding-brazing (MAG brazing) of copper-iron joints

- 92%Ar+8%CO2 – for semi-automatic welding of thin products made of structural steel (1-5mm) + for high-speed welding (linear welding speed up to 2 m/min on an automatic or robot) + for pulse welding

- 80%Ar+20%CO2 – for semi-automatic welding and surfacing of ordinary and high-strength structural steels + for semi-automatic welding of high-alloy (stainless) steel with flux-cored wire

- 75%Ar+ 25%CO2 – for semi-automatic welding of main pipelines and products made of structural steel, where there are many vertical seams. In some cases, other welding mixture compositions are also used

- 82%Ar+ 18%CO2 – for semi-automatic welding and surfacing of ordinary and high-strength structural steels in machines with firmware settings for such a mixture;

- 92%Ar+2%O2+ 6%CO2 – analogue of the mixture (98%Ar+2%CO2);

- 86%Ar+12%CO2+2%O2 – analogue of the mixture (92%Ar+8%CO2);

- 85%He+13%Ar+1.5%CO2 – for semi-automatic welding of high-alloy steels of large thicknessi>

svarnoy.info

INERT - do not enter into chemical interaction with metals and practically do not dissolve in metals.

Argon (Ar) is a colorless, odorless, non-flammable, non-toxic gas, almost 1.5 times heavier than air. Insoluble in metals in both liquid and solid states. It is produced (GOST 10157-79) in two grades: highest and first.

Premium grade gas contains 99.993% argon, no more than 0.006% nitrogen and no more than 0.0007% oxygen. Recommended for welding critical metal structures made of active and rare metals and alloys, non-ferrous metals.

First grade gas contains 99.98% argon, up to 0.01% nitrogen and no more than 0.002% oxygen. Recommended for welding steel and pure aluminum.

Helium (He) is a colorless, odorless, non-toxic gas, much lighter than air and argon. It is produced (GOST 20461-75) in two grades: high purity (up to 99.985%) and technical (99.8%).

It is used less frequently than argon due to its scarcity and high cost. However, at the same current value, an arc in helium releases 1.5 - 2 times more energy than in argon. This contributes to deeper metal penetration and a significant increase in welding speed.

Helium is used for welding chemically pure and active materials, as well as alloys based on aluminum and magnesium.

Nitrogen (N2) is a colorless, odorless and tasteless gas, non-toxic. Used only for welding copper and its alloys, in relation to which nitrogen is an inert gas. It is produced (GOST 9293-74) in four grades: highest - 99.9% nitrogen; 1st - 99.5%; 2nd - 99.0%; 3rd - 97.0%.

ACTIVE - protect the welding zone from air, but they themselves dissolve in the liquid metal or enter into chemical interaction with it

Oxygen (O2) is a colorless, odorless, and tasteless gas. Non-flammable, but actively supporting combustion. Technical gaseous oxygen (GOST 5583-78) is produced in the following grades: 1st grade - 99.7% oxygen; 2nd - 99.5%; 3rd - 99.2%. It is used only as an additive to inert and active gases.

Carbon dioxide (CO2) is colorless, with a slight odor, with pronounced oxidizing properties, and is highly soluble in water. It is 1.5 times heavier than air and can accumulate in poorly ventilated areas, in wells and pits. It is produced (GOST 8050-85) in three grades: highest - 99.8% CO2, 1st - 99.5% and 2nd - 98.8%. Carbon dioxide of the 2nd grade is not recommended for use. To reduce the humidity of CO2, it is recommended to install the cylinder with the valve down and after 1 - 2 hours open the valve for 8 - 10 s to remove water. Before welding, a small amount of gas is released from a normally installed cylinder to remove trapped air.

Cast iron, low- and medium-carbon, low-alloy structural corrosion-resistant steels are welded in carbon dioxide.

GAS MIXTURES - serve to improve the welding process and the quality of the weld.

A mixture of argon and helium. Optimal composition: 50% + 50% or 40% argon and 60% helium. Suitable for welding aluminum and titanium alloys.

A mixture of argon and oxygen with an oxygen content of 1-5% stabilizes the welding process, increases the fluidity of the weld pool, and the transfer of electrode metal becomes fine-droplet. The mixture is recommended for welding carbon and stainless steels.

A mixture of argon and carbon dioxide . A rational ratio is 75-80% argon and 20-25% carbon dioxide. This ensures minimal spattering, high-quality seam formation, increased productivity, and good properties of the welded joint. Used for welding low-carbon and low-alloy structural steels.

A mixture of carbon dioxide and oxygen . Optimal composition: 60-80% carbon dioxide and 20-40% oxygen. Increases the oxidizing properties of the protective environment and the temperature of the liquid metal. With this mixture, electrode wires with a high content of deoxidizing agents are used, for example Sv-08G2STs. The seam is formed somewhat better than when welding in pure carbon dioxide. The mixture is used for welding carbon, alloy and some high-alloy structural steels.

mixture of argon, carbon dioxide and oxygen ensures high stability of the process and avoids porosity of the seams. Optimal composition: 75% argon, 20% carbon dioxide and 5% oxygen. Used for welding carbon, stainless and high-alloy structural steels.

Features of obtaining welding mixtures

A mixture of gases for welding can be obtained from two cylinders using a gas station mixer. However, the simplest mixers cannot ensure the stability of the mixture when the gas pressure in a cylinder decreases. In addition, the components of the mixture in the cylinders do not run out synchronously and the welder must constantly monitor the remaining gas and frequently replace the cylinders. The behavior of carbon dioxide is especially insidious, for which it is impossible to determine the remaining gas in the cylinder and it always ends suddenly. High-quality imported station mixers with inlet flow control are very expensive (2000 Euro).

The most productive method is the factory one, where the components of the mixture in strictly dosed quantities are alternately fed into the cylinder through a valve. In this case, for (Ar+CO2) mixtures, the first component to be filled is carbon dioxide, which settles in the lower part of the cylinder. Argon, which is lighter than carbon dioxide and accumulates in the upper part of the cylinder, is filled next. Therefore, mixtures when filled alternately often turn out to be poorly mixed and do not correspond to the declared composition. In addition, the actual composition of an incorrectly prepared mixture changes both over time and with changes in air temperature.

To ensure uniformity and stability of welding mixtures, it is recommended to use a special tube on the valve inside the cylinder. In the absence of such a tube, for better mixing, it is recommended to store the container with the mixture in a horizontal position and rotate it from time to time (for example, roll it on the floor). It is recommended to store cylinders with welding mixture indoors. After a long stay in the cold and transfer of the cylinder to a warm room, the equilibrium temperature in it, equal to the ambient air temperature, is established over a long period of time (about a day).

Features of welding with argon mixtures

During the welding process, it is important to take into account some features of the welding mixtures used. First of all, you need to position the torch closer to the welding zone and, if possible, keep the torch closer to the vertical position. The electrode extension on the burner should be no more than 15-20 mm. When these dimensions increase, air leaks and the formation of pores in the weld are possible.

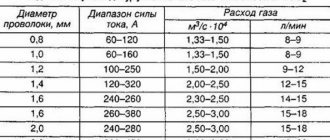

Secondly, when working with mixtures, it is important to correctly set the gas flow rate in the welding torch. It is recommended that the gas flow rate in the burner (in l/min) should be set approximately equal to the burner diameter (in mm). In fact, 10-15 l.min. is usually sufficient. Physically, the gas flow can be controlled directly on the burner, for example, using a gas rotameter). When the gas flow rate in the burner decreases below 5-7 l/min and when the gas flow rate increases to more than 25-30 l/min, air leaks and the formation of pores in the weld are possible.

Thirdly, the presence of argon or oxygen in the mixture increases the fluidity of the molten metal in the weld pool. Therefore, when working with mixtures, the gap between the workpieces should be significantly smaller than for carbon dioxide. For the same reason, difficulties may arise when welding vertical seams. To compensate for this effect, it is necessary to reduce welding modes or use mixtures with a minimum argon content.

When working with welding mixtures, the consumption of welding wire is significantly reduced (up to 20%) and therefore excess wire often leads to the formation of a reinforced weld bead. In addition, the welding modes for welding mixtures do not correspond to the usual welding modes for pure carbon dioxide. Therefore, it is necessary to correctly set the welding modes (arc voltage, current or welding wire feed speed) and practice new welding skills, including increasing the welding speed.

When working with argon mixtures, the thermal conductivity of the gas flow in the burner decreases and the heating of the burners increases. When working in forced modes, it is necessary to use burners that are more powerful than usual.

In the formation of a high-quality, reliable, durable weld, isolation from gases contained in the environment is necessary. Shielding gases are used to preserve the arc and weld pool. They exist in two types.

The first include inert gases . This is argon and helium, which do not react chemically with metal and do not dissolve in it, and are used in welding structures made of aluminum, titanium and their alloys.

What is better: carbon dioxide or welding mixture? — Metals, equipment, instructions

In the formation of a high-quality, reliable, durable weld, isolation from gases contained in the environment is necessary. Shielding gases are used to preserve the arc and weld pool. They exist in two types.

The first include inert gases . This is argon and helium, which do not react chemically with metal and do not dissolve in it, and are used in welding structures made of aluminum, titanium and their alloys.

The second group includes active gases (carbon dioxide). They interact with ferrous metals (carbon, low-alloy steels) and dissolve in them.

Welding mixture or carbon dioxide - gas for welding

The most common shielding gases are carbon dioxide or welding mixtures, the choice of which largely determines the work process. Also, do not forget that the welding mixture or carbon dioxide can be used for various types of welding and, accordingly, in one case or another, the efficiency and quality of the work will be different.

Very often, welders do not pay due attention to the composition and quality of technical gas, needlessly downplaying its contribution to the welding process. However, practice shows that the gas composition most directly affects the depth of penetration, porosity, reliability of the weld, smoke emission and other equally important parameters.

For a reliable seam, use high-quality welding mixture or carbon dioxide

Carbon dioxide

Carbon dioxide is a chemically active element. In welding production, colorless and odorless carbon dioxide has established itself as an inexpensive substance . When connecting metal parts, it acts as a shielding gas in the formation of the weld seam. Its greatest application is in semi-automatic welding. The shelf life of a forty-liter cylinder is 2 years . For individual needs: for home, garage, cottage, you can purchase cylinders of smaller capacity.

Before welding, metal sheets with a thickness of more than 10 mm are cut into edges to improve the weldability of the weld.

During the carbon dioxide welding process, metal structures do not undergo deformation , which helps to avoid defects during operation. Thorough cleaning of the material is not required, since before joining the parts, the quality of the seam will not suffer from this.

The operating method is based on the initiation of an electric arc, which leads to metal melting, and the process is accompanied by the supply of carbon dioxide, a protective gas. The feed envelops the welding zone and plays the role of protection. The weld seam is not subject to oxidation.

When processing thick metals, carbon dioxide generates a lot of heat, which creates favorable conditions for the use of this method.

Welding mixture

The main component of argon welding is argon . It is used when working with high-alloy steels. This gas is used both in pure form and with additives: carbon dioxide, oxygen, hydrogen, helium.

Types of mixtures: argon with carbon dioxide, argon with oxygen. There is another type, this is carbon dioxide with oxygen.

Argon and oxygen compositions are suitable for working with low-carbon steel. The oxygen content imparts plasticity to the seam and leads to a reduction in pores. Easy transfer of the electrode stream simplifies the process.

The combination of argon and oxygen is applicable for welding alloy and low-alloy steel, which allows you to achieve excellent results due to the low porosity of the material.

A welding mixture of argon and hydrogen is used to join nickel alloys and stainless steel.

A welding mixture of argon and helium is used in welding light, copper, nickel alloys and aluminum.

Mixing of gases is carried out at manufacturing plants or directly at workplaces using a rotameter.

Common features between carbon dioxide and welding mixtures:

- Carbon dioxide, like the welding mixture, serves as protection during work against oxidation of the joints of metal structures.

- Carbon dioxide and welding mixture are supplied in forty-liter cylinders.

- Excellent tightness and protection from corrosion ensures the safety and security of the cylinders. Depending on the contents, there are markings on the surface of the container.

- By category of mechanization : semi-automatic, automatic welding.

Welding mixture or carbon dioxide - gas for welding

The most common shielding gases are carbon dioxide or welding mixtures, the choice of which largely determines the work process. Also, do not forget that the welding mixture or carbon dioxide can be used for various types of welding and, accordingly, in one case or another, the efficiency and quality of the work will be different.

Very often, welders do not pay due attention to the composition and quality of technical gas, needlessly downplaying its contribution to the welding process. However, practice shows that the gas composition most directly affects the depth of penetration, porosity, reliability of the weld, smoke emission and other equally important parameters.

For a reliable seam, use high-quality welding mixture or carbon dioxide

What is better - carbon dioxide or welding mixture?

Carbon dioxide is the only substance that is used in the welding process without the addition of inert gases.

In addition, this is also one of the most inexpensive options, so it is very popular if material costs play a priority role. Carbon dioxide is the most common of the chemically active elements used in the MAG method.

It provides a fairly large thermal effect, which is important when processing thick metals. But at the same time, the arc is not very stable, which leads to frequent formation of splashes.

Therefore, its use in its pure form is usually limited to short-arc work. If you are interested in refueling with carbon dioxide, we recommend reading the article carbon dioxide: where to refuel is not an idle question.

Carbon dioxide cylinder for welding machine

Considering that any pure technical gas has both its advantages and disadvantages, the use of protective welding mixtures in the correct proportion often makes welding more efficient, increases productivity and allows for better quality welds, thanks to the following features:

- reduction of splashes;

- increasing the rate of metal deposition;

- increasing the plasticity and density of the seam;

- reduction of smoke;

- increasing arc stability.

You can find more information in the article: Welding mixture in cylinders is the optimal solution.

Before deciding which is better - a welding mixture or carbon dioxide, welders usually compare the complexity of the work, the required quality and the feasibility of material costs, and then make their choice.

Main types of protective gas welding mixtures

— Argon and carbon dioxide

This composition is most effective when welding low-carbon steel. The addition of carbon dioxide makes it easier to carry out jet transfer of the electrode, the seams are more flexible, and the likelihood of pores is minimal.

Argon and carbon dioxide

— Argon and oxygen The addition of a small (about 5%) amount of oxygen to argon makes it possible to perform better welding of alloy and low-alloy steel, due to the lower porosity of the treated surface.

Argon and oxygen

— Argon and hydrogen Used for welding nickel alloys and authentic stainless steel using the TIG method. In addition, it can be used as a forming gas.

Argon and hydrogen

— Argon and helium This composition allows for high-quality welding of light, copper and nickel alloys, chromium-nickel steel and aluminum using MIG and TIG methods.

Argon and helium

— Argon and active gases Thanks to this combination, double savings are achieved. Used for manual and automatic MAG welding of low-alloy, alloy and high-alloy steels.

Argon and active gases

— Universal shielding gas This is high-frequency argon, which has universal applications, but is most common when working with aluminum and non-ferrous metals.

Universal shielding gas

If you want more information about gas mixtures, check out this section.

Gas mixing methods

There are two main ways to obtain a protective gas mixture - at the manufacturing plant and directly at the work station.

The production method involves the use of special gas mixers, thanks to which two or three different components are mixed. To obtain the correct proportions, the required diameters in the flow holes are selected and the mixer itself is calibrated.

Application of a rotameter

The simplest mixing method, which can be done right at the workplace, is to use a rotameter - a cone-shaped glass tube with a float placed in a metal frame. The principle of operation of this element is to balance an aluminum or steel float with the flow of escaping gas. The higher the float is, the correspondingly greater the flow rate.

Rotameters

The composition of the argon-carbon dioxide welding mixture or carbon dioxide with oxygen is regulated using reducers on gas cylinders.

By monitoring the readings on the rotameter and adjusting the flow rate, the required ratio of the components used is achieved.

However, this method, as a rule, does not allow achieving maximum accuracy and high quality seams. Therefore, for precise welding work, it is better to contact the manufacturer.

High-quality protective gas mixtures can be ordered from Promtekhgaz. Among the main products there are:

and other compositions, which can be found on the website.

Difference between welding mixture and carbon dioxide

The welding mixture is used for argon welding where non-ferrous metals are present, such as titanium, aluminum, magnesium, copper and high-alloy steel alloys. And in carbon dioxide they join metal parts from carbon and low-alloy steels.

Advantages of using gas mixtures in welding:

- When using gas mixtures, the metal melting speed is faster than when working with carbon dioxide. During operation there is no large splashing of electrode material, which leads to metal savings.

- Ensuring plasticity and tightness of the connection of parts.

- Increasing the strength of structural joints.

- Reducing the harmfulness of the amount of chemicals released in smoke.

- Maintaining consistency in the work process when the rhythm of wire insertion is disrupted.

Advantages of welding in a carbon dioxide environment:

- Possibility of monitoring the work process.

- There is no need for auxiliary devices for introducing and removing flux.

- Reliable quality of product joints.

- Automatic and semi-automatic welding can be performed in different positions. For example, make ceiling, vertical, horizontal seams.

- Budget cost of carbon dioxide.

Features of argon and carbon dioxide compounds

Before deciding which gas to use in the mixture, you need to consider the features of using each of them.

According to TU 2114-001-99210100-09, all of the above compositions can be formed in a wide variety of proportions, differing in the percentage of each component. In the vast majority of these proportions, argon or oxygen is contained in volumes that make up the bulk of the substance (from 88 to 98%). The additives that complement them (carbon dioxide, in particular) rarely exceed 5-15% by volume.

Argon in proportion to helium is most often used for the processing of non-ferrous metals and their derivatives. The main types of workpieces for which argon-arc welding is used are copper, aluminum, nickel, and chromium-nickel alloys.

Welding mixtures consisting of a combination of argon and carbon dioxide are often used to heat the metal before welding or to gradually cool it after completion of work. As a rule, such a procedure is organized in cases of extreme necessity.

This gaseous composition is quite explosive, so working in a CO2 environment requires the operator to observe safety measures during its preparation and use.

The process of welding metal workpieces in mixtures with a high carbon dioxide content requires special attention. The fact is that when it combines with atmospheric oxygen, carbon monoxide is formed, dangerous to human health, to protect against which the operator must work in a special mask.

Thus, argon and carbon dioxide in combination with a number of active additives are universal welding gas mixtures used when working with most grades of ferrous and non-ferrous metals. Their combination, along with high efficiency of use, is characterized by a relatively low price.

Special aspects of the welding process using gas mixtures

The connection of metal products occurs at an angle forward . Therefore, when the wire comes out, it is necessary to take into account the diameter of the electrode for a better weld result. There should be no air in the burner or hoses.

It is necessary to use gas mixtures that comply with GOST standards. This is necessary in order to eliminate the incorrectly selected percentage of impurities contained in the mixture. The reliability of the connection of metal parts depends on the amount of harmful gases present in dissolved form: nitrogen, hydrogen and their compounds.