Varieties

It should be remembered that for each metal you need to choose the right type of wire. The quality of welding and seam will depend on this. Using clean, non-rusty and free of roughness wire will make the seam much more flexible and of better quality, which means it will provide maximum protection against corrosion. There are these types of wire:

- Copper-plated wire is a wire product that is used for arc welding of carbon and low-alloy steels, ensuring uninterrupted operation of any welding machine. When used, it minimizes metal spattering and also guarantees high quality welds.

- Powder - usually has the form of a tube consisting of low-carbon steel, filled with special deoxidizer powders and slag-forming substances. Typically used for automatic welding, it helps minimize the formation of slag and helps reduce the amount of work required to clean up seams.

- Solid wire is used for semi- and automatic welding and for the manufacture of electrodes.

- Non-copper-coated wire is used for mechanized welding, as well as when working with parts made of low-carbon steel, which does not require correction of the quality of the seams.

- Activated wires are products that also consist of powder fillers and are used for welding in carbon dioxide.

- Gas welding – used for welding work with carbon and low-carbon types of steel.

- Aluminum - widely used in semi-automatic welding of aluminum structures, gives the welds low porosity and is used in the dairy and shipbuilding industries.

- Stainless steel wire is used to connect stainless steel types, the deposits of which protect against corrosion and cracks.

- Flux - used for semi-automatic welding of carbon, medium-carbon and low-carbon types of steel.

- Alloyed - helps to carry out any welding in different gas mixtures, is an ideal welding material for argon welding.

Aluminum wire

Used when working with aluminum alloys in which the silicon content does not exceed 3%, and copper - from 3 to 5%. Products manufactured for semi-automatic welding machines are made of aluminum, which has a positive effect on seam formation:

- gives additional strength;

- exactly matches the color of the blanks;

- has the same corrosion resistance as any other aluminum alloy.

Most often used in automotive production and shipbuilding. In third place in demand are organizations where welded structures interact with water. Characterized by excellent ductility and low weight; Most often used in gas welding. Suitable for joining other non-ferrous metals.

In practice, there are no metal parts or structures that consist of pure aluminum. Additional inclusions are always used to improve certain characteristics. This statement is also true for the welding wire itself, although often the amount of additives is measured to not exceed one percent. For example, only 0.2% titanium allows a specialist to make a fine-grained seam, which is extremely necessary when performing precision work.

However, according to GOST, pure aluminum wire is defined as a separate category. In addition to it, there are alloys with magnesium, copper or silicon. In addition to the provisions of the state standard, there are technical conditions that regulate the production of other alloys: with chromium, as well as with silicon and magnesium.

An important condition for a high-quality connection is the correspondence of the composition of the workpieces and the consumable material. Only magnesium, which actively evaporates at high temperatures, can be considered as an exception. Its composition in the additive can be 10-20% greater than the nominal value.

Classification

When choosing a welding wire, you need to immediately decide what goals you want to achieve, and also carefully study the purpose of each type. For this purpose, there are groups of classifications containing alloying elements in the composition:

- Contain a low carbon content in the filler material.

- The composition contains a small amount of alloying substances.

- High alloy wire for welding.

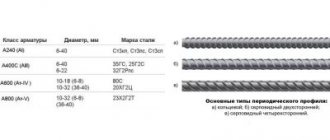

Steel welding wire is considered the most popular for use in various welding purposes. In accordance with GOST 2246-70 standards, as many as 77 types of different sections are distinguished, in millimeter sizes:

- Dimensions of 0.3-1.6 mm are used for welding metal products in shielding gas using automatic or semi-automatic welding.

- For the manufacture of electrodes, sections of 1.6-12.0 mm are used.

- To work with submerged arc welding wire, sections with dimensions of 2.0-6.0 mm are used.

Wire for stainless steel

This filler material is used in cases where steel containing chromium or nickel is welded in an inert environment. Main advantages:

- the result is a high quality seam;

- there are no cracks on the surface of the welded joint;

- the seam is resistant to corrosion;

- a small amount of splashes;

- arc stability.

Stainless steel welding wire has an important advantage: it creates a weld with an increased service life. It is made from high-alloy steel, in which the content of nickel, chromium and other similar inclusions is high. They minimize the likelihood of rust formation or the onset of corrosion processes.

Wire can be solid or cored. The first is used for working in an inert environment or submerged arc. Shielding gases are necessary to prevent the penetration of atmospheric oxygen, which could oxidize the stainless steel during the thermal joining process. Of course, this will negatively affect the quality of the weld.

Powder consumables are a thin-walled tube into which flux and additional elements for gas formation are poured. Their advantage is that an inert environment is not required. I form the protective shell with such filler materials myself. They are usually called self-protective.

During operation, the consumable passes through the current-carrying tip. Because of this, its diameter may decrease slightly, which ultimately reduces the quality of the welded joint. Therefore, wire is usually divided into normal and high-precision. The diameter varies over a wide range of values: from 0.13 to 6 millimeters. The key parameter influencing the choice of filler wire for welding stainless steel workpieces is the matching of the material of the parts and consumables.

Marking

Marking of welding wire is used to understand what materials the welder will have to deal with. Every welding master should have a good understanding of markings in order to avoid problems with the final work, as well as to ensure their own safety.

The first digits of the marking indicate the diameter, measured in millimeters. Then there are two specific letters that indicate the purpose of the products (SV - welding and so on). A further indicator shows the carbon content in the welding wire, measured in hundredths of a percent. Next are letters indicating the presence of certain alloying components (X - chromium, etc.). If the content of these elements is more than 1%, their indicator is located after the letter. The designation of the letters A or AA means purity relative to harmful impurities. Welding wire products for creating electrodes have the letter E in the designation, while copper-plated wire is marked with the letter O.

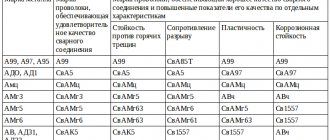

Types of welding wire by composition and diameter

- Flux cored is a hollow welding wire with a special flux filler. In this case, flux evaporation forms a protective gas bubble in the weld pool, which allows the use of consumables without a gas flow. Welding with flux-cored wires can be carried out under intense wind currents. The technique of using self-shielding wire is similar to the technology of welding using conventional wire material. Flux-cored wire has differences in marking with the designation “PP” and “PS”; with digital indication of brand and diameter.

- Copper-plated welding wire - with a copper alloy coating up to 6 microns thick. The key role of this layer is to ensure the tightest possible contact between the structures being welded. Welds created using such wire are distinguished by high mechanical endurance and weak response to strong temperature changes. Another indisputable advantage is the saving of consumables by up to 40% compared to welding with conventional wire. Note - this variety is absolutely not suitable for welding stainless steels.

- Aluminum welding wire used for welding in a protective gas environment with automatic and semi-automatic units. The consumable material is used for welding products made of aluminum alloys. The aluminum additive requires hermetically sealed storage due to the fairly rapid oxidation of the aluminum layer with oxygen in the open air.

- Welding wire for stainless steel. Material in this category is alloyed with chromium or nickel. Accordingly, the marking will contain the symbols “H” or “X”, as well as numbers for the percentage of alloying elements.

For use in semi-automatic welding units, wire with diameters of 0.6 mm, 0.8 mm, 1 mm, 1.2 mm, 1.6 mm is produced. Flux cored (flux) wires are manufactured in a thickness range from 0.6 to 6 mm. Filler rods, like the wire materials used for the manufacture of electrodes, are produced in a range of diameters from 1.6 to 5 mm.

Chemical composition for welding steel

Electrodes used in steel welding must guarantee good mechanical properties of the weld joint at a high level, as well as high productivity when welding parts. A consumable electrode is a welding wire of infinite length.

There are three groups of welding wire products according to the chemical composition of GOST 2246-70:

- Carbon steels (contain carbon in an amount of no more than 0.12%) are used for welding work with low-carbon and medium-carbon steels.

- Alloyed, designed for welding low-alloy and heat-resistant steels.

- Highly alloyed, used when working with chromium-nickel, stainless and other types of alloy steels.

Copper-clad wire

The material has the same set of advantages as wire for welding stainless steel. Plus, it also helps reduce tip consumption, regardless of the brand of welding machine. The main purpose is to join high-alloy and carbon steels in a protected environment.

The consumable is supplied to the consumer market wound on a plastic cassette. Thanks to ease of use, the productivity of specialists increases. The standard thickness of copper-plated wire is 0.6; 0.8 and 1 mm. It simplifies the re-ignition of the welding arc and maintains the stability of its combustion in different modes.

A classic example of such a consumable material is SV-08G2S wire, which contains 1% silicon, 2% manganese and 0.8% carbon. Another option is esab brand welding wire, designed to work with a wide range of steels, including tool, marine, stamped; stainless steel, aluminum and even cast iron.

Manufacturers of welding wire products

Here are some Russian welding wire manufacturers:

- "SvarMontazhStroy" - LLC, a well-known Russian company for the production of wire for any type of welding. Thanks to modern equipment and European technologies, the production of products meets the highest standards.

- The organization Petromet LLC, which belongs to the Leningrad Steel Rolling Plant, is engaged in the manufacture of welding wire products.

- Veld-Metiz LLC is a Russian company located in Moscow, producing various types of wire.

- OJSC Volgograd Steel Wire Rope Plant.

- OJSC West Siberian Metallurgical Plant, located in the city of Novokuznetsk.

Read also: How much is a cube of croaker?

Thus, welding wire products today are an effective and practical product that is widely used by welders to create flexible electrodes, as well as as a filler material in the case of manual, semi- and automatic welding.

The characteristics by which welding wire is classified are as follows:

- purpose;

- type of surface;

- structure;

- chem. composition.

Depending on their purpose, products can be general or special purpose. Special-purpose wire is intended to perform specific work - underwater welding, welding of reinforcement, tank welding, etc. This wire has a chemical composition that simplifies the above work and helps obtain a welded joint of the highest quality.

General purpose wire is intended for welding, used in surfacing work and in the manufacture of various types of electrodes (the letter E is present in the marking).

Depending on the type of surface, the wire is produced non-copper-plated and copper-plated (the letter O is present in the marking). Copper-plated wire is used for welding structures and products made of carbon or low-alloy steel. Its purpose is to create anti-corrosion protection for the seam, as well as to promote stability of the arc. This is especially true when carrying out gas welding.

According to the structure, the wire can be solid, powdered or activated. The composition of the steel from which the wire is made is of great importance when choosing it for welding a specific grade of metal and depends on the symbol - marking. Wire designation

Chem. The composition of the steel grades from which the wire is made is specified in GOST 2246-70 and according to it there are 6 grades made from steel grades with low carbon content, 30 grades from alloy steel and 41 grades from high-alloy steel. The wire is considered low-carbon if its total content of alloying elements is less than 2.5%, alloyed if the total content of these elements is in the range from 2.5 to 10%, and high-alloyed - more than 10%. The wire has a symbol that indicates the quantitative content of various elements in its composition.

The marking consists of numbers and letters, where the numbers are the number of elements that make up the wire in %, and the letters are the name of the chemical element. Welding wire may contain the following elements:

- A (N) – nitrogen;

- B (Nb) – niobium;

- B (W) - tungsten;

- D (Cu) – copper;

- M (Mo) - molybdenum;

- H (Ni) – nickel;

- C (Si) - silicon;

- T (Ti) - titanium;

- Yu (Al) - aluminum;

- F (V) - vanadium;

- X (Cr) – chromium;

- Z (Zr) – zirconium.

A number must be placed before the marking. After it, St. is written with a hyphen. The number indicates the Ø of the wire in mm, and St. indicates that it is intended for welding. After St there are numbers indicating the amount of carbon (in hundredths of a percent). At the end of the marking there may be letters:

- A – the content of phosphorus (P) and sulfur (S) in steel is reduced;

- AA - the wire is made of metal, which has a minimum amount of P and S, i.e. the metal is purified as much as possible from these impurities.

Sulfur and phosphorus negatively affect weldability, therefore, when welding critical structures, be sure to choose wire grades with a reduced amount of them.

An example of a symbol for the most used grade of wire when carrying out welding work and its explanation:

3-Sv08G2S

- 3 – diameter in mm;

- Sv – welding wire;

- 08 – contains 0.08% carbon;

- G2 – contains 2% manganese;

- C – contains up to 1% silicon.

Sv08G2S is also used for manual arc welding, when performing surfacing work and when performing work using semi-automatic and automatic machines. It is used to weld critical pressure vessels, structures made of various steels, pipelines, boilers, etc. Solid diameter wire is available in Ø from 0.3 to 12 mm.

Question 1. Welding wire (purpose, requirements, chemical composition, marking).

For welding steels, special steel wire is used in accordance with GOST 2246-70.

Mainly low carbon and low alloy steel is used. There are 77 grades of welding wire of various chemical compositions. The following requirements are imposed on the welding wire: • it must melt calmly and evenly; • the melting temperature must be less than or equal to the melting temperature of the base metal; • must be free from rust and dirt; • must correspond in chemical composition to the chemical composition of the metal being welded. Let's look at the symbol for wire using an example. 2Св-08А, where: 2 – wire diameter 2 mm; Sv – welding wire; 08 – 0.08% – carbon content; A – increased quality of metal. The brand may contain two letters AA (Sv-08AA), which indicates that this wire material is of particularly high quality. Quality means a reduced content of harmful impurities in steel - sulfur and phosphorus. An increased carbon content in the wire leads to a decrease in the ductility of the metal. Alloying elements may be present in the wire grade (Sv-12GS; Sv-15GSTYUTSA): G – 1% manganese; C – 1% silicon. If there is no number after the letter indicating the alloying element, then the content of this element in the steel is up to 1%. The number shows the content of the element in whole fractions of a percent. Symbols of alloying elements: C – silicon N – nickel M – molybdenum T – titanium Y – aluminum C – zirconium G – manganese X – chromium B – tungsten F – vanadium The wire varies in diameter. Wire diameter – from 1 to 12 mm. Wire with a diameter of 1.6 to 6 mm is used for manual arc welding (metal electrode rod). Wire with a diameter of more than 6 mm is called rods and is used for welding cast iron and non-ferrous metals, surfacing work. Wire with a diameter of 2 to 5 mm - for automatic welding. The diameter of the wire for gas welding is selected depending on the thickness of the metal and the welding method. For right-hand

, the diameter of the filler wire is d=S/2.

For left-hand

, the diameter of the filler wire is d=S/2+1.

Read also: Cutters for cutting trapezoidal threads

Question 2. High-performance types of manual arc welding (meaning, types, technique).

Welding productivity refers to the number of welds in meters made in a certain time interval. This can be achieved using various progressive techniques and improvements in manual welding (organization of the welder’s workplace, reducing the time to switch from one operation to another). All this allows welders to increase the arc burning time during working hours by 10-15%, since the time for changing the electrode is 7-10% of the working day. To increase the productivity of welding work, there are also special technical measures and methods, namely: • welding with high-performance coated electrodes; • welding with double electrodes, comb electrodes, three-phase arc; • deep penetration welding; • lying electrode welding; • welding with an inclined electrode.

Let's consider these methods. Welding with high-performance coated electrodes.

Electrodes coated with iron powder are the most effective.

This increases the deposition rate. When welding with coated electrodes with iron powder, not only the metal of the electrode rod, but also the iron powder introduced into the coating composition takes part in the formation of the weld. These electrodes should be called high performance electrodes. The performance of electrodes is characterized by the mass of electrode metal transferred to the product per unit of time. These electrodes include electrodes of the following brands: ANO-1, OZS-3, ANO-19, which, with a content of 50-65% iron powder, give 65-70 g/min of deposited metal (compared to 23-30 g/min for conventional electrodes : ANO-4, MP-3, OZS-4, etc.). However, it should be taken into account that high-performance electrodes allow welding only in the lower and inclined (angle 15-20°) positions. Power sources for welding with these electrodes must have an increased open circuit voltage. Welding with double electrode, electrode comb, three-phase arc.

When welding with a double electrode, the process is carried out with two rods connected to each other by resistance spot welding (Fig. 33, a).

The arc passes from one rod to another, alternately melting them. Welding productivity increases by 20-40% compared to welding with a single-rod electrode. This increase is achieved by alternately heating each of the rods with an arc burning between adjacent rods and the product, increasing the arc burning time, and reducing the time for changing electrodes. The electrodes are positioned so that their common axis coincides with the axis of the seam or, if the edges are large, is perpendicular to this axis. The welding current is: • from 100-180 A – with an electrode diameter of 3+3 mm; • 300-400 A – with a diameter of 6+6 mm. With dual electrodes you can weld metal up to 12 mm thick in one pass. The electrodes can be placed several rods in a row in the form of a comb (Fig. 33, b). The arc is excited at an electrode located at a closer distance from the work being welded. When the electrode melts, the arc passes from one rod to another, etc. The electrode comb allows you to go deep into the cutting of edges. Welding productivity is doubled compared to welding with a conventional electrode. The productivity of manual arc welding can be increased by an even greater amount if you use three-phase current (Fig. 33, c). When welding with a three-phase arc, two electrodes are used, to which two phases are supplied from the power source, and the third phase is supplied to the product being welded. At any given moment, during the process of changing the sinusoidal current, one or two arcs can burn. In this case, a large amount of heat is released, the metal melting rate increases, and welding productivity increases by 50-60% compared to single-phase arc welding. However, when welding with a three-phase arc, the electrode holder is heavily weighted, which leads to fatigue of the welder. Therefore, it is better to perform such welding using mechanized methods. Deep penetration welding.

This type of welding is also called support welding.

For welding, electrodes with increased coating thickness are used. The steel rod of the electrode melts somewhat faster than the coating, as a result of which a sleeve (visor) is formed at the end of the electrode from the coating. By resting the electrode sleeve on the surface of the workpiece, the welder moves the arc along the seam. The gases formed during the melting of the coating with their pressure displace the liquid metal from the weld pool, forming a bead; the product is melted to a greater extent than when welding with an electrode by weight. In this case, the volume of deposited metal in the weld is significantly reduced without reducing the strength of the weld. This welding method allows you to reduce the depth of cutting edges and weld metal of considerable thickness without cutting edges at high speed. Welding is performed without oscillatory transverse movements of the electrode. The technique of support

is that after igniting the arc, the welder sets the electrode at an angle of 70-80° to the plane of the product, lowers the electrode coating onto the surface of the product, and the arc will automatically move along the axis of the seam.

The support welding method is especially advisable when making fillet welds in the “boat” position, using electrodes of the OZS-3 brand. Welding with support in a vertical position in the direction from top to bottom can be performed with ANO-9 electrodes. Welding with an inclined electrode

(Fig. 34, a).

The electrode rests with the edge of the coating on the metal being welded. The second end of the electrode is clamped in a cage, which during welding is freely lowered, sliding along the rod. The angle of inclination of the electrode remains constant. The arc is excited in the same way as when welding with a lying electrode. The productivity of a welder when using these methods increases, since one welder can work at several positions at once. For welding with an inclined and lying electrode, special electrodes of the OZS-12, OZS-15N (inclined electrode), OZS-17N brands are required. Electrodes are made with diameters of 4, 5, 6 mm and lengths from 450 to 700 mm. Welding with a lying electrode

(Fig. 34, b). One or more electrodes, the length of which is usually twice as long as standard ones, are placed in the groove of the parts to be welded. A copper lining protects against metal leakage when making a butt weld. When making a fillet seam, no backing is required. From above, the electrodes are pressed against the edges of the parts with a copper or bronze block. The arc is excited by the auxiliary electrode and then continues to burn, melting the electrode and the base metal. The length of the arc is equal to the thickness of the coating, which is 1.5-3.0 mm. Welding with a lying electrode can also be carried out under a layer of flux. It can be used to make both straight and curved seams, which requires special devices.

Read also: Copper bracelets: benefits and harms reviews

3. Task. The metal for welding is 8 mm thick. Explain your steps to prepare metal edges for welding.

Depending on the thickness of the metal being welded, welding of the product can be done either with or without cutting edges. Cutting the edges of the metal begins with a thickness of 5 mm, and it is necessary for the best penetration of the metal over its entire thickness. In this case, the cutting is carried out in a V-shape, although other types of cutting are possible (depending on the thickness of the metal and the type of structure). After cutting, the edges of the joined elements, as well as the adjacent surfaces to a length of 15-20 mm, are cleaned of oil, scale, rust and dirt, since the quality of the weld depends on the condition of the surface of the products being welded. This is done with a steel wire brush.

Purpose

According to their purpose, welding wire is divided into general and special purpose products. General purpose wire is used for welding (marked Sv) or surfacing (Np) work for all types of steel, as well as for the manufacture of electrodes (E). Special-purpose wire in most cases is made of the same material as the product being welded, with some additives:

- For semi-automatic or automatic welding of aluminum or its alloys, wire made of the same material or with additives of magnesium and silicon is used. When using argon welding, flux is additionally used;

- To work with stainless steels or heat-resistant alloys, high-alloy heat-resistant welding wire is used. It contains silicon to ensure weld quality and carbon to prevent intercrystalline corrosion;

- work with copper is carried out with copper wire under a layer of flux;

- for welding nickel, wire made of the same material is used with the addition of manganese (up to 2%), silicon (up to 0.8%), titanium (up to 0.1%) and magnesium (up to 0.3%);

- Cast iron is welded with wire containing iron, nickel, copper, manganese, silicon and carbon;

- For welding titanium, argon arc welding using titanium flux-cored wire is used.

How to choose the right welding wire

- For welding low-carbon and low-alloy steel parts, it is recommended to use copper-plated wire (type 09G2S) in a carbon dioxide atmosphere. Copper coating will provide the welds with the necessary strength and tensile strength.

- Stainless alloys (austenitic and austenitic-ferritic alloyed with chromium or nickel) are welded with stainless wire alloyed with the same elements. The protective gas environment is inert argon or helium with the addition of a carbon dioxide mixture.

- Aluminum welding wire is used for welding aluminum alloys. An important nuance is the need to carefully remove the oxide film from the surfaces being welded.

- Powder “self-protective” film is used for welding a wide class of ferrous metals, where the use of gas cylinders is impossible or impractical. The only negative is the high cost of consumables.

- The diameter of the welding wire is selected in accordance with the thickness of the parts being welded. For example, it is better to weld products with thin walls using wire with a diameter of 0.8-1 mm. If the surfaces to be welded have a thickness of more than 5 mm, then the diameter of the wire material must be at least 1.6-2 mm.

will offer you a wide range of welding wire of various brands, allowing you to make the right choice for high-quality welding of various types of metals.

Characteristics and advantages of the VR-1 mesh

The main elements are welded strictly at an angle of 90 degrees on special equipment using a resistance welding machine. The shape of the cells in most cases is square. The cell has typical side dimensions of 50 (50 by 50, 100 by 100, 150 by 150, etc.). Each manufacturer may offer different cell sizes and rod thicknesses, but all this will be within the appropriate GOST. Production according to individual sizes is allowed.

Products can be untreated or coated with zinc to protect against corrosion. The thickness of the protective layer may vary. The larger it is, the higher the anti-corrosion properties and service life will be. Galvanized products can be used in conditions with high humidity. The VR-1 mesh with a protective coating costs several times more than the usual one. Therefore, if your budget is limited, then it is worth purchasing more budget options.

Construction mesh VR-1 for strengthening concrete structures has the following advantages: • Versatility. The material can be used for various construction and industrial purposes; • High quality indicators (strength, resistance to mechanical stress and other indicators); • Long service life. When used under normal conditions, the material can last for several decades; • Economic benefit. Compared to other building reinforcement materials, mesh is relatively inexpensive.