Updated: 04/22/2021 16:53:16

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

Band saws are great tools for increasing productivity in carpentry and carpentry shops. With their help, you can process much more materials than using a classic hacksaw or jigsaw. In addition, they make cuts more even and are also suitable for figured cutting.

We have compiled a rating of the 7 best band saws that will find their use among both home craftsmen and professionals.

How to choose a band saw

When choosing a band saw, it is worth determining not only its purpose (wood or metal), but also its class. There are three groups:

- Household.

These are relatively low-performance devices with a power of up to 500 W. They are enough for fairly leisurely processing of various materials. The main advantage of household band saws is the price; they are much cheaper than professional devices, and can cope with most tasks associated with sawing materials during processes such as repairs; - Semi-professional

. Devices with power from 0.5 to 1.5 kW. Thanks to equipment with a width of up to 100 mm, the productivity of semi-professional wood band saws is up to 10 cubic meters per work shift. Suitable for small carpentry and joinery workshops; - Professional.

High-power, multifunctional solutions. Connect to a three-phase network (380 V). Power – from 1.5 kW. Equipment – up to 300 mm, productivity – up to 15 cubic meters of wood, including frozen wood, per shift. It is recommended to purchase these tools for factories, since even in relatively large workshops their productivity will be excessive.

The main parameters of band saws – both for wood and metal – are:

- Depth.

Distance from tabletop to border. Determines how thick a block can be cut. The most important parameter in combination with power is what you should pay attention to first. For example, household band saws with a depth of up to 60 mm are suitable exclusively for processing boards and sheets (plywood, laminate, etc.), while professional ones with a depth of up to 500 mm can handle even thick logs; - Kerf width

. Determines the maximum allowable width of the processed board; - Canvas material.

The best solution is a carbon steel blade, for both wood and metal saws. It is reliable, durable and stable; - Number of blade teeth

. The best option is 180 or 210 teeth. Such blades provide a smooth, uniform cut; - Stops, rotary and inclined table, work area lighting.

These additional features make using the band saw more convenient, especially if curved cutting is required; - Supports multiple speed modes

. A useful feature for both wood and metal saws. Simplifies the processing of materials with varying degrees of hardness. - But the main parameter for a band saw is, of course, class, which manifests itself in power

.

TOP 5 popular models of band saws

Let's move from theory to practice. Let's take a closer look at the 5 most popular band saws among inexpensive models for the amateur workshop.

BISON ZPL-350-190 (for wood)

Entry-level machine for working with wood. Allows you to make straight, oblique or inclined cuts, as well as curly trimming. If necessary, you can also saw plastic.

ZUBR ZPL-350-190 is the cheapest model on the market. Device power - 350 W. This is enough for small wooden blocks, but you shouldn’t count on high performance. The cutting depth is limited to 90 mm and the width to 180 mm. With such a tool you can easily make a country bench or stool, but you won’t be able to work with large workpieces.

To ensure even cuts, the package includes an angular stop and a longitudinal guide. A vacuum cleaner can be connected to remove chips.

The ZUBR ZPL-350-190 band saw is suitable for those who have not yet decided on the choice of tool for the workshop. Price is the main advantage of this model, covering other disadvantages. If it turns out that you need a band saw for everyday work, you will probably want to buy a more advanced machine.

JET JWBS-9X (for wood)

Inexpensive option for beginners. Compared to the ZUBR saw, the power has not changed - still the same 350 W. The advantage of the Jet machine is higher quality workmanship. Judging by customer reviews, the manufacturer maintains stricter tolerances, so working with this model is more pleasant.

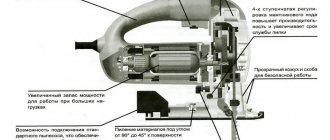

The cutting depth decreased to 80 mm, but the width increased to 230 mm. Given the low power, these parameters are not so important: cutting a thick workpiece will be difficult in any case. The Jet saw is often chosen as an alternative to a jigsaw. With similar capabilities, it produces a thinner and more even cut that requires almost no processing. A pleasant bonus will be the creation of figured carvings.

Only the rip fence is included as standard. The chips are thrown out through the vacuum outlet, but the adapter is designed for industrial models. In garage conditions, the issue of connecting the hose will have to be decided independently.

Overall, the Jet JWBS-9X is a good entry-level machine. You shouldn’t expect much power from it, but it’s a good option as a first tool.

Metabo BAS 261 Precision (for wood)

High-quality and durable tools from a German manufacturer. At 400W it still belongs to the entry level. The cutting depth increased to 103 mm, and the width reached 245 mm.

But the main advantage of this model is the quality of workmanship. The design has become more durable: for example, the rollers are made of steel rather than plastic. The difference in body materials is also reflected in the weight of the device: the Metabo machine weighs 32.5 kg, while the Jet JWBS-8-M weighs only 20 kg.

Owners of the machine note that the saw works great straight from the factory. The flywheels are perfectly balanced, which eliminates vibration and unevenness when cutting. The quality of the cutting blade is also not satisfactory. The package includes a parallel and angular stop, as well as three adapters for the vacuum cleaner hose.

As a result, the Metabo BAS 261 Precision band saw has taken an intermediate position between semi-professional and “home” models. It is still quite difficult to cut thick workpieces with such a device, but there is no doubt about its reliability.

JET JBS-12 (for wood)

The model that comes closest to the semi-professional class. The 800 W motor allows you to seriously work with thick workpieces. This is also facilitated by the spacious working area: the cutting depth is 180 mm and the width is 300 mm. Despite the increased power, the saw operates from a 220 V network.

The tool is designed for working with wood, but if desired, you can also cut plastic.

An important advantage over more expensive models is compactness. With a relatively large cutting depth, the machine will not take up much space in the workshop. The saw comes with metal supports so that it can be installed on the floor. The kit also includes a parallel and miter gauge.

An important advantage is 2 speeds of web movement. Fast mode is designed for soft woods and small workpieces. At low speed it is more convenient to saw hard workpieces.

JET JBS-12 is suitable for both amateurs and craftsmen who make things to order. With proper care, the tool will last a long time and will delight you with stable results.

Rating of the best band saws

| Nomination | place | Name of product | price |

| The best compact (cordless) bandsaws | 1 | Milwaukee HD18 BS-402C | 45 700 ₽ |

| 2 | Makita 2107FK | 21 605 ₽ | |

| 3 | Bosch GCB 18 VL-I 0 | 16 599 ₽ | |

| The best bandsaws for wood | 1 | JET JBS-12 | 42 240 ₽ |

| 2 | Enkor Corvette-35 | 39 900 ₽ | |

| The best metal band saws | 1 | JET J-349V | 42 00 ₽ |

| 2 | Encore Corvette-422 | 24 700 ₽ |

Selection of tooth pitch and composition of the belt blade.

A – Width. Distance from the back of the saw to the tip of the saw.

B – Saw base. Distance from the back of the saw to the interdental cavity.

C – Length. Canvas length.

D – Thickness. Thickness of the canvas.

E – Saw back. The side of the saw opposite the teeth.

F – Distance between teeth. The distance between the tips of adjacent teeth.

G – Tooth pitch. Number of teeth per inch.

H – Interdental cavity. The cavity between two teeth. The cavity is designed to remove chips from the cutting zone.

I – Tooth surface. The surface of the tooth involved in cutting. The tooth can have a positive, negative or straight angle.

J – Tooth setting. The distance between the two tips of the teeth, indicating the maximum deviation from the vertical axis. The setting of the teeth determines the cutting width of the material.

K – Posterior edge of the tooth. The surface of the tooth opposite the angle of attack. Depending on the purpose, it may have a separate angle or profile.

Constant pitch - the distance between the teeth does not change. Blades with a constant tooth pitch have the same spacing between teeth and the same tooth profile. Tooth pitch (TPI - teeth per inch) is the number of cavities between teeth per 1-inch (25.4 mm) interval. Today, it is an outdated technology and is practically not used for cutting metals.

Variable pitch - small and large teeth alternately.

With variable pitch blades, the spacing between teeth varies to reduce vibration and improve chip removal and a more precise cutting surface. Variable tooth pitch is indicated by a hyphen, indicating the largest and smallest pitch. Variable pitch blades are used for sawing most metals and are best suited for sawing structural components or for sawing under vibration and shock loads. These saws last longer.

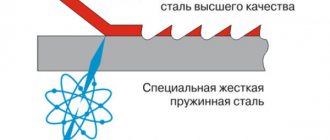

The canvases are also divided according to the type of material from which they are made:

- Bimetallic band saws are a tool produced by electron beam welding of the base blade and the cutting edge of high-speed steel teeth.

- Carbide band saws are a high-performance tool for cutting a variety of materials, including materials that cannot be processed with bimetal band saws.

Selecting tooth pitch for profile workpieces

This selection table is used to easily determine the appropriate tooth pitch for cutting profiles and pipes.

On the horizontal scale, select the maximum dimensions of the part to be cut. Then select the changed wall thickness in the vertical column and find the recommended tooth pitch in the table. For faster cutting, the next larger tooth pitch can be used. It is not recommended to use a finer tooth pitch, since overfilling the cavities between the teeth with chips will lead to rapid wear of the blade. Batch cutting:

- For round pipes, it is necessary to double the thickness of one wall, and then find a suitable tooth pitch.

- For square and rectangular pipes, take into account the maximum width of the package to be cut and the wall thickness.

ƒ‰ … ˆ †‰

Selecting tooth pitch for profile workpieces

This selection table is used to easily determine the appropriate tooth pitch for cutting profiles and pipes. On the horizontal scale, select the maximum dimensions of the part to be cut. Then select the changed wall thickness in the vertical column and find the recommended tooth pitch in the table. For faster cutting, the next larger tooth pitch can be used. It is not recommended to use a finer tooth pitch, since overfilling the cavities between the teeth with chips will lead to rapid wear of the blade.

Batch cutting:

- for round pipes, you need to double the thickness of one wall, and then find a suitable tooth pitch.

- for square and rectangular pipes, take into account the maximum width of the package to be cut and the wall thickness.

‡ ƒ ˆ€

Saw geometry

Explanation of tooth shape designations and recommendations for choosing a tape:

S → constant pitch, rake angle 0°

For cutting short-chip materials, steels with high carbon content, tool steels and cast iron, workpieces with small cross-sections, thin-walled profiles. This tooth shape is used primarily for cutting pipes and thin-walled profiles, as well as for shallow cuts. For cutting fragile (brittle) materials and workpieces with large cross sections.

K → constant pitch, rake angle 10°

For cutting long-chip materials, tough materials, non-ferrous metals and steels with carbon content < 0.8%, tempered steels, stainless and acid-resistant steels, for workpieces with large cross-sections. This is the most versatile tooth shape and is used in most cases if the pitch allows.

W → variable pitch, rake angle 0°

WP → variable pitch, rake angle 10°

WEP → variable pitch, rake angle 18°

The variable pitch makes it possible to achieve cutting with low vibration.

The WEP mold is used for machining steels that produce chips (eg stainless steel).

The best compact (cordless) bandsaws

Milwaukee HD18 BS-402C

Rating: 4.9

Why it: A versatile handheld band saw.

The manufacturer itself positions this saw as a device for metal processing. And this is not surprising. The Milwaukee HD18 BS-402C, despite the fact that it is a manual band saw powered by batteries, has increased power and can easily cope with most tasks for quickly processing any materials - pipes, rods, not too thick trunks and other workpieces.

The cutting width of the device is 85 millimeters, the cutting depth is also 85 millimeters. The belt rotation speed without load is 146 rpm, one mode. The saw is powered by a 4 Ah battery. There is illumination of the working area.

The saw has a rich set of accessories. It comes with two batteries, a charger for them, a saw blade and a transport case.

Advantages

- Rich equipment;

- High power;

- Convenient design.

Flaws

- Relatively small depth and width of cut;

- Slow battery charging.

Band saws for cutting metals

Effective cutting of metal workpieces cannot be performed without the use of special technological equipment - a saw blade. Currently, the modern metalworking market offers band saws made of carbon steels, as well as bimetallic ones (spring base, teeth made of high-speed steel or carbide). Depending on the design features and the cutting modes used, the equipment in question makes it possible to achieve high productivity and a significant reduction in the cost of performing the required technological operations. The output is products with excellent cutting quality without any external defects.

Middle segment (from 16,000 to 22,000 rubles)

Makita 2107FK

pros

- Works quietly

- Built-in fluorescent lighting with independent switch

- Speeds are adjustable (60 and 80m/min)

- The power cord is reinforced

- Comfortable use and replacement of tape (1140x13x0.5mm)

Minuses

- No stand included

- The speed control is poorly placed

- No fluid supplied for lubrication and cooling

From 21560 ₽

Will continue the best band saws Makita 2107FK - this is a good semi-professional tool with a power of 710 W for cutting wood, metal, rubber with dimensions of 120x120 mm. Weighing 5.7 kg and dimensions 52.3x18.8x26.9 cm. Supported by bearings on both sides for smooth movement of the tape.

Milwaukee M12 BS-0

pros

- Weight 3.2 kg and compact

- There is overload protection

- LED lights

- Versatility of cold, spark-free cutting of materials (plastic, steel, copper, etc.)

- Precise cutting thanks to 8-ball bearings and comfortable handle

Minuses

- Charger and battery are not included

From 16700 ₽

The band saw machine is easy to use with one hand. Can cut overhead at a speed of 85m/min. The REDLITHIUM-ION battery with a charge indicator allows you to work 2 times longer on a single charge and provides 20% more power. It also increases the service life by 2 times and does not fail even at 20°C below zero. Works with all Milwaukee M12 batteries. The blade has 18 teeth per 1 inch with a tape length of 687.57 mm. Cutting height 41x41 mm.

DeWALT DCS371N

pros

- Bright LED backlight

- Lightweight (3.9 kg) and compact (38.5x28 cm)

- Canvas (835x12x0.5 mm) can be easily changed

- There is a built-in hook for storage

- Additional rubberized ergonomic handle

- 3 years warranty

Minuses

- 80 dB noise

From 21540 ₽

A professional manual model with a 460 W motor cuts 174 m per minute in hard-to-reach places. Precise cuts, with a cutting depth of 63.5 mm, on metal, aluminum and plastic in confined spaces. The absence of sparks allows you to saw in a fire hazardous environment. Lithium-ion battery 18 V without self-discharge and memory effect