The connecting part for industrial and domestic pipelines is made in the form of a pipe section bent at a certain angle. It allows you to change the direction of the highway without violating its tightness. The operational scope of the elements is incredibly wide. Most often they are used when laying above-ground and underground gas, oil, and water supply networks.

Pipeline fittings are made in different ways. Based on design features, scope of use, and execution technology, the following models are distinguished:

- steeply curved;

- bent;

- welded (sectional and sector);

- stamp-welded;

- chiseled.

Production of steep bends

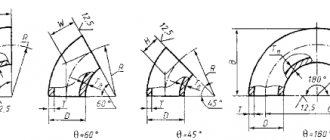

The bending radius of the fittings is equal to 1.5 nominal diameter (DN). They can be bent at different angles; the most popular are models that are rotated 45 and 90 degrees.

The production of shaped elements is regulated by documents GOST 17375-2001, GOST 30753-01, OST 34.10.699.97, etc.

Seamless components are produced by hot drawing. First, the craftsmen cut the pipes, i.e. carry out the preparation of pipes of a certain size. Billets made of carbon and stainless steel are placed in a special furnace and heated to a plastic state. Then they are pulled through a special template - a horn-shaped core, giving the knee the desired bending angle (from 30 to 90 degrees). Next, the forms are straightened on a vertical hydraulic press to adjust the geometric parameters. This process is called "calibration". The final stage: mechanical processing of the sections on a cross-cutting machine.

Complex and labor-intensive technology makes it possible to obtain durable seamless fittings with a cross-section from 25 to 820 mm. They are designed for internal pressure in the network up to 16 MPa.

Production methods of different steel bends

All steel bends are divided into several main types:

- steeply curved;

- stamp-welded;

- welded sectional;

- bent.

Let's look at the main ways to perform the above varieties:

Steeply curved. Products of this type are regulated by the state. standards 17235–2001 and 17235–83, as well as technical documentation (TU). Such parts are produced by pulling a segment of pipe through a mold. Thanks to this method, products with high quality properties are made. The materials for such models are carbon steel and stainless steel. The bending angle obtained by drawing through the mold varies from 30 to 90°. The very small cross-sectional criterion for such models is 18 mm, and the largest is 426 mm. The maximum operating pressure that such a pipe outlet can withstand is 16 MPa.

Processing of workpieces for future taps can be done cold or hot

Bent. The production of bends of this type is created on pipe bending equipment. During bending, the workpiece can be in two states: cold or hot. Such models have a straight section and are used in cases where, for one reason or another, it is not possible to use steeply curved products.

You need to pay attention! The main disadvantage of bent elbows is that they have a rather impressive mass, which complicates their installation on the pipeline.

These products can have a bend radius from 2 to 90°. These details are regulated by GOST 24950–81 and the corresponding technical conditions. The lowest operating temperature for these connectors is -50 °C, and the highest can reach +510 °C. Bent models can be used in pipelines with the highest pressure (up to 100 MPa).

Stamp-welded. They are made using welding equipment. The material for manufacturing is special sheets of alloyed or stainless steel. Thanks to this method, products of large sizes (up to 420 mm) are obtained. Basically, such models are used as structural components of main gas and oil pipelines. The regulatory documentation in this case is provided by the technical specifications.

Welded sectional. These products are manufactured by welding certain sections of pipes made of carbon or low-alloy steel. From a design point of view, these products are considered less reliable, since they are not considered a single piece, which is why they are used in communications with low pressure criteria (up to 2 MPa). The highest operating temperature for such products does not exceed 425 °C. Such expanders have sizes from 108 to 1620 mm. The main operational area is thermal power plants.

Expanders made of polymer-based materials are used when connecting polyethylene pipes, polypropylene, PVC and others

Manufacturing of bent elbows

To develop parts in accordance with GOST 24950-81, pipe bending equipment is used, which gives them a bend radius from 2 to 90 degrees.

The steel workpiece during bending can be in a cold or hot state (cold/warm deformation method).

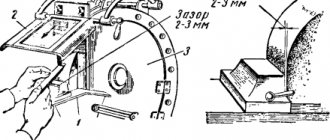

In general terms, the creation procedure looks like this: a tubular base is placed on a support. One edge of it is pinched, the other is jacked up. In order to distribute the load on the walls in the bend zone evenly and to ensure the absence of corrugation, the cavity of the reinforcement is filled from the inside with a loose mixture. Plugs are installed along the edges. At the point of deformation (usually the middle part of the pipe), the template is heated with a gas-air burner or induction method.

Next, the pipes are pre-cleaned, subjected to flaw detection, straightening, and balancing. Craftsmen mark the length of straight sections of future components and the deformation zone. During deformation, the following parameters are carefully controlled: turning radius, flow rate of the heating component, supply volume of the cooling element. Next, the shapes are cut, the edges are cut for welding. Experts check the wall thickness at the bend on the inside and outside of the device.

Before going on sale, metal products are marked and equipped with polymer plugs. A protective layer is applied to the steel surface to resist corrosion.

These fittings are installed in situations where, for some reason, it is impossible to install steeply curved elbows. The advantages of metal products with a straight section include resistance to high pressure: up to 100 MPa. They can withstand temperature fluctuations from -50 to + 510 degrees Celsius. In addition, the hydraulic resistance in the section of the main line with bent bends is lower than in the area where steeply curved devices are installed. In this case, there are no blockages or accumulation of mechanical impurities in the working environment. Among the disadvantages is the impressive weight of the structures, which complicates their installation in the pipeline.

Compared to hot drawing technology, this method has some advantages:

- increased productivity;

- energy saving (savings up to 80%).

Scope of application of bent bends

The budget for a pipeline project is always a priority. Therefore, developers first use inexpensive fittings - sectional, stamp-welded and steeply curved. The queue for expensive bent bends occurs in the following cases:

- high medium pressure;

- particularly aggressive environment;

- special operating conditions.

In other words, bent bends are used in critical sections of overpasses in Moscow or when transporting media that destroy the materials of conventional fittings. The choice of steel grades for tubular blanks of bent elbows is much wider.

In Soviet times, all housing departments/housing offices had manual pipe benders for making bends on site due to a shortage of these fittings. Currently, their independent production on site is strictly prohibited by building codes. Since these organizations do not have supplies of high-quality raw materials and equipment for flaw detection. All cold water/hot water supply lines and drainage systems are assembled only from factory products.

Manufacturing of welded bends

Sheets of carbon, low-alloy steel are used as blanks. Welded products are also created from stainless alloys.

Welding equipment is used to produce parts. Sectional metal products are structures created from individual pipe sections welded together. They have vulnerable spots (seams), therefore they are adapted to low pressure: up to 2 MPa. Typically, elbows with a size (with a cross-section) from 108 to 1620 mm are chosen when constructing thermal power plants.

Stamp-welded fittings, which are also made from steel sheets by welding, are in demand when laying large-scale oil and gas pipelines. The technology makes it possible to obtain large-diameter components with thick walls with minimal waste. The section size can be up to 1420 mm.

Despite the fact that there are several OST plus standard specifications (for example, OST 34-10-752-97), welded fittings are often produced for a specific engineering project. At the same time, be sure to check the welding seams for strength and tightness.

Types of steel bends

Stamp-welded

They are produced by welding blanks from stamped steel sheets of the required thickness. This technology makes it possible to produce products with increased strength characteristics, with a sufficiently large wall thickness and a diameter of up to 1420 mm. The bends obtained by this method are intended for use in pipelines of oil and gas production facilities. The main materials used for the manufacture of bends by stamping are stainless steel, structural steel and alloy steel. The technical characteristics of these bends must comply with departmental technical specifications (for example, TU 1469-001-01293553-2016).

Welded sectional

It is obtained by welding individual sectors (sections) of pipes. This type of tap is less expensive, but it is inferior in reliability. Sectional products are used mainly in main pipelines operating at fairly high pressure values of the working medium (maximum 10 MPa) and temperature (up to 450°C), for example, in pipelines of thermal power plants. The diameter of the finished product can range from 325 to 1620 mm. Sectional bends are made of low-alloy and carbon steel grades.

Bent

They are made by bending a metal pipe, both hot and cold, on specialized pipe bending machines. Such bends are a straight section of pipe with the end bent at the desired angle. A straight section can significantly increase the weight of the entire structure, which negatively affects the overall cost, the need to use special reinforcements, etc.

Bent products are produced with a bending radius of 20 DN (DN is the nominal diameter of the pipe), the bending angle can vary from 2º to 90º. The main document in accordance with which this type of bends is manufactured is GOST 24950-81. Suitable operating conditions: the pressure of the working medium in the pipeline can reach 100 MPa, the temperature ranges from minus 50 to plus 510ºС.

Steeply curved

Bent bends are often used when it is not possible to mount steeply curved bends. The difference between the latter type is the larger bending radius of the pipe. According to technical characteristics, this type of bends must comply with GOST 17235-83 and GOST 17235-2001. The production of steeply curved bends is carried out by pulling a straight pipe through a special template with a given bending angle (30º, 45º, 60º and 90º). This technology allows us to produce high quality products. The materials from which these bends are made are steel grades: carbon (art. 20) and stainless steel (art. 10Х18Н10Т). Please note that, if necessary, it is possible to produce a bend of this type with a non-standard bending angle according to an individual drawing or order.

Production of plastic elbows

Connecting parts made of polymer materials are inferior in strength to their steel counterparts, but have their advantages. Among them: light weight, ease of installation (no welding equipment is required during installation) and manufacturing, corrosion resistance.

Such structures are produced on the basis of polyvinyl chloride (PVC) or low-density polyethylene (HDPE). The raw material is pressed through a molding tool (extruder) to obtain a device of the desired shape. Then the bases are calibrated, cooled, and cut.

Polyethylene connecting parts are usually used when laying internal sewer systems. The diameter of products used to supply water in residential buildings is not regulated by strict standards. Typically this figure is 20-25 mm. The standard diameter of a plastic sewer outlet is 110 mm.

Types of bends

From a constructive point of view, a bend is a bend that is made at a certain angle. The selection of these products is made depending on the operational tasks. They are classified according to a number of characteristics:

- material of manufacture;

- manufacturing option;

- size;

- bending angle.

All expanders can be made of either metal or plastic. Let's look at the key materials from which these products are made:

- steel (stainless, alloy and carbon);

- low pressure polymer ethylene (LDPE);

- polyvinyl chloride (PVC).

You need to pay attention! Each allotment, without exception, has its own brand, which is assigned to it in accordance with the state. standards (GOST). The brand of the device makes it possible, if desired, to find out all the data about it.

If the communication cross-section criterion is less than 50 mm, then steel fittings are used to organize the branch. All steel bends are divided into two groups:

For the manufacture of bends, metals and alloys are used - steel (also stainless), cast iron, copper and others

The presence of a seam in steel models is determined by the production option. Steel fittings are produced using special pipe bending equipment, and plastic fittings are mainly produced using the extrusion method.